Seventh Week

Seventhclass

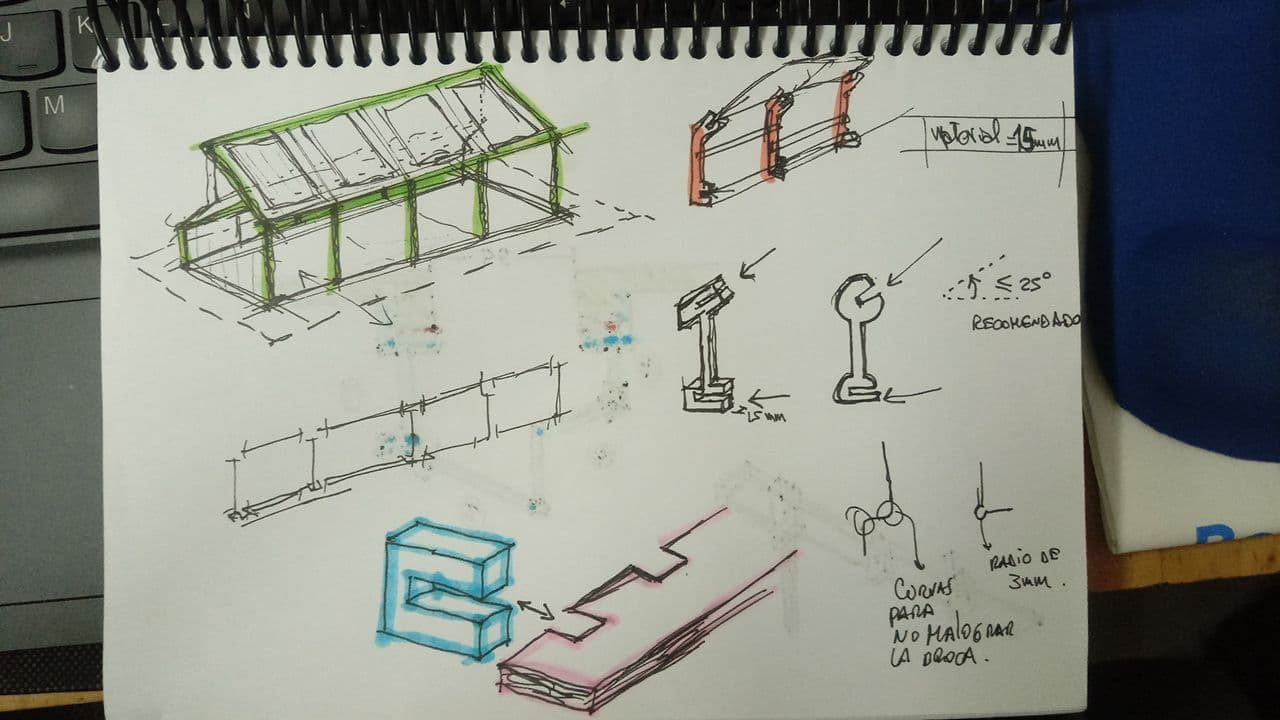

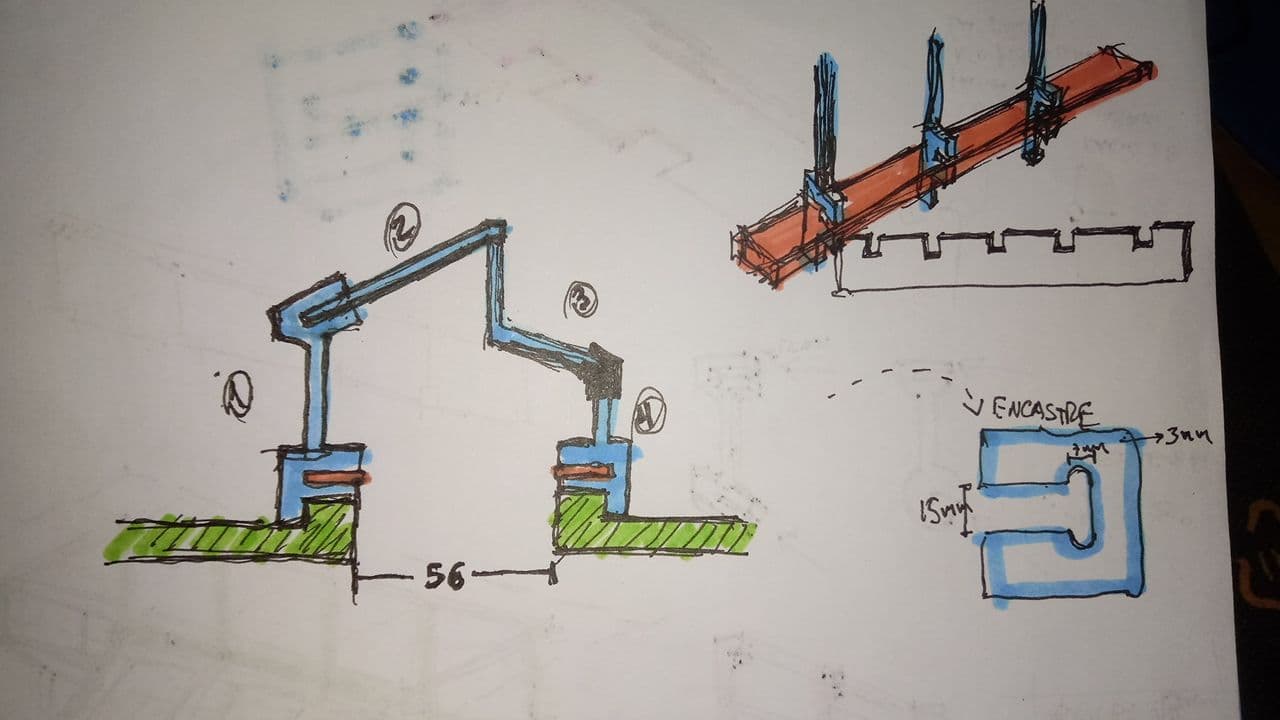

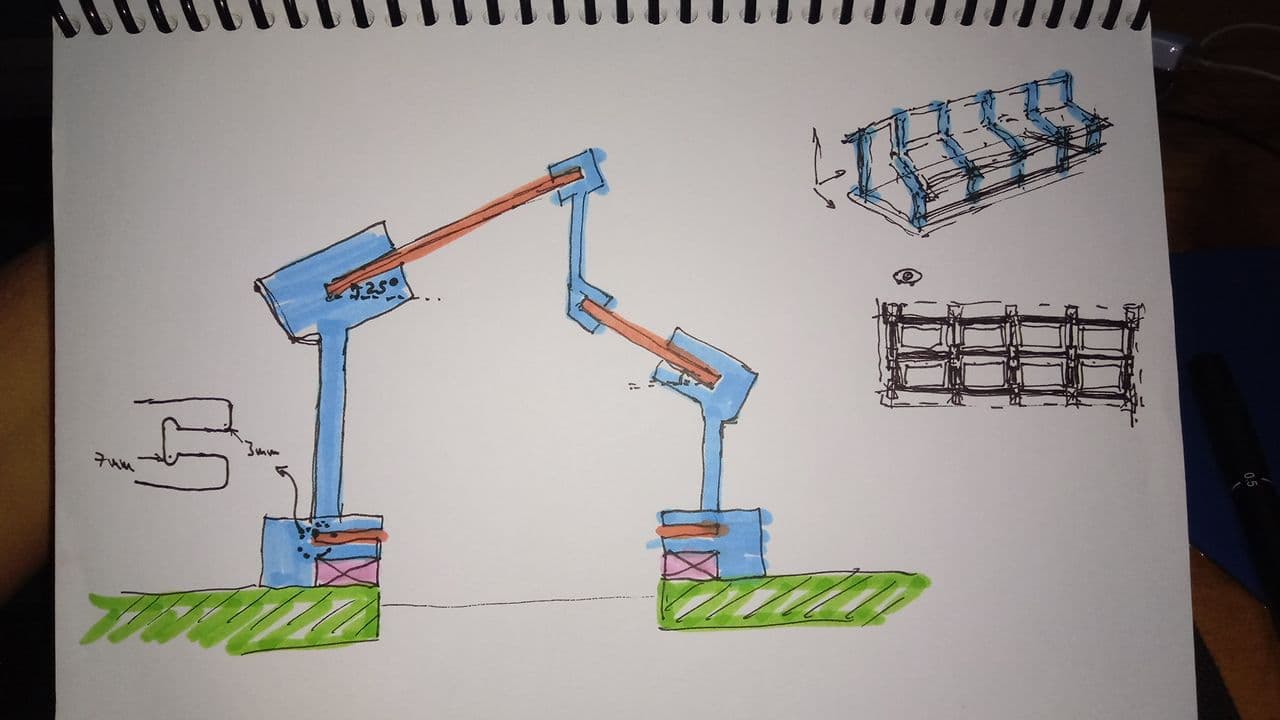

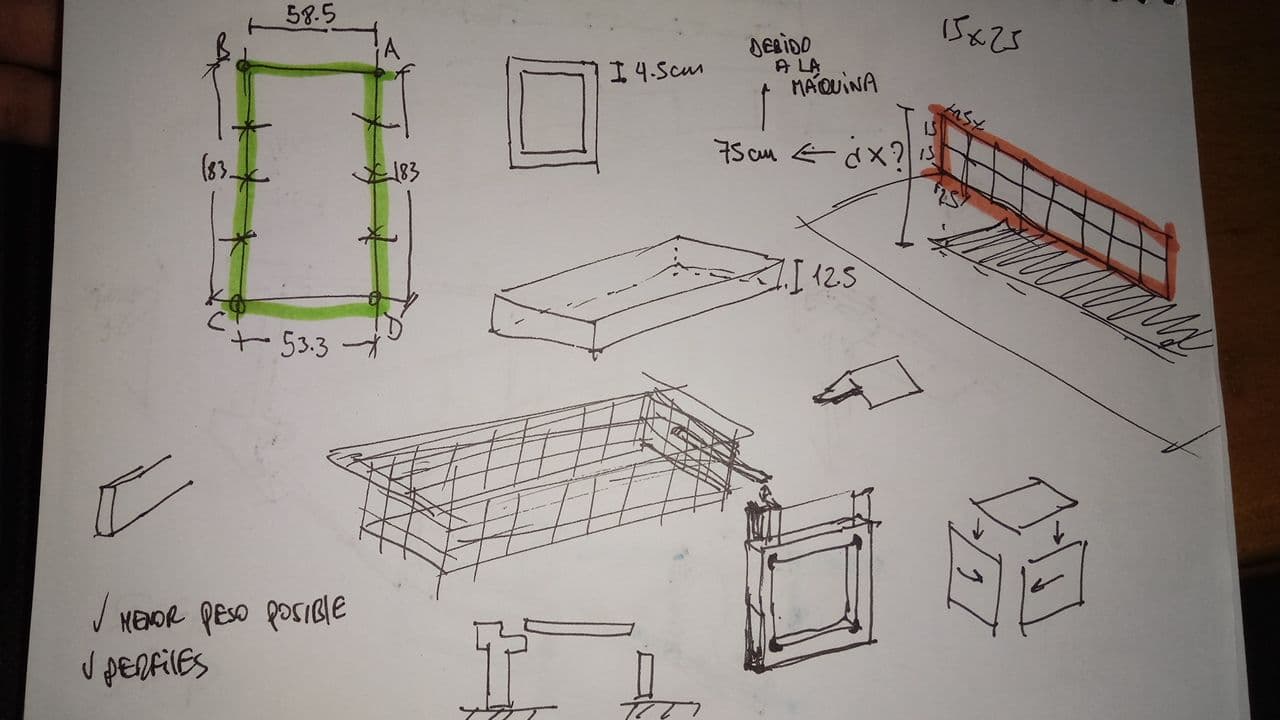

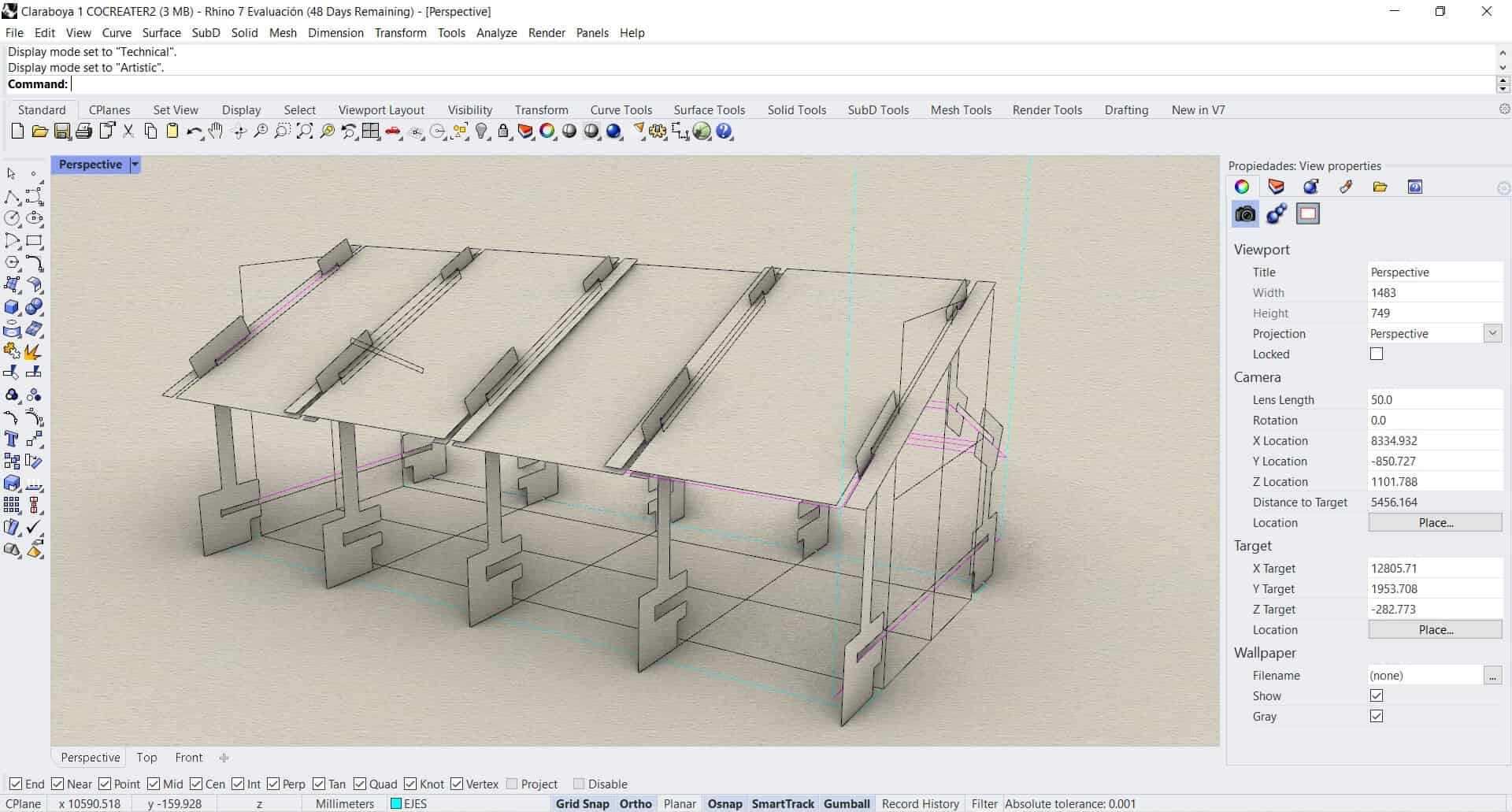

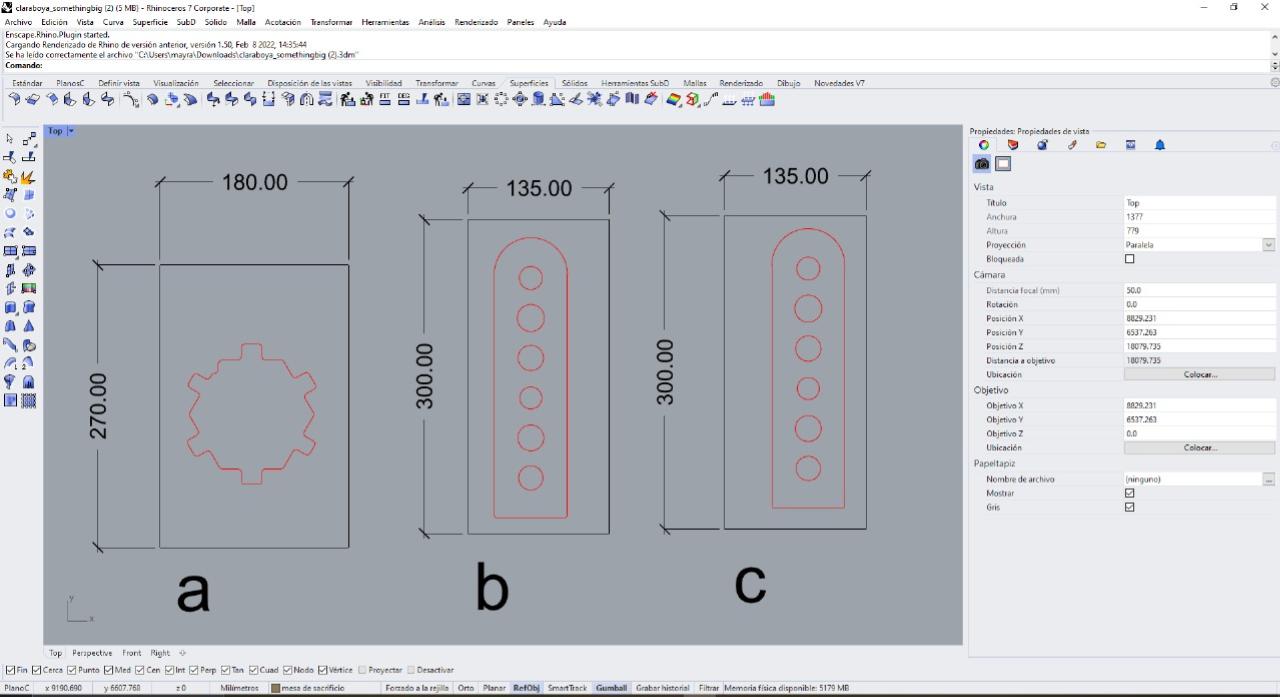

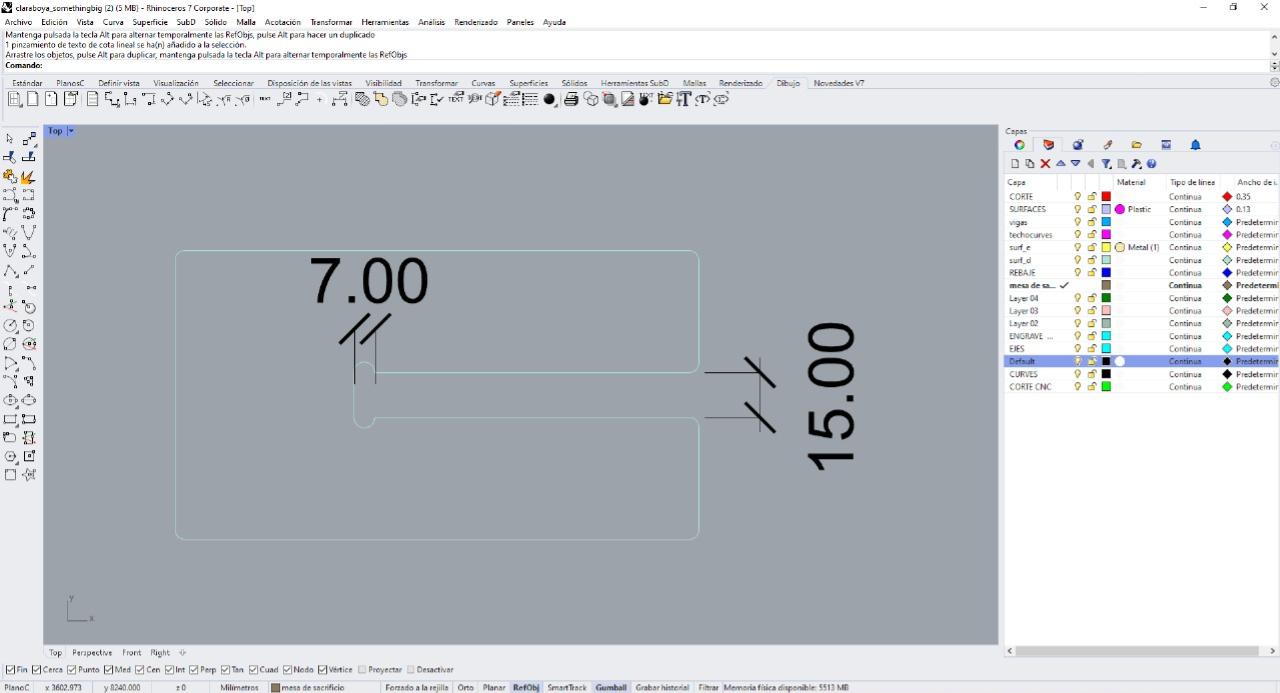

Seventh week in the Fab Academy and this time we have to make a human scale design, I am excited about this week as I have never handled a large machine before and I have never worked with wood in large designs so it is being a great new learning experience.

We don't have a ShopBot in our lab so we ventured to get one, first it takes us a long time to get the tools but still our job is to solve it so thanks to the team and their predisposition we always innovate solutions for everyone. Next I will describe the step by step of what happened this week, I recommend once again to keep moving, in case you haven't managed to have a complete lab you can use the alliance with some people that count with what you need and contact them, always working as a team helps a lot. Great team Fab Lab Lima! 😍

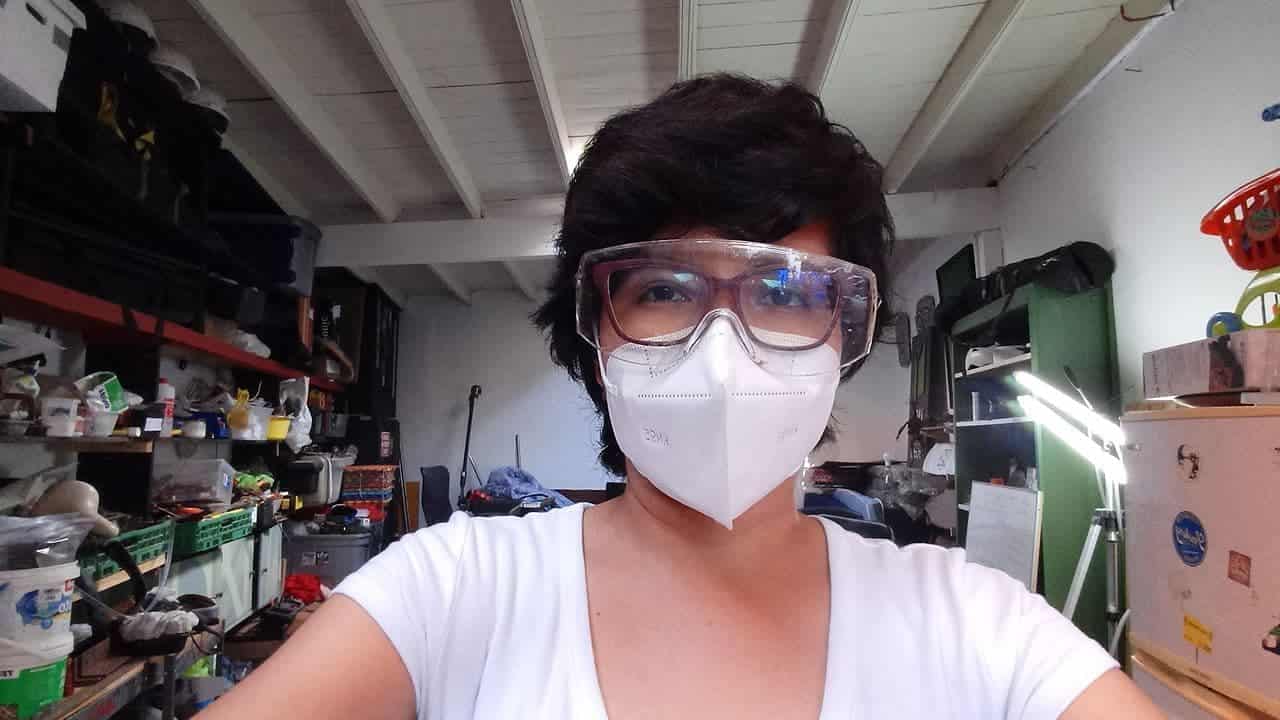

Me

My experience

A new place

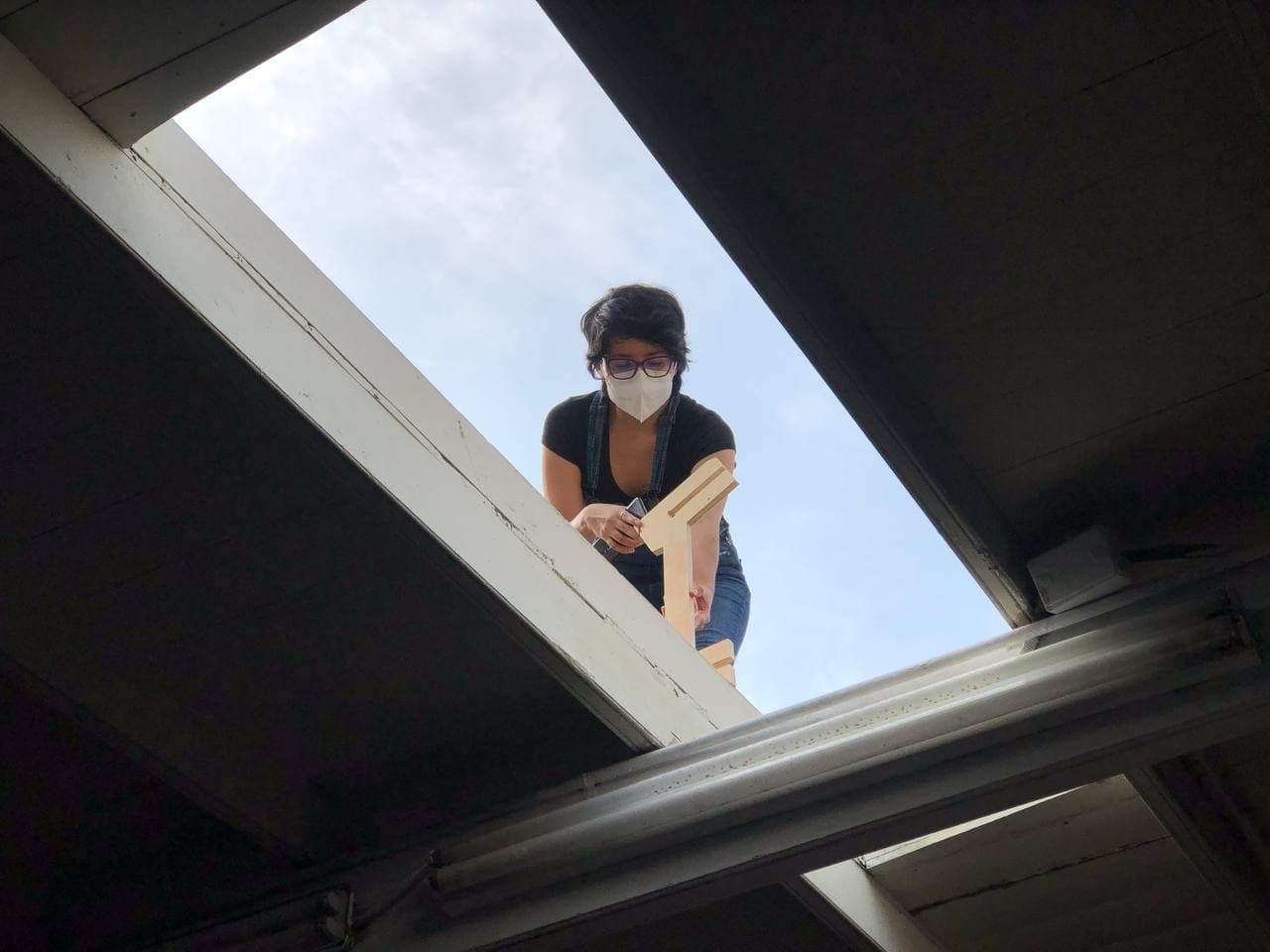

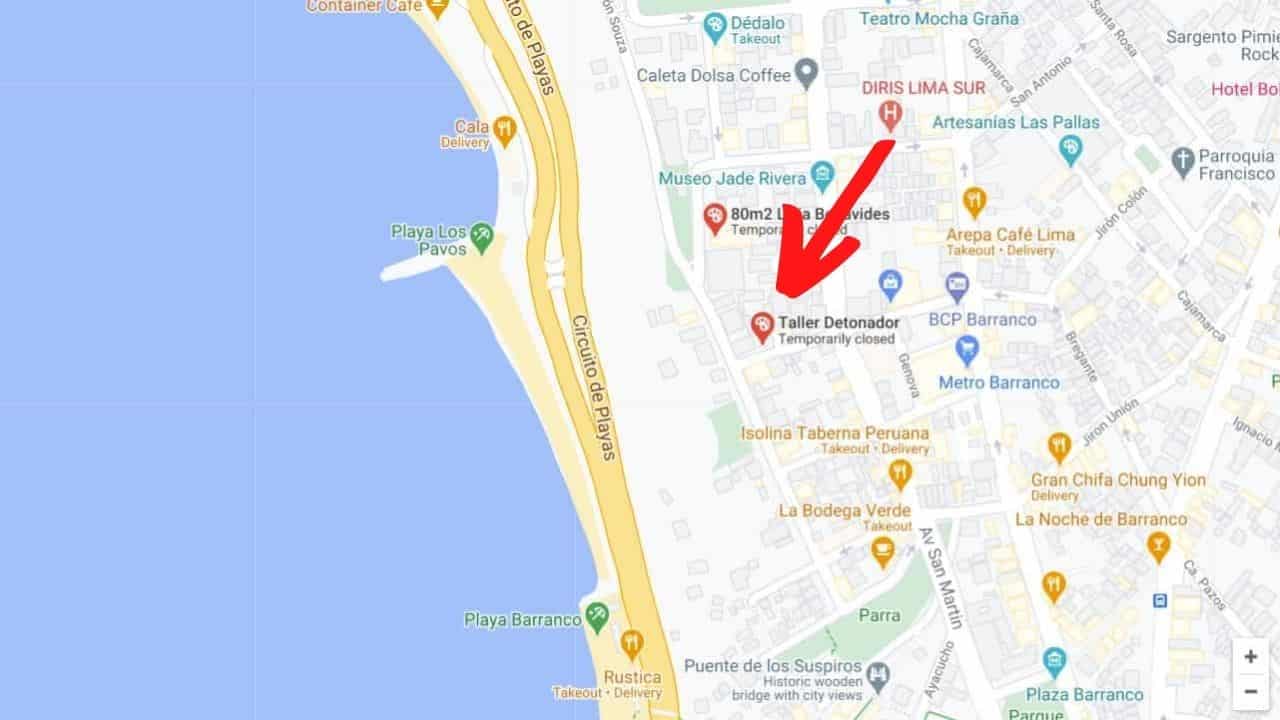

I find it very interesting to start in the world of machines (mechanics), carpentry and to test the knowledge we acquired in previous weeks such as electronics. To solve this week's assignment the Fab Lab Peru team has moved all over the place. We do not have special machines for this work in our lab because it is a small space but thanks to our colleague Stefany Casanova we have managed to recycle one that does the same job. Also thanks to Stefany's brother we are working in a very nice workshop located in the district of Barranco - Lima, this is a very spacious art workshop that contains many tools with which we have been able to work, definitely the team is very grateful to work in this place. Here I show you some pictures. 🥰 (Detonador)

Near the sea of Barranco 🥰

Barranco - Lima

Taller Detonador

Taller Detonador

Taller Detonador

Taller Detonador

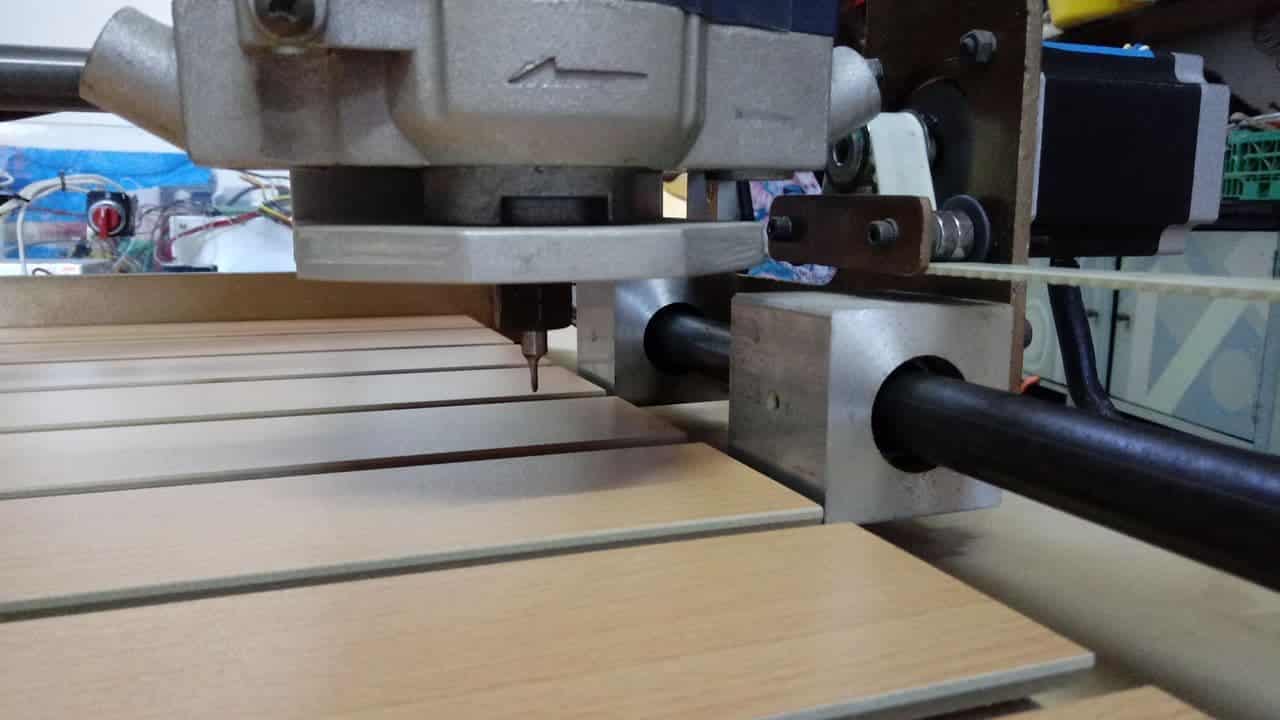

The machine

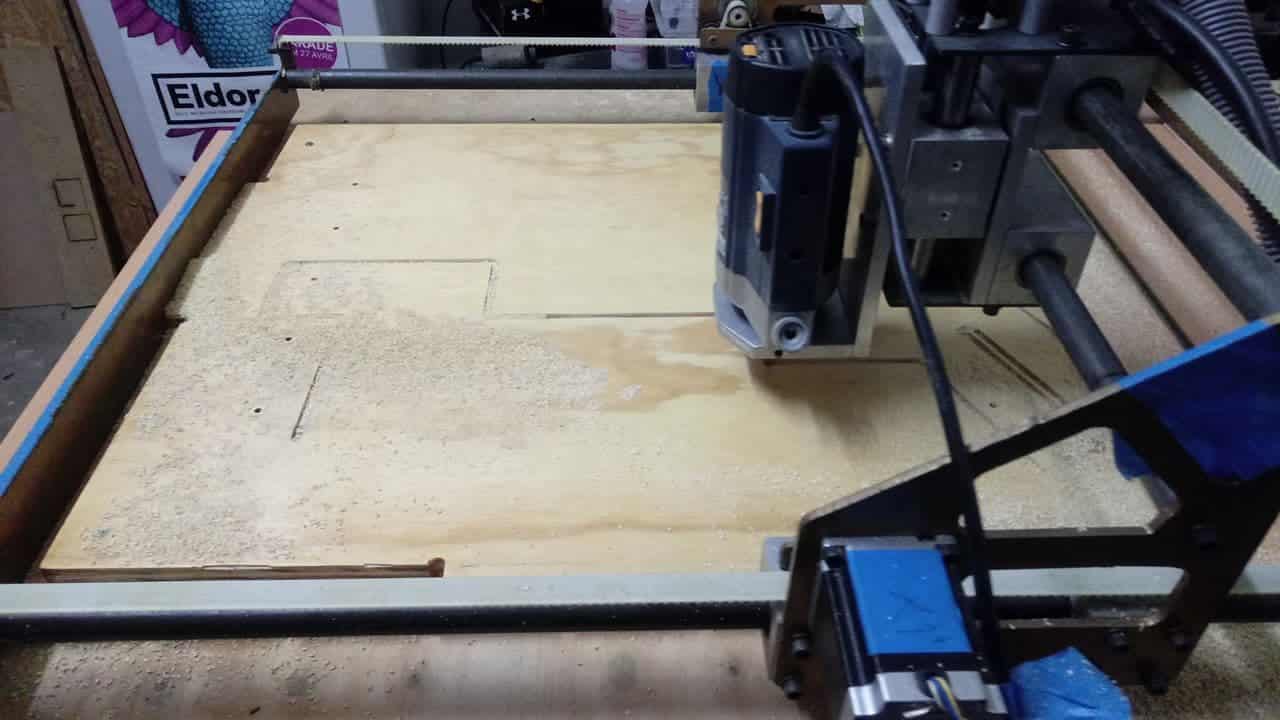

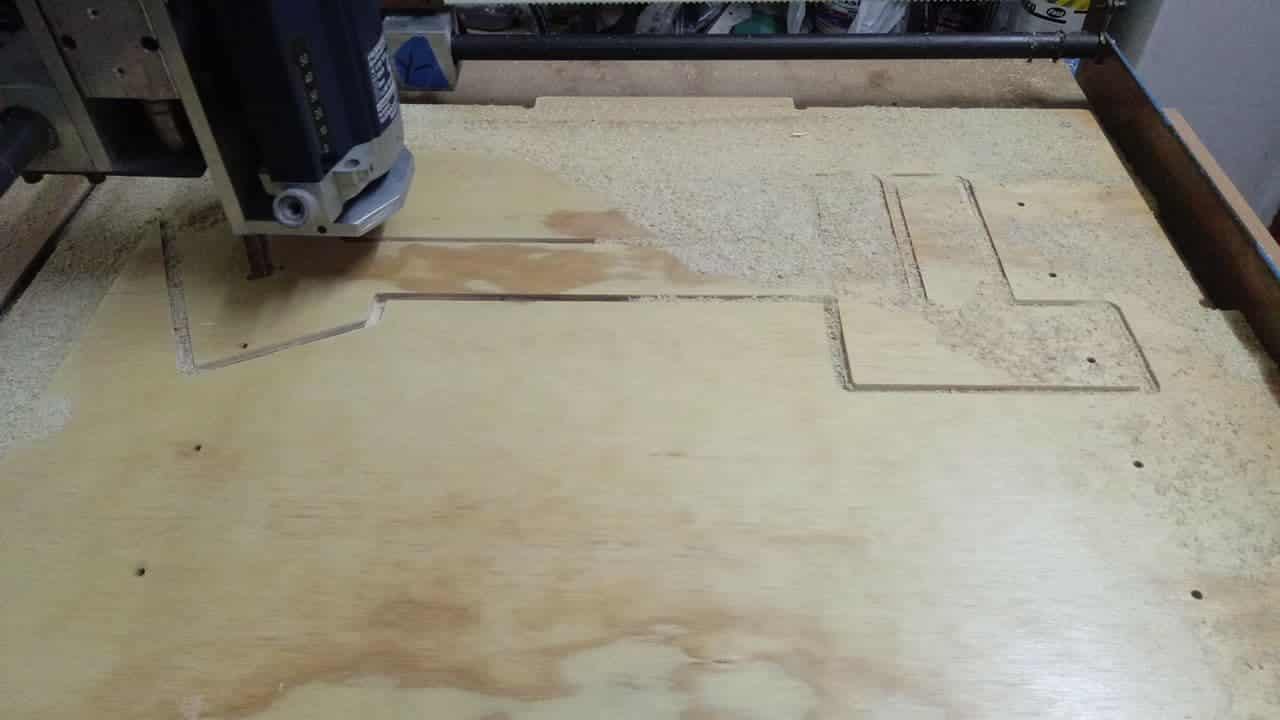

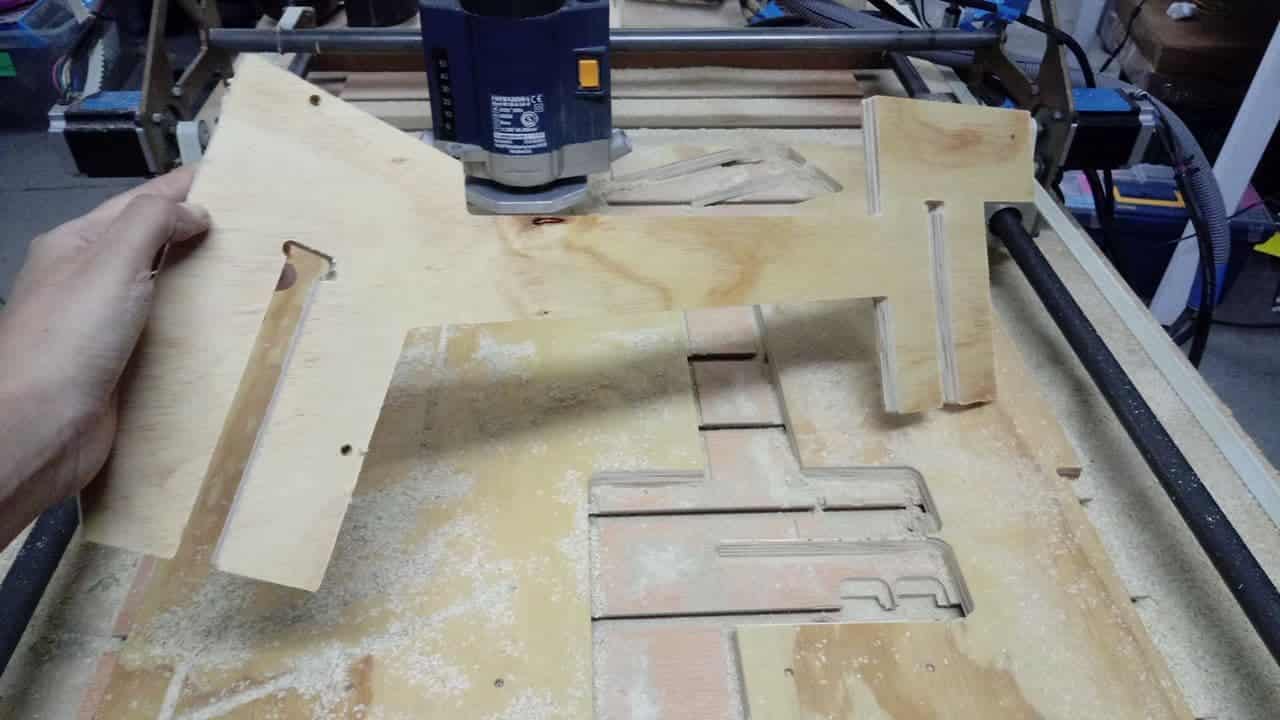

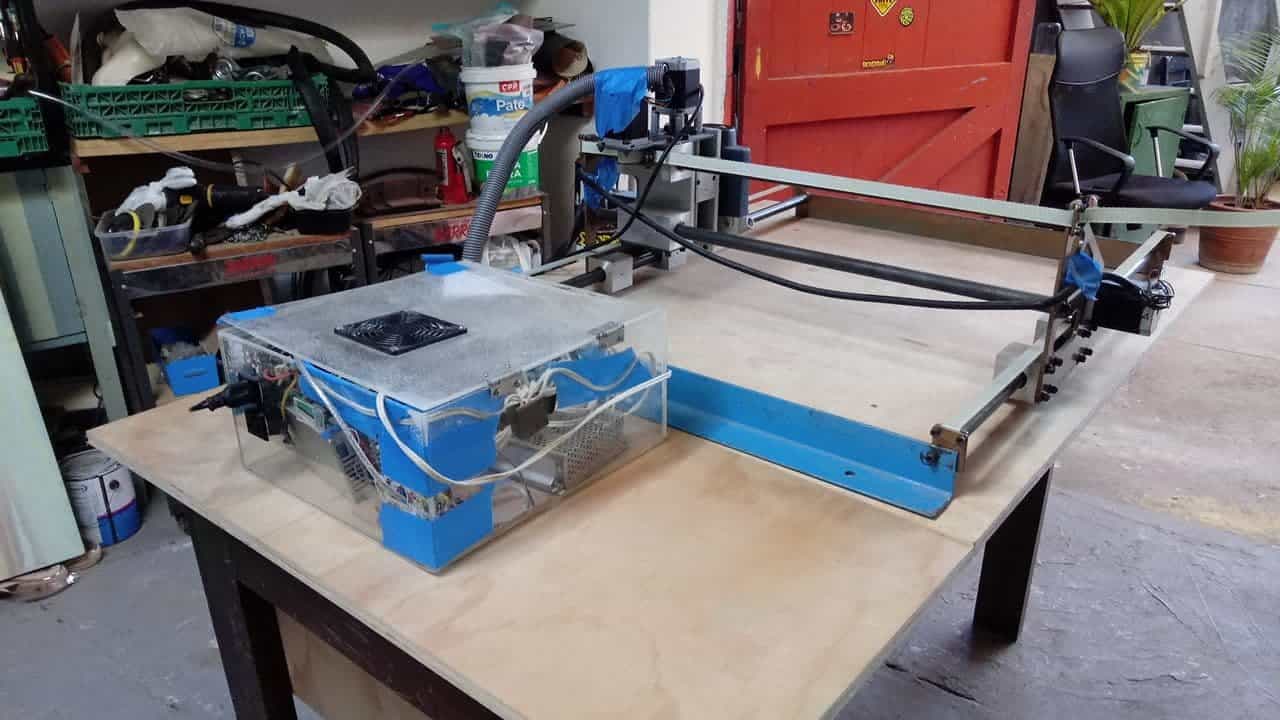

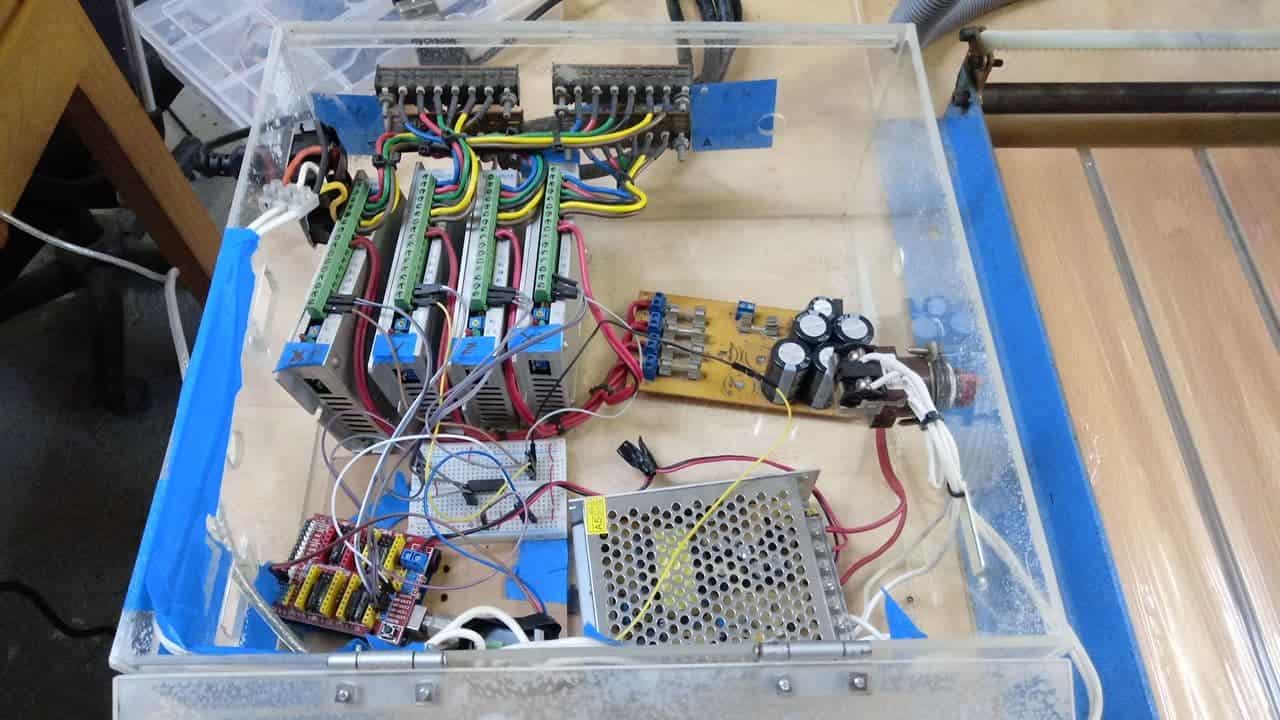

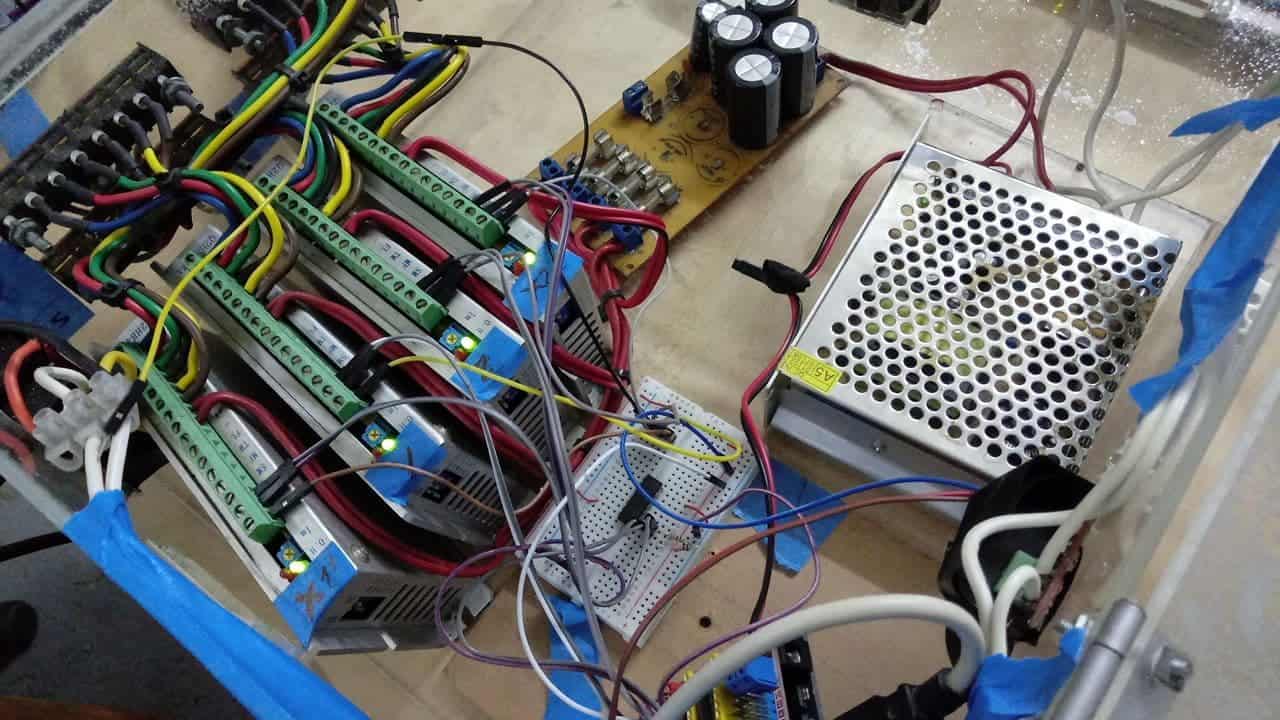

The machine we have at our disposal is a very old one, it was created for a thesis of a person 20 years ago and thanks to Stefany Casanova who was the one who brought it to the workshop is that we will use it, it is interesting to see all its features because they use many components and connections that could be replaced by a card as in the current machines, here I attach some pictures. 😃

Machine

Machine

Machine

Machine

Electronic connections

Electronic connections

Self-tapping screws

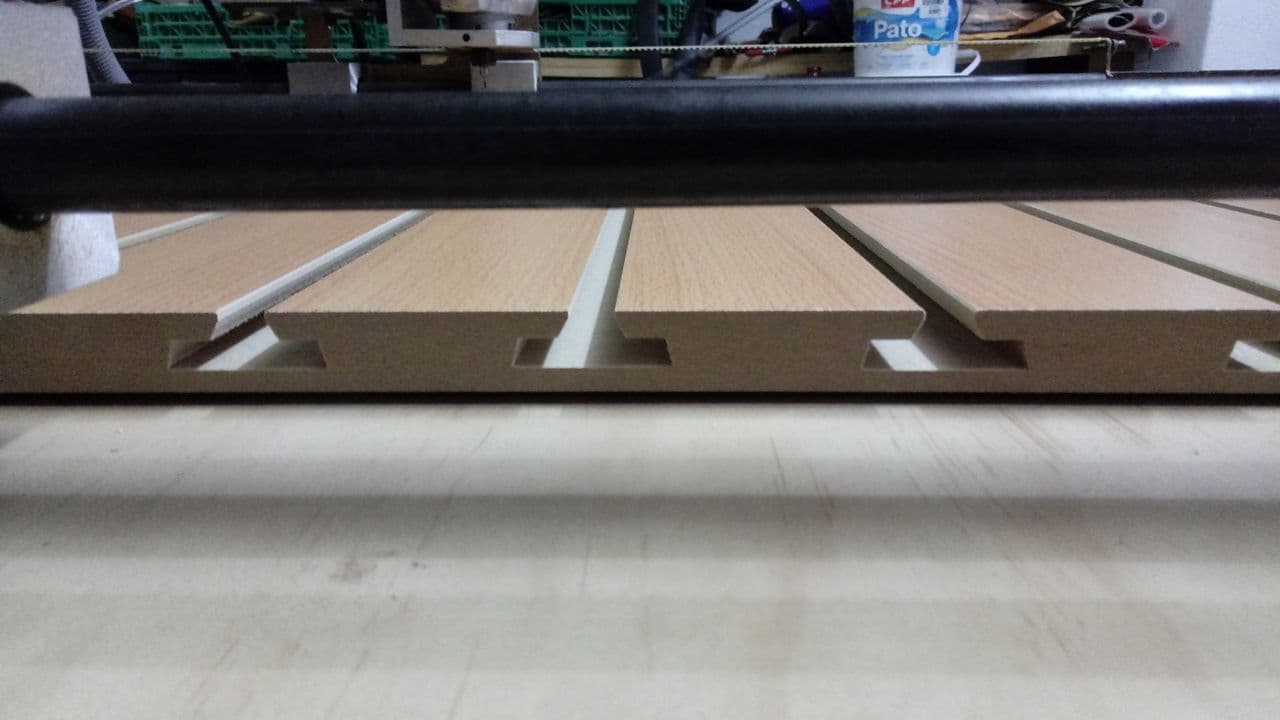

Sacrificial bed profile

Bolting down the sacrificial bed

Bolting down the sacrificial bed

Drill bit

Drill bit

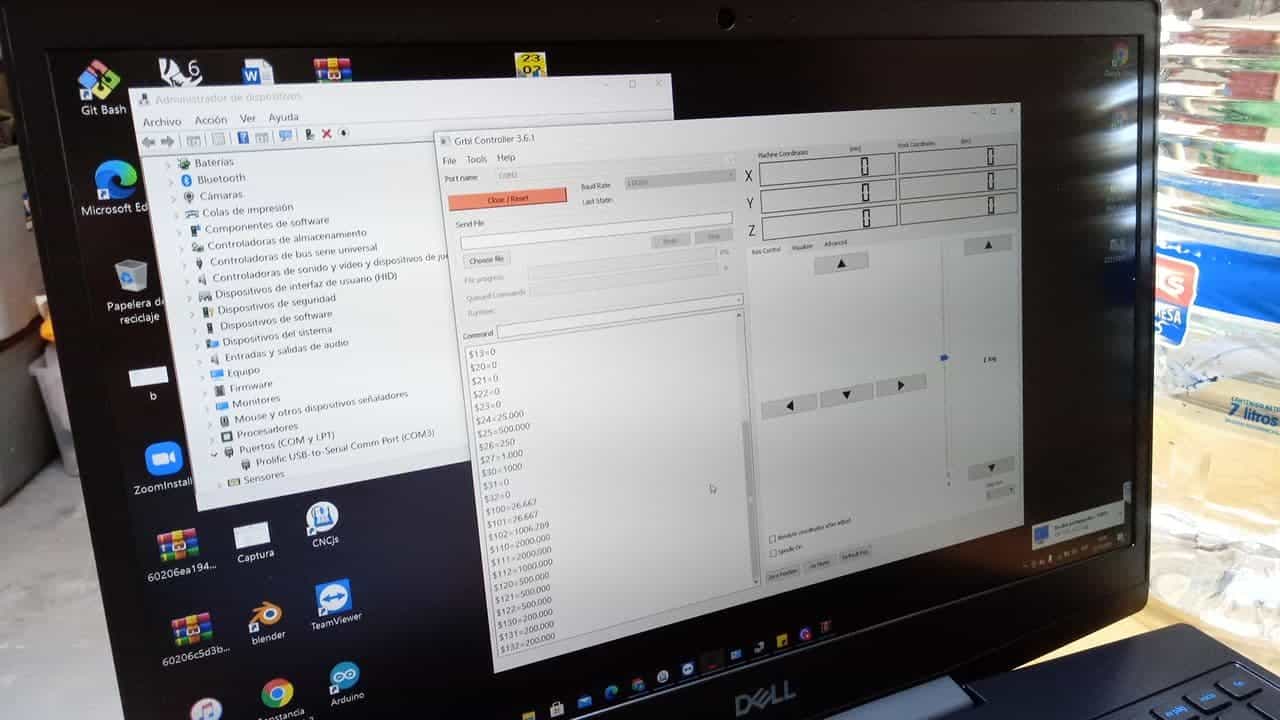

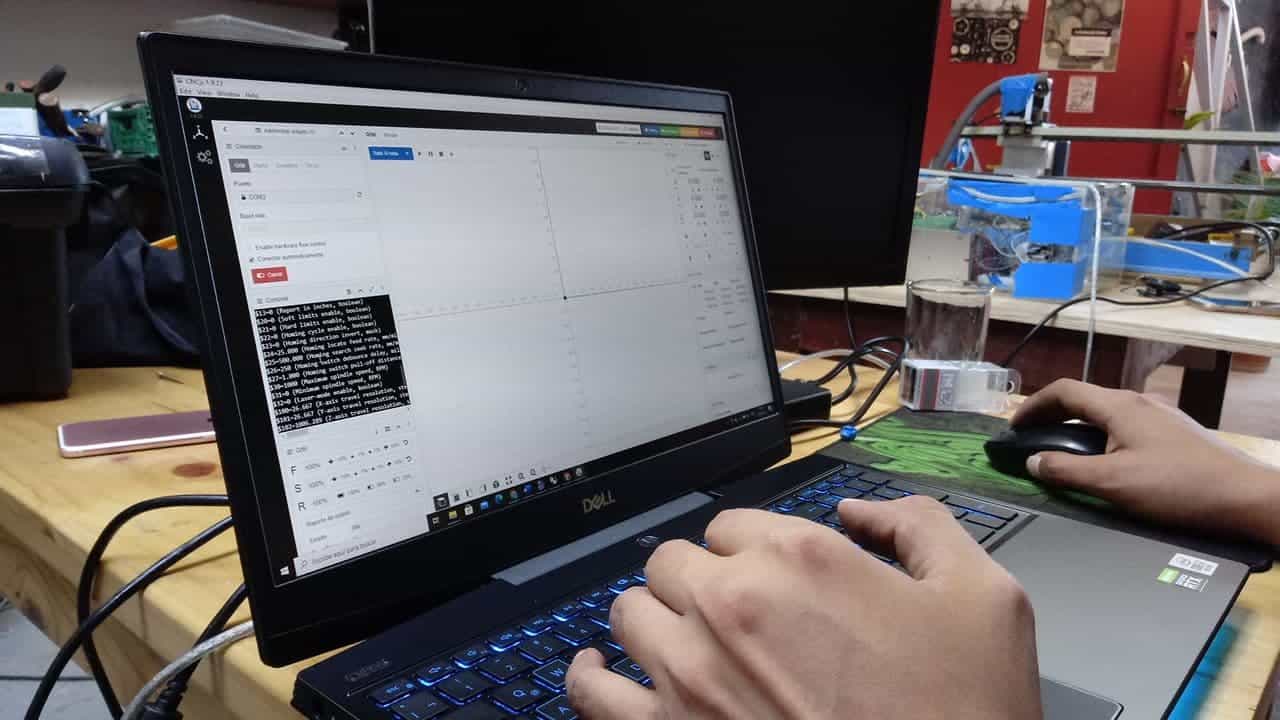

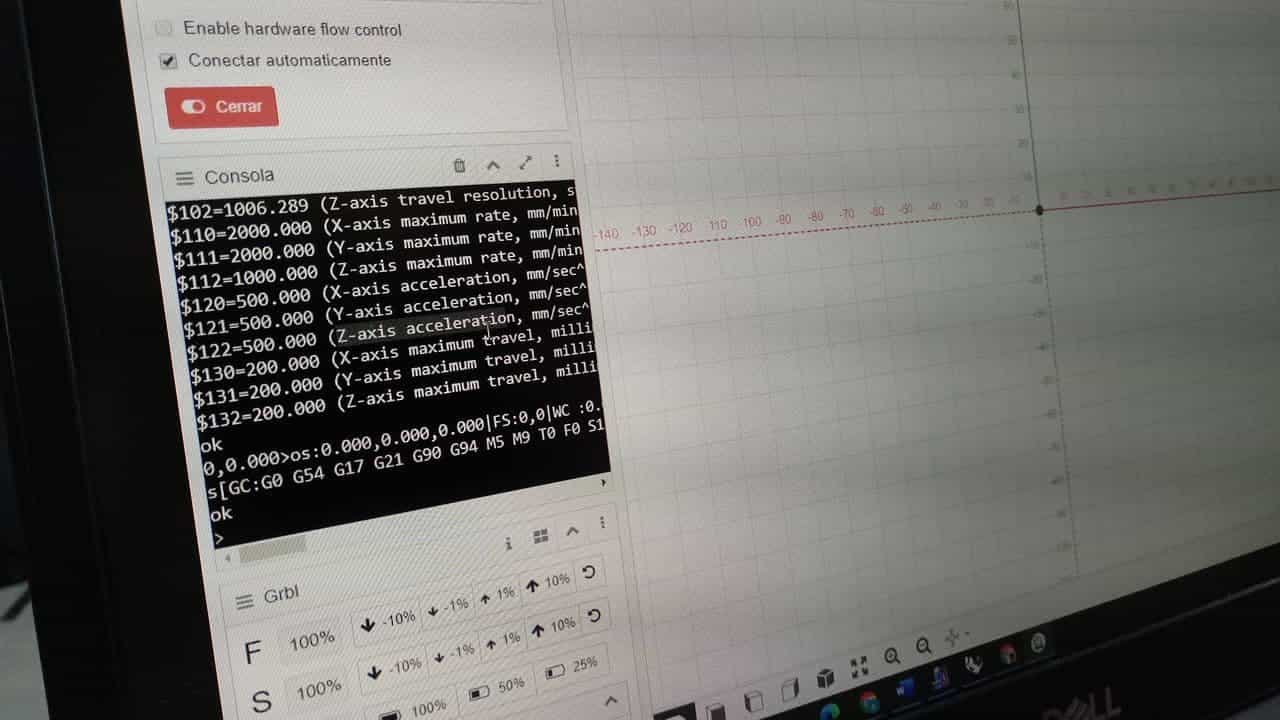

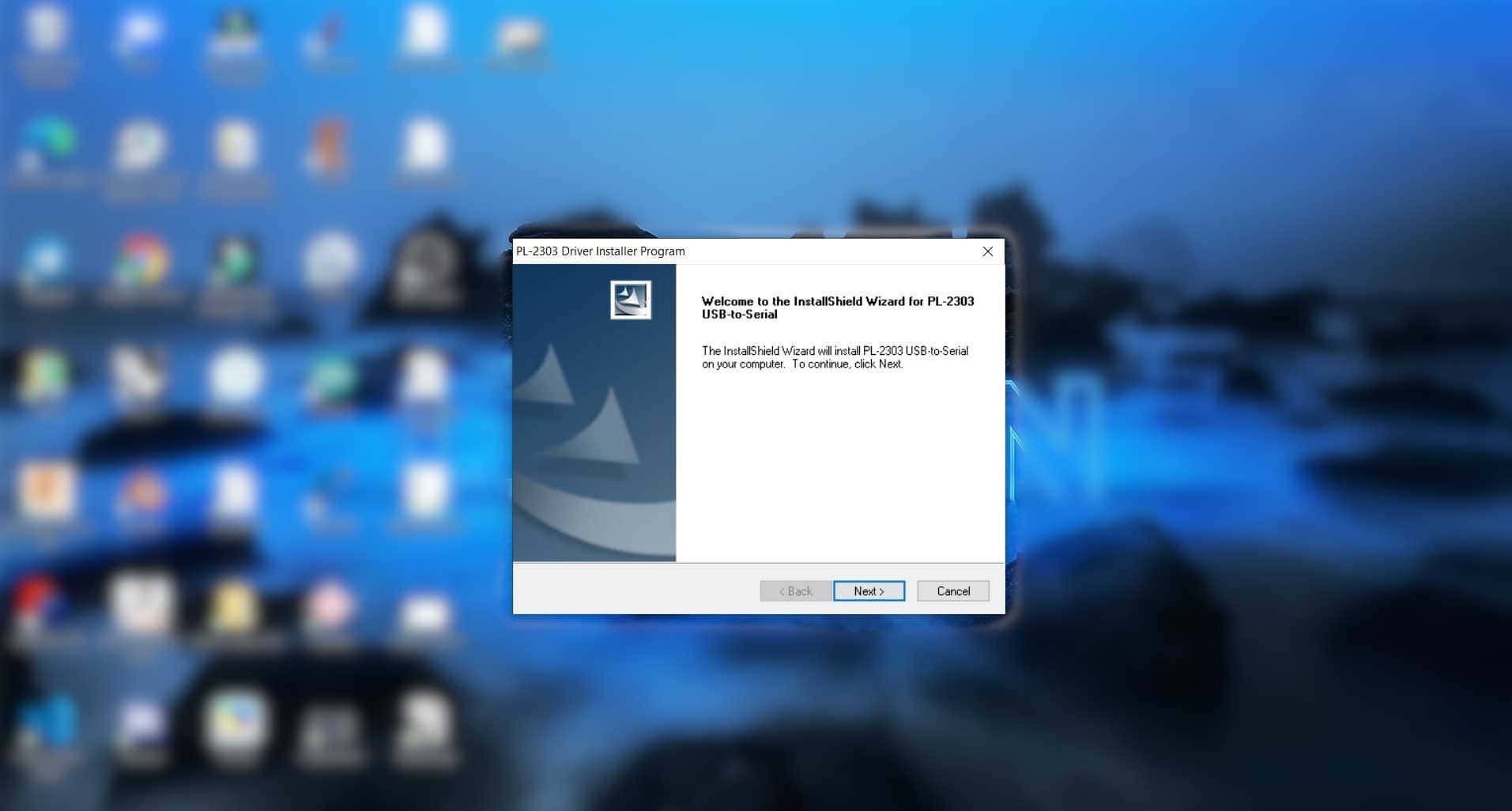

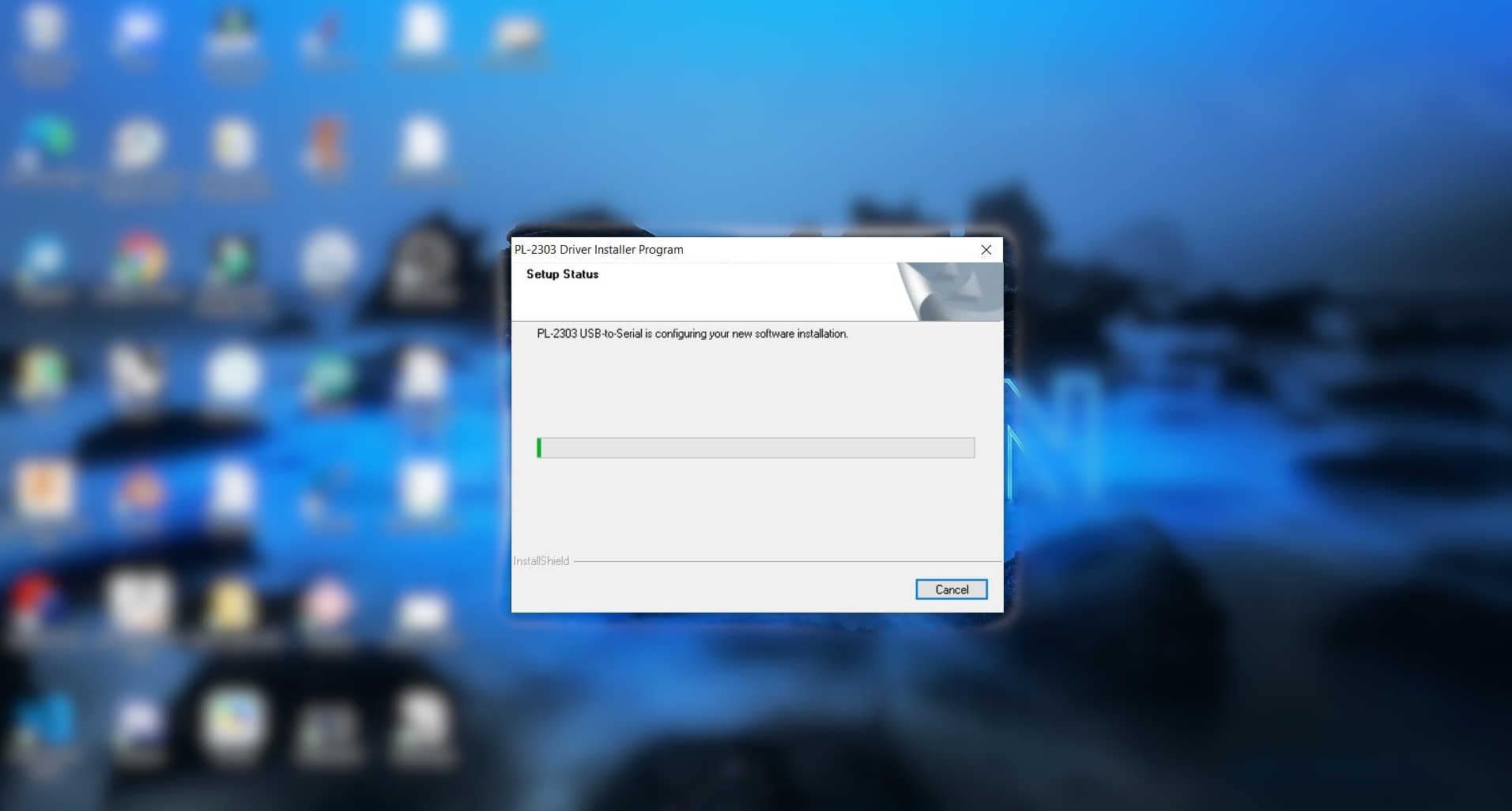

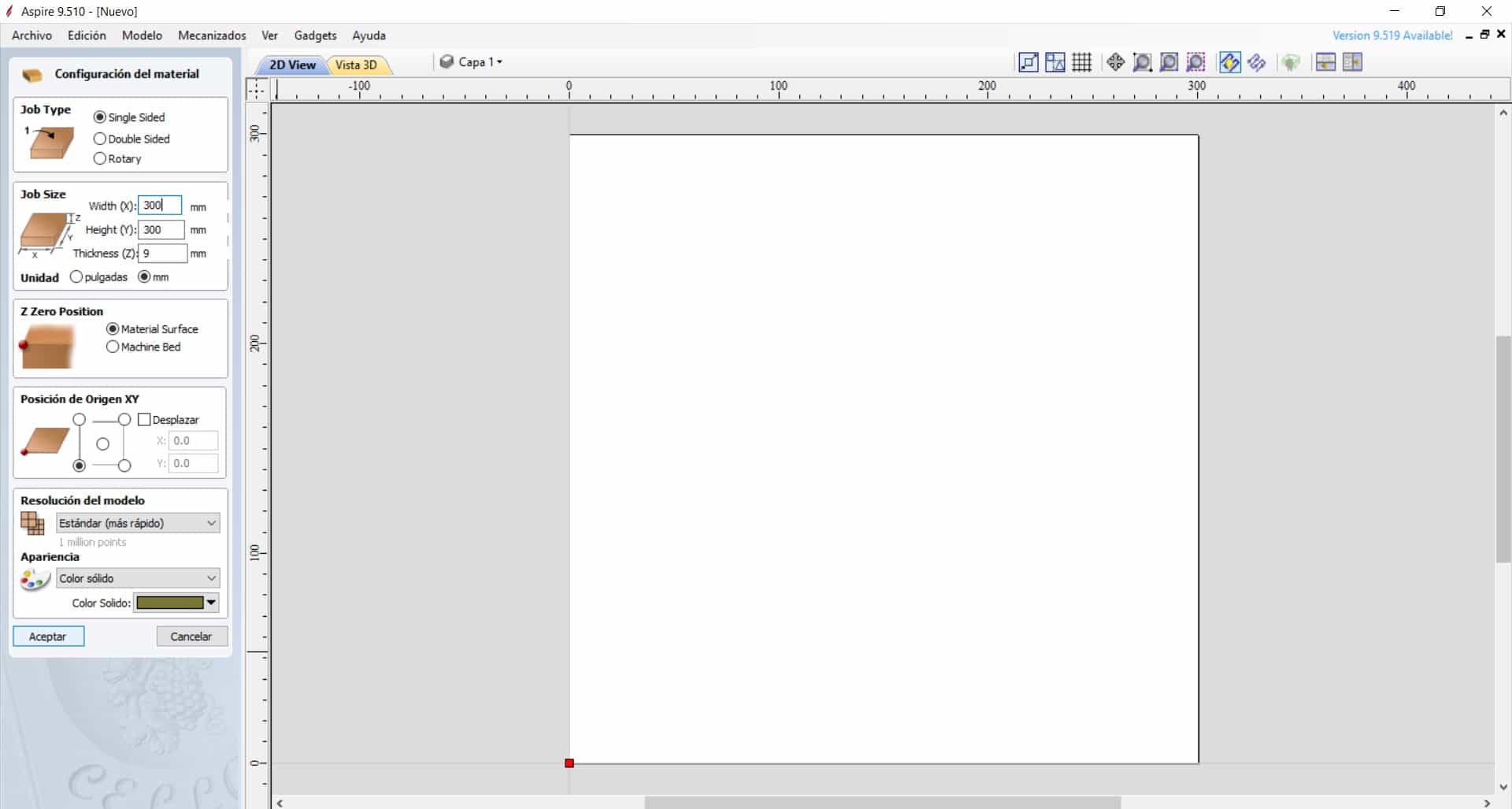

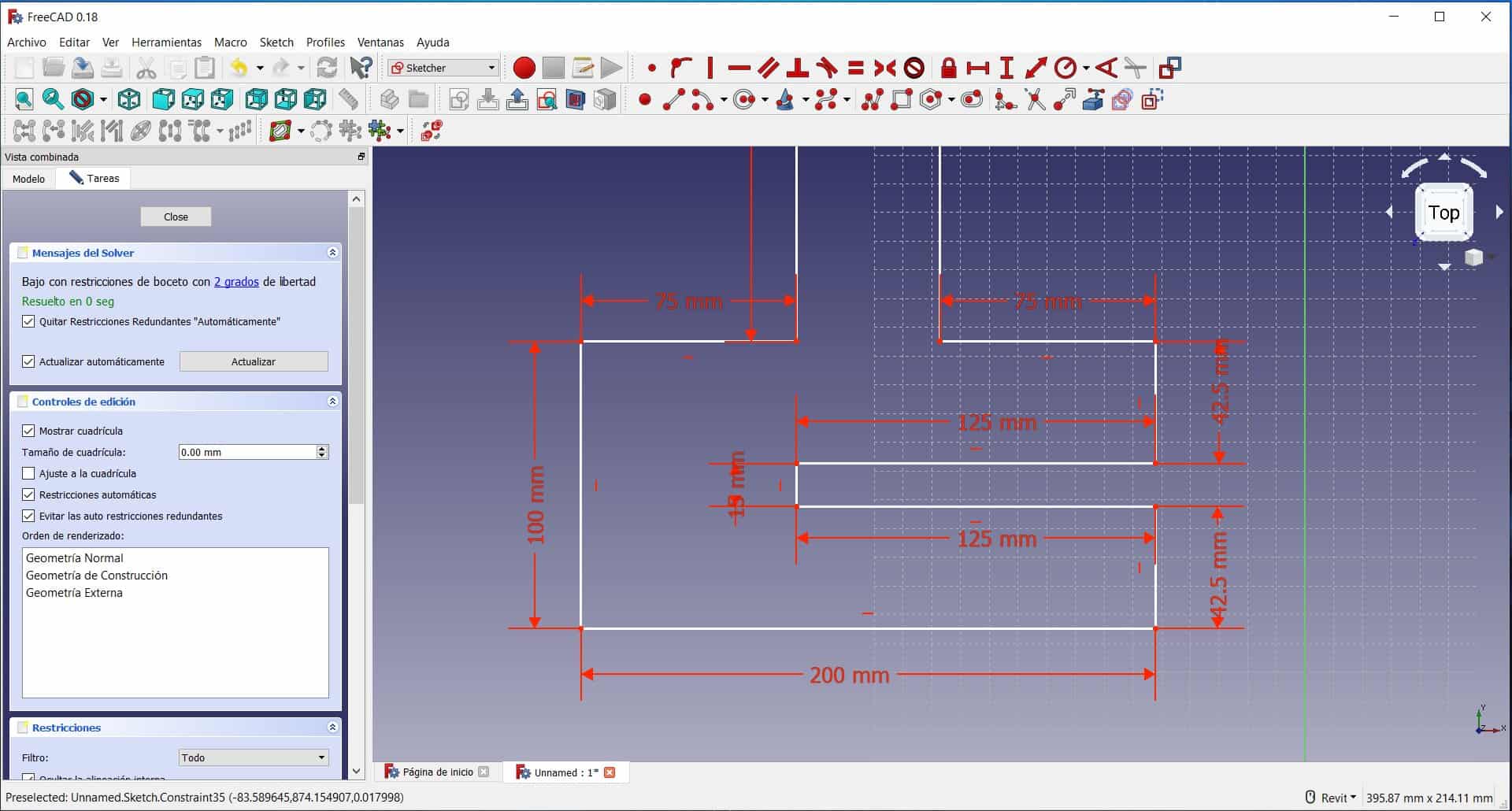

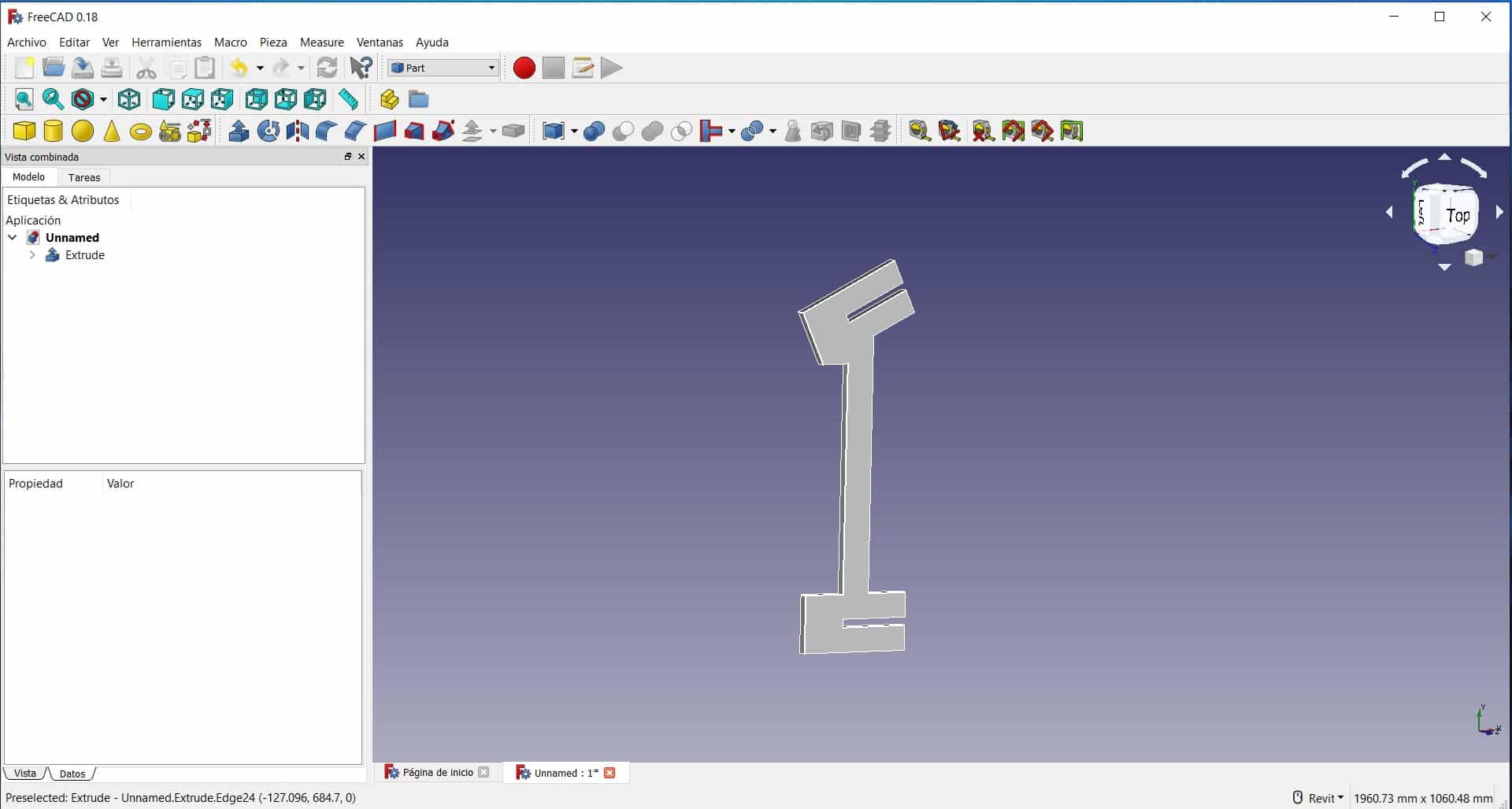

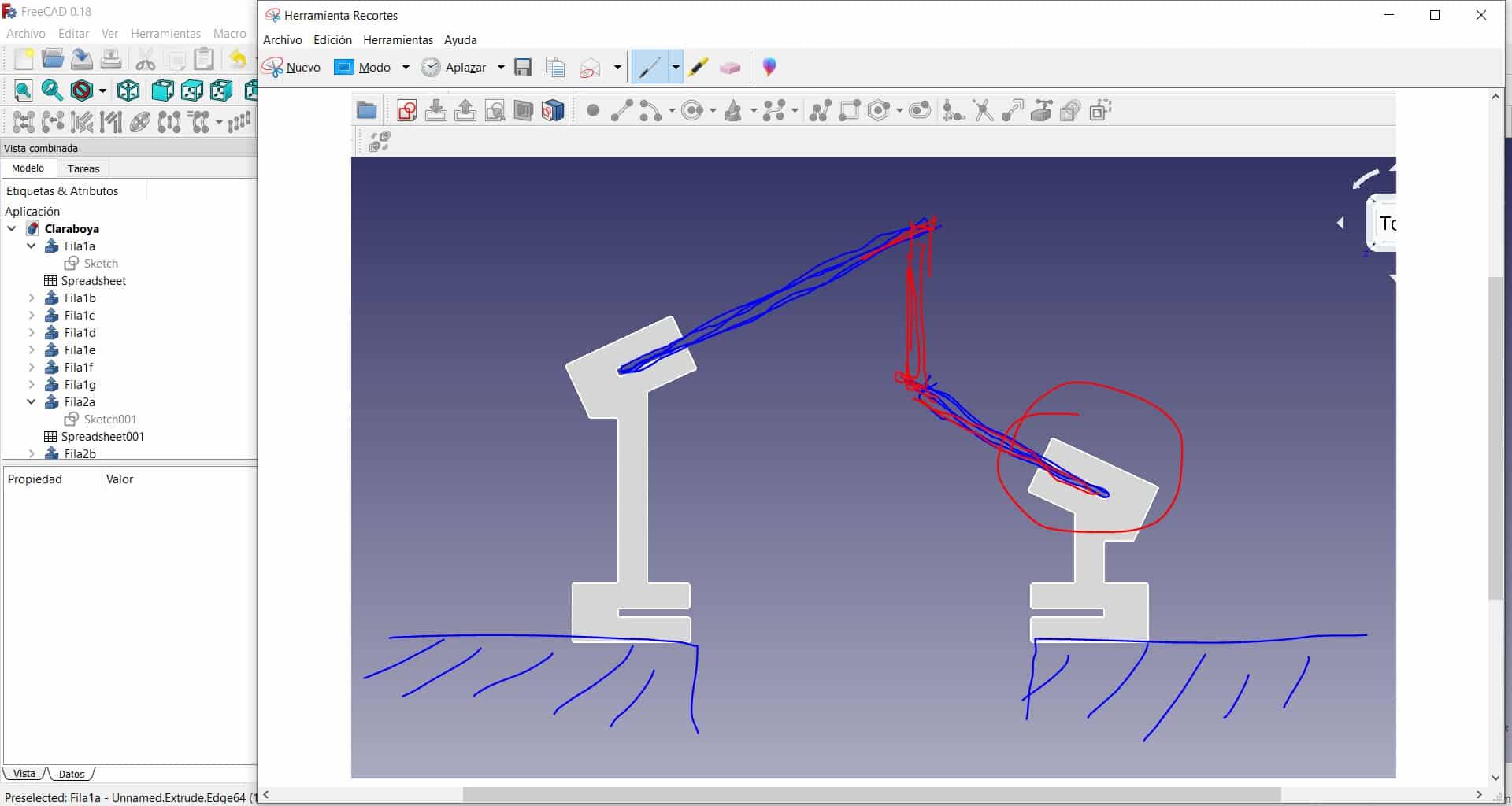

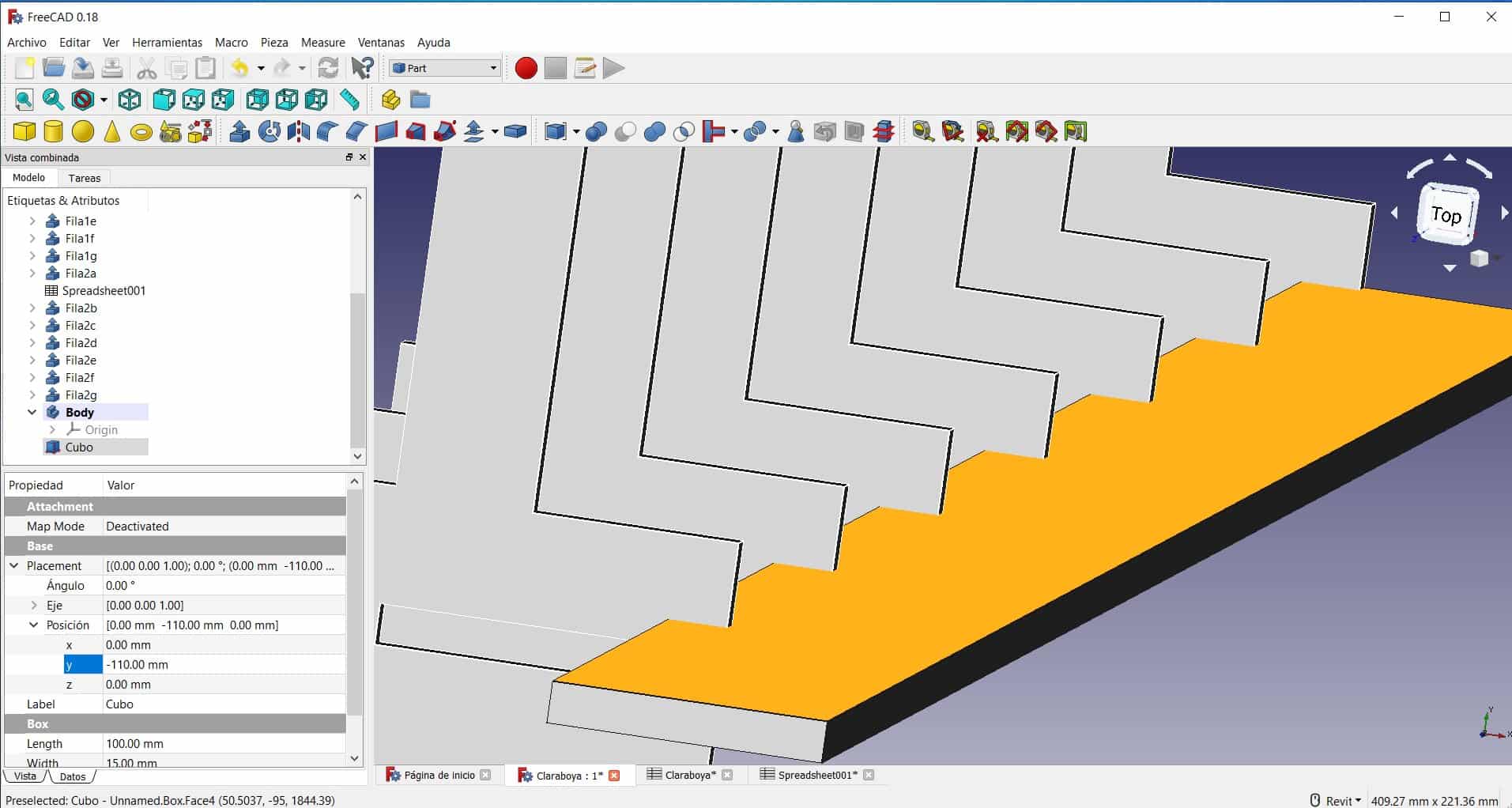

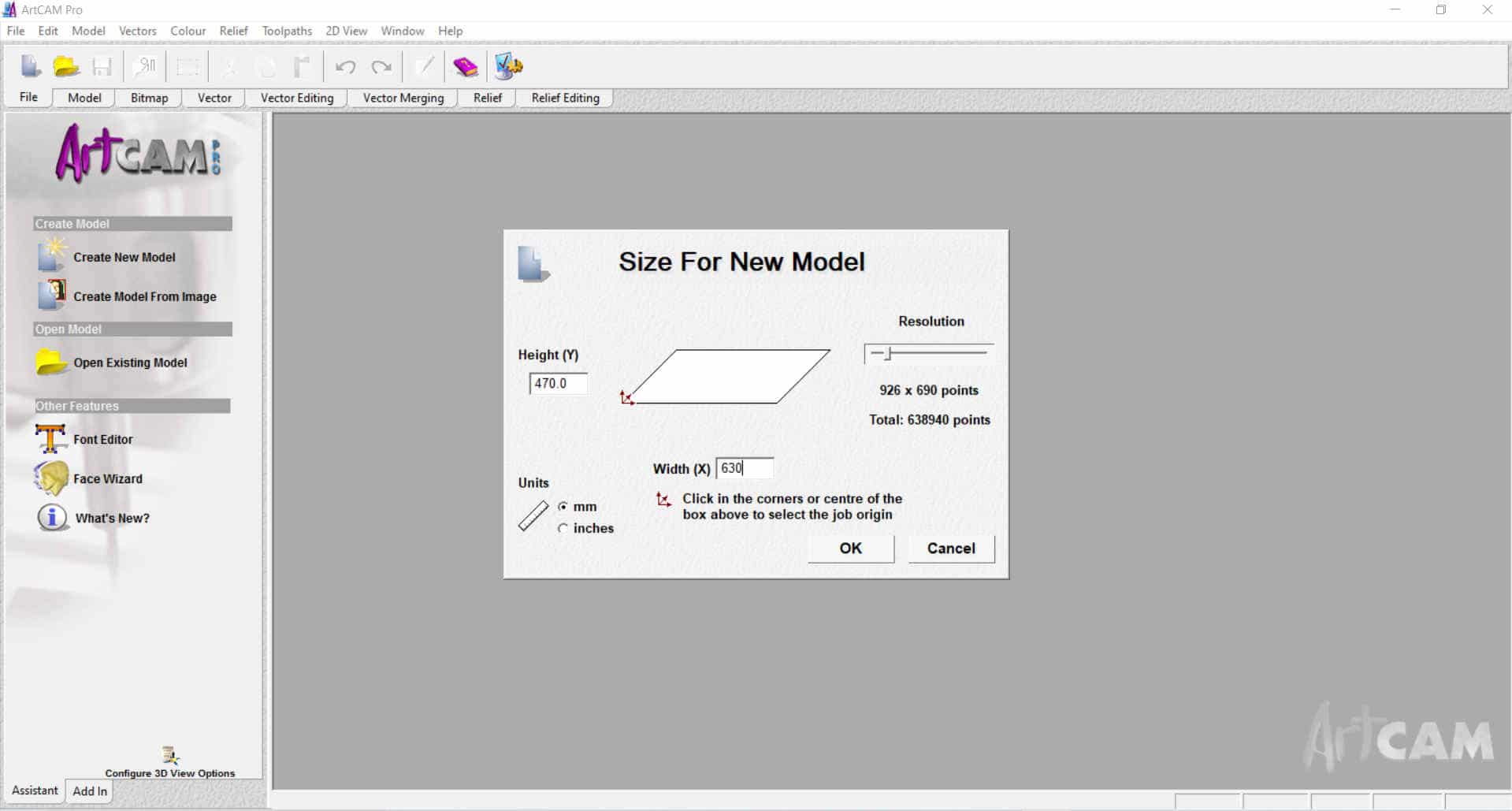

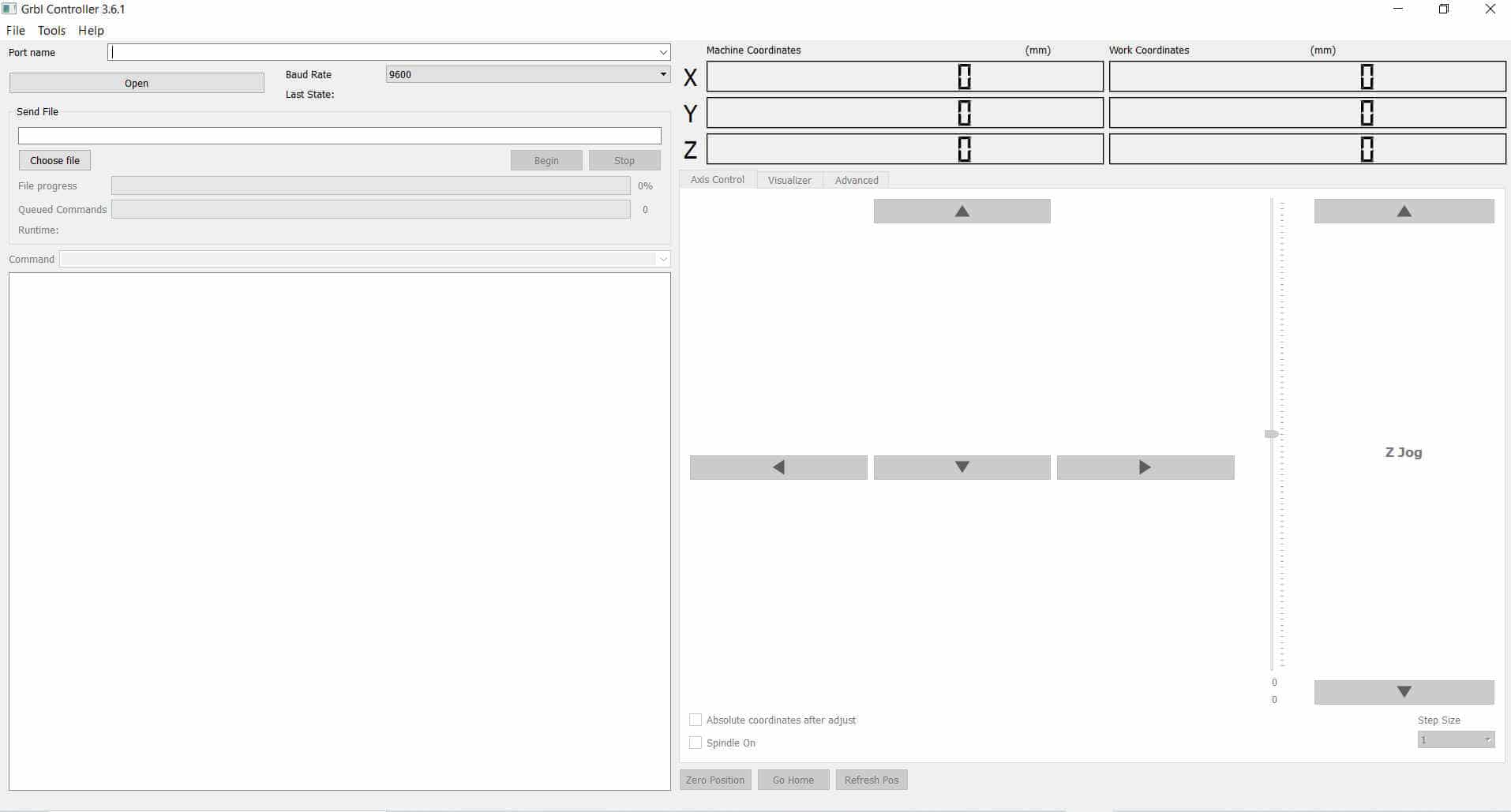

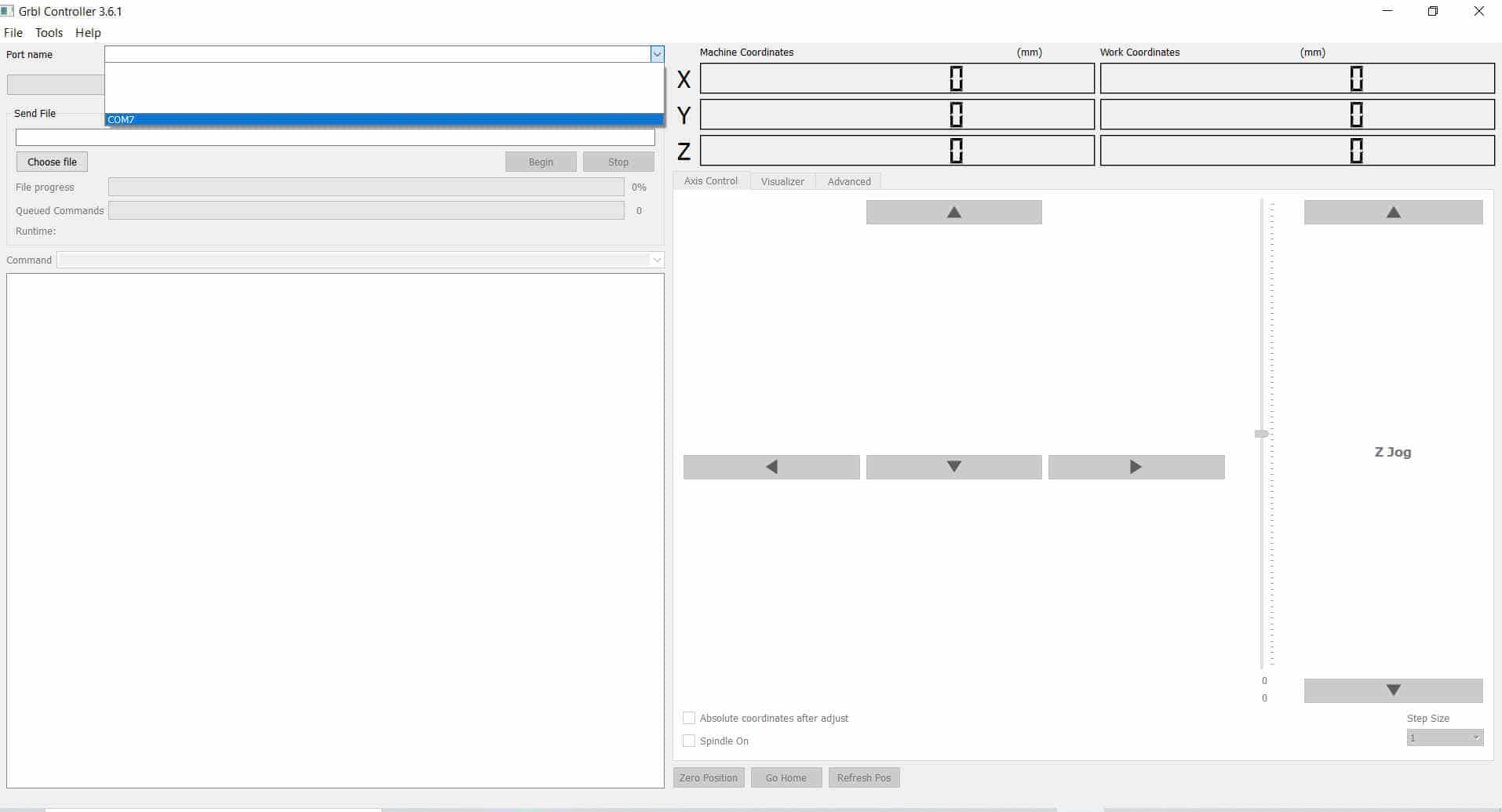

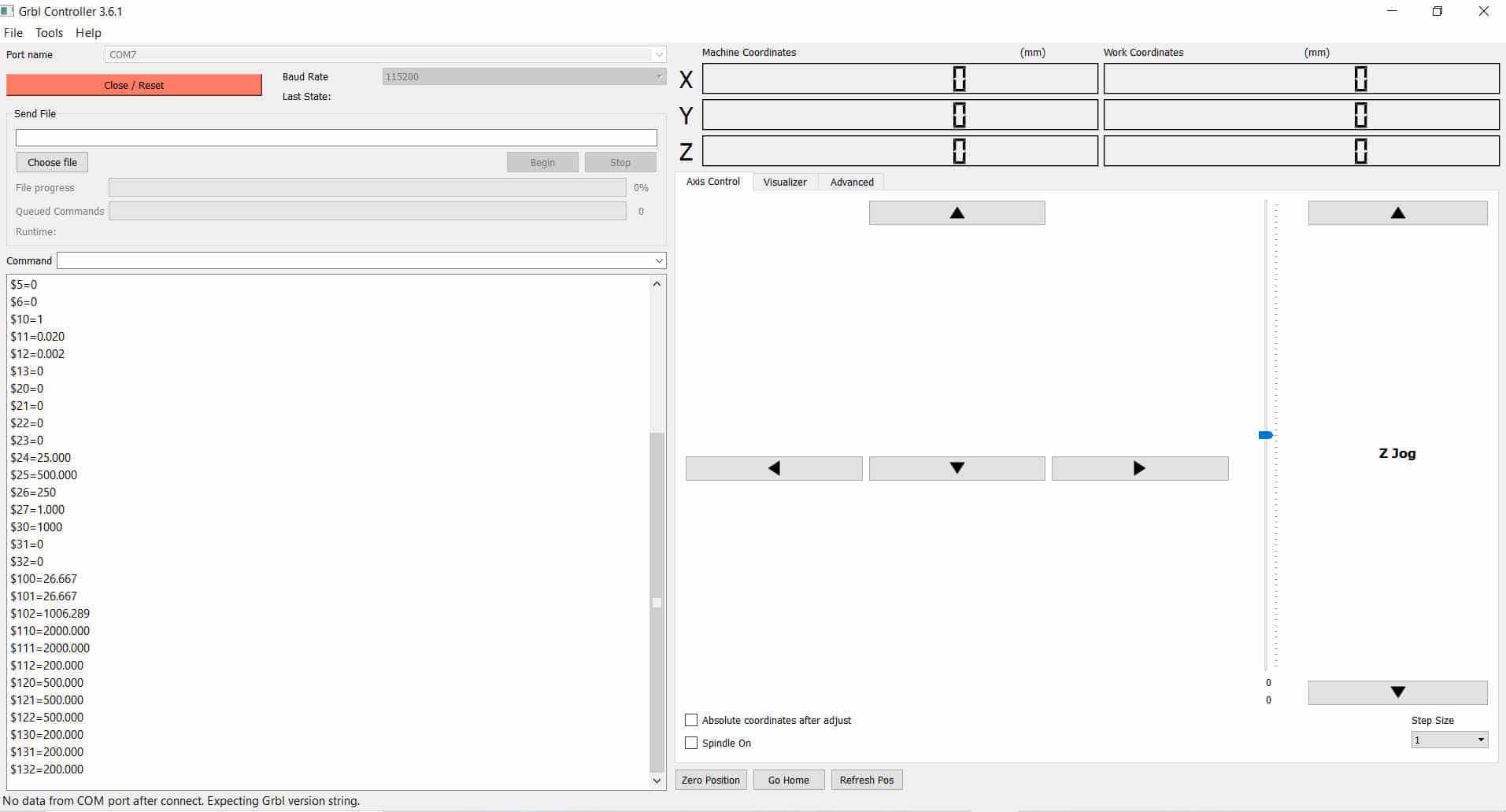

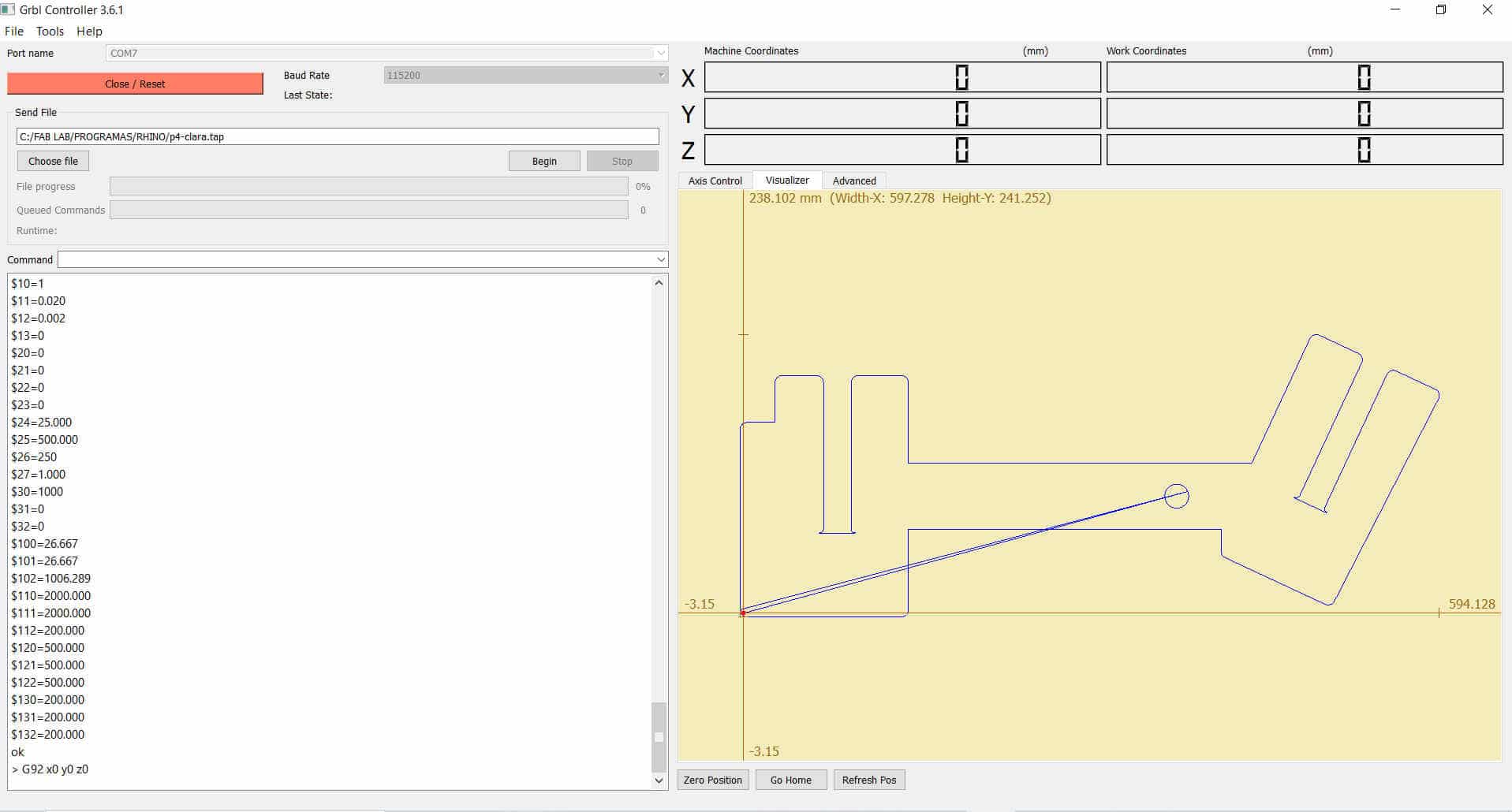

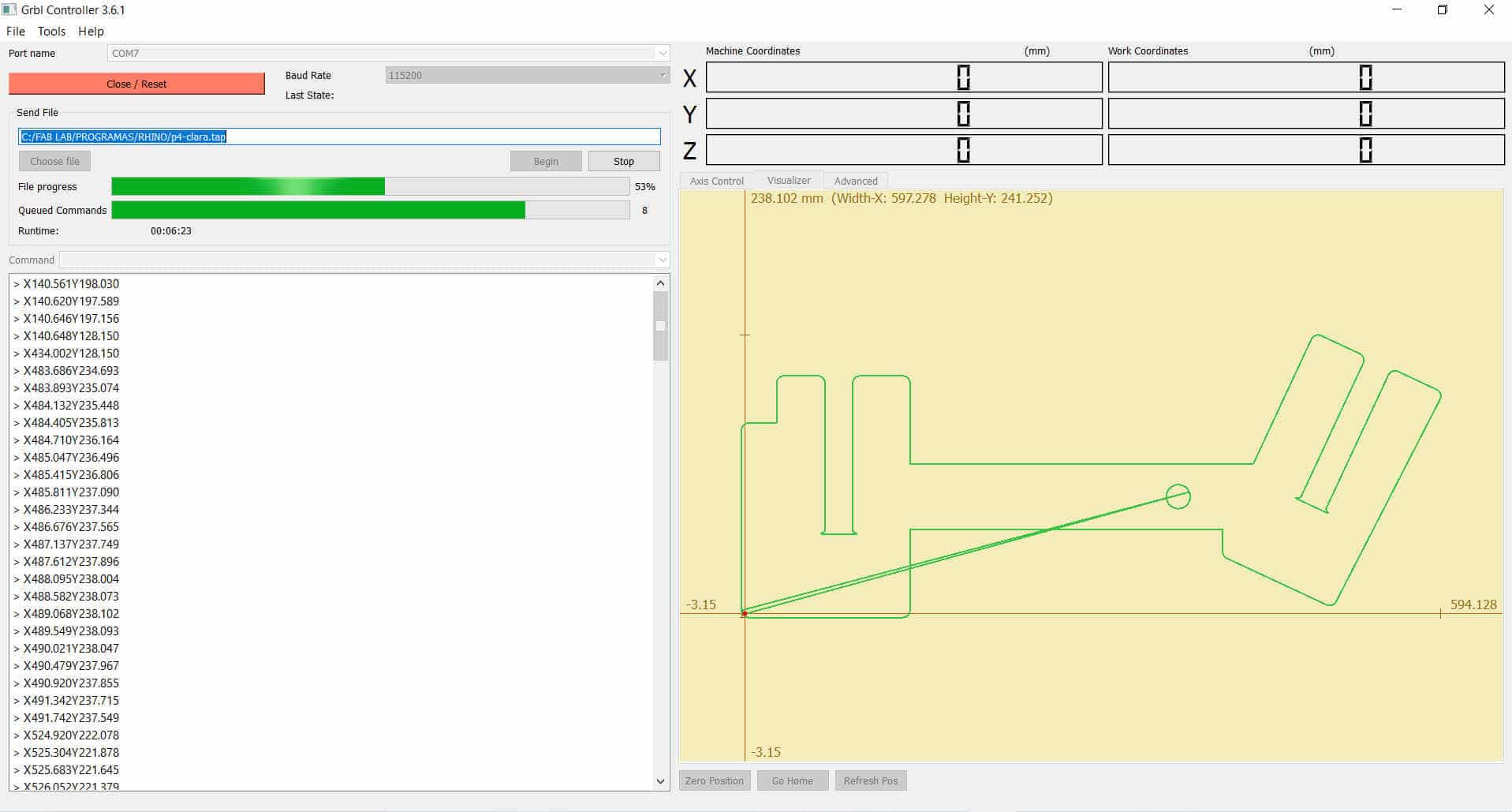

As this machine is quite old, we first had to get it to work, so we made some adjustments and revisions to both the mechanical and electronic parts. After many tests we managed to get it to respond to our computers. Here is a moment of happiness when I was able to control it from my laptop. 🤩

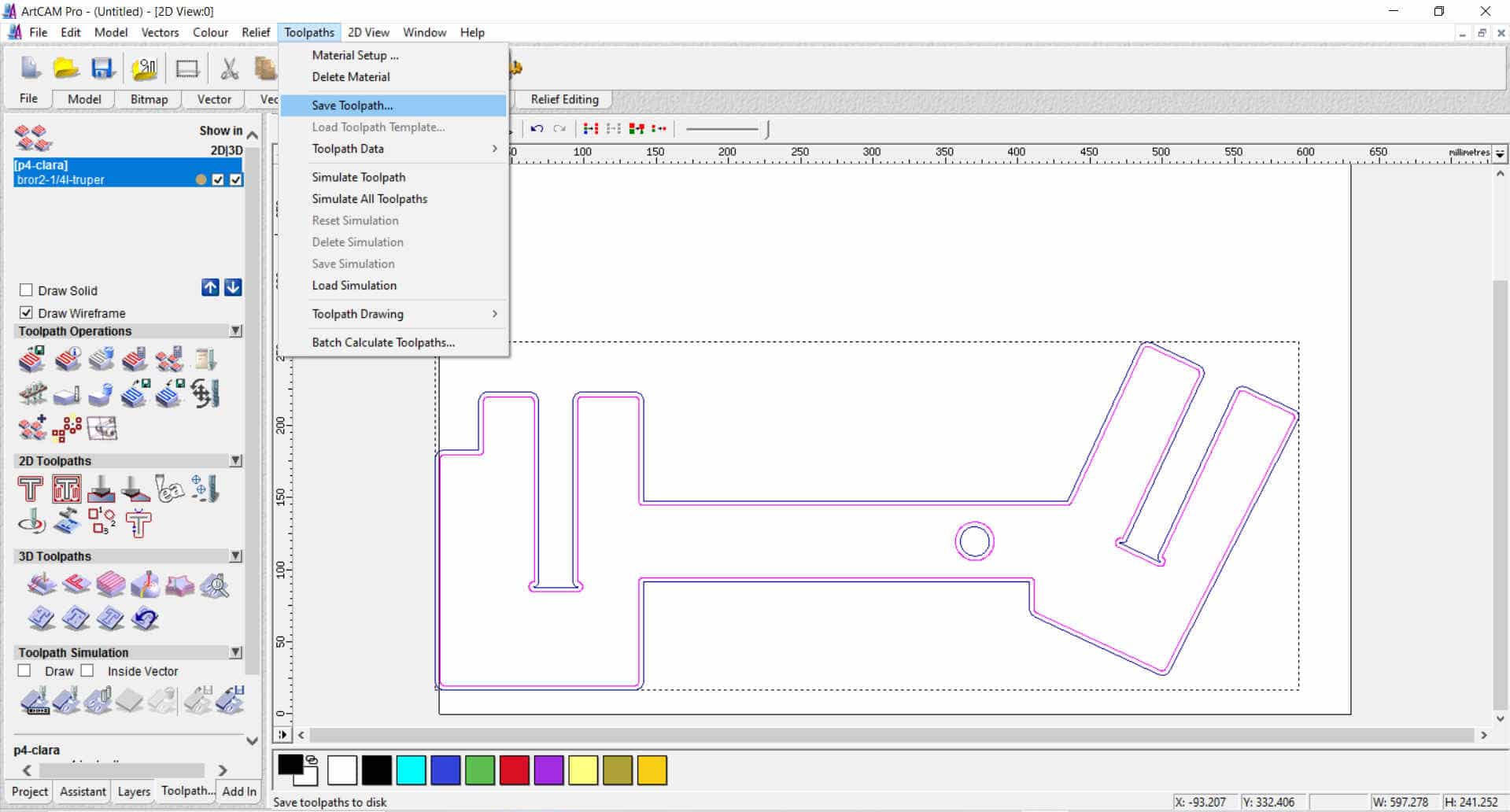

But none of this was easy! Below I will show you the whole adventure of the configuration we needed to do to make this machine work. It has been a terrible and beautiful adventure. 😆 All this was possible thanks to many people, among them our partner Juan Casanova (Stefany's brother) for helping us with the GCODE issue.