The beginning

In this task, we worked as a team to measure the power consumption of an output device connected to a custom board designed as part of our final projects. The board, based on an

ATtiny1614 microcontroller, was used in conjunction with an

MG996R servo as the output device.

The main objective was to analyze both the

voltage (V) and current (A) consumed by the system, which is essential to evaluate its energy efficiency. To do this, we used a digital multimeter and performed measurements in different states of the system: at rest and during servo activity. These measurements were essential to understand

the variations in power consumption and to determine whether the power supply can meet the demands of the circuit under various operating conditions.

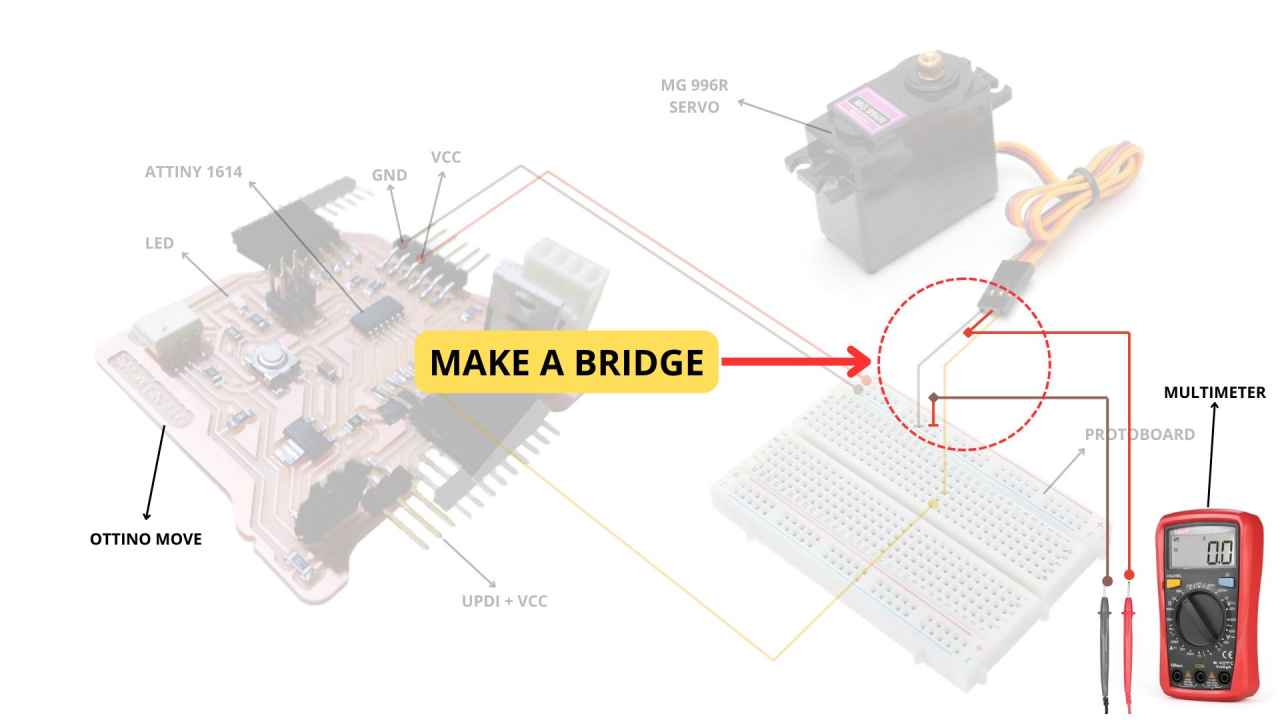

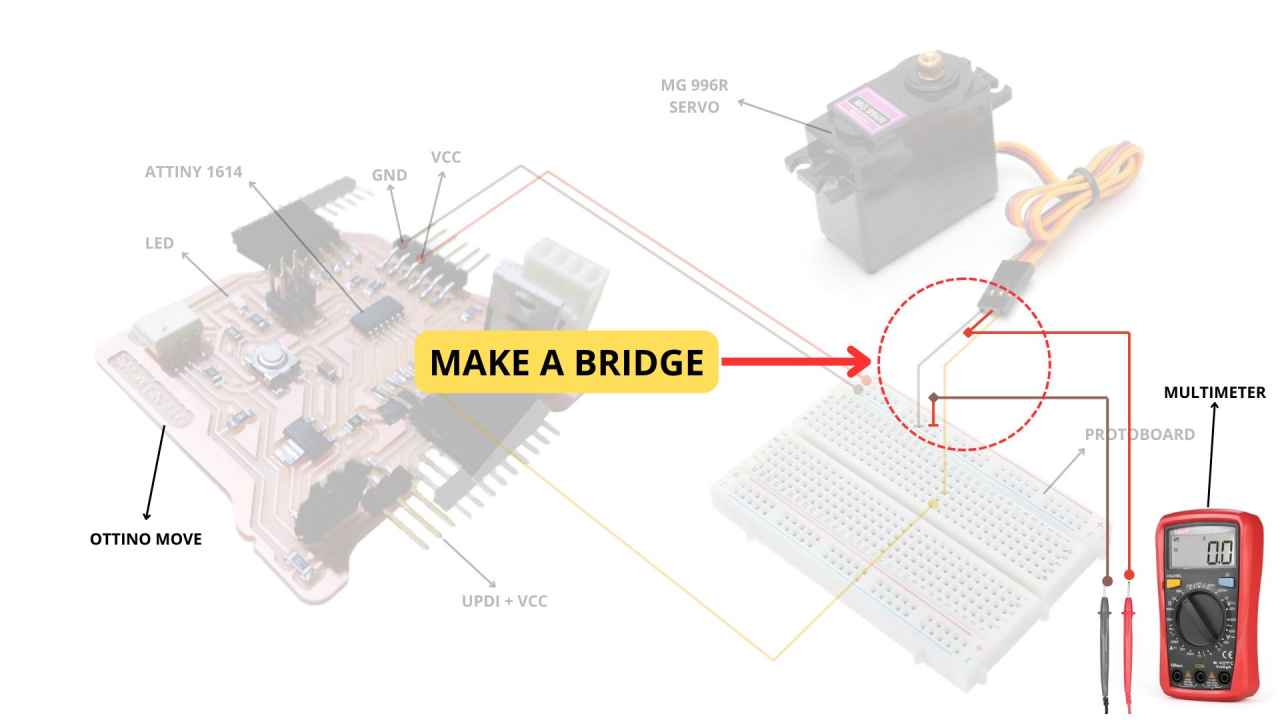

During the process, we faced technical challenges, such as understanding and correctly measuring amperes.

One of the most complex moments was setting up a bridge with the multimeter to measure series current, as it required interrupting the circuit and properly connecting the measuring device. These difficulties taught us the importance of

understanding electrical connections and the correct handling of measuring instruments.

In the end, we were able to obtain accurate data on both the

voltage and amperes consumed by the system. This experience not only allowed us to document the energy behavior of the circuit, but also strengthened our practical skills in electronics and measurement, essential for the development of the

final project. In addition, we learned significantly about teamwork and technical problem solving. 💪🥰

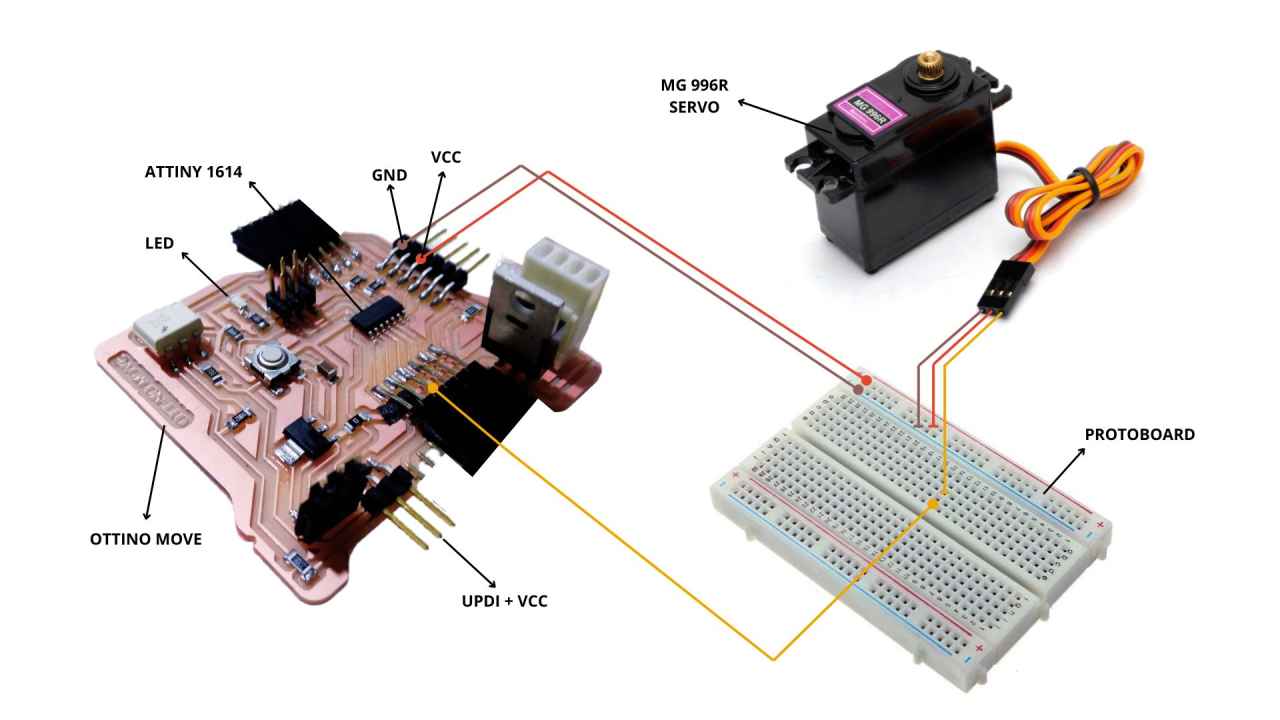

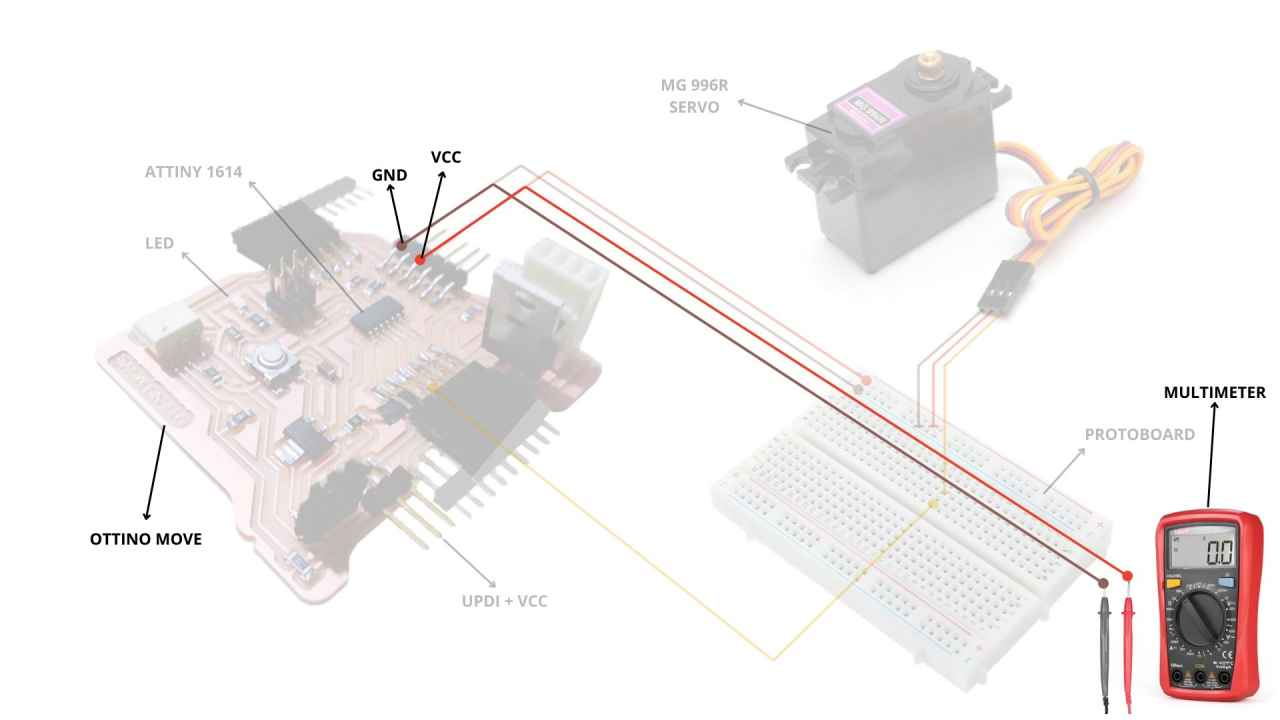

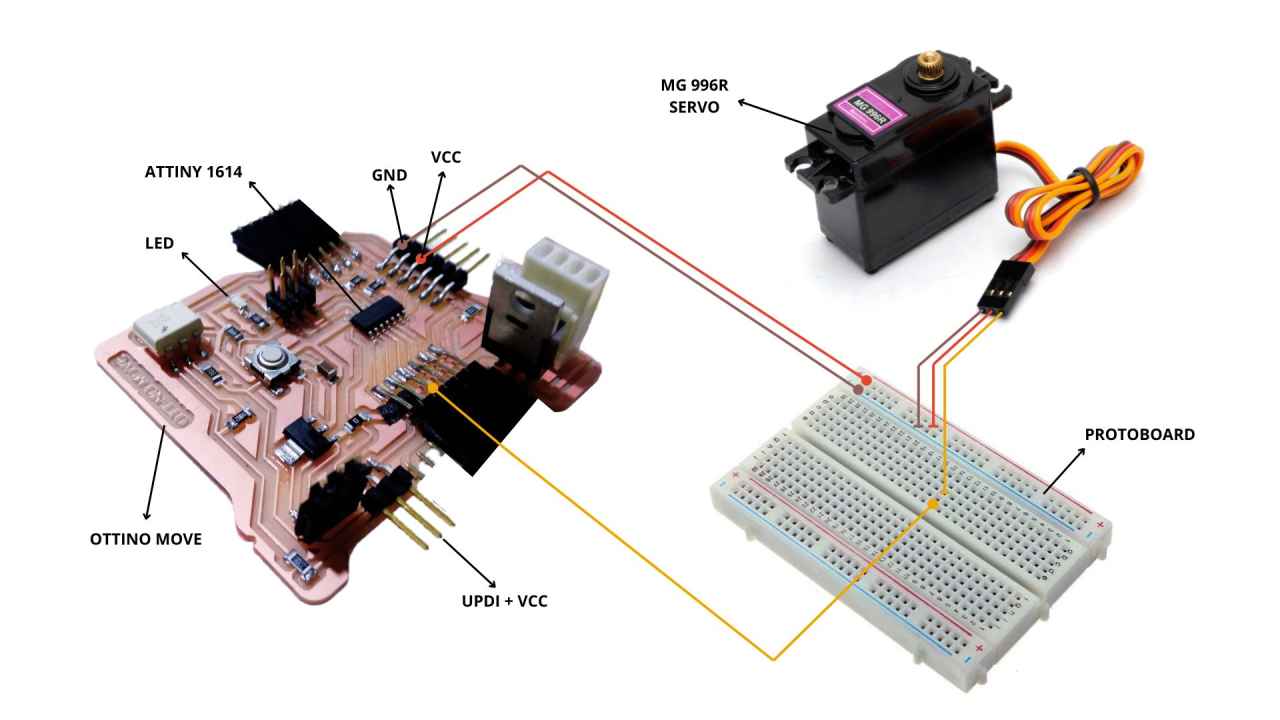

CONNECTION DIAGRAM:

Measure the power consumption of an output device

Next we share in detail how we get the measurements. It is important to note that if you do not know

how to use the multimeter, you should be guided by the diagrams, otherwise, you will not be able to get the measurements correctly.

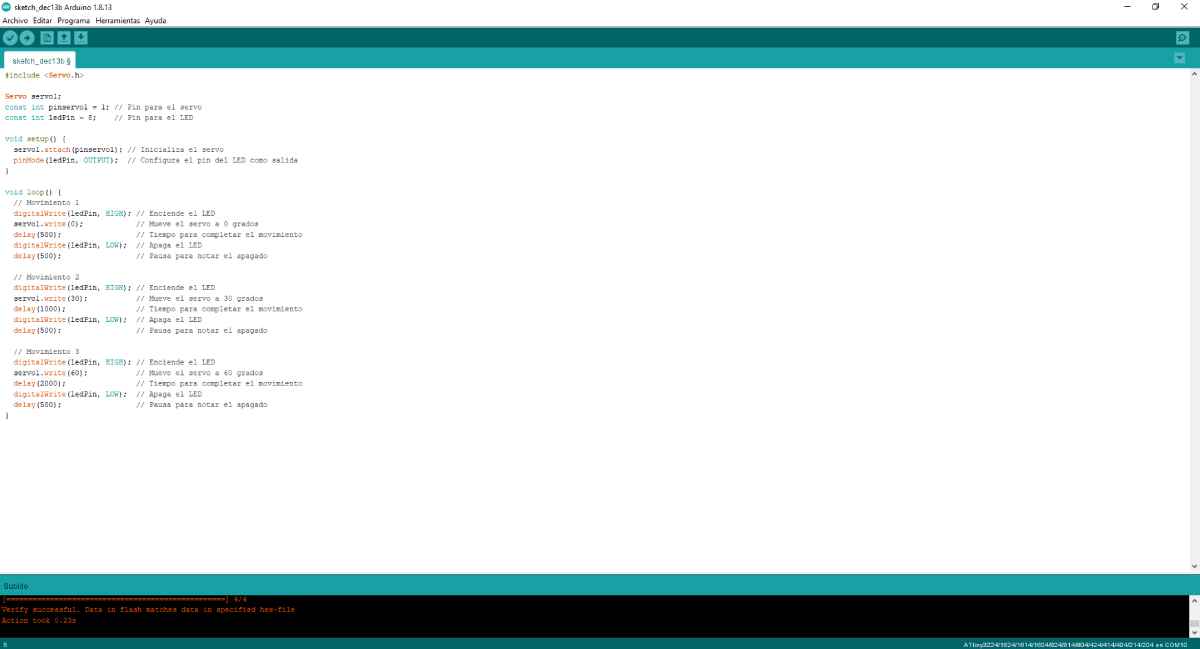

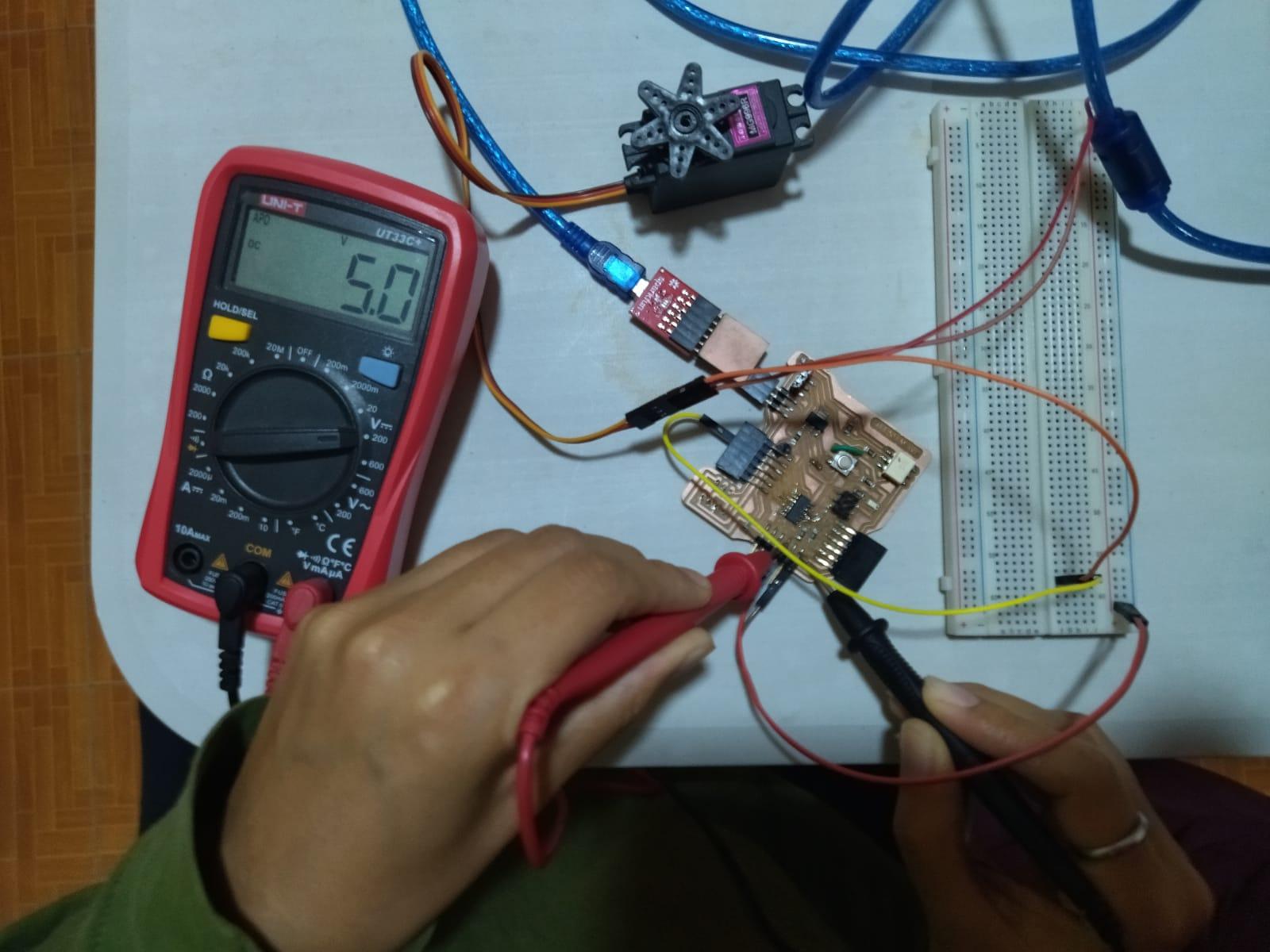

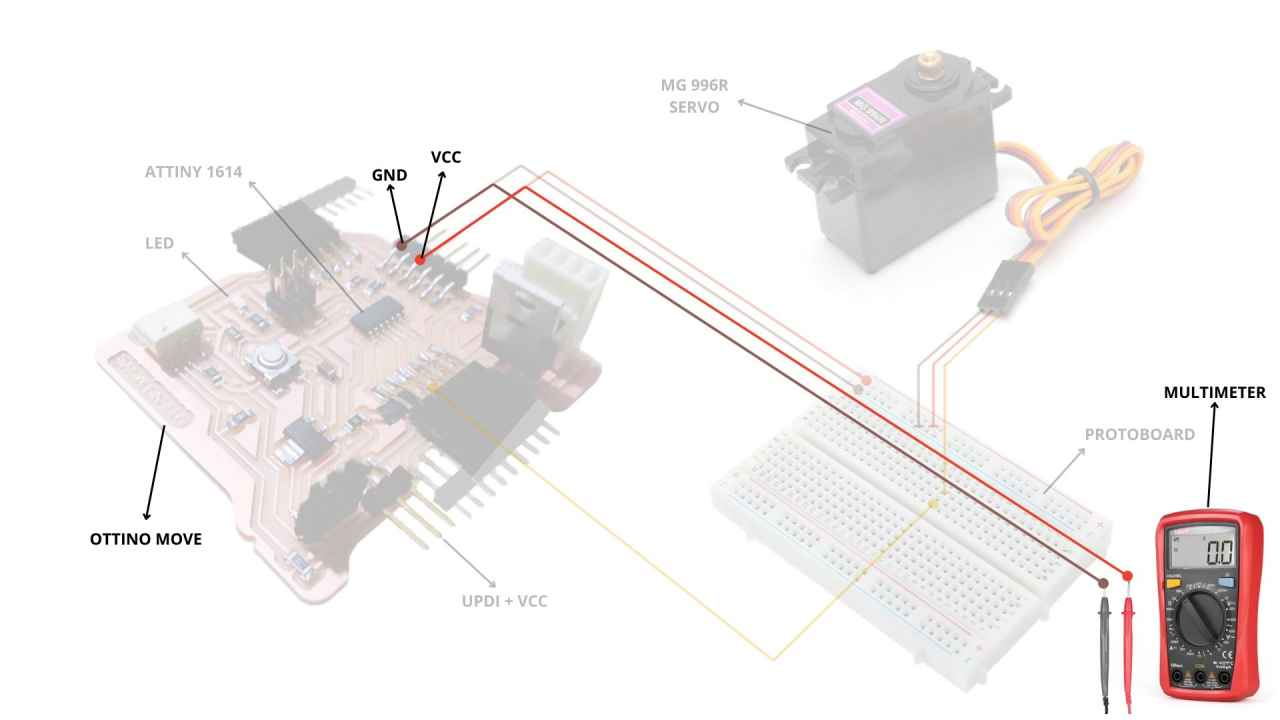

Voltage

To perform the measurements, We set the multimeter to DC voltage mode and measured in parallel between the power pin (VCC) and GND of my system. In my case, the code loaded into the ATtiny1614 caused the servo to move at different angles (0°, 30°, and 60°), while the LED turned on and off in sync with each movement.

Results Obtained

Measured Voltage:

1. During the measurements, the system voltage stabilized at 5.0V, confirming that the power supply is adequate to operate both the ATtiny1614 and the MG996R servo.

2. Slight initial oscillations were observed when the multimeter was turned on, possibly due to circuit stabilization or servo start-up.

Voltage Analysis

1. Voltage Stability:

The system maintained a constant voltage of 5.0V during all operations, which is critical to ensure proper operation of the microcontroller and servo.

2. Initial oscillations:

These could be due to the natural behavior of the system during connection of the multimeter and start of operations. To mitigate them, the use of a decoupling capacitor in the power supply could be considered.

HOW TO CONNECT - VOLTAGE:

Amperios

We now use the digital multimeter in mA current measurement mode to observe the power consumption during output device operations.

Results Obtained

Measured Current:

During the measurement, the current oscillated to a maximum value of 150 mA (0.15 A) when the servo was moving.

At rest (no servo motion), the current consumption was significantly lower, around 50 mA.

Multimeter Status:

The multimeter was set correctly in the milliampere (mA) range, which allowed accurate readings of the system consumption to be obtained.

Current Consumption Analysis

Current Variation:

The increase in current up to 150 mA is consistent with the characteristics of the MG996R servo, which has a higher consumption when moving, especially if it encounters any resistance or load.

The low idle consumption indicates that the system is efficiently designed to minimize power usage when the servo is not active.

Power Supply Review:

The power supply used is adequate, as it can smoothly handle the increased consumption during servo movements.

Maximum Power Calculation:

With the voltage of 5V and the maximum consumption of 150 mA, the maximum power consumed by the system can be calculated as: P=V×I=5 V×0.15 A=0.75 WP = V \times I = 5, \text{V} \times 0.15 \, \text{A} = 0.75 \, \text{W}P=V×I=5V×0.15A=0.75W

This indicates that the system is relatively energy efficient.

HOW TO CONNECT - CURRENT: