Itan Fuentes Santamaria

Email: itan.fs@hotmail.com

Phone: 2227535416

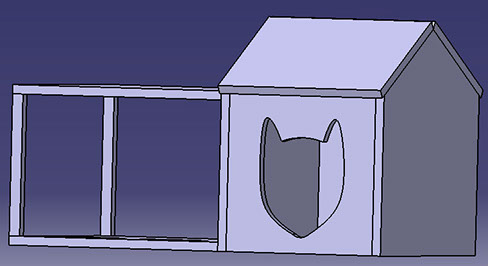

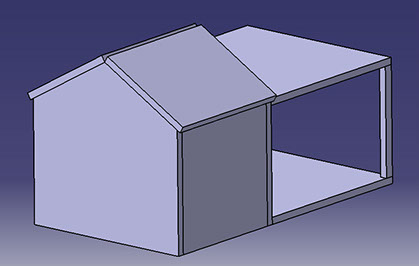

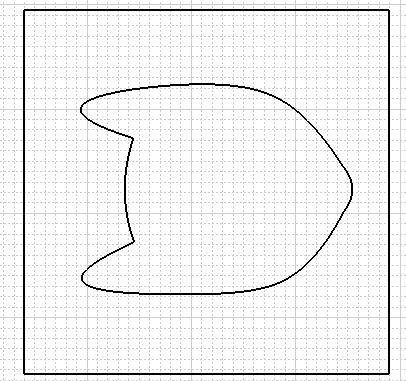

First i decide which model to make and then model it in catia and then make an DXF format to put in the CNC router and cut the material

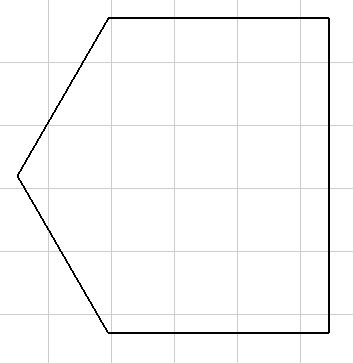

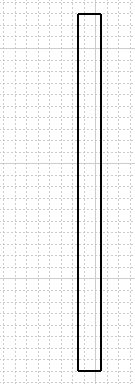

some of the DXF's ready to be cut

setting the machine.

for this part i had to set the cutting parameters, this where,

Feed: 60mm per second,

Mill speed: 10,000 rpm

endmill: two flutes endmill (this because of the material, if we use a four flutes endmill it will generate too much heat and this would be risk because of a possible ignition of the wood, BE CAREFUL

Working on the final details....

and voilà.................

i have to say that in this assignment i forgot that i had to do it with press fit assembly, i use some nail and then i redesign the walls.

another problem that i had was the warping of the wood, i had to put some double face tape to fix the wood table to the working bed in order the mill end don't cut out of the limits of the drawing.

Find the Design HERE