Final Project:¶

This page will be my final project blog where I will post progress, updates, changes, and more.

What Is It And What Does It Do?¶

My final project is a quadplane with vtol capabilites and assisted flight with features such as return to home and position hold. The aircrafts main puropse it to survey a specific aera. Additionally it can also carry a small payload. This is mainly because i want to drop around 50 of those party city paratroopers from it because it will be fun. For more information on the brainstorming of this project see my Princiles and pratice page under assignemnts.

Has This Been Done Before?¶

This question is answered with both a yes and a no. by definiton several quadplanes have been made before but more often then not they are industrial grade UAV’s that arent avaliable to the average RC enjoier. However, this doesent mean that smaller personal quadplanes dont exist. People have built quadplanes that they would use personally but there are no personal quadplanes on the market for the average joe.

Parts I Need to Make/Alter In Some Way.¶

- GPS sensor. This will connect to the autopilot and allow the position hold and return to home features.

- 40 Amp ESC. These will be The Esc’s for the quad copter part.

- Speedomiter. This will tell the raido how fast the aircraft is flying via telemetry.

- Lidar Altimiter. This will allow the position hold featre to also work on the Z axis.

- Fueselage and wings. The fuseslage will be 3d printed using LWPLA and the wings will have theire skeleton 3d printed then wrapped in a tissue paper like substance. (The Wings Are Still Subject and Likely to Change In The Near Future.)

- Control Horns. these will be 3d printed and allow movieble control surfaces.

- Interchangable Cargo Pod With mounting system.

Parts I Will Order Pre-Made¶

- Flight controller because I dont trust myself to make one and they are extreamly complicated. Additionally my knolege is insufficent to even think about making one.

- Moters because making a brushless moter is a final project in of itself and would take way to much time.

- 4S Lipo Battery because it is the best fit from size and weight to fuel volume. Aditionally it is the best for the motors I plan on using.

- Wheels. I thought about making these for modling and casting week but the materials we had were not the most optiomal.

- Propellers. I thought about making these for molding and casting week but I wasent sure how strong they would be. Additionally i dont know how strong the molding and casting materials are.

- Reciver and transmitter. This is the heart of the aircraft and I want a pair that i know would work well and can be salvaged if all goes wrong.

- Salaveged ESC and Moter. I Have an old rc sailplane that has seen better days and is no longer airworthy after a battery failure mid flight. The moter and paired speed controler are still in great working condition so I will just use thoes for the pusher prop on my aircraft.

- Other necessary RC plane equitment. Serveos, Rc plane wires and, Control rods.

Starting Construstion On The Aircraft:¶

With output week right around the corner, I planning on making a Servo tester to help align and test the effectivnes of the Servos before they are installed in the aircraft. This is very helpful as it makes aligning the servos a much quicker process. For more in depth documentation on my Servo tester please visit my Output week documentation where I explane the whole process in great detail.

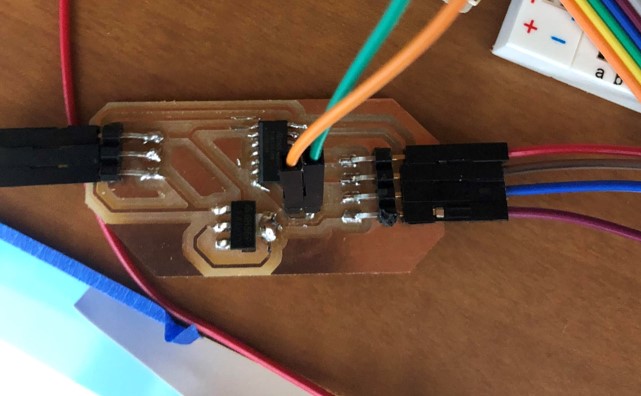

Right after Output week, we had input week comming up so I decided I would make an Accelemotor Position logger. I decided to use a LSM303DHLC and upon doing some searching, I discovered that I could use this sensor to take care of 3 of my inputs. The Altimiter, Spediomiter, and Position Holder. For more explaniton on how I made this sensor please visit my Input Week Documentation.

Update Number One: April 28, 2022:¶

Since the first log on my final project alot has changed. To begin I relized I have not done a great job of explaning my plan of action. My goal come the end of Fab Academy is to have that actuall airplane part up and running ad having achived stable flight with some basic flight assist features such as Altitude and Speed Hold features and the camera mapping mount. If time allots, I will begin planning out the VTOL section of this aircraft. However I still plan to make this aircraft VTOL in the comming years as it will be difficult to finish this all in a month. Also due to some feedback from Neil himself, Rather then 3d printing the aircraft, It will be made out of a lightweight yet durable composite. I have done a bit of research on this and am thinking of molding the composite. I am against a skinned balsa wood composite because this aircraft is ment to be able to take a bit of a beating. additionally this aircraft is ment to haul a small bit of cargo. all this plus high G vtol transitions will signifigantly damage the aircraft. Aditionally the prototype will be a bellylander at first further inhibiting the balsa composite idea. Although a mold will require alot more time and thought to create, It is alot more viable based on what i am going to do. For the wings I may do a foam core skinned in carbon fiber as these can hold some hardpoints for the vtol booms, however theye are cheaper, simpiler, and more replacable then the composite wings would be. Especally considering that the wings will need to have holes in them for the wiring to travel through. The main booms of the aircraft wll still be constructed out of Carbon or Carbon Fiber spars leading to the Elevator and rudder of the Aircraft. The origional design sketches for the aircraft are still relevent.