19. Project Development¶

Week 19, June 01

What tasks have been completed¶

Product Design and mechanical design phases are concluded.¶

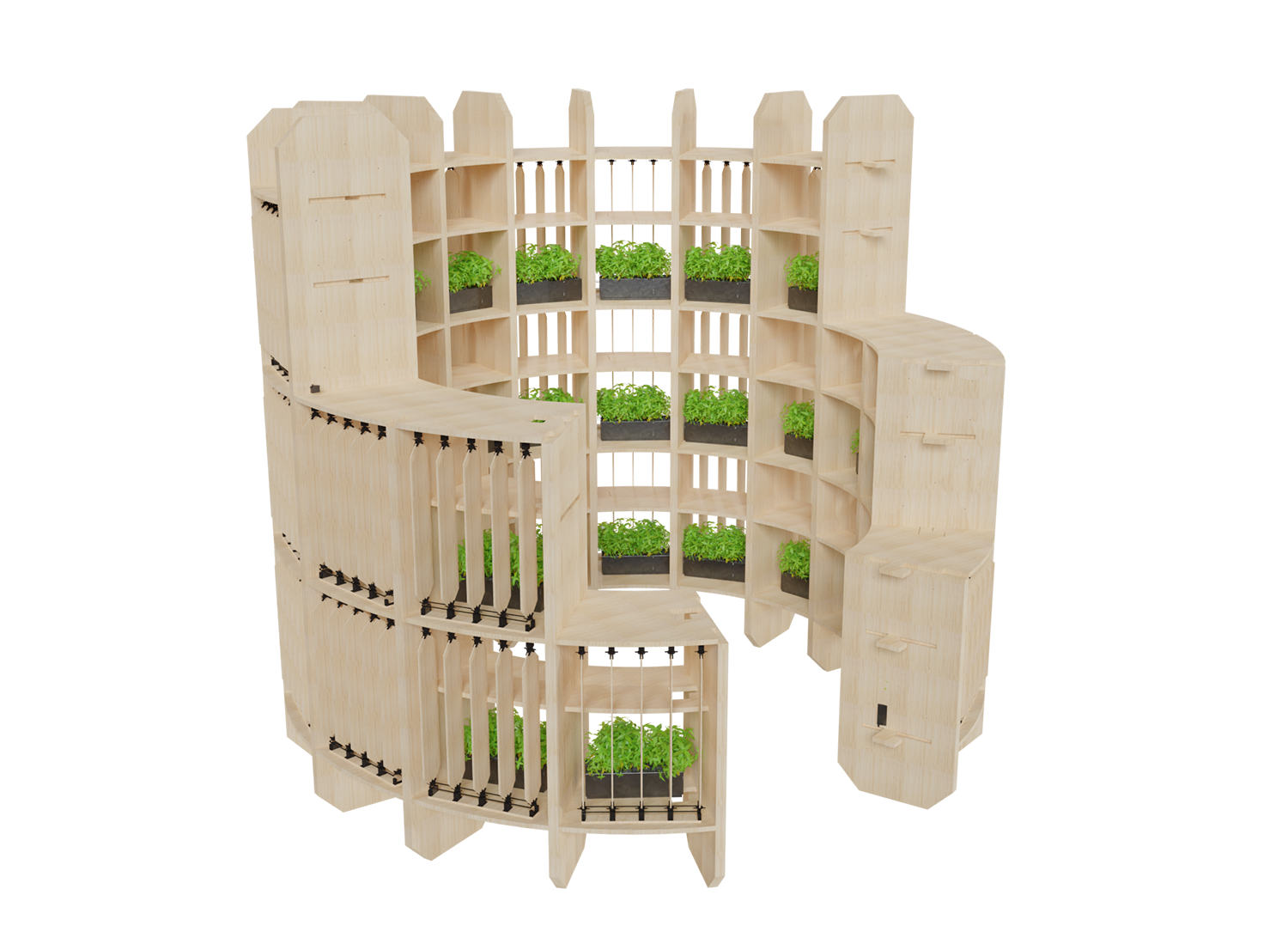

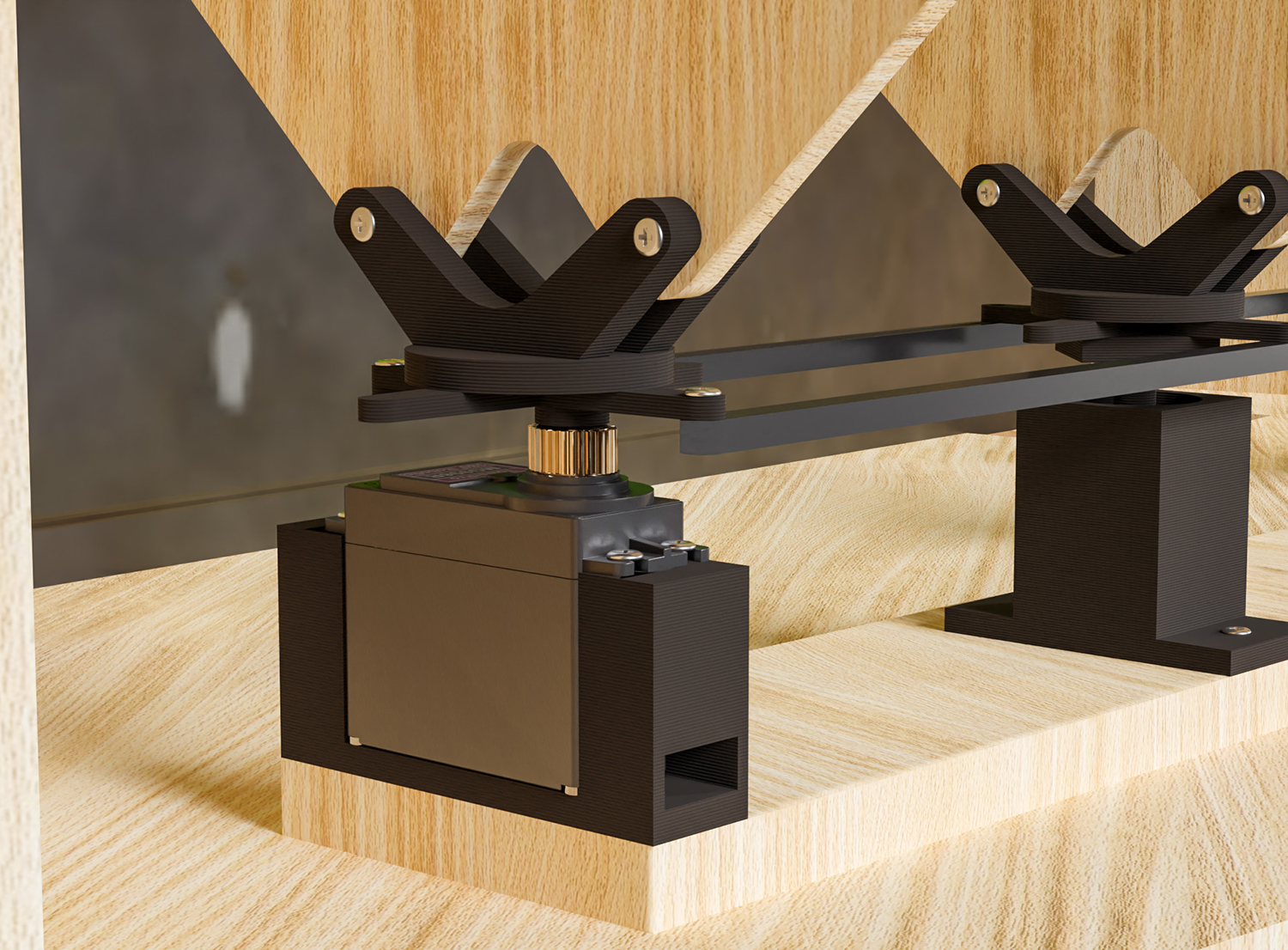

I have fully developed the armature design and mechanical design in Fusion 360. This includes all definitions necessary for the assembly of all pieces of the Cylinder. Also all definitions for the correct assembly of servos and the blinds including the transmission rods and the bearings.

Electronics design, networks and programming are concluded and tested.¶

I have a working input sensor, and a board designed to control two servos, with additional pins for transmitting and receiving data. Both boards (light sensor and servo control) communicate with each other using serial.

Thus, we can control the movement of the servos through the amount of light detected by the phototransistor.

What tasks remain?¶

Presently I am assembling the Cylinder and the blinds. The main tasks moving forward are these:

Image: render of the full project - for this iteration, as final project in fab academy, I am building the first level

(1) Finishing Assembly of all mechanical parts:¶

And testing the motion of the blinds and transmission rods. This includes also putting the servo motors in place.

(2) Making all electronic and electric connections:¶

Between the light sensor board, servo PCB and servos, load program and re-test functioning.

Other than that, I need to systematically register the assembly process, make the video and the poster.

Image: render of servo, transmission rods and blind supports

What is working, what isn’t¶

Working¶

The product design and mechanical design in Fusion is great. It is really a fantastic tool to work with complex systems that have many parts. However, It is not - or at least it is not for me - a software that lent itself to design, that is to say to conceive the forms and the mechanisms. But it is an extraordinary tool to manage complex drawings once you have all definitions done. I have overcome this, by making all conceptual drawings and sketches either in graph paper, boards, or in Rhino. Then, once the general decisions are made, I draw everything on Fusion and just make small adjustments to unforeseen details, as required.

Not Working:¶

At the moment I really don’t have any part of the project not working. Facing a lot of micro challenges in the assembly process, like cleaning properly the supports from 3d printing, finding small screws and nuts in the right size and enough quantity in the local market, etc.The toll of the assembly process of a prototype I guess.

What questions need to be solved:¶

Will everything fit together and move in the end?

What will happen when:¶

In the following week I want to finish all object assembly and mechanical assembly, leaving time for the testing of the motion of the blinds once everything is in place. This is considering that I am scheduled for the final presentation on June 13.

Image: World famous Neil’s prissioners - A.K.A We won’t be sleeping much next week - from left to right / Daniel Ughelli / Juanca Cristaldo / Claudio Coronel & Abdón Troche

Image: World famous Neil’s prissioners - A.K.A We won’t be sleeping much next week - from left to right / Daniel Ughelli / Juanca Cristaldo / Claudio Coronel & Abdón Troche

What have you learned:¶

I have learned that it is critical to have a detailed list of tasks to do, divided in three columns. One for tasks related to design, documentation, assembly, etc. In general terms, processes that do not require anything else than my work. A second column is necessary for all the pieces that need to be fabricated, either electronics, additive processes or subtractive processes. Finally the third column refers to materials that need to be obtained. This way I can have a clear vision of all the work to be done, neatly grouped in categories, that help to planify the work each day.