6. 3D Scanning and printing:¶

This week our assignment was to 3d print a object that could not be made subtractavly, and as a group, characterize the limits of 3d and resin printers.

Chosing What To Print:¶

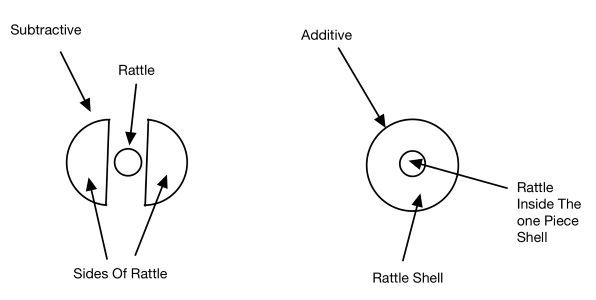

So the general theme for this week was to make something that couldnt be made in a subtractive way. This was arguably the hardest part of this whole week because I hade some confusion about what could and couldnt be made subtractivly. After alot of brainstorming i started using the classic ship in a bottle as a starting base. The general idea was that I needed to have something that was build with something already inside of it. An example of this would be a childrens rattle but insted of but it is a solid object insted of 2 halves put together. Another example of a objects that couldnt be made subtractivly is 3D printed chainmill. Here as a sketch depiting what I mean as this is a bit difficult to explain in words:

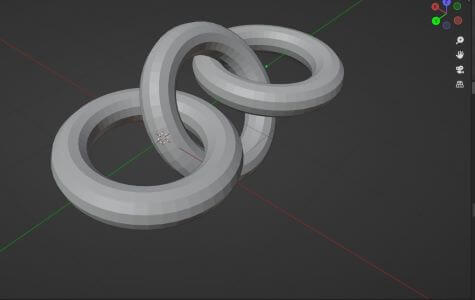

I decided to make a simple chain for this week as it wouldnt be to complicated and it would meet all the requirements for this week. Designing it was reletivly easy as i did it in blender. I have offically come to the conclusion that Fusion 360 is great for 2d Creations but when it comes to 3D, Blender is far better as in my eyes, it runs alot smoother and is more fluent. It did not take long to create the chain and after a bit of time I was ready to print. Here is a photo of what the design looks like in blender:

Here is the Chain File

3d Printing The Chain:¶

Down As Of Now. I Am redoing this week as I was not happy with the first result. It was not apperant how it could not be made subtractavly. I had made a airfoil with a small lip inside to give it support but it was difficult to get an angle that depicted this correctly.

Group Project:¶

For our group project we needed to characterize the design limits for 2 3d printers and 2 resin printers. Here is the link to the group documentation page.

3D Scanning:¶

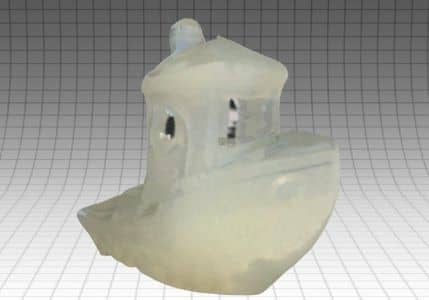

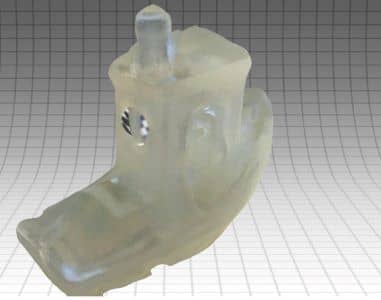

Last but not least I needed to 3d scan an object. The scanner we have at the lab is extremely outdated so i used my phone to do this. Because I did not have LIDAR on my phone i needed to print out a mat that i would place the object i wanted to scan on. I decided to scan one of the benchys I made on the resin printer. The scanning process just involved me moving the camera around it several times and when i was done it would compile the model. Here is what the final result looked like. I call it the google earth benchy because it looks like a google earth car.