Molding and Casting

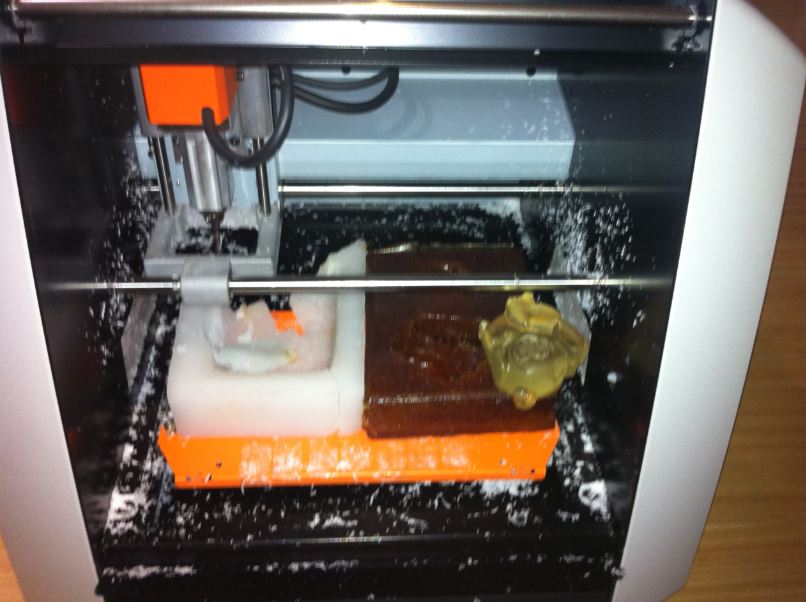

At the beginning with the help of Ivonne Rossy Parian Yallico I get a machinable wax with temperature resistance and impact, like I show you below, however after melting the wax and high density polymer had to wait a long time to cool, to force the cooling wax dried non-uniform way, you can see these deformations in the central figure.

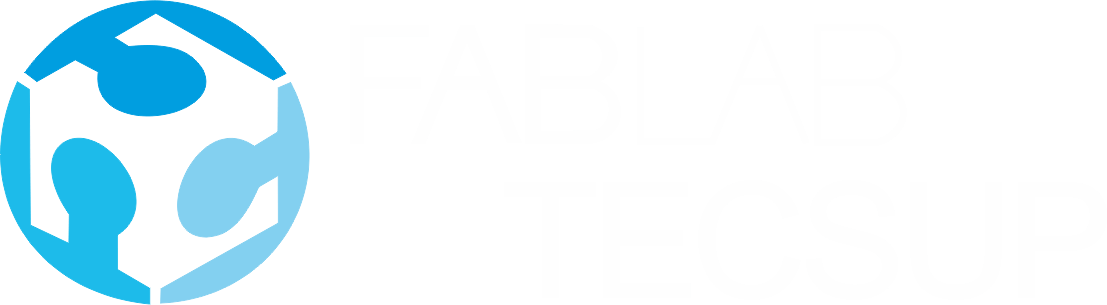

For made this machinable wax I had to make a mixture of paraffin with low density polyethylene. The mixture was 60% of paraffin and 40% of low density polyethylene, likw I show below.

At the beginning I had to make some initials test with the machinable wax, because some of them did not have mechinable properties, I try to mechinable my name into the wax, like I show you below, but the wax needed more low density polyethylene in the mixture, so after many test finally I get a right porcentage of mixture, 55% of paraffine and 45% of low density polyethylene.

finally I made a small rabbit to my baby but I had troubles with the air bubbles, like I show in the next figure. so I made some test with chocolate but I think this need more test to find the right mixture, but I show you below.

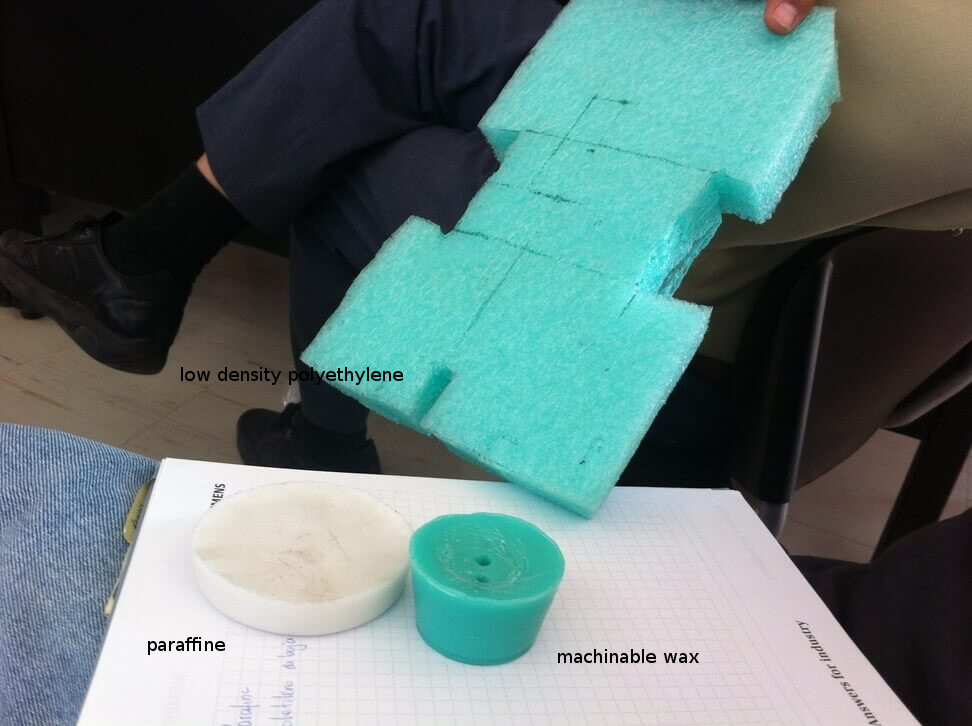

I had some troubles with the resine, because it generated bubbles, as you can see in the figure below, I use de roland srm-20 program, with some parameters. like spindle velocity = 1000 RPM, feed velocity 10mm/s.

bubbles in the final design is formed due to poor mixing of the components, after several tests I saw that when the liquids to mix are poured, whether they are made from a height and pour vigorously, the container will be formed bubbles. One has to be careful when liquids are poured, this has to be done patiently and slowly.

I had some conclusions about this assignment, one of them is that the machinable was is expensive, so I had to made this domestic wax, It need to test more and more to find the right mix. The feed and spindle velocity must be fast because the wax is soft.

The time to made the machinable wax was from 6 to 10 hours because it had to dry slowly.

To made the final product I used a resine, it dryed in 10 hours aproximately.

You can download de archives

here