Itan Fuentes Santamaria

Email: itan.fs@hotmail.com

Phone: 2227535416

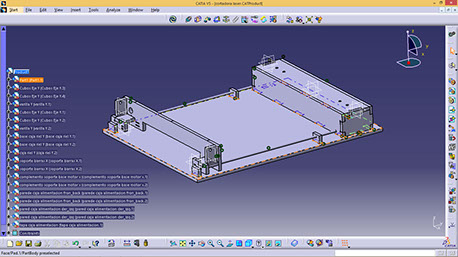

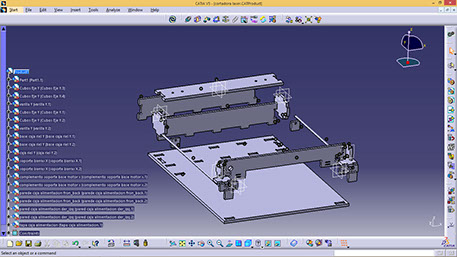

First i start with the design, i did it in Catia

i have to mention that did this modeling in catia sometimes it can be really hard, the program is very technical, this means, some easy thing can turn into hard thing to do, for example the assembly, sometimes there are two or more way to do something but only one way is the right .

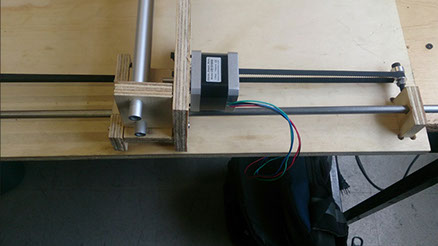

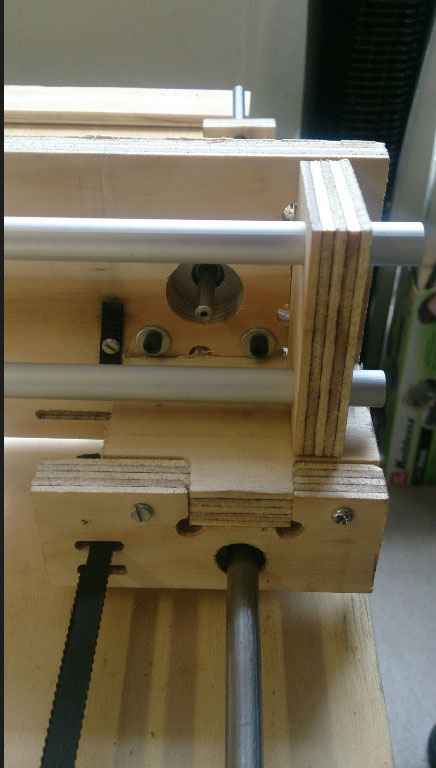

for the idea i wanted to put a cantrail supported by two axis (axis Y) this axis have 2 linear bearings which helps the cantrail to move along the axis

for the axis X y made a support just above where the linear bearings are and place the motor for axis X in one of this supports.

Also i add another support fixed in the cantrail to hold the bars of the axis

and finally, to hold the electronic and the power supply i put a box in the back.

i did all the assembly with dog bone, and in some places i had to use some screws to reinforce the assembly

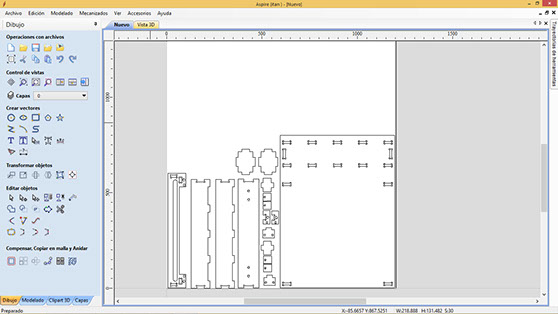

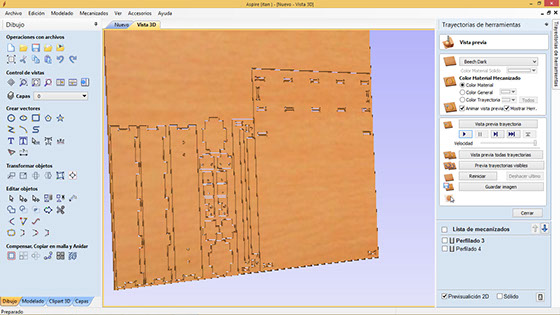

once i finish the design, i use the software Aspire to do all the pieces in a CNC router. i use 12mm wood and more less 1 square meter (850mmx1200mm).

one of the advantages of this software is that when you make the tool path, the software generates a TXT document with the ISO code (G code), this means you can grab this TXT files, modify it or use it in other CNC machine... AWESOME!..

once the G-code is ready, i send it to the router.

in the router we have we need to put some double face tape to fix the wood to the main table and avoid any movement.

Electronic

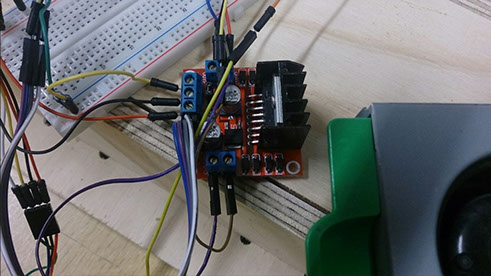

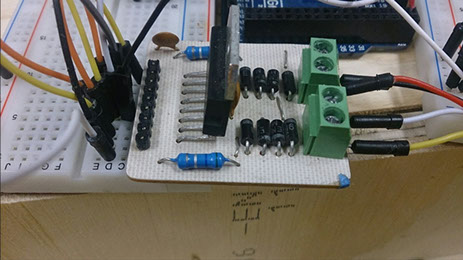

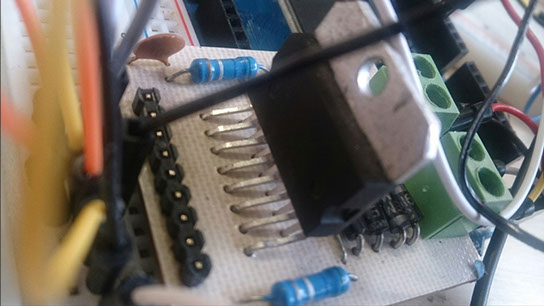

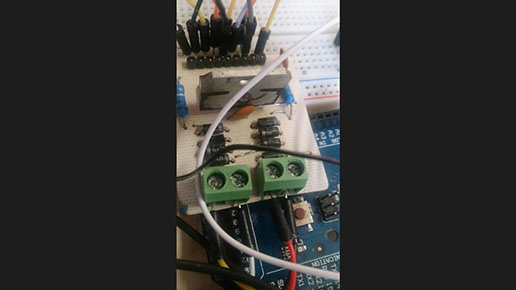

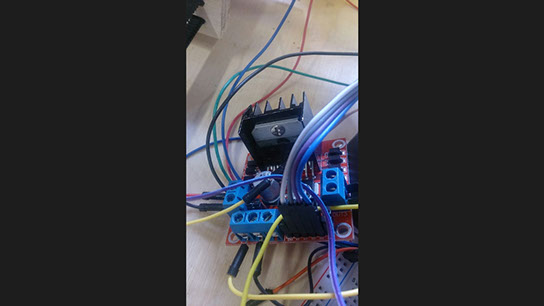

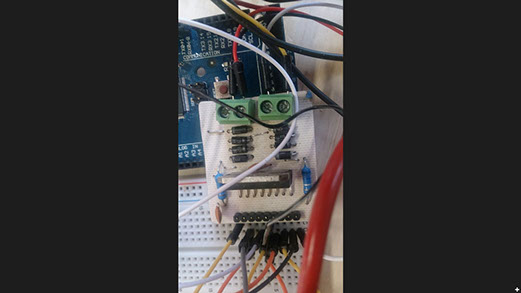

For the electronic i decide tu use Nema 17 motors, H bridge, an Arduino and a computer power source

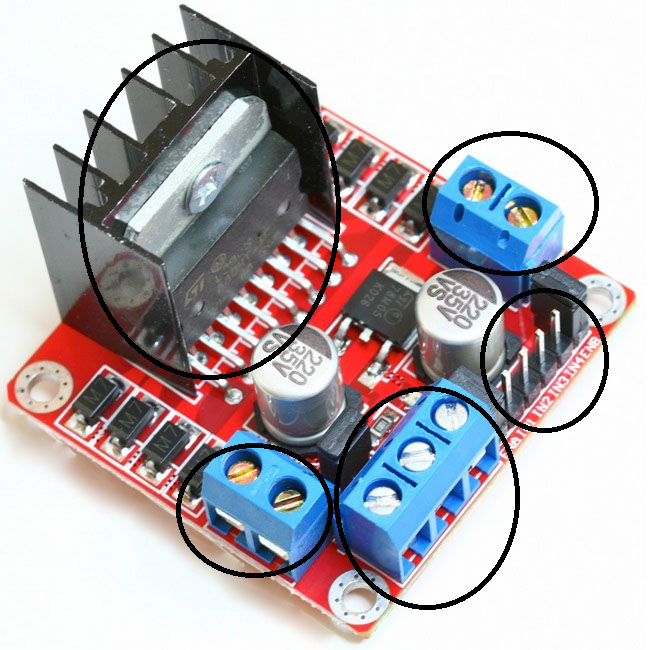

Dual H bridge

output 2

output 1

12V

GND

5V

inputs

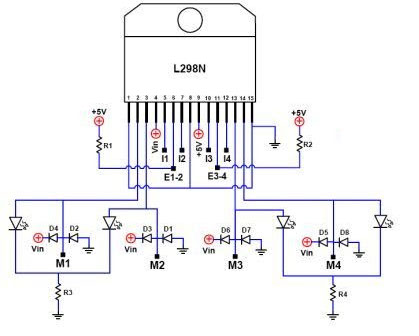

The Dual H-bridge is perfect when you need to use step motors because with this kind of h-bridge you can control perfectly the movement of one motor, but you need to send pulses (signals) to activate it, there is where a microcontroler is needed, and i decide to use and arduino mega for it's capacity of inputs and outputs .

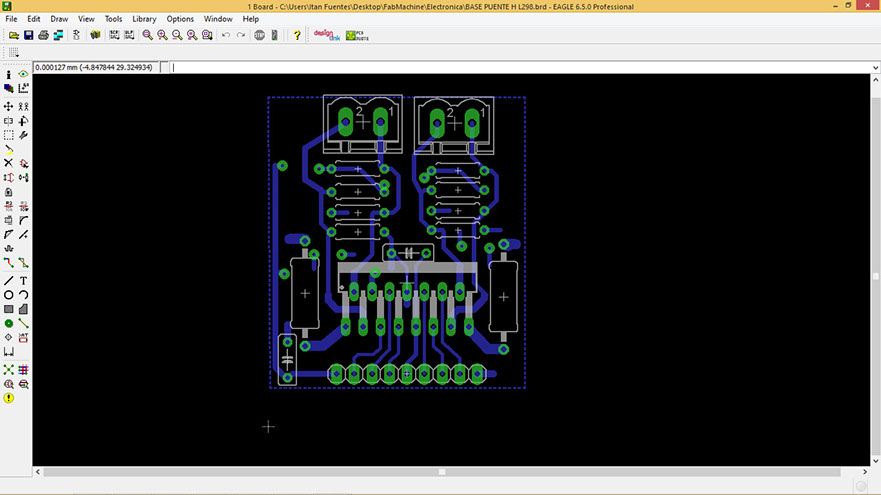

I also made my own h- bridges . i left them with al the rest of the info

Power supply

For the power supply of all the machine, i use a computer power supply, and the most important thing it's recycled. but it have the enough capacity to power the hole system and it have different voltage output (5v, 3.3v 12v) at different amp output.

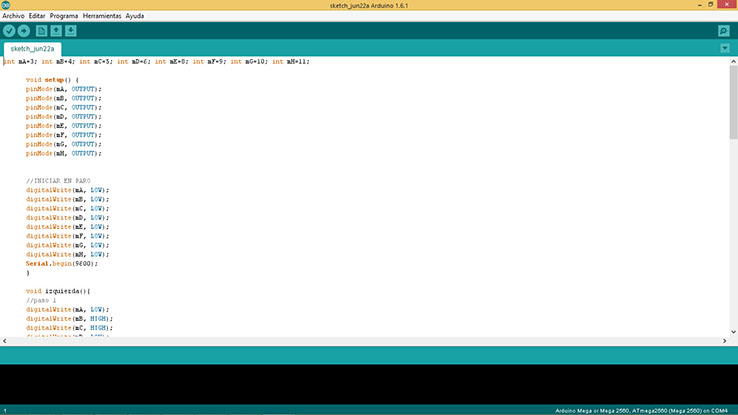

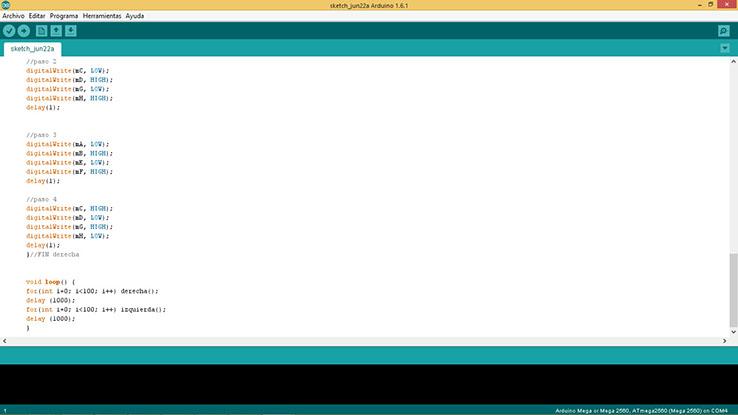

Programming

For the programming i started to build it by my own in arduino IDE i left what i got in the hole archive