3D Scanning and Printing¶

This week, our group - Darren, Terry, and me (Jason) try to use the 3D printer and test the design rules, also explaining the limits of our 3D printer.

Group Assignment¶

- [✓] Test the design rules for our 3D printer

- [✓] Explain the limits of our 3D printer

- The Document by Jason Leung

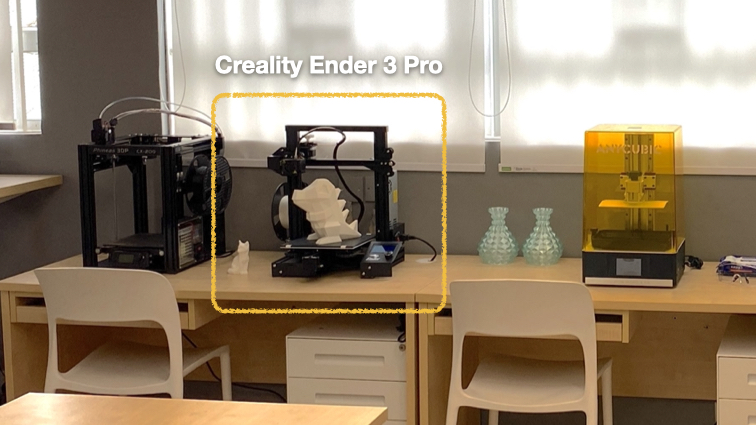

The machine we use for testing¶

Ender-3 serials 3D printer

Technical specifications

- Modeling Technology: FDM (Fused Deposition Modeling)

- Printing Size: 220x220x250mm

- Printing Speed: 30-60mm/s

- Filament: 1.75mm PLA, ABS, TPU, PETG, etc.

- Nozzle Diameter: Standard 0.4mm, can be in 0.2, 0.3 mm

- Printing Precision: ±0.1mm

- Bed Temp.: ≤110℃

Filament material¶

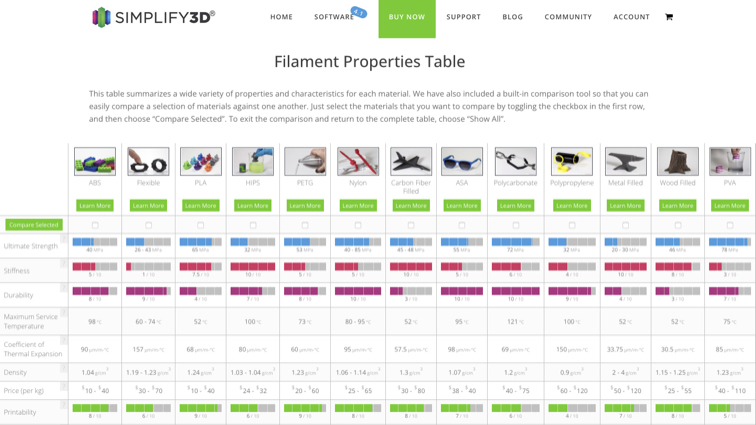

We have the 3D printer, the next step is to find suitable filament.

We research in many places, this comparison table is ideal for us to understand the properties of materials.

After some discussion, we finally chose PLA for the following reasons

- PLA’s ingredients are natural, non-toxic, and degradable (may be…)

- High printing success rate, suitable for beginners

- Suitable for our 3D printer

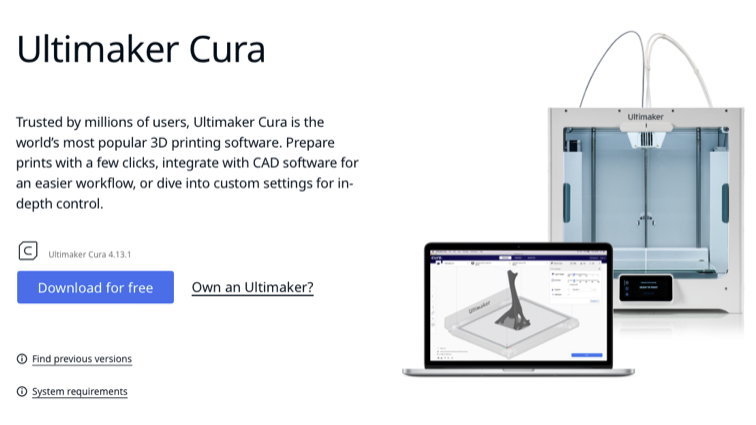

Slicing software¶

We need slicing software to convert from a model in STL format to printer commands in g-code format.

Here’s why we chose Cura for 3D object slicing.

- Free, full feature, and powerful

- Simple to use

- Commonly used by 3D printer players, easy to find support

Print out design rules tester for 3D printer¶

Design rules 3D model can be download from FabAcademy

Default settings for our 3D printer - Layer Height: 0.2mm - Wall Thickness: 0.8mm - Top/Bottom Thickness: 0.8mm - Printing Temperature: 185C - Printing Temperature Initial Layer: 185C - Build Plate Temperature: 55C - Print Speed: 40mm/s - Initial Layer Speed: 18mm/s - Flow: 100%

Let’s go for printing!

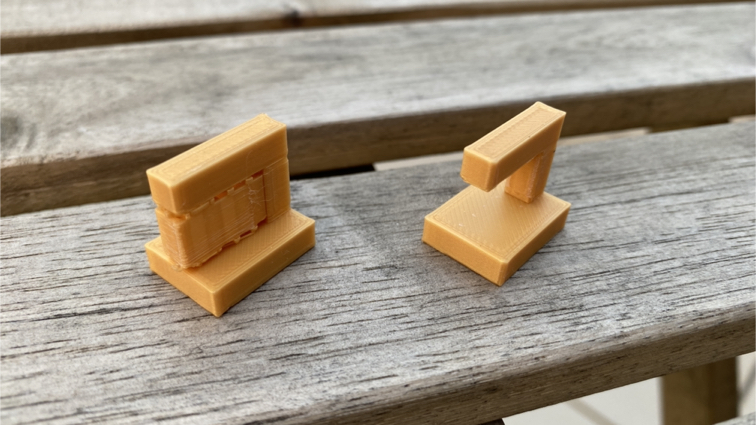

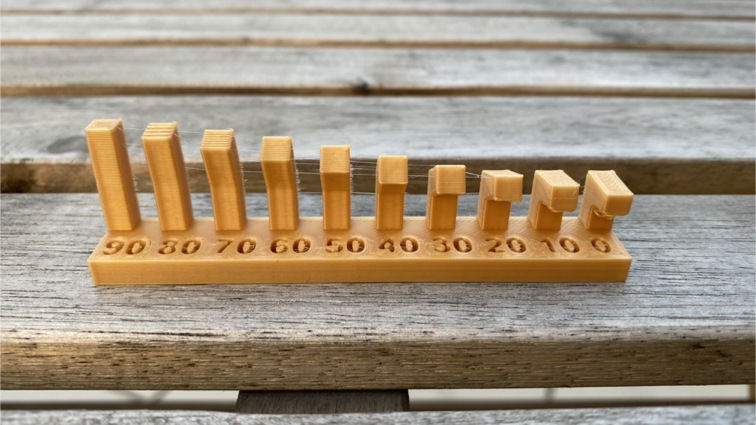

▼ Rule 1 - Overhang (with supports)

▼ Rule 2 - Clearance (with supports)

Too close (0.1mm) object will stick together

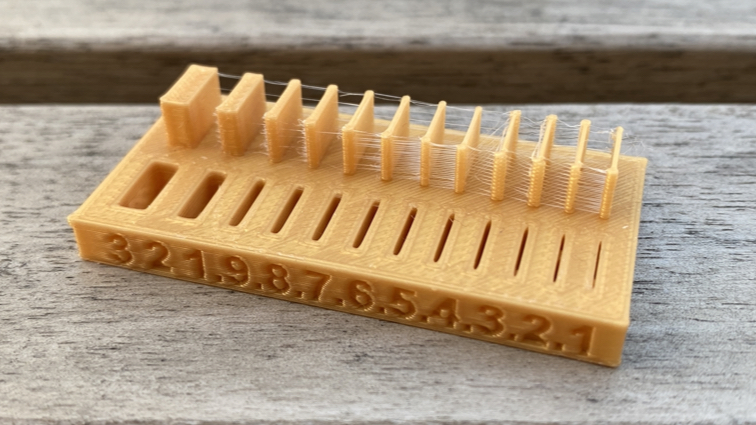

▼ Rule 3 - Angle

Overhag angle less than 30 degree

More wall thickness can improve quality

▼ Rule 4 - Overhang

Top layer is ok, overhang bottom poor quality

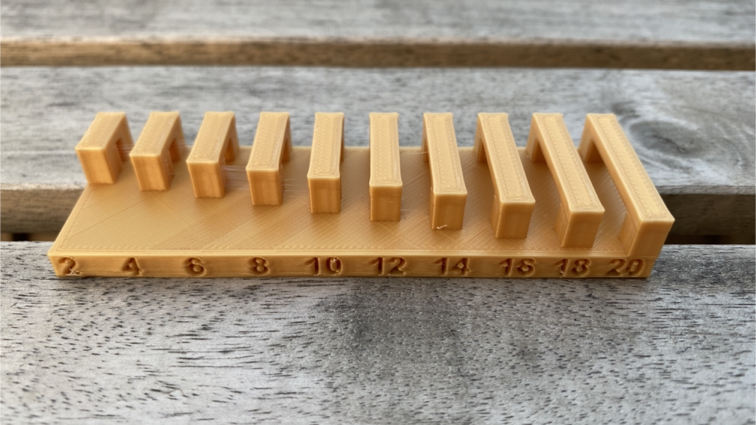

▼ Rule 5 - Bridging

Bridging less than 18mm is ok

Higher print speed can improve quality

▼ Rule 6 - Wall thickness

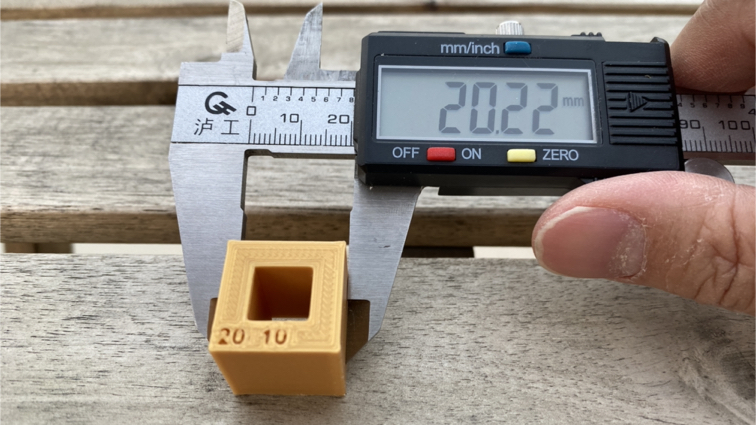

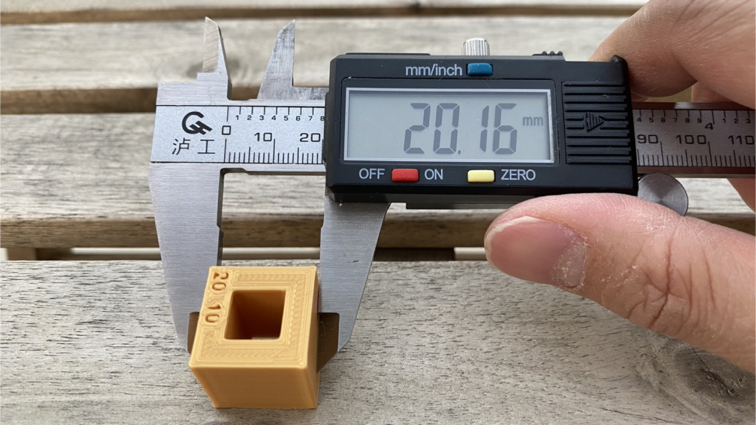

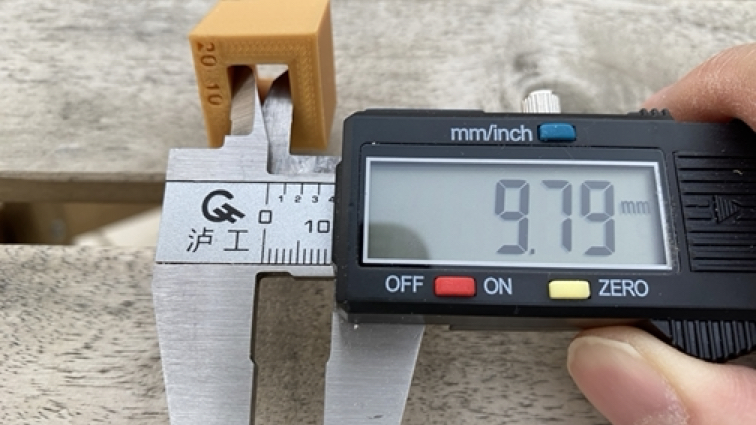

▼ Rule 7 - Dimension

Dimension tolerance is about ±0.2mm

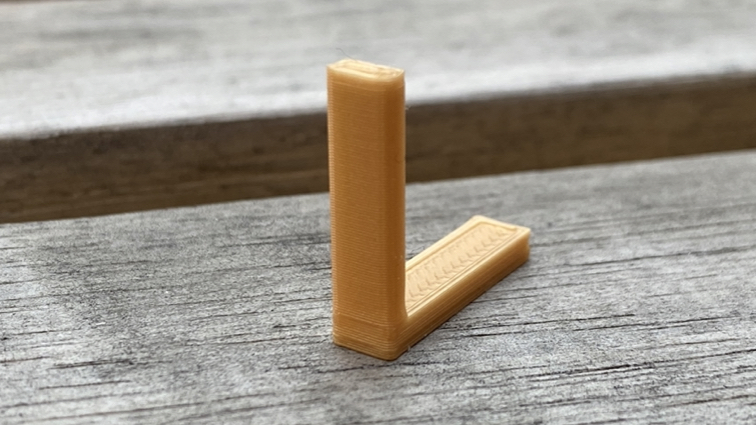

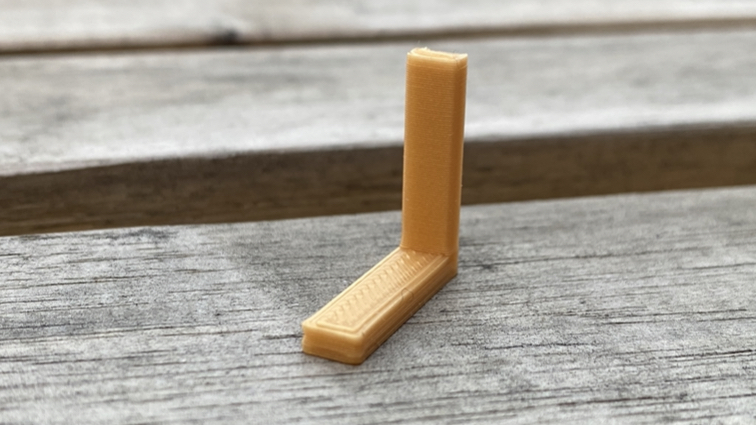

▼ Rule 8 - Anisotropy

More fan power can improve quality

▼ Rule 9 - Surface finish

▼ Rule 10 - Infill test

The limits of our 3D printer¶

Finally, we summarize some limitations of our 3D printer

- Overhag angle less than 30 degree

- Bridging less than 18mm

- Infill more than 10%

- Print speed less than 60mm/s

- Tolerance is about ±0.2mm

- Size of the Product limited in Printing Size 220x220x250mm

- Production speed limited in Fused Deposition Modeling (FDM) Technology