Week 2 - Computer aided design

In this assignment i learned to use three kinds of softwares, one of them is rhinoceros, another is Inventor and the last is solidworks, but I used solidworks since many years ago.

I sketched and modified a design of stirling motor the last year in solidworks like I show below, and you can download

here

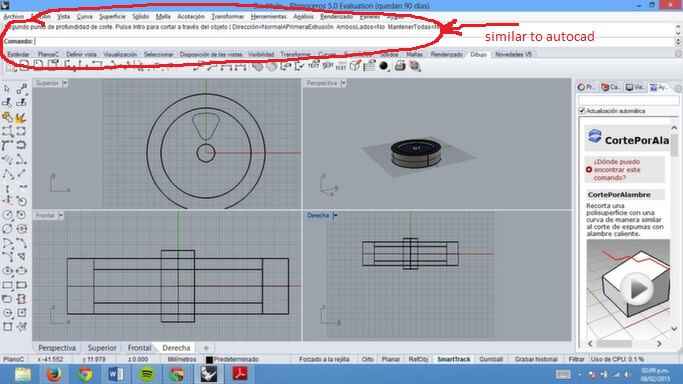

I started to learn rhinoceros 3D in the last days, it was really dificult at the beginning but the commands are similar to autocad, like the coordinates (x,y) to reference a line or circles, so while i used it more times, this became not so dificult.

when I drew a steering wheel in Rhinoceros, i used lines and curve, and i had to use the initial and final coordinates from the curves, it was the matter, because my sketch had not the coordinates, it had dimensions that is usually used in this kind of sketch then of many hour at the end finally i got it.

The advantage of rhinoceros are the views and the easy of working in 2D then extrude 3D.

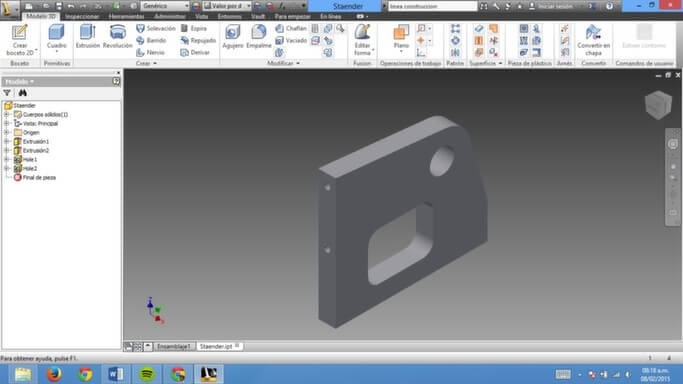

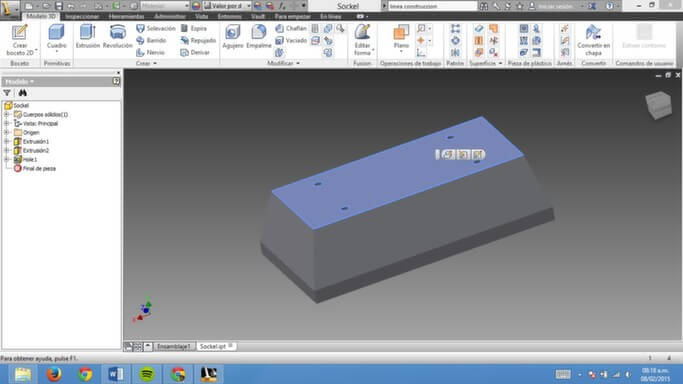

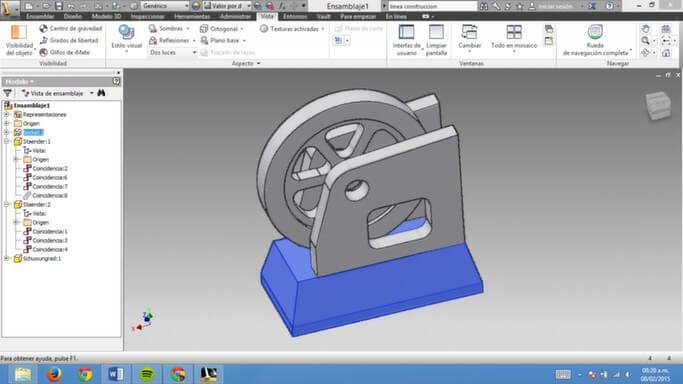

Then I drew some pieces of the stirling engine but this time in design this pieces in Autodesk Inventor like I show below.

I though that inventor would be dificult but for my happyness it was very similar to solidworks, I found similars commands, the structure of the tools are similars like extrude, draw tools, the solid tools and so on all tools.

The assembly tools in Inventor are differents in solidworks, however, for me is more easy the assembly in solidworks but this assessment is from a beginner in inventor.

There are always any problems and i had a problem in the panel control of view, because is different to solidworks.

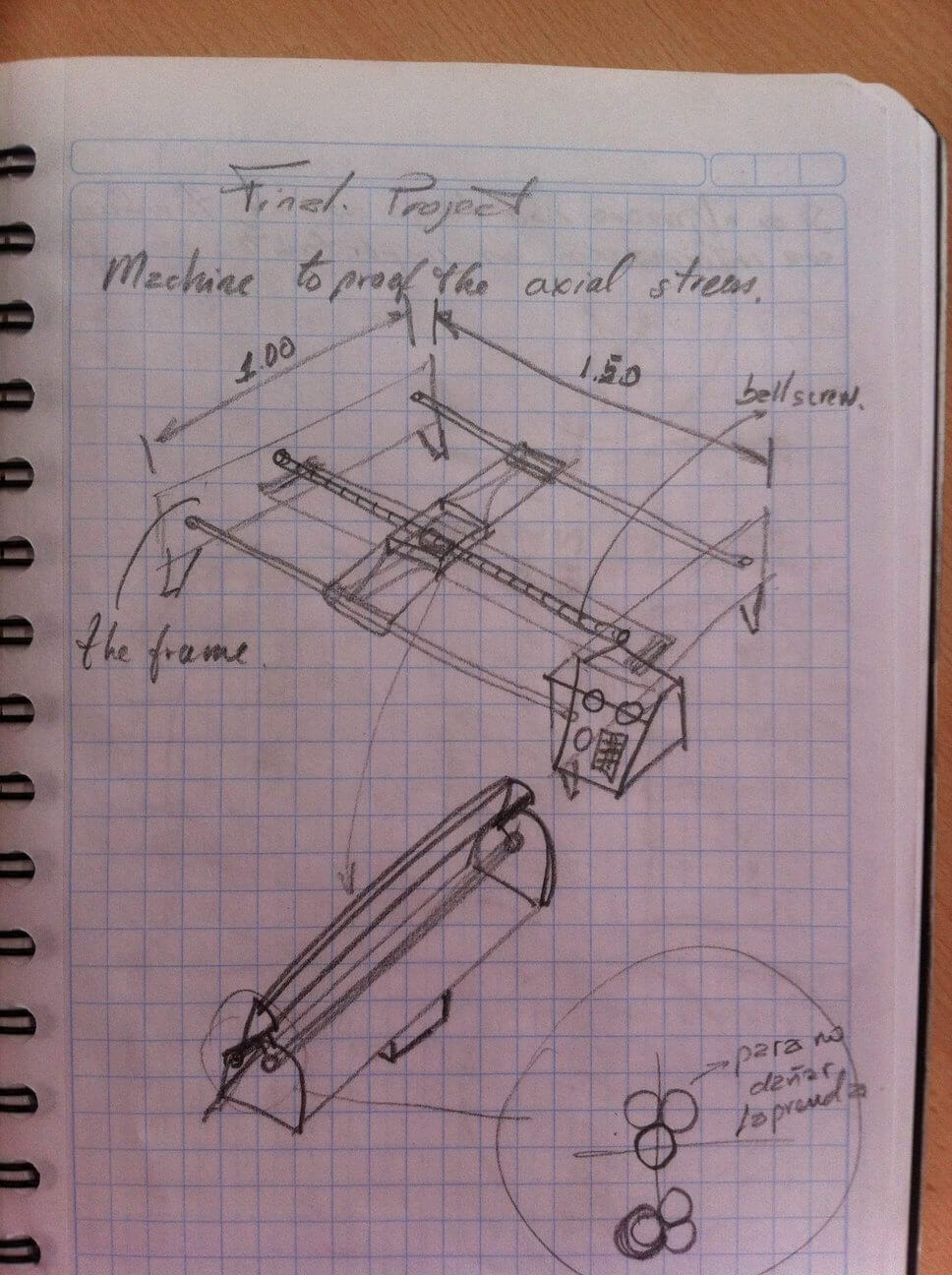

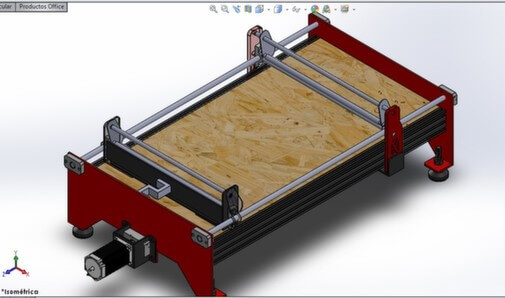

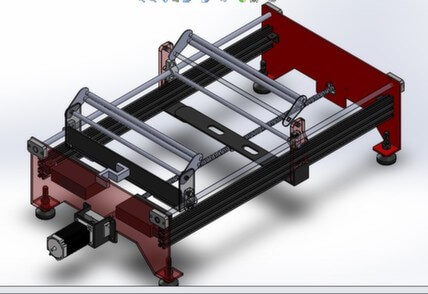

Finally i worked to design my final project in solidworks because it is easy to me, it took me several days because it was an imagination work, firts I scketch the pieces in different files, and then it was assembly, as I show you below:

In my design i used step motor, a ballscrew, aluminium bar, guide bar at the both sides, load cell, strain gauges, mechanic system to clamp tissue of alpaca hair, and many mechanics pieces to assembly the axial stress machine of alpaca tissue.

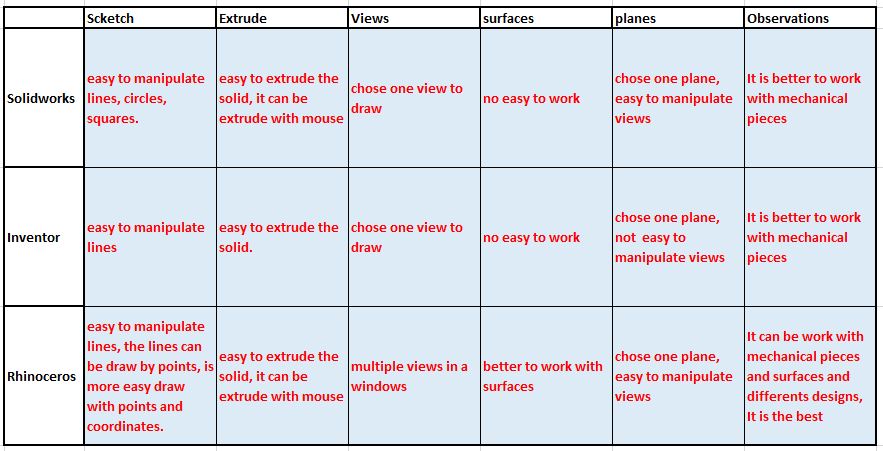

There are many differences between the softwares, I show you a table with some advantages and disadvantages.