Itan Fuentes Santamaria

Email: itan.fs@hotmail.com

Phone: 2227535416

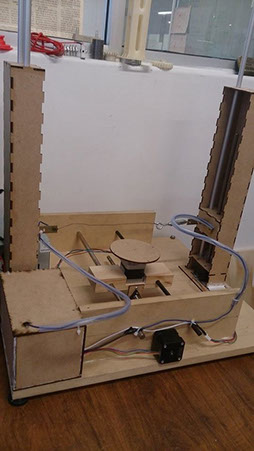

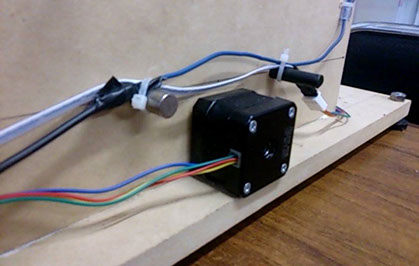

I want to say something important of this assignment, two of the axis were recycled from an old copy machine. in this kind of machines we can find a lot of expensive things like axis, linear bearings, bearings, motors, endstops, a lot of switches, etc. So if you know where to find an old copy machine, grab it buy it or something, it's a gold mine of expensive things.

I have to say that i was not nearly the Fab Lab and i had to do my part with conventional tools, measurements, holes, cutting and assembly. but guess what???? IT WORKS :)

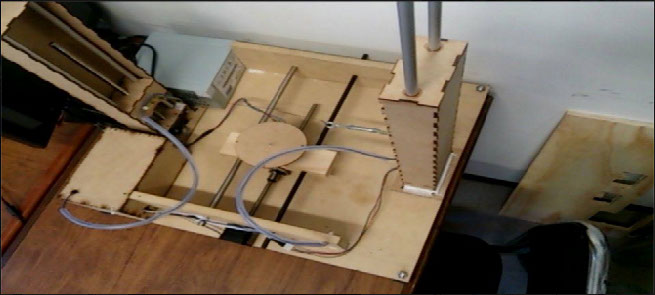

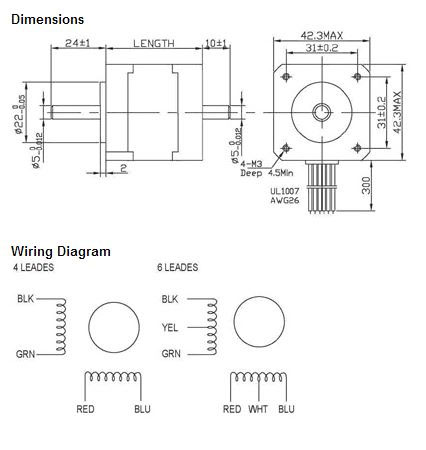

One of the biggest problems was to put everything aligned. To put the motors and axis aligned a i had draw a lot of lines and measure point to point and print some datasheet as guide

i made the same for the axis, a lot of lines and measurement and manually drill the holes. everything alined

for the final part, i was back in the fab lab where i used the laser cutter to made the proper adaptations for the ball screw