Assignment

Final ProjectMasterpiece

In this work week, I will focus on exploring and defining the applications and implications of my final project: an interactive device for children in the form of a hemisphere, which integrates a motorized zoetrope and an infrared sensor to activate it intuitively. This project combines ergonomic design, digital fabrication, and interactive technology to offer a unique playful and educational experience.

The device's main purpose is to teach children the basics of animation through a practical and dynamic approach. Thanks to its semi-spherical design covered with TPU, children can manipulate it safely and comfortably, while its internal structure, constructed with MDF, provides support and durability. The infrared sensor detects the proximity of users' hands to trigger the zoetrope's movement, allowing for an interactive experience that encourages learning through play.

At this stage, I will detail how my project addresses specific needs, the technologies and processes I have integrated, and the educational, social, and technical implications of its implementation. I will also reflect on its potential impact and areas for improvement, ensuring that the device is functional, safe and accessible to its target audience. 💃

What will it do?

The interactive device will be an educational and playful tool for children. This hemispherical-shaped project will allow children to explore the concept of animation through an integrated zoetrope. It will also encourage curiosity and learning through direct manipulation and the use of interactive technology, such as an infrared sensor that activates the movement of the internal zoetrope. 💪

Who's done what beforehand?

Zootropes have been known for a long time, however, in fab academy, there are few projects that have chosen this toy to develop their own version. I found some pages of students from previous years but not all of them managed to finish, the case that I found interesting and that is 100% developed was the following one:

Fab Academy 2017 - Juliana Henno Zoetrope 3D

The project “Sisyphus - The Interactive Rock” is an interactive installation that takes as inspiration the myth of Sisyphus. It is a rock that, when touched, begins to move as if it were in a constant effort, thanks to a system of motors and sensors controlled by a microcontroller. It is made with lightweight materials and a design that mimics the natural appearance of a rock. The idea behind the project is to make people reflect, in a fun and visual way, on the constant effort and persistence in life.💪

What will you design?

Structure: An interactive hemisphere, designed to be ergonomic and suitable for children to manipulate.

Internal mechanism: A motorized zoetrope controlled by an infrared sensor that will detect the proximity of children's hands to activate it.

Outer cover: A TPU (thermoplastic polyurethane) surface to make it soft and safe to the touch.

What materials and components will be used?

Internal structure: MDF (medium density fiberboard).

Outer cover: TPU to ensure softness and durability.

Electronic components:

Infrared sensor for motion detection.

Stepper motor for zoetrope movement.

Microcontroller (Arduino or ESP32) for system control.

Power source: Rechargeable battery.

Others: Cables, connectors, adhesives and safety finishes.

Where will come from?

All these products are easy to find, here in Lima I found them in the center of the city, where they sell all kinds of accessories. In the case of TPU and MDF I will count on the material that is in our home as well as the machines that are operational.

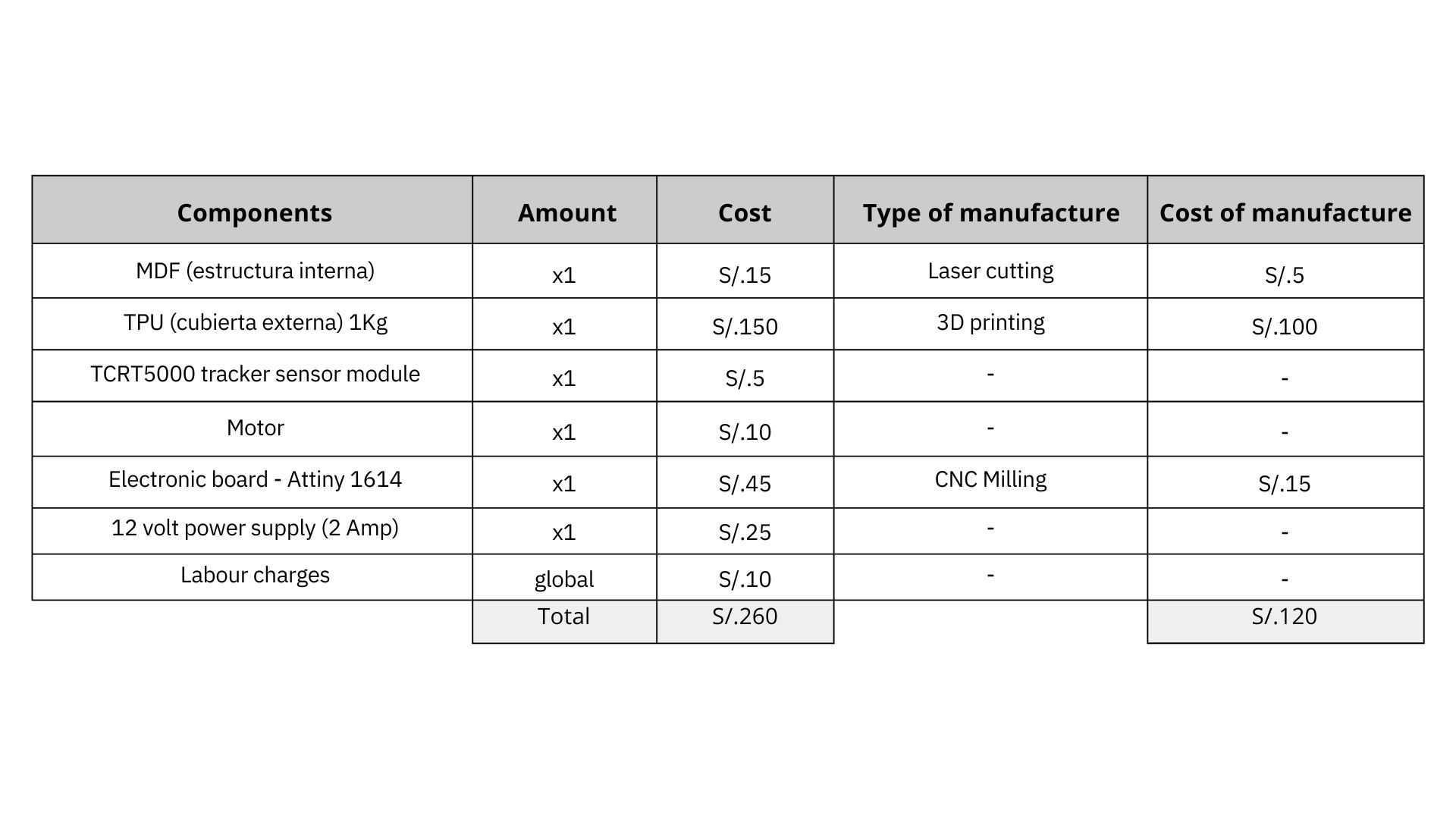

How much will they cost?

What parts and systems will be made?

Internally: Hemispherical structure and zootrope supports in MDF, using laser cutting.

Externally: TPU shell molded or thermoformed to ensure a tight and secure fit.

Zoetrope: Manufactured with printed images and laser-cut supports.

What processes will be used?

- 2D and 3D design: Modeling of the hemisphere, the internal structure, and the parts of the zootrope.

- Subtractive manufacturing: Laser cutting for the MDF.

- Additive manufacturing or thermoforming: Creation of the TPU outer shell.

- Electronic production: Assembly and programming of sensors, motor and microcontroller.

- Integration and assembly: Final assembly of all parts.

All this I have already worked on in the following weeks:

- Computer aided desing

- Computer controlled cutting

- 3D printing

- Electronics design

- Electronics production

- Embedded programming

- Computer controlled machining

- Output devices

- Input devices

What questions need to be answered?

- How to ensure that the TPU adheres properly to the MDF?

- What is the optimal sensitivity of the infrared sensor for children?

- What rotation speed is suitable for clear zoetrope images?

- How to ensure the safety of children during use?

How will it be evaluated?

Interactivity: The sensor must accurately detect proximity and activate the zoetrope.

Safety: The device must be smooth, without sharp edges, and made of non-toxic materials.

Durability: Withstand continuous use by children.

Visual effect: The zoetrope should generate a clear and attractive animation.

Assignment

Project Development

what tasks have been completed, and what tasks remain?

Completed tasks include the design of the zootrope, the choice of materials such as MDF for the internal structure and TPU for the outer shell, and the implementation of the electronics with the infrared sensor, stepper motor and microcontroller. Pending tasks include the complete integration of the control system, the final programming of the microcontroller and the testing of the user interaction, as well as the optimization of the final assembly.

What's working? what's not?

What works so far is the physical structure of the zootrope, with the installation of the basic components such as the motor and infrared sensor separately.

What questions need to be resolved?

Accurate calibration of the stepper motor must be resolved to ensure that the zoetrope motion is smooth and synchronized with the animation. Durability testing also remains to be done to ensure that the device is robust enough for child use.

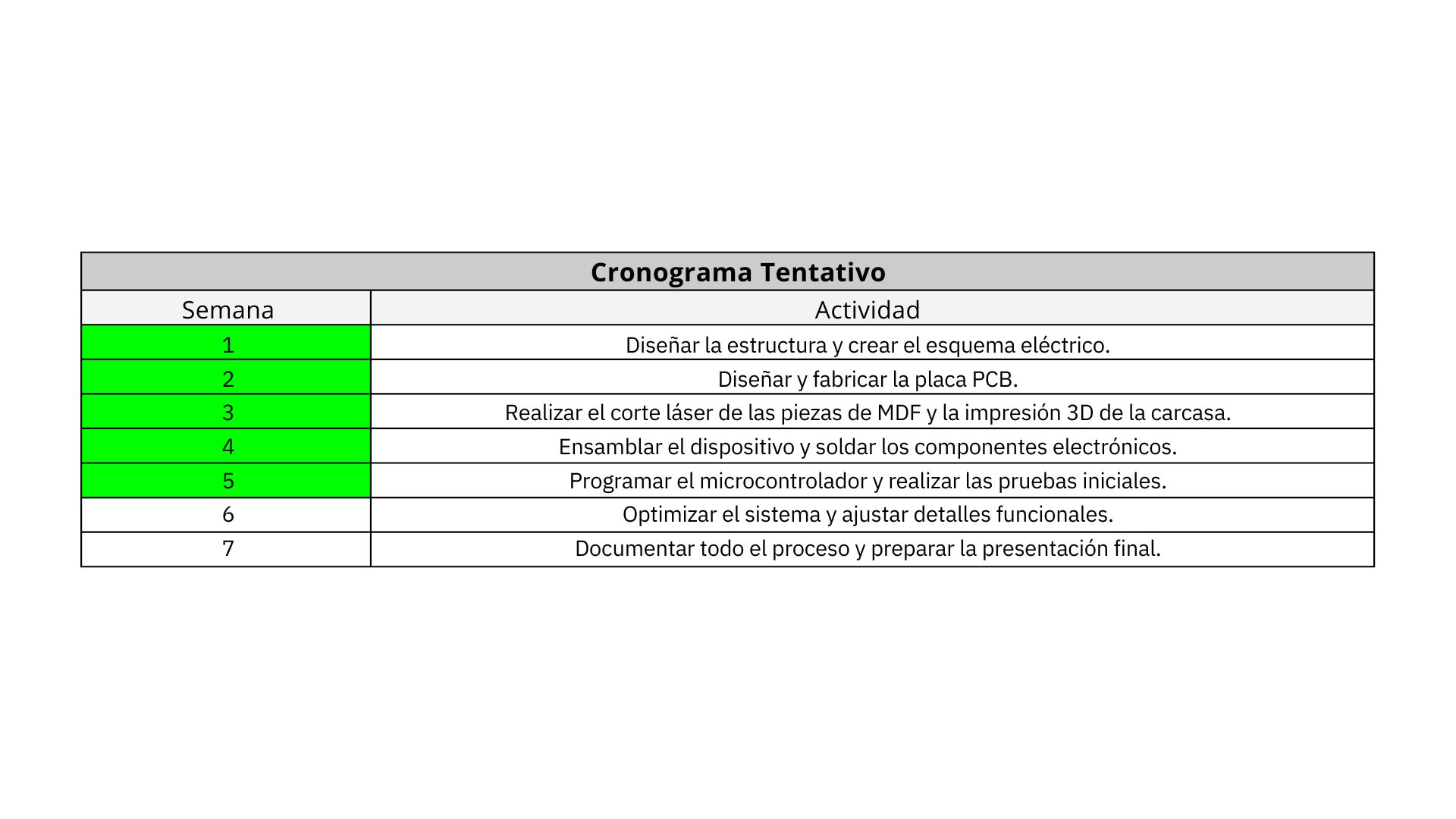

What will happen when?

Final testing and full integration of the system is expected to take place in the next few days, with the goal of having a working prototype ready for evaluation in the near future.

What have you learned?

They have learned to integrate different technologies, such as stepper motors, infrared sensors and microcontrollers, in a practical and interactive project. In addition, experience has been gained in digital fabrication and the selection of appropriate materials for each part of the device, understanding the importance of a well-balanced design between functionality and ease of use for children.