Ninth Week

Ninthclass

Ninth class at Fab Academy and this time they gave us a week break, for sure it would have been much more useful if there were no holidays since in Lima Peru there was a total curfew during Holy Week, but at least it has also allowed us to take a break from the intense pace we are living with this diploma. In my case unfortunately I had to stay at home and work remotely because a relative at home has a case of covid, as a precaution and care of my teammates I did not approach them for more than a week, then I did a COVID test and happily I came out negative, after that I could meet and continue working in our new space DETONADOR.💪

Exploration

My experience

A new learning experience

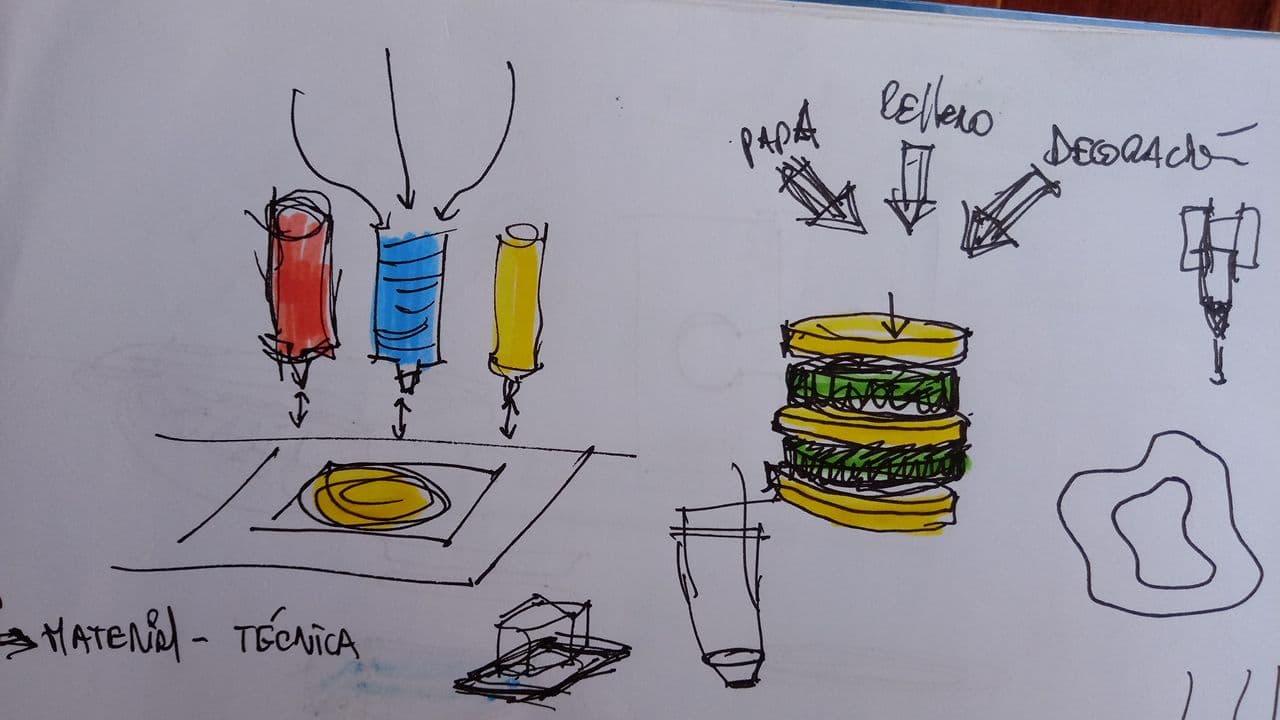

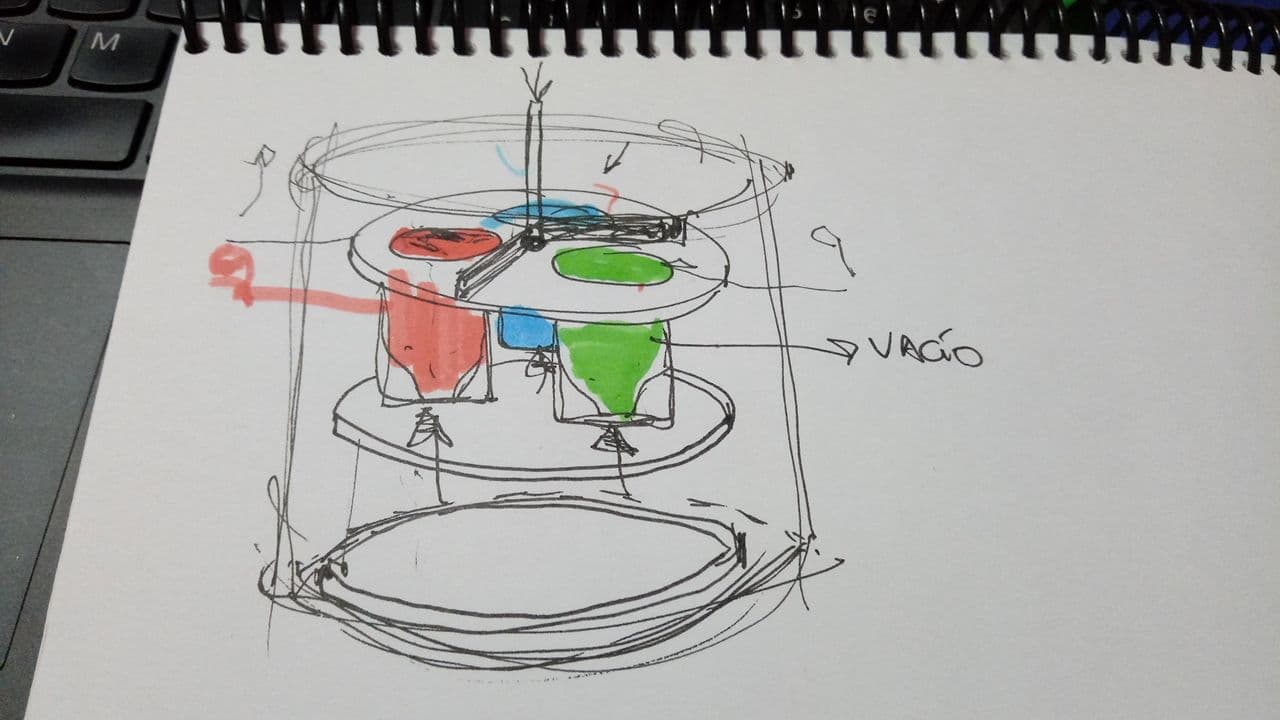

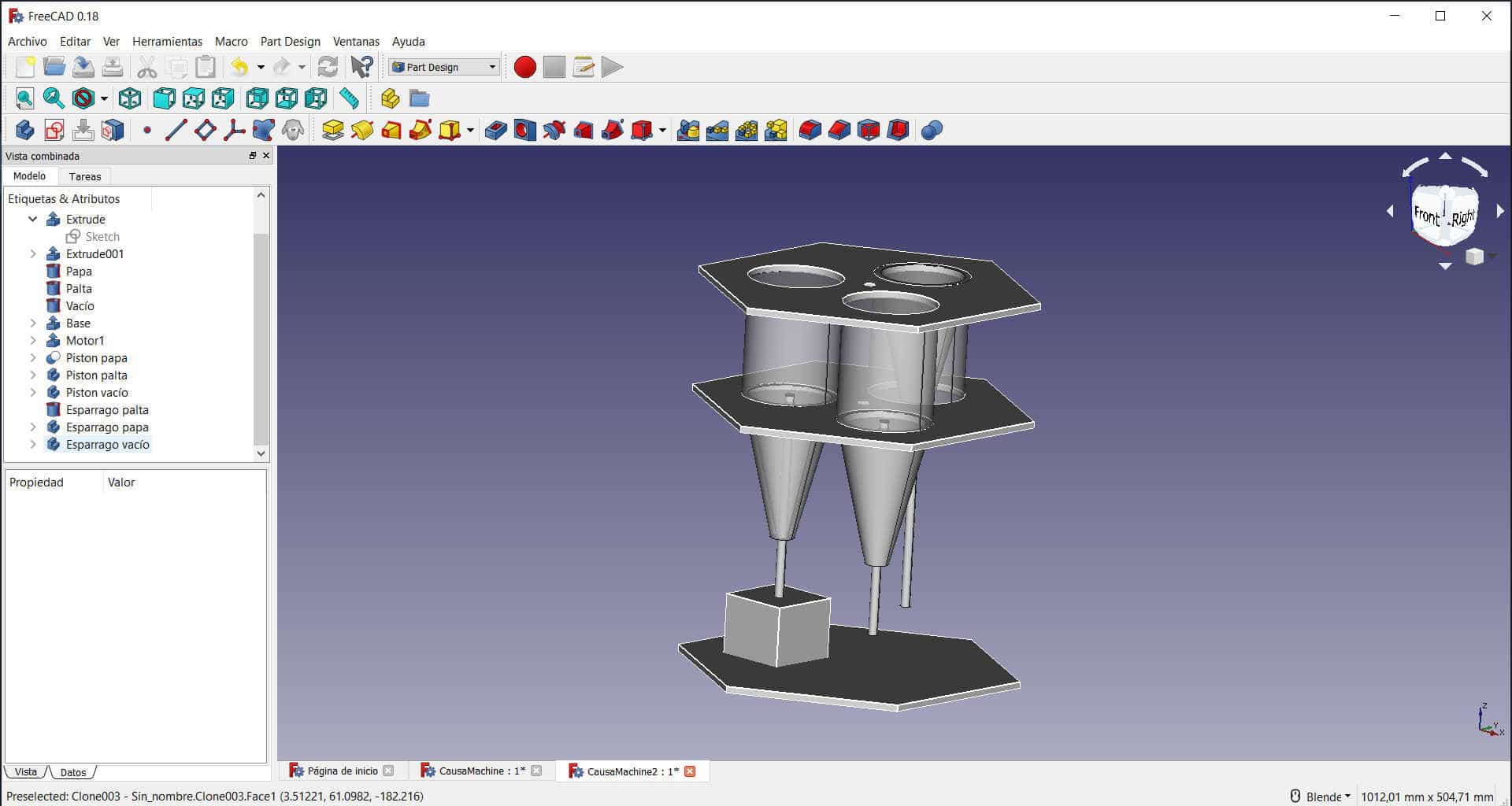

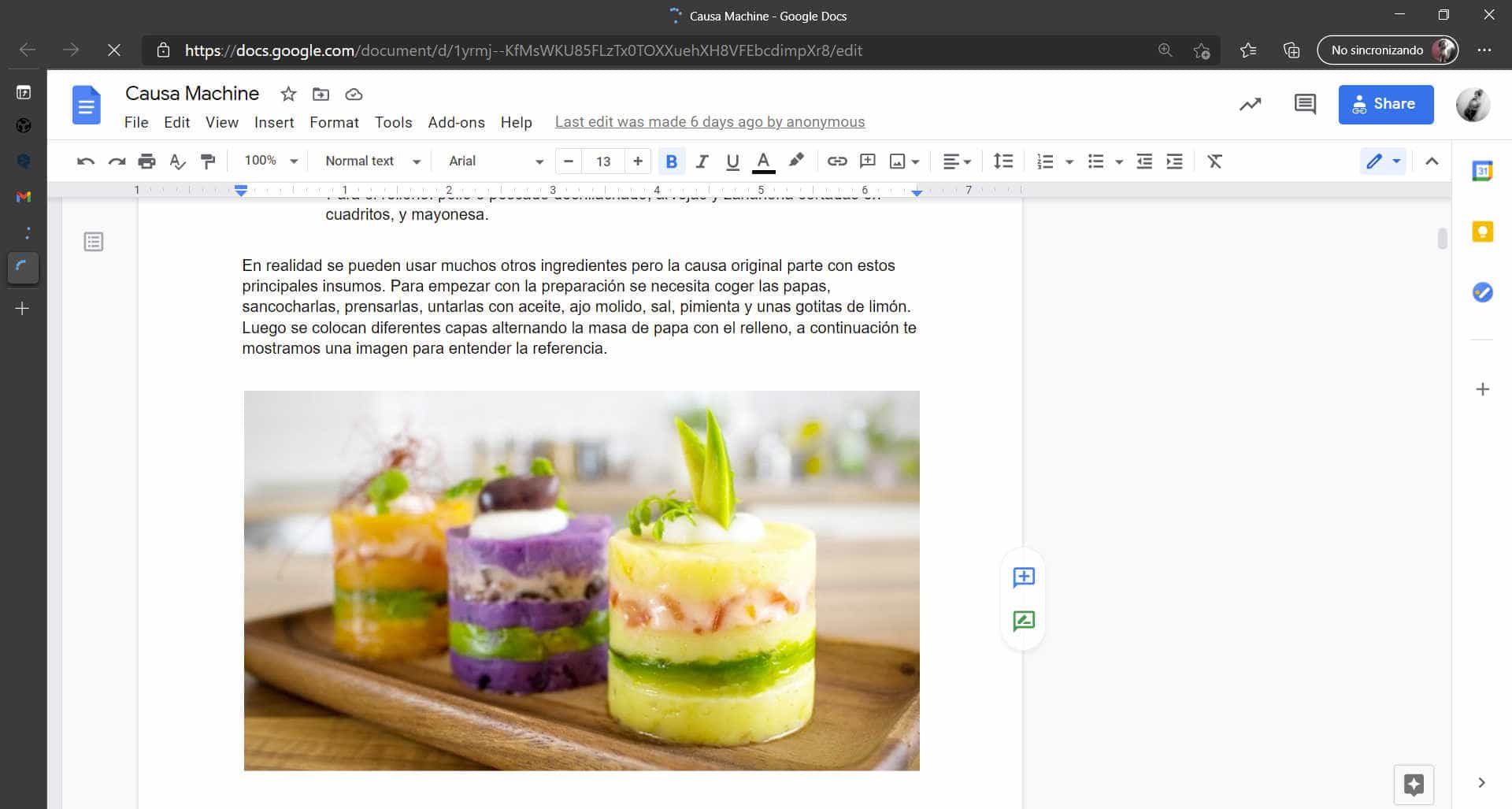

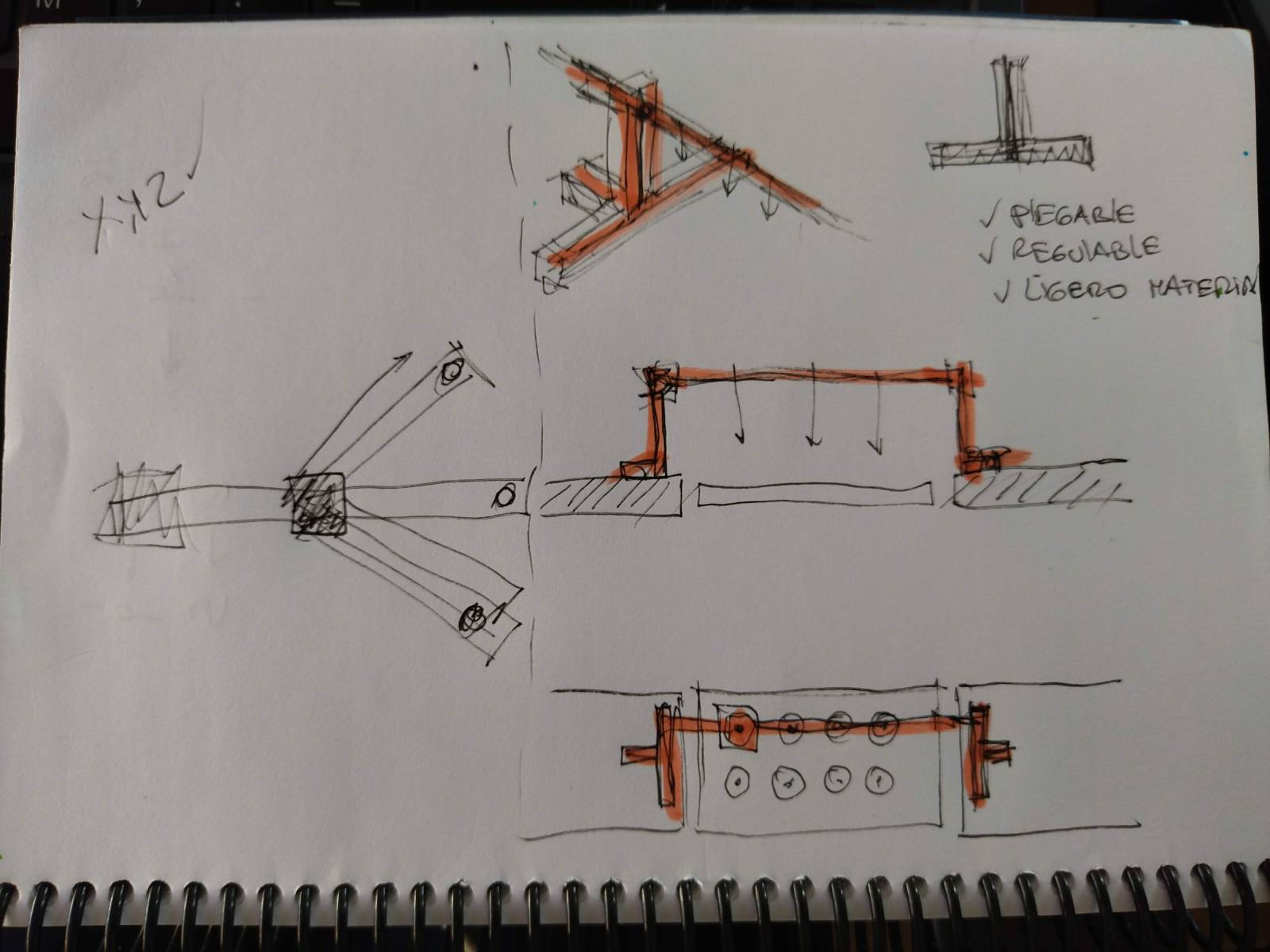

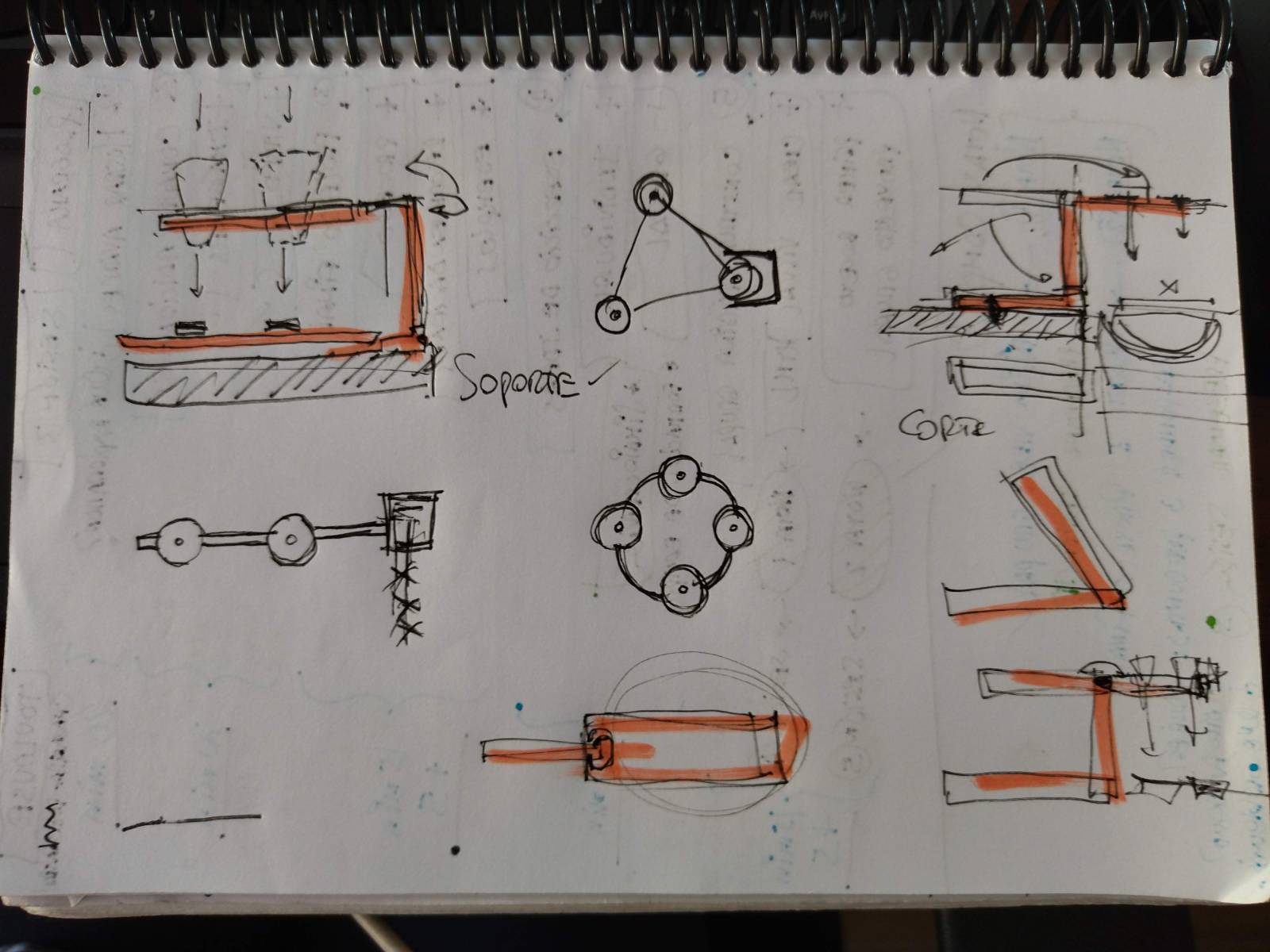

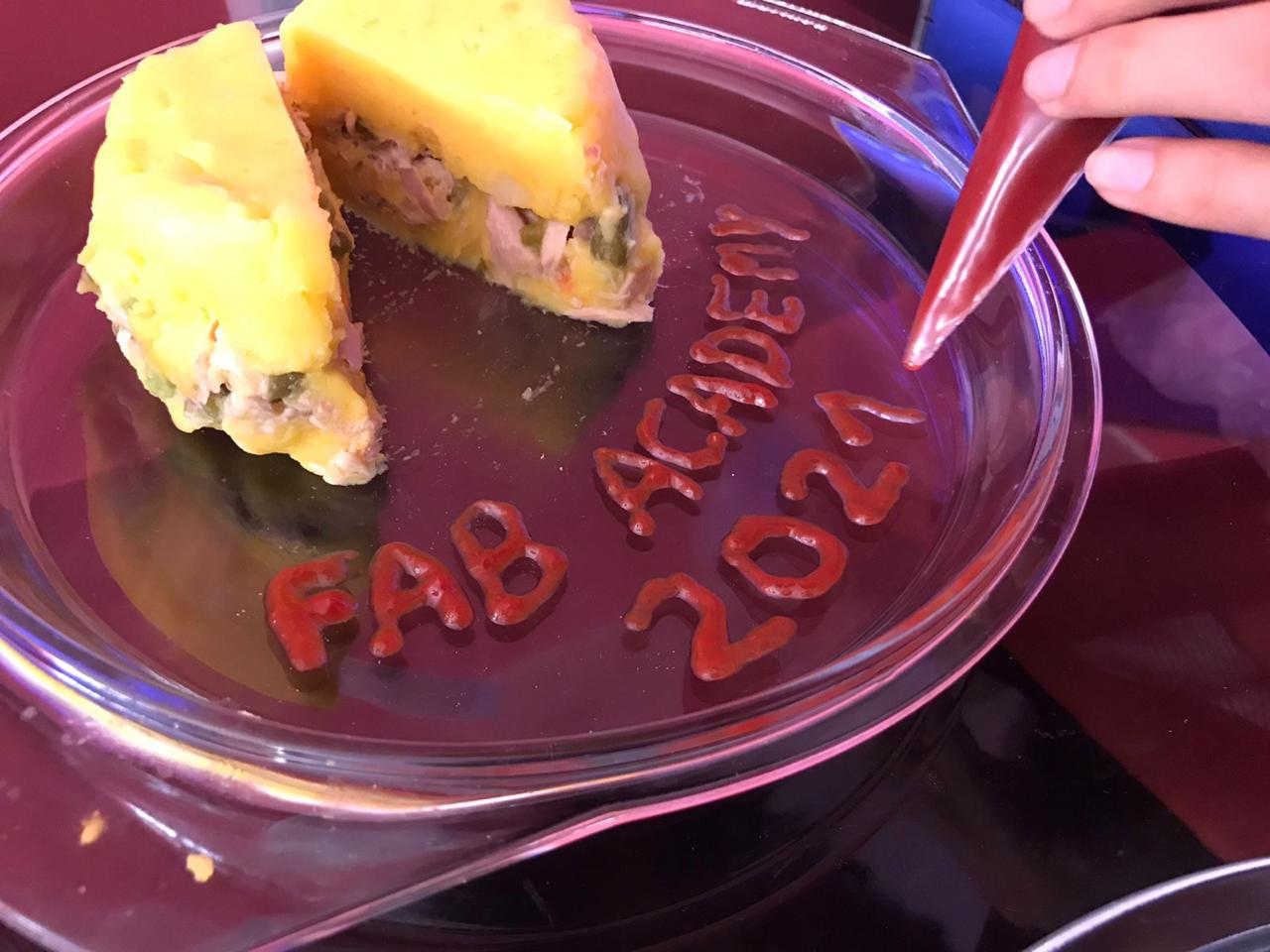

This week I was really looking forward to it, I knew it would be a challenge but I never really imagined I would get to build something this crazy. With the Fab Lab Peru team we chose to do a project that we had been thinking about for a while, in 2019 we wanted to provide a different experience to people traveling to Lima Peru, one of the most outstanding things in Peru is the food so we thought of giving a unique experience to people who came to try the typical Peruvian dishes, as it could not be only a conventional experience we decided to use technology to our advantage and create a machine that prepares these dishes. As a conclusion we chose a dish called "Causa Limeña", this historical dish in our city is a mixture of history and flavor since its creation was 200 years ago as a result of the fight for our independence. What better invention for this bicentennial? A causa machine! 🤩

Here is a little bit of my exploration and progress this week.

First step

Before starting with the individual explorations of the material we had some meetings with José Duarte, he is a well known Peruvian Chef who really had a lot to tell us about this well known Peruvian dish. It was a lot of fun to meet him and learn as I in particular was not yet very clear on how to go about preparing a causa that would be suitable to be served with a machine. Below I will show an exploration I did.

´

Meeting

Meeting

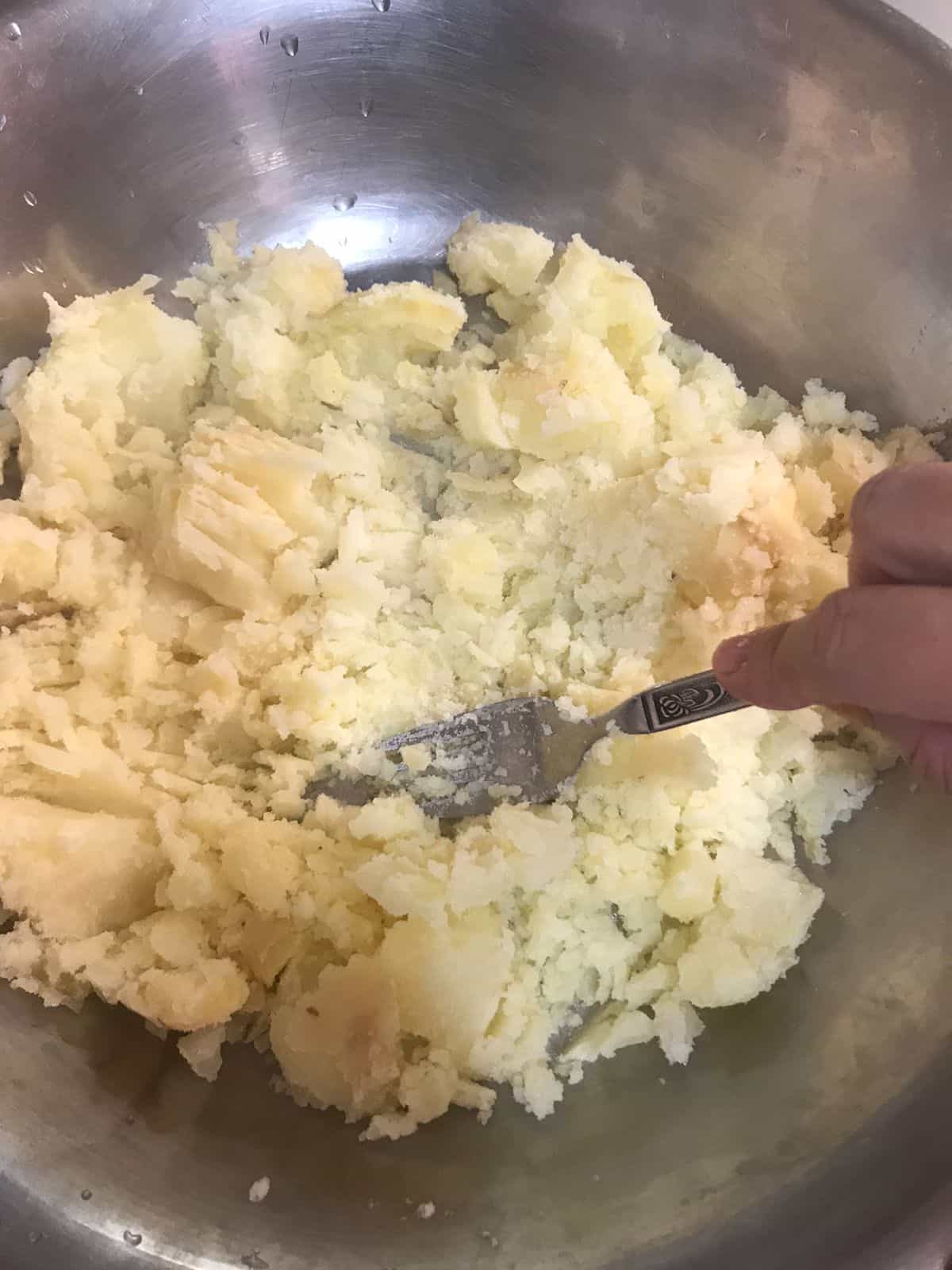

First we mash the potato

We use some lemons

We boil some vegetables

Mix the vegetables with tuna

Blend yellow chili

Mix with your hands

Add lemon to the mixture

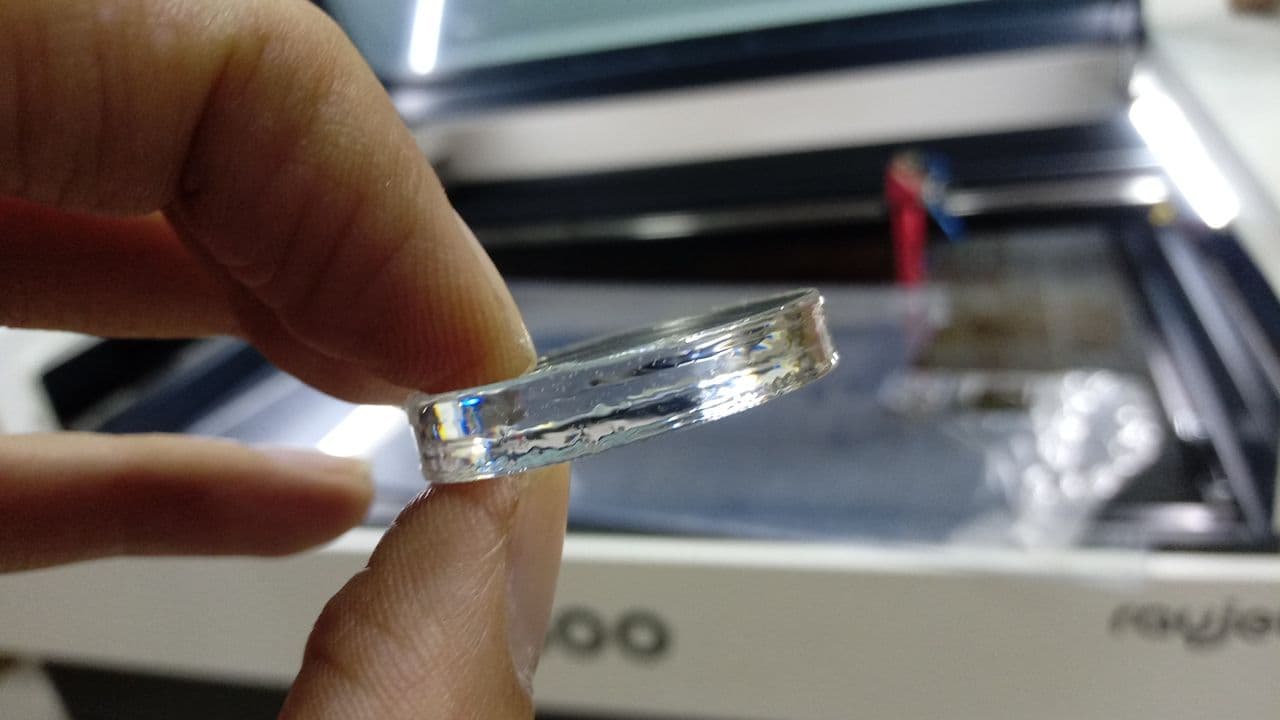

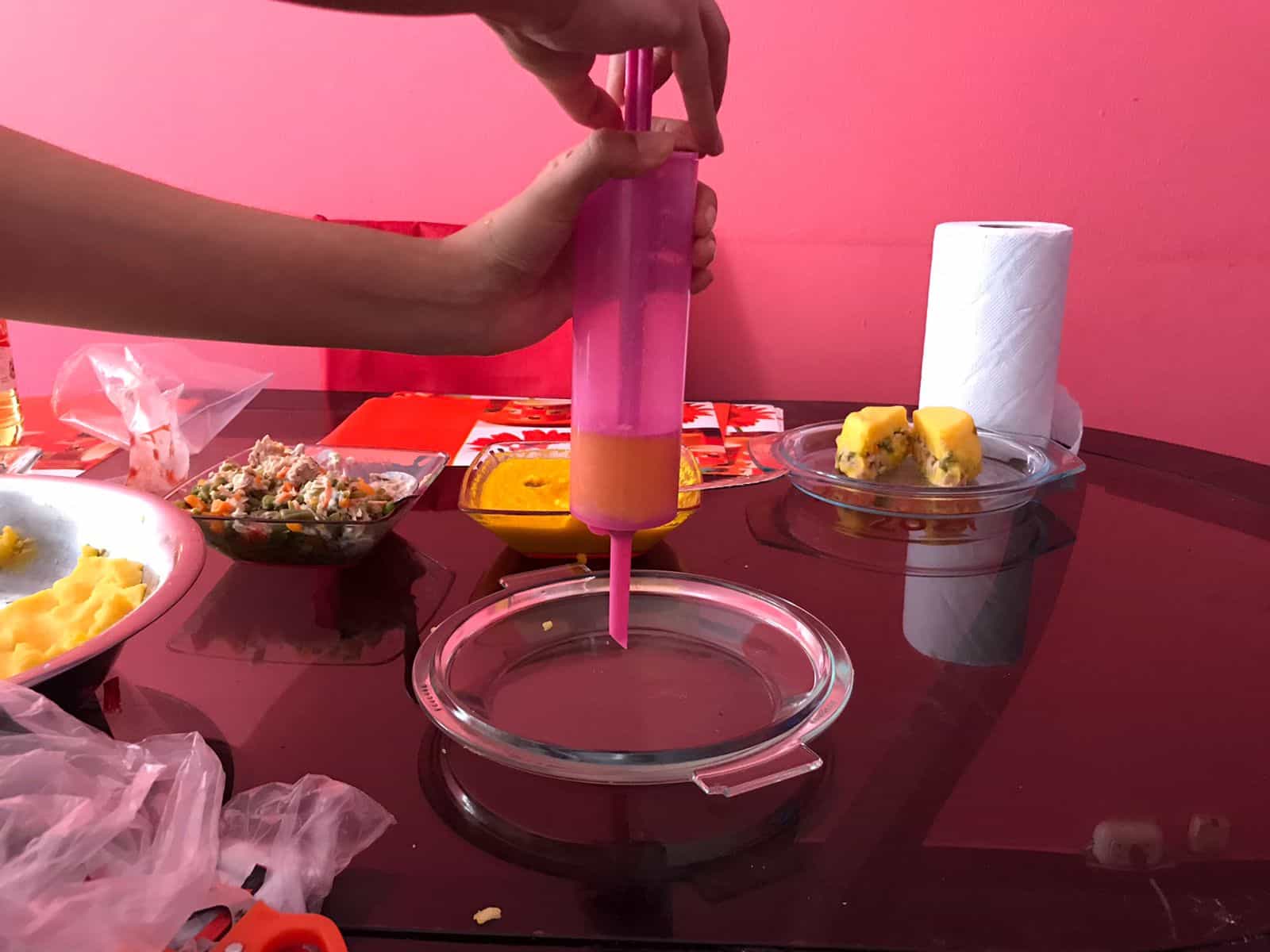

I used a homemade extruder

I put the potato dough

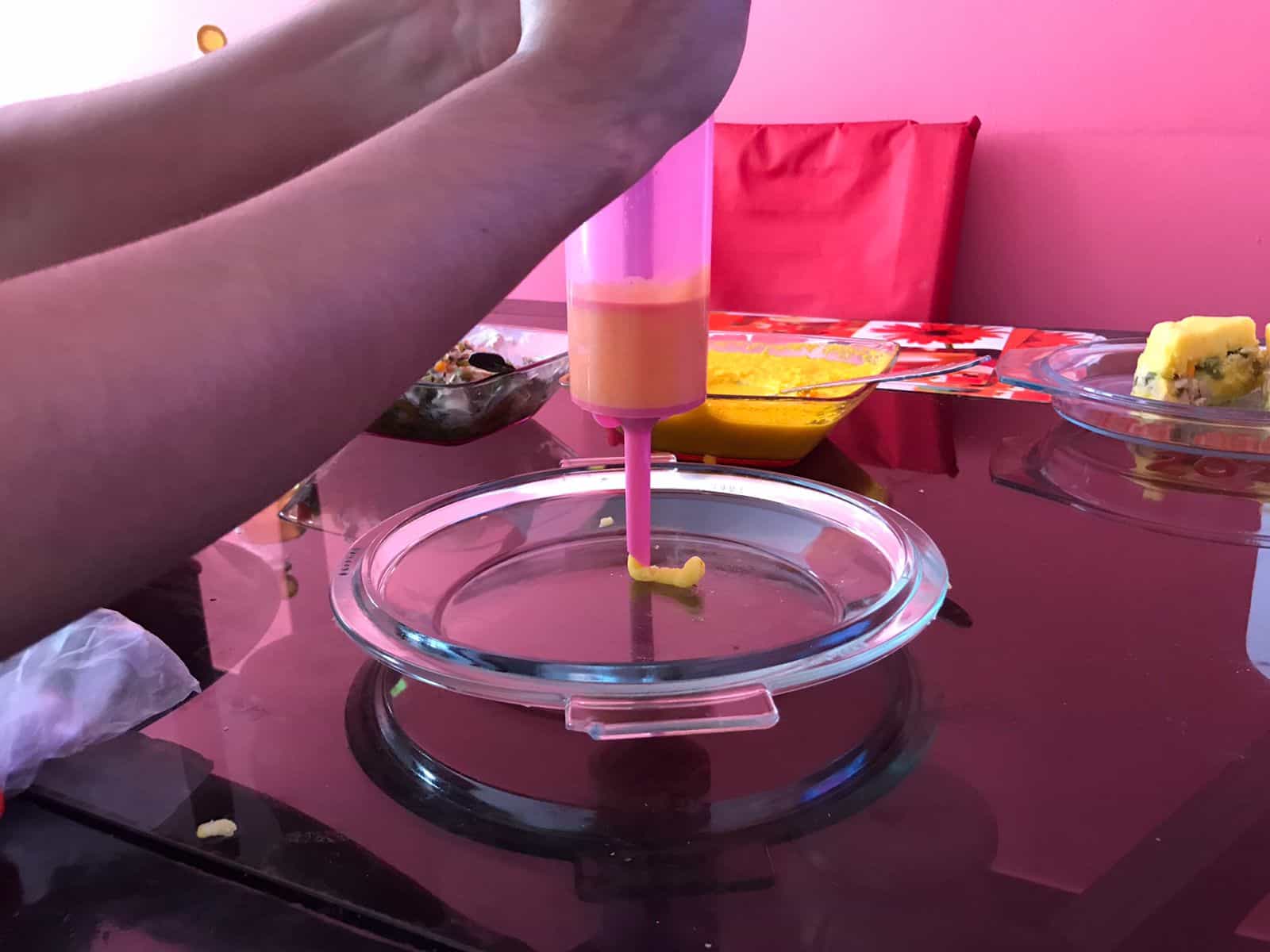

I pressed the piston

There was a lot of pressure to do

The texture of the potato was very coarse

First Conclusion

The first conclusion I had was that it would be very important to get a texture that is not so difficult to extrude, if this stayed like this it could make the motors work more than they should and that was not good. To achieve this trade-off we had a lot of explorations with the whole team and finally we came to the conclusion to use some different ingredients to make the dough lighter. As a first prototype I imagined that the cause would end up like the following pictures.😃

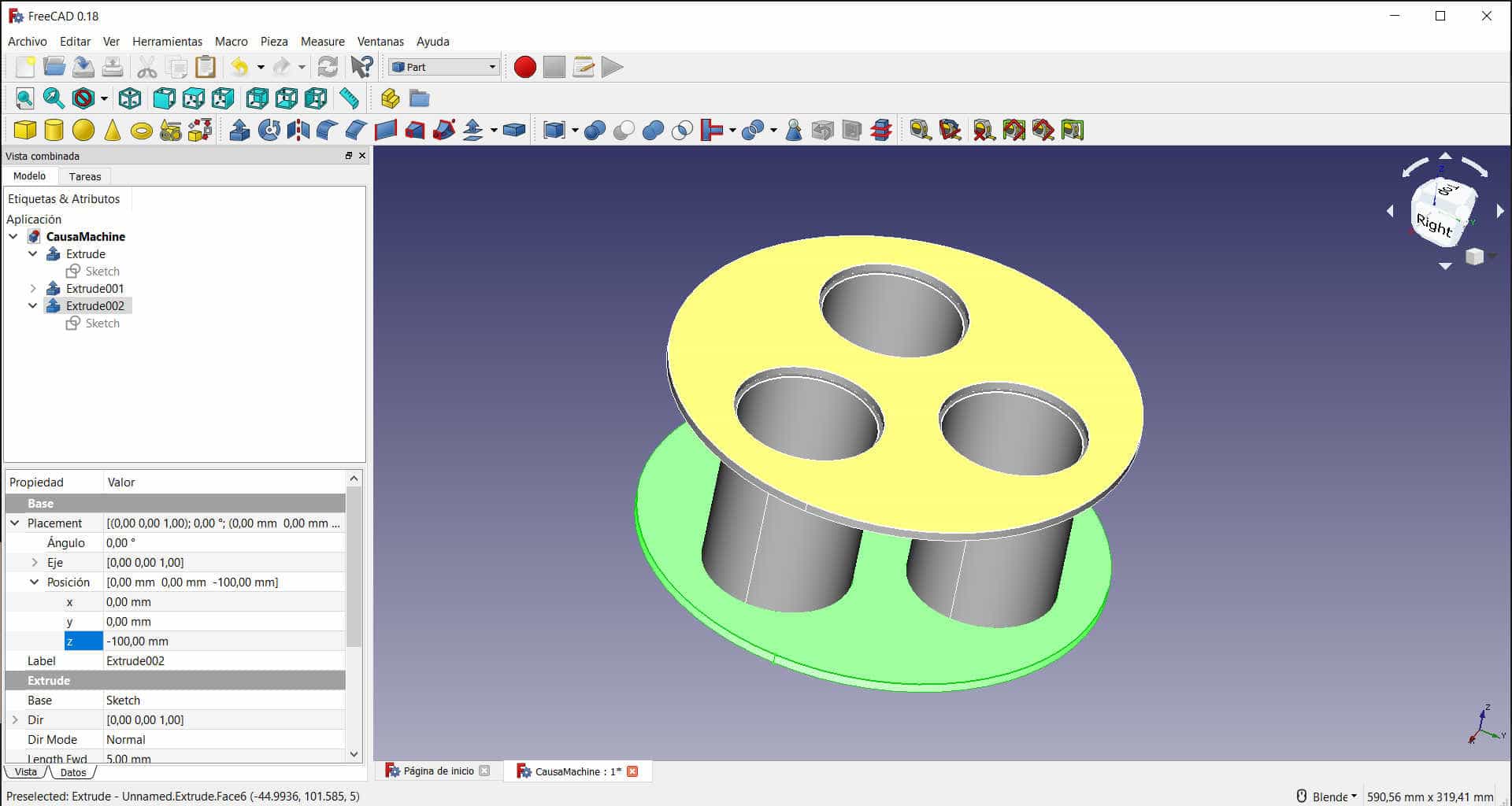

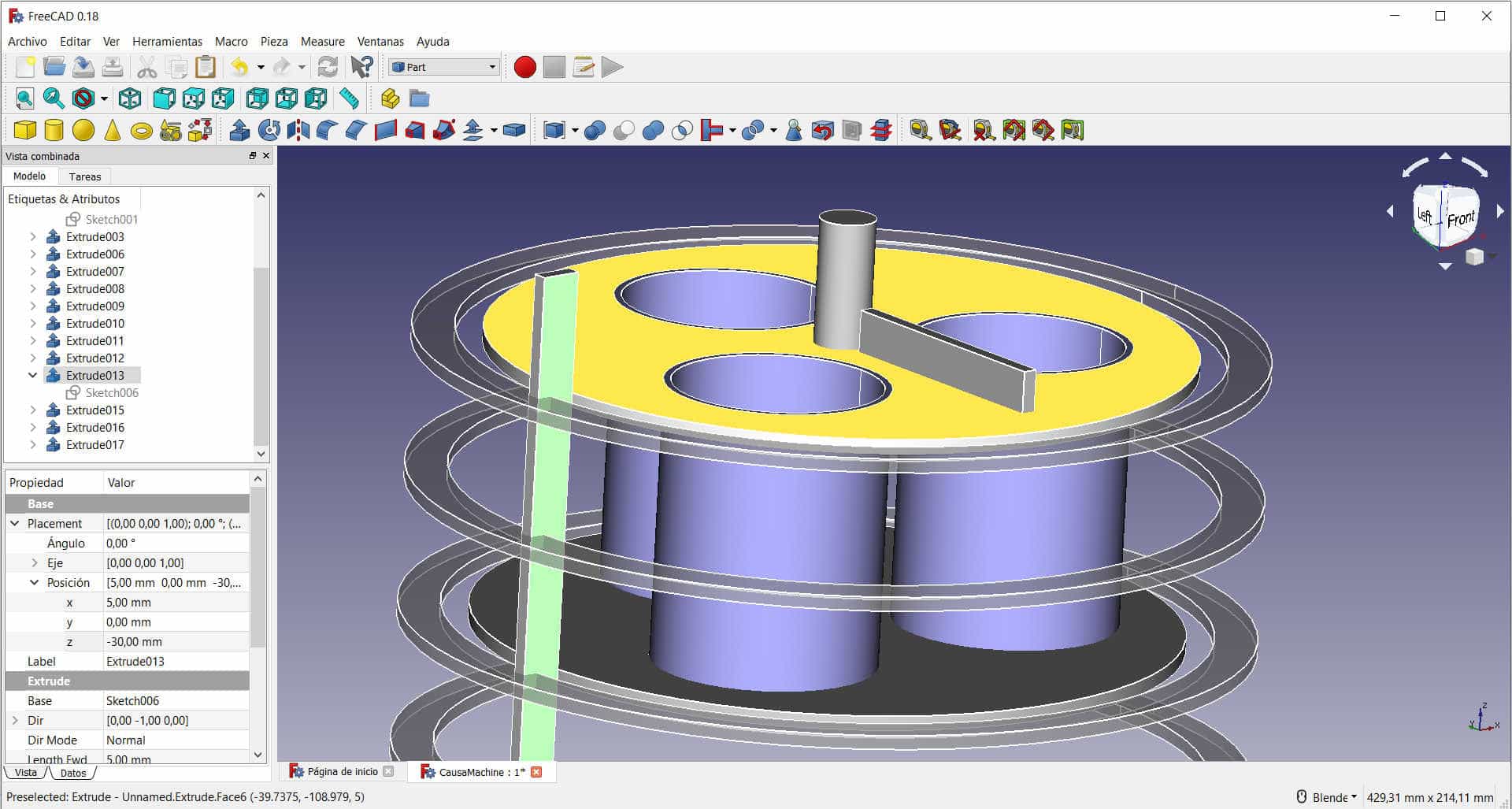

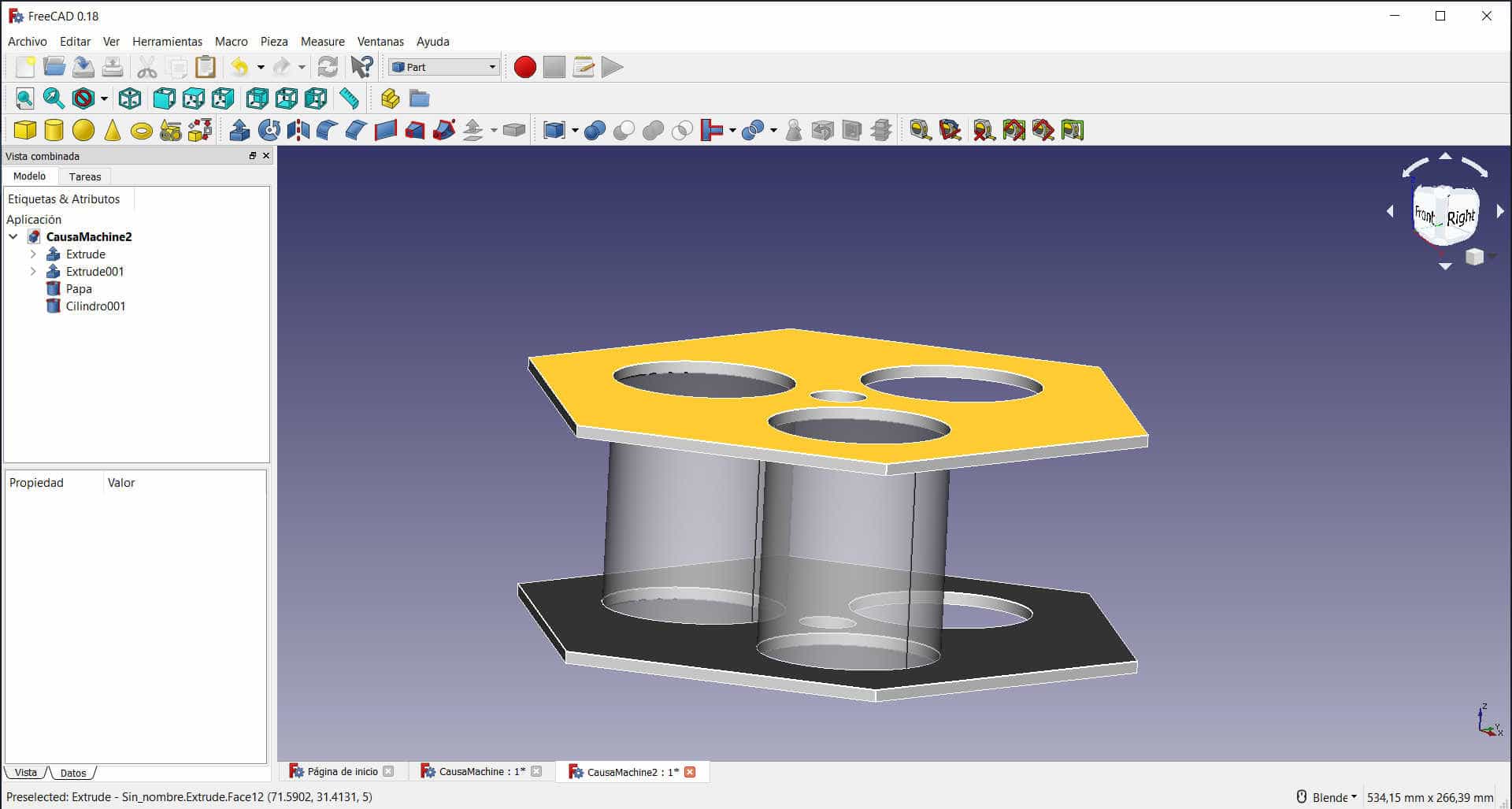

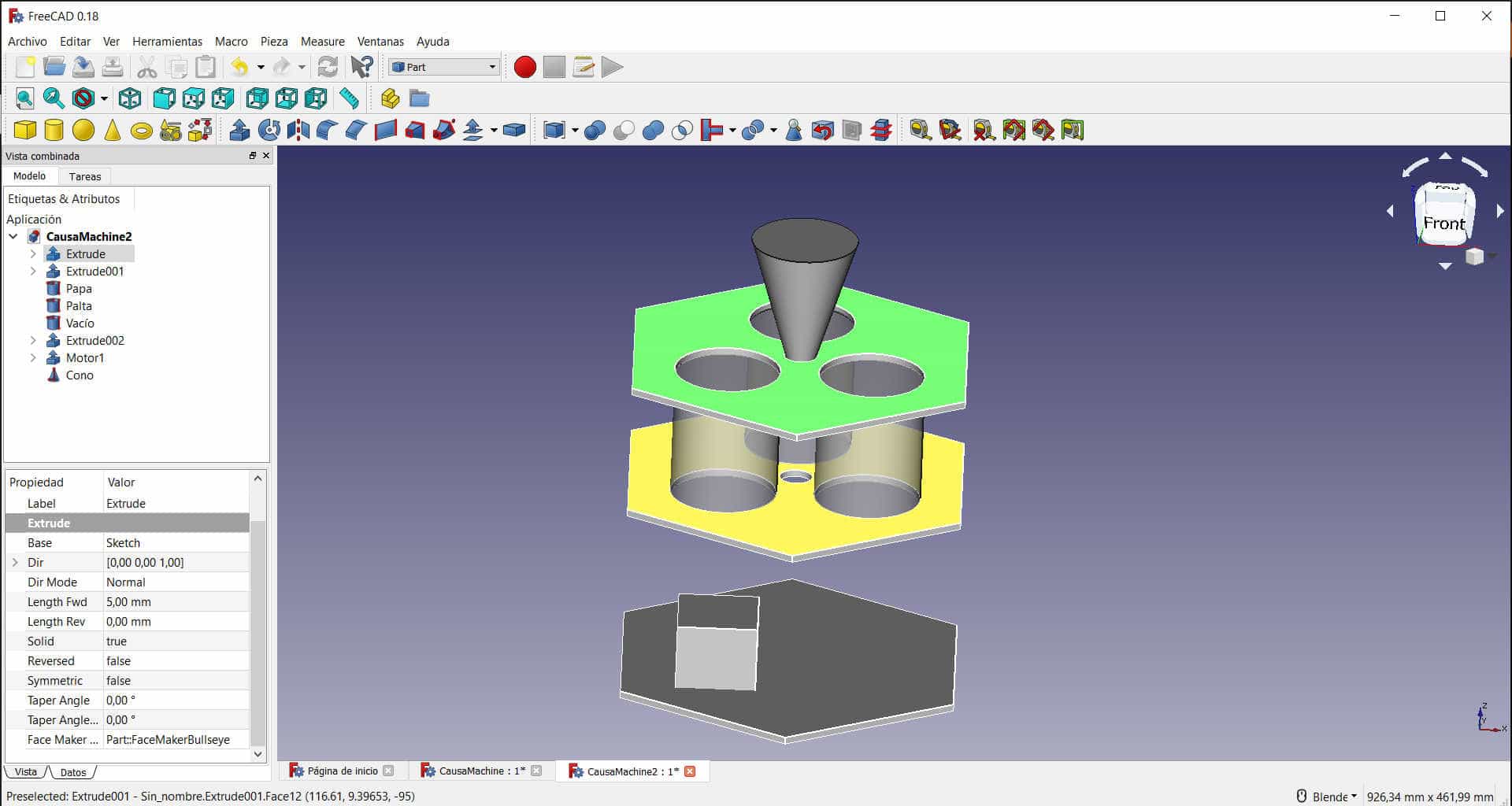

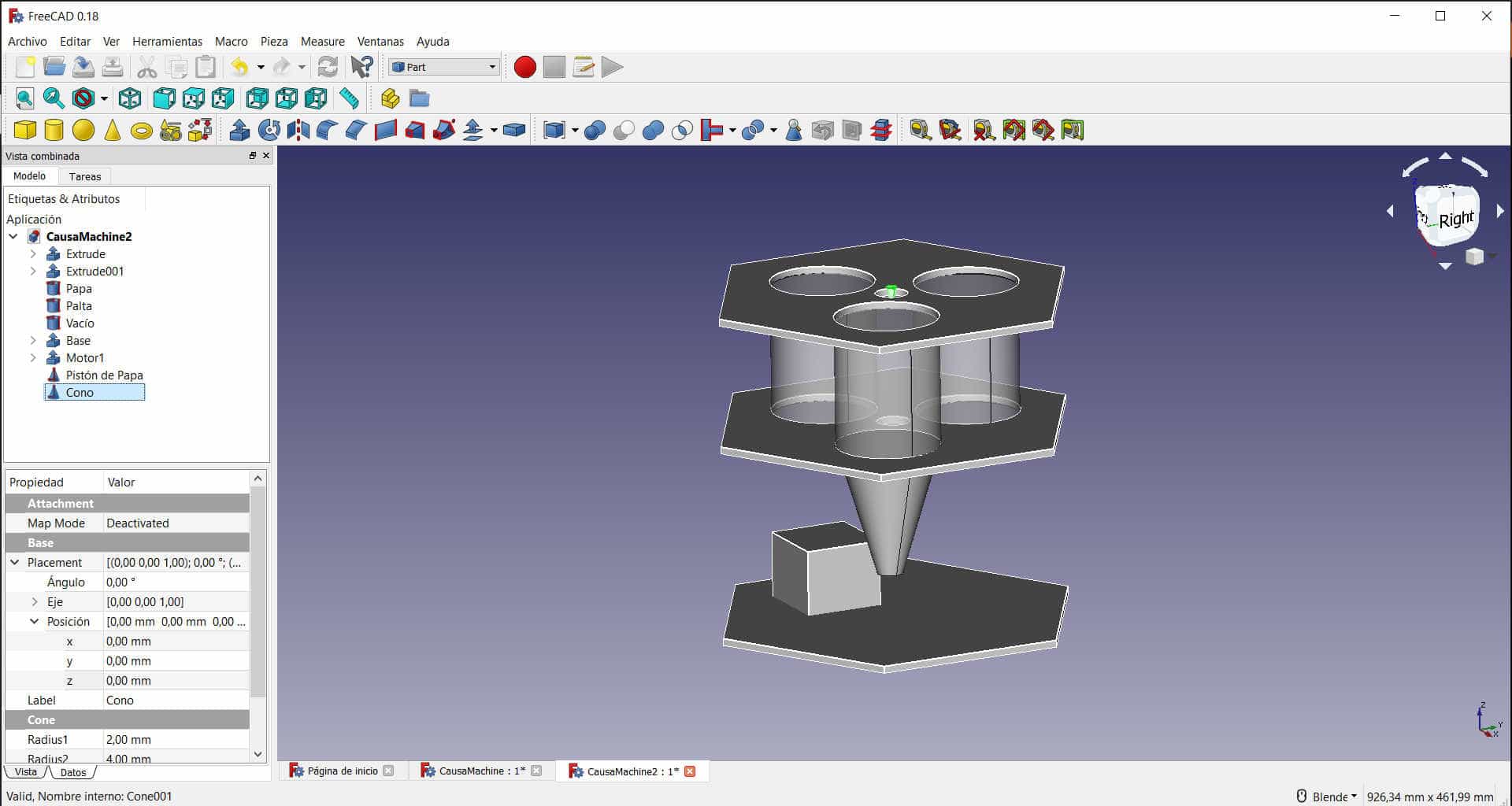

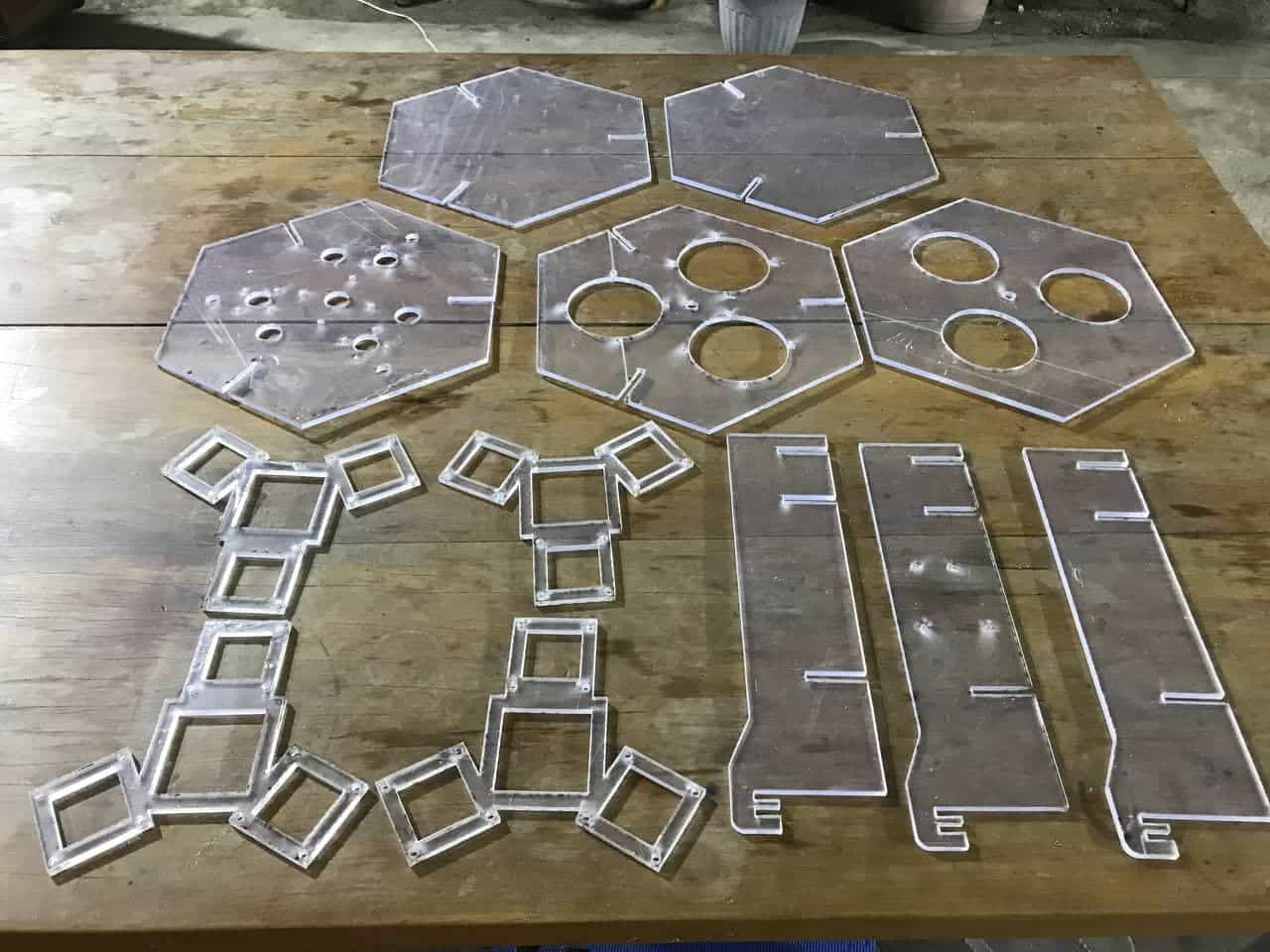

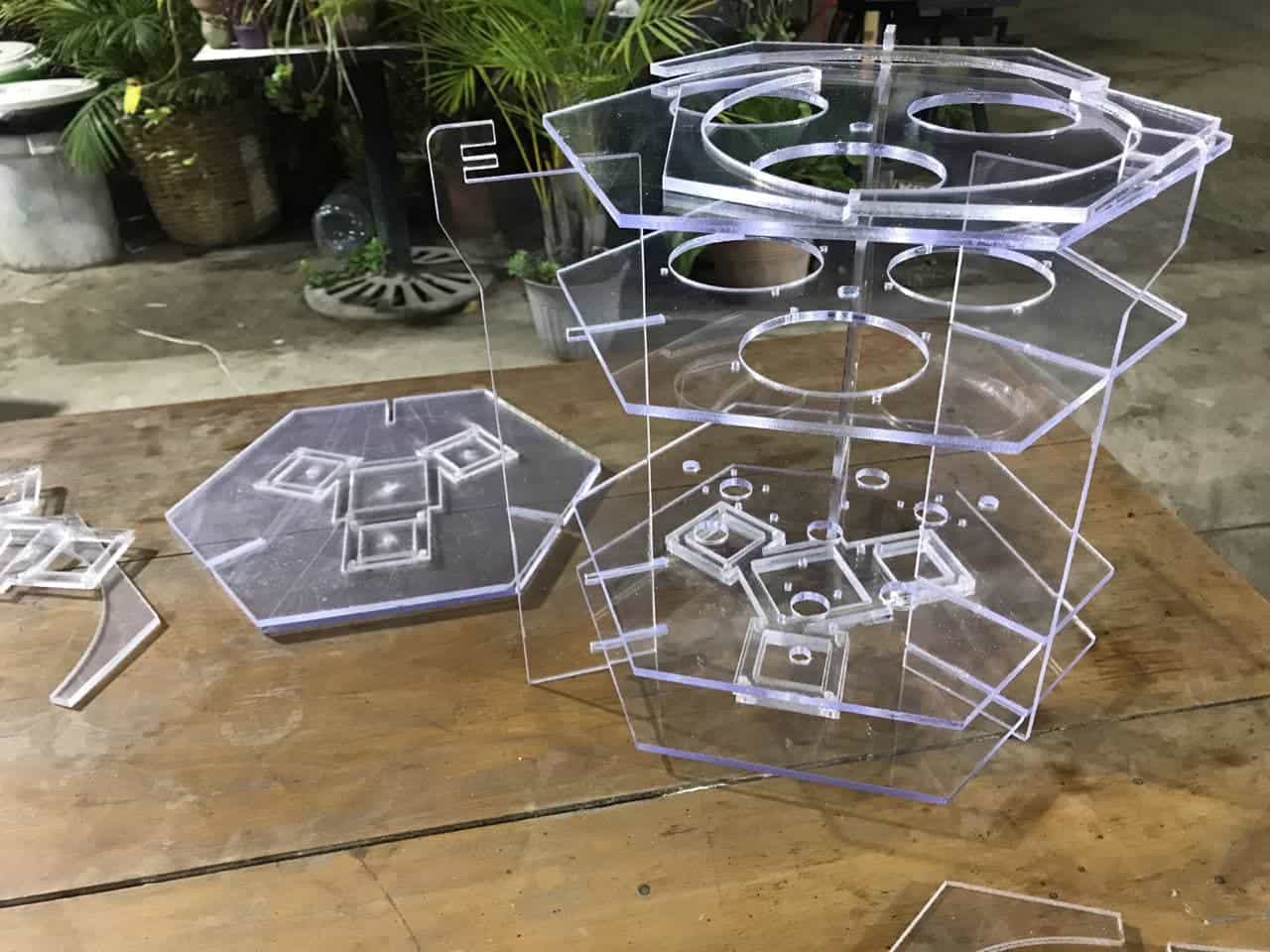

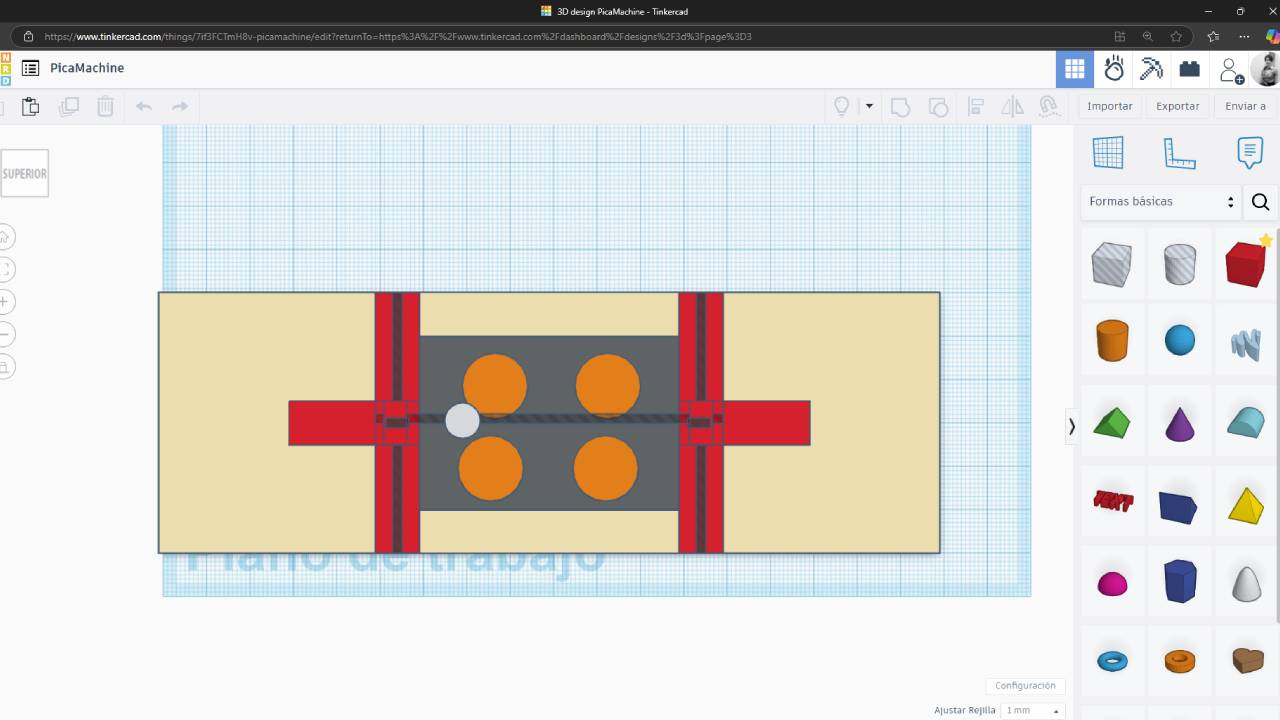

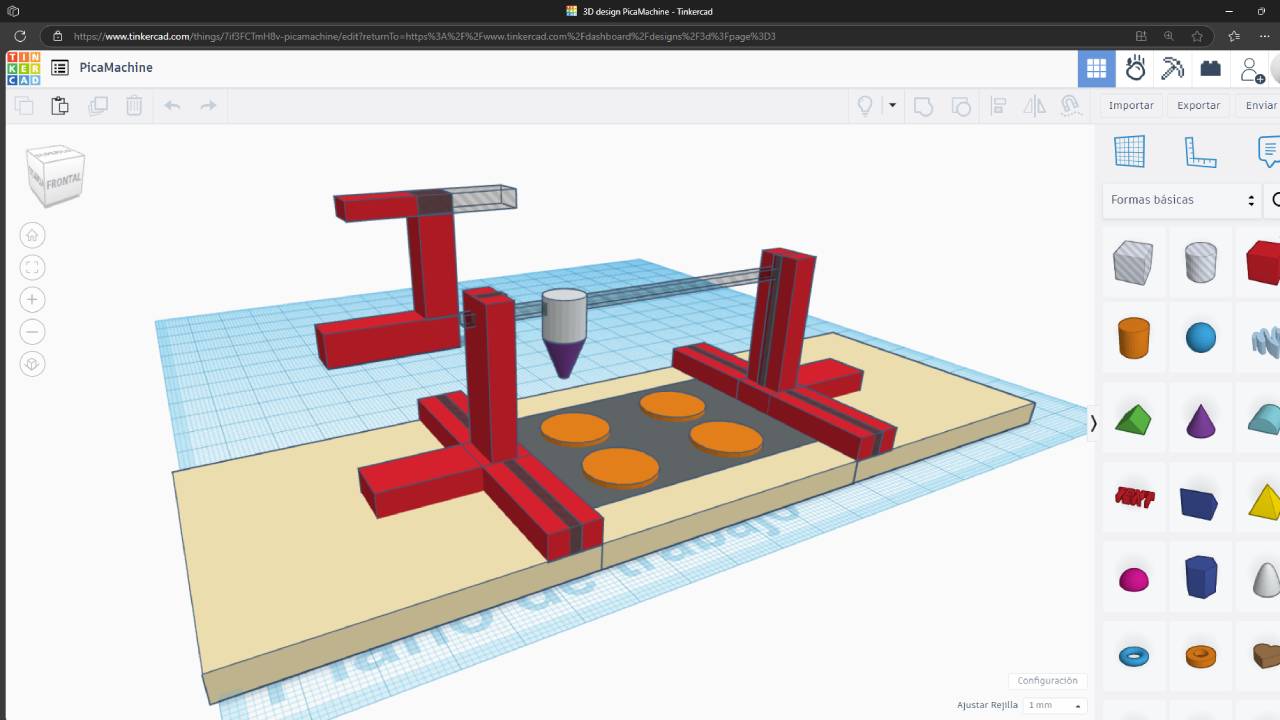

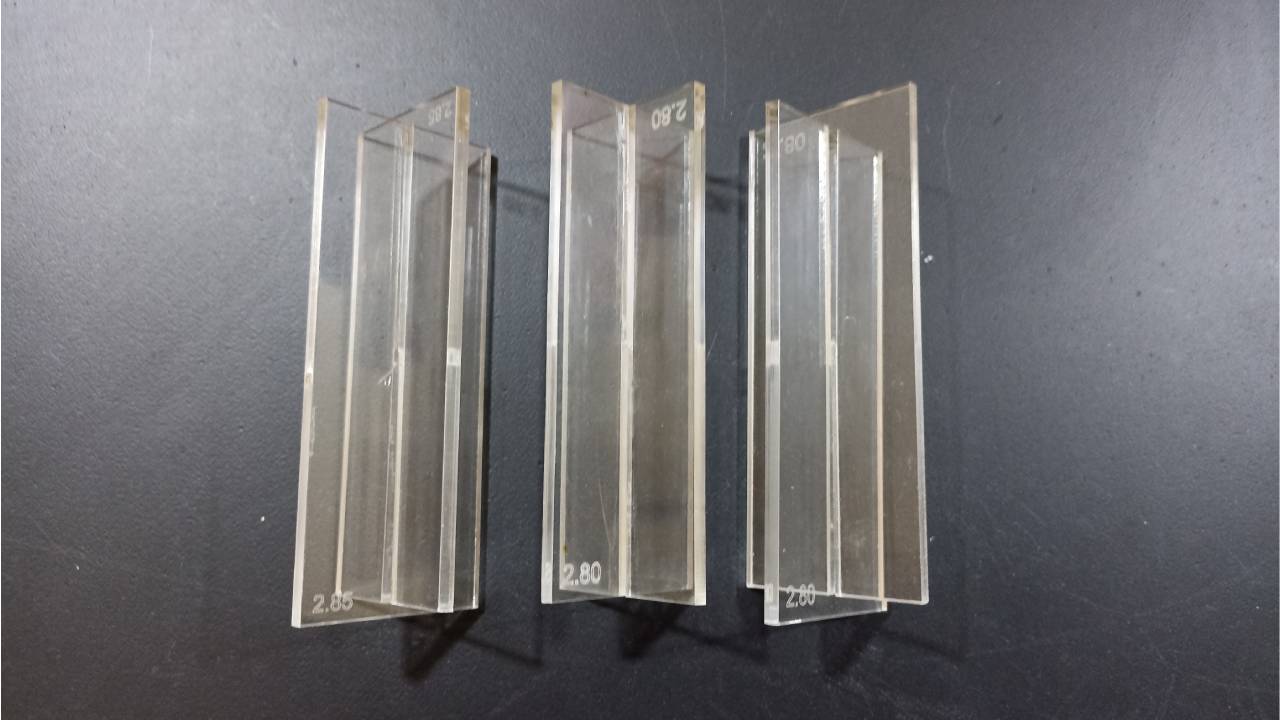

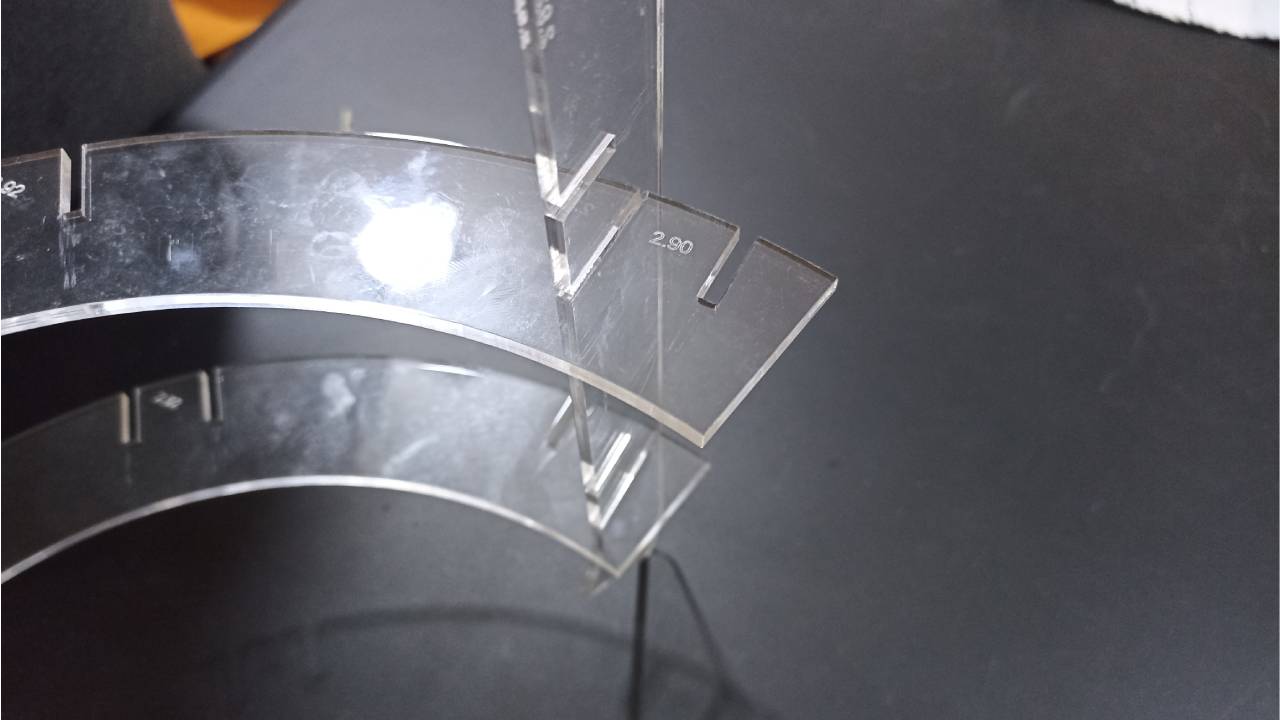

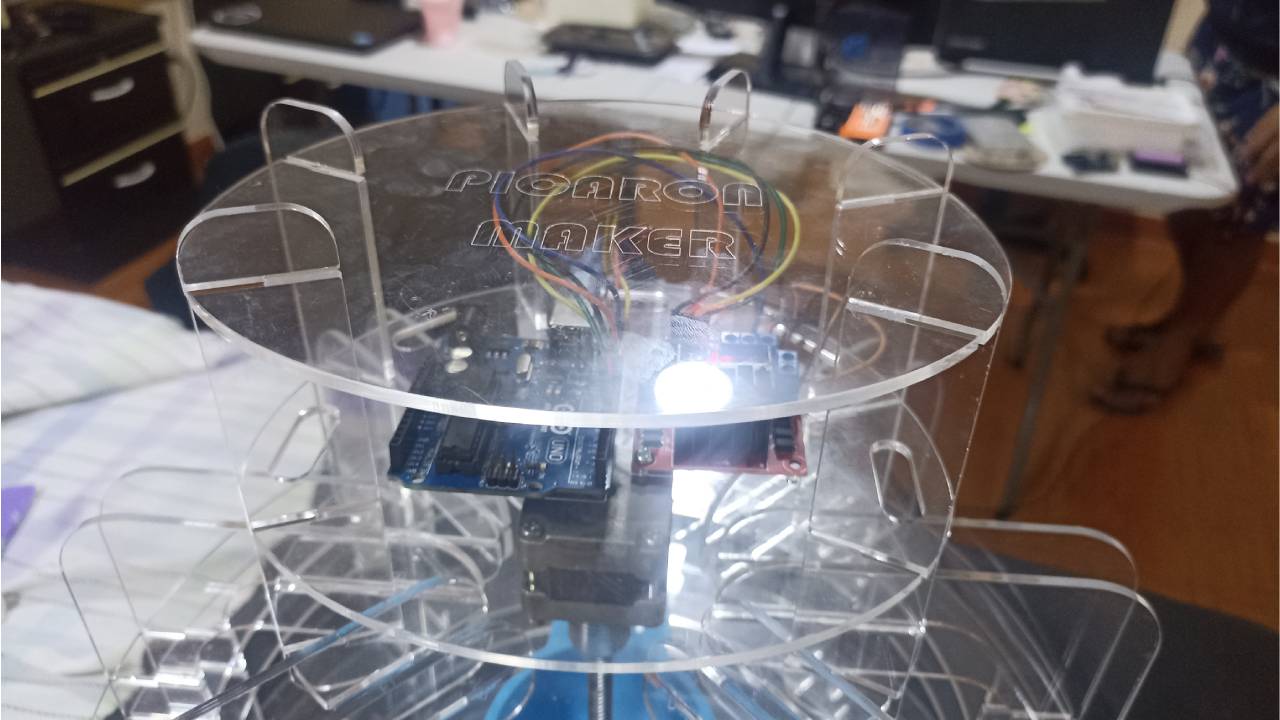

Machine

Machine

Machine

Machine

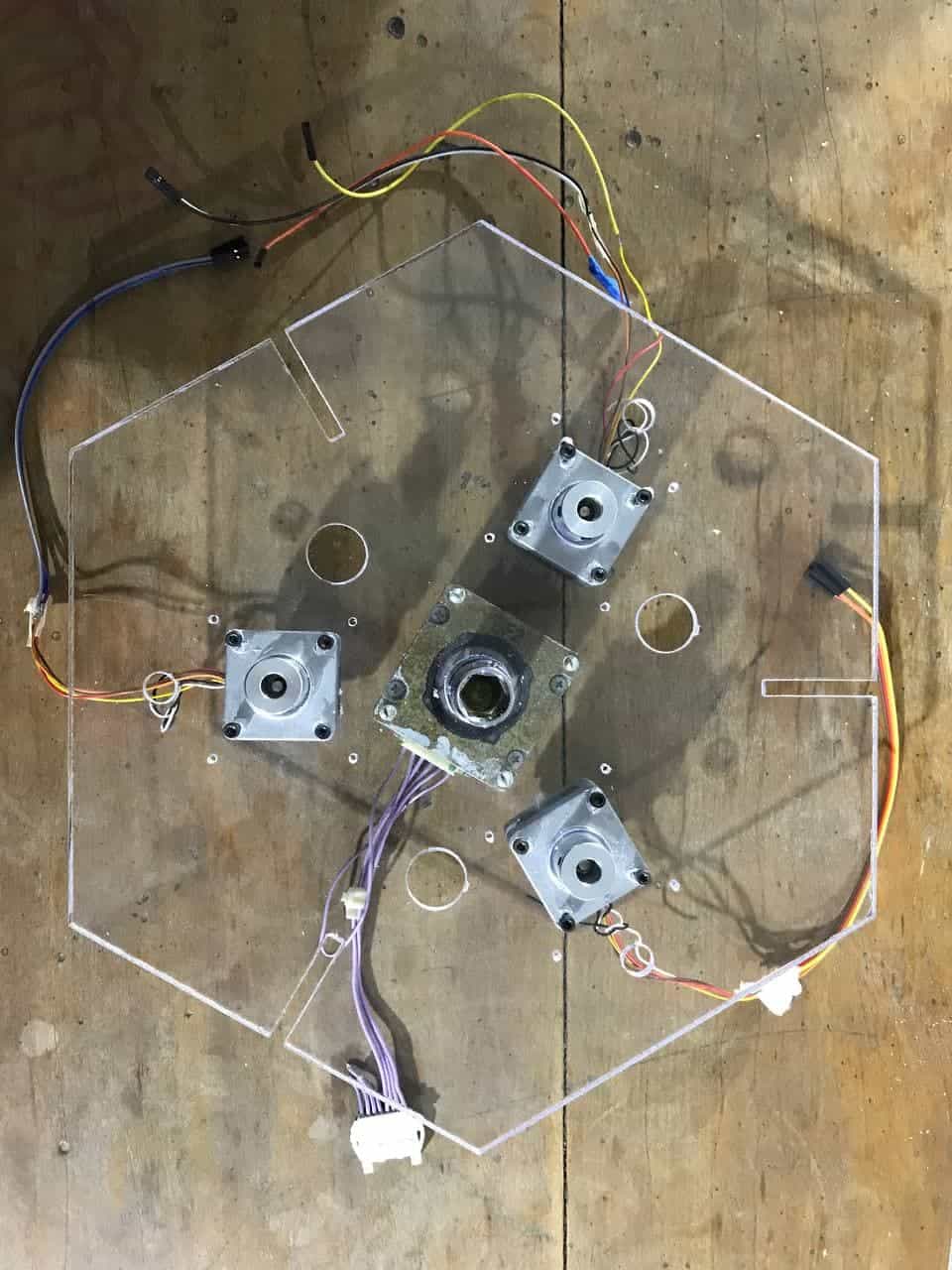

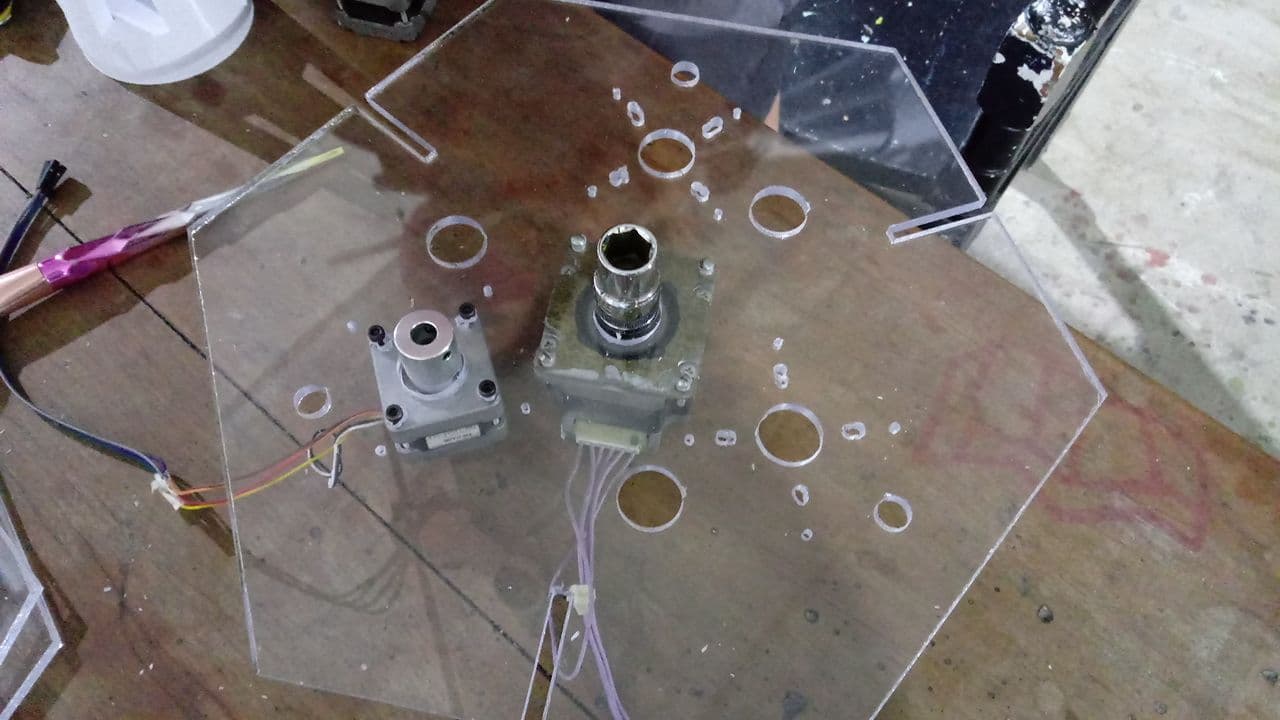

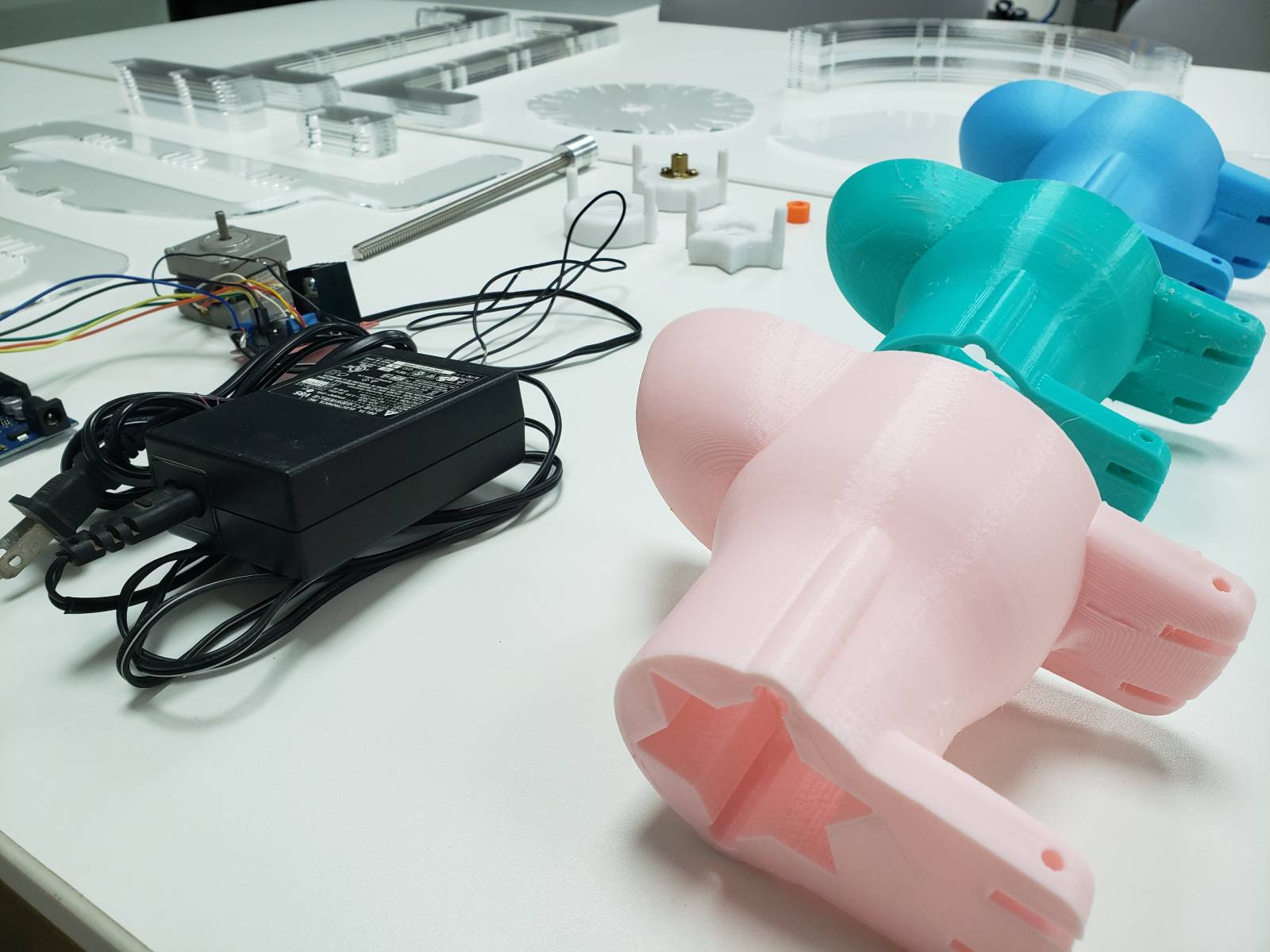

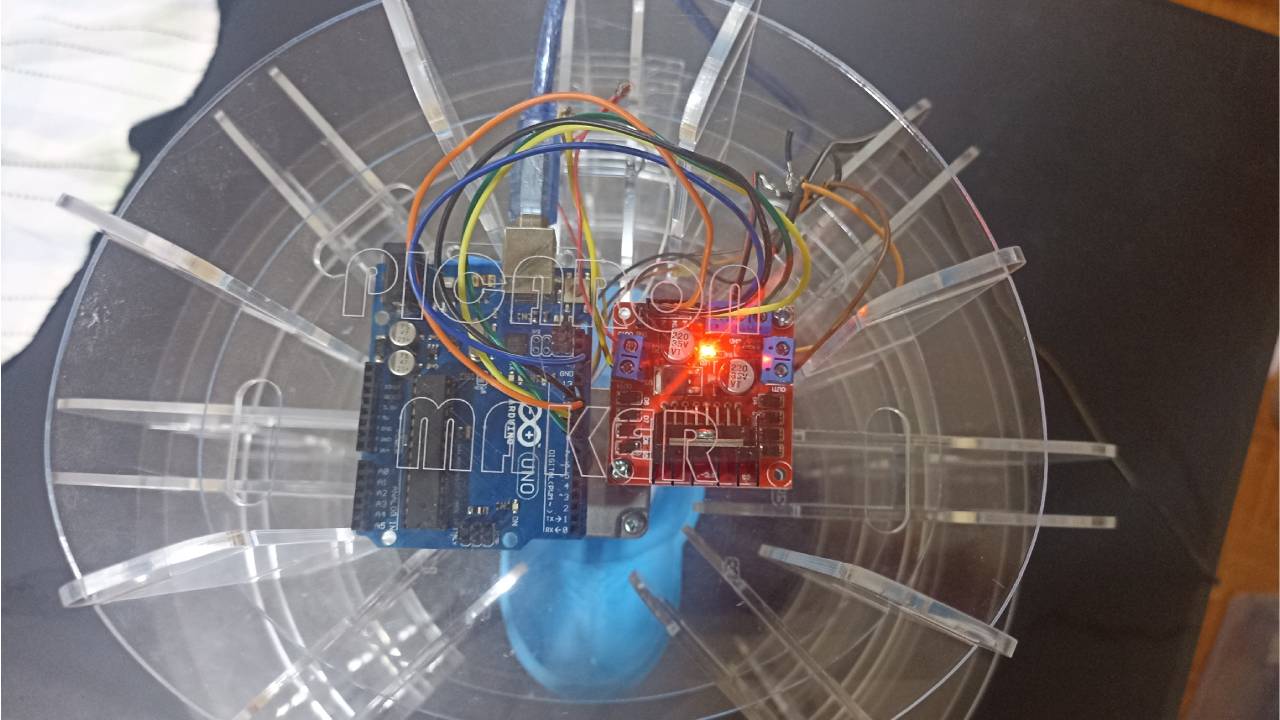

Electronic connections

Electronic connections

As this machine is quite old, we first had to get it to work, so we made some adjustments and revisions to both the mechanical and electronic parts. After many tests we managed to get it to respond to our computers. Here is a moment of happiness when I was able to control it from my laptop. 🤩