Computer-controlled machining

For this assignment I wanted to make something useful to my baby son and I got a image from internet, based in it I began my design in solidworks

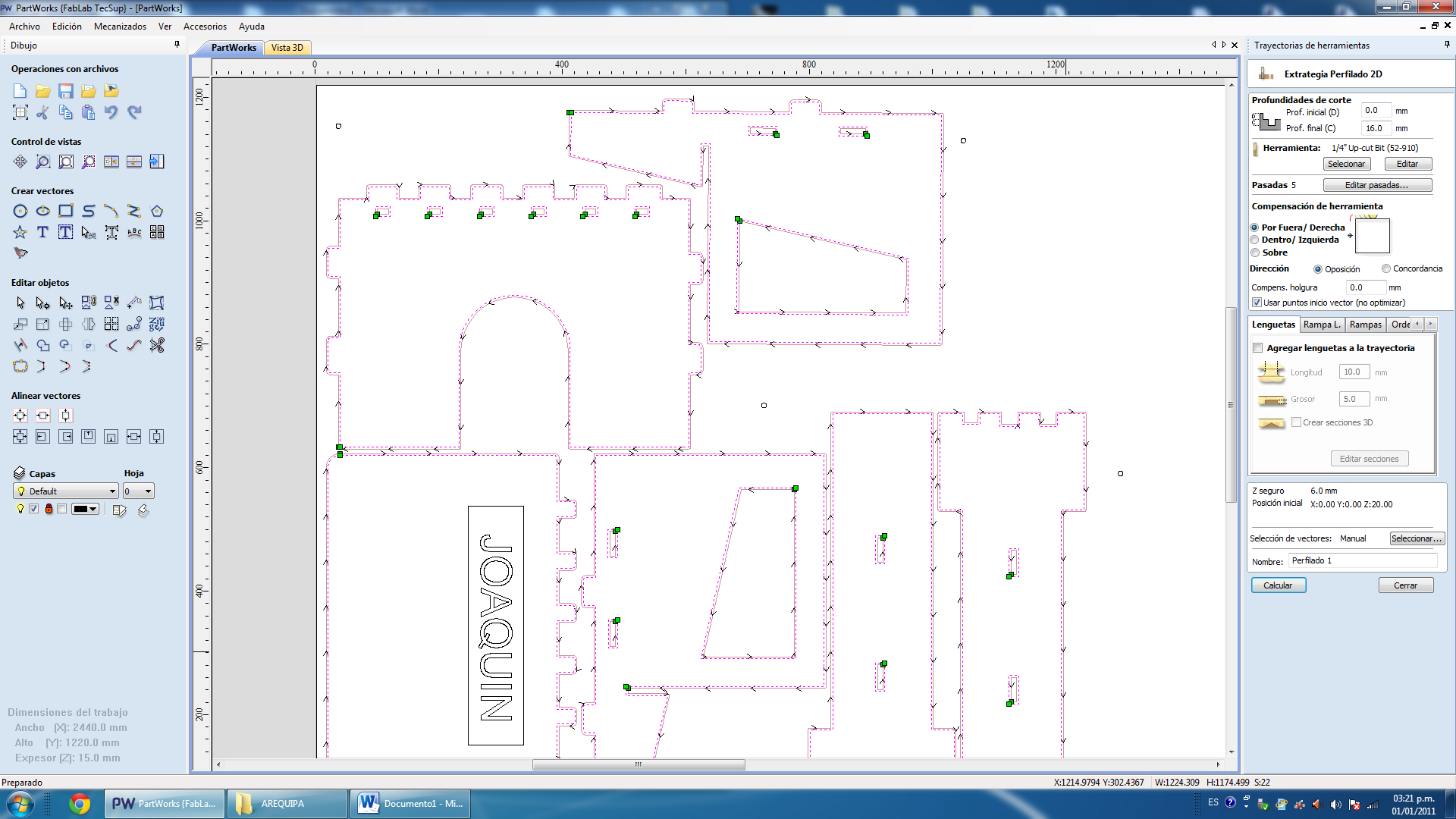

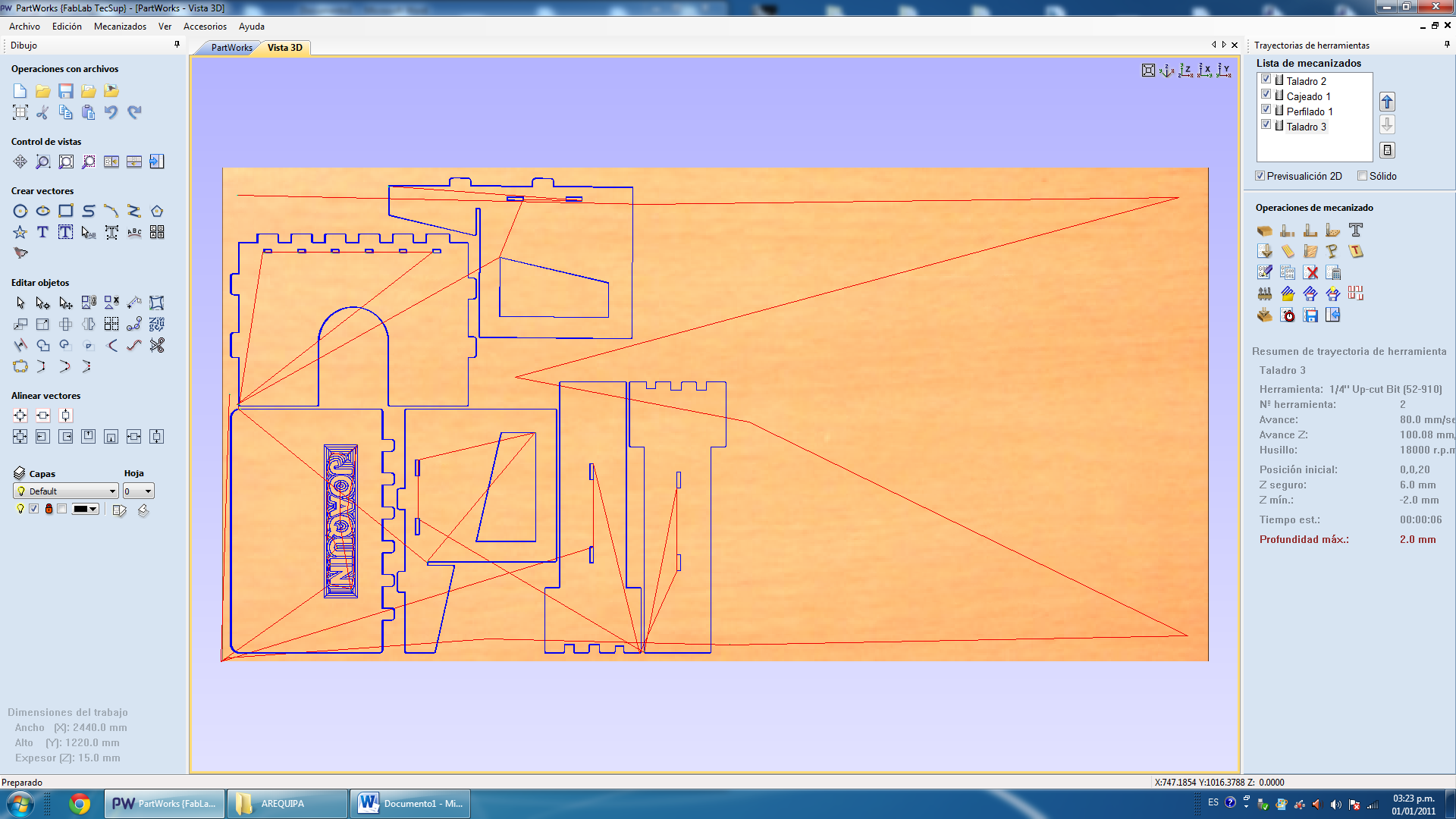

After that I saved the solid part in "dxf" format to open in another software that control the shopbot called partworks, like I show below.

In this software I had to set some parameters like angular velocity of the chuck, machining processes.

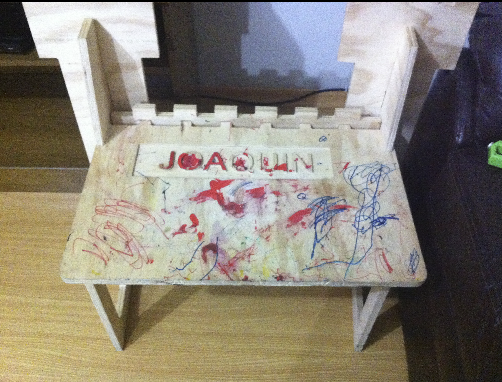

I had to make the desktop twice because at the beginning I did not take the right adjustment, so the press-fit doesn't worked. finally the assembly show below.

At the end my baby son was the more happy with this assignment and me too.

finally after my baby son used his desk, he was just as I show below

I could learn that shopbot machine is accurate, but after a day use their precision decreases and our court will not have the same tolerances as mentioned in the datasheet of the machine, which is why it is better testing fit to take account of the accuracy and tolerances for a good fit or tighten.

I used playwood 12 and 15 mm thick. the spindle speed was 18,000 rpm, the feed rate was 80 mm / sec and the depth of grinding was 3.2 mm per layer

You can download the design files in the next

Link