Week 6 - Electronics design

1. EQUIPMENT

The equipment used was:

SRM-20 MonoFab Roland

This machine is capable of cutting a wide variety of materials, including chemical wood, acrylic, and ABS. It is also capable of a range of accuracy settings from prototype to product design. In the last assignment i used

The maximun cutting area in the x-y plane is 152.4 mm x 203.2 mm ; and in the z directios is 71mm; for more details you can see the

user's manual SRM-20

2. SOFTWARE

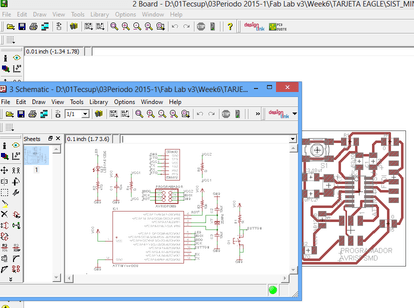

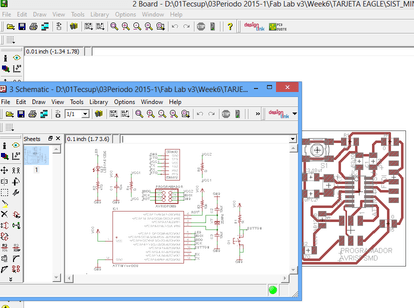

Electronic Design

Eagle is a powerfull software that provides quality PCB design, where you can use a schematic editor, layout editor to make an excelent design.

Eagle is a powerfull software that provides quality PCB design, where you can use a schematic editor, layout editor to make an excelent design. You can download de eagle schematic

HERE

.

This software help us to export the pads and trajectories in png format, and then it can mill the printed board circuit.

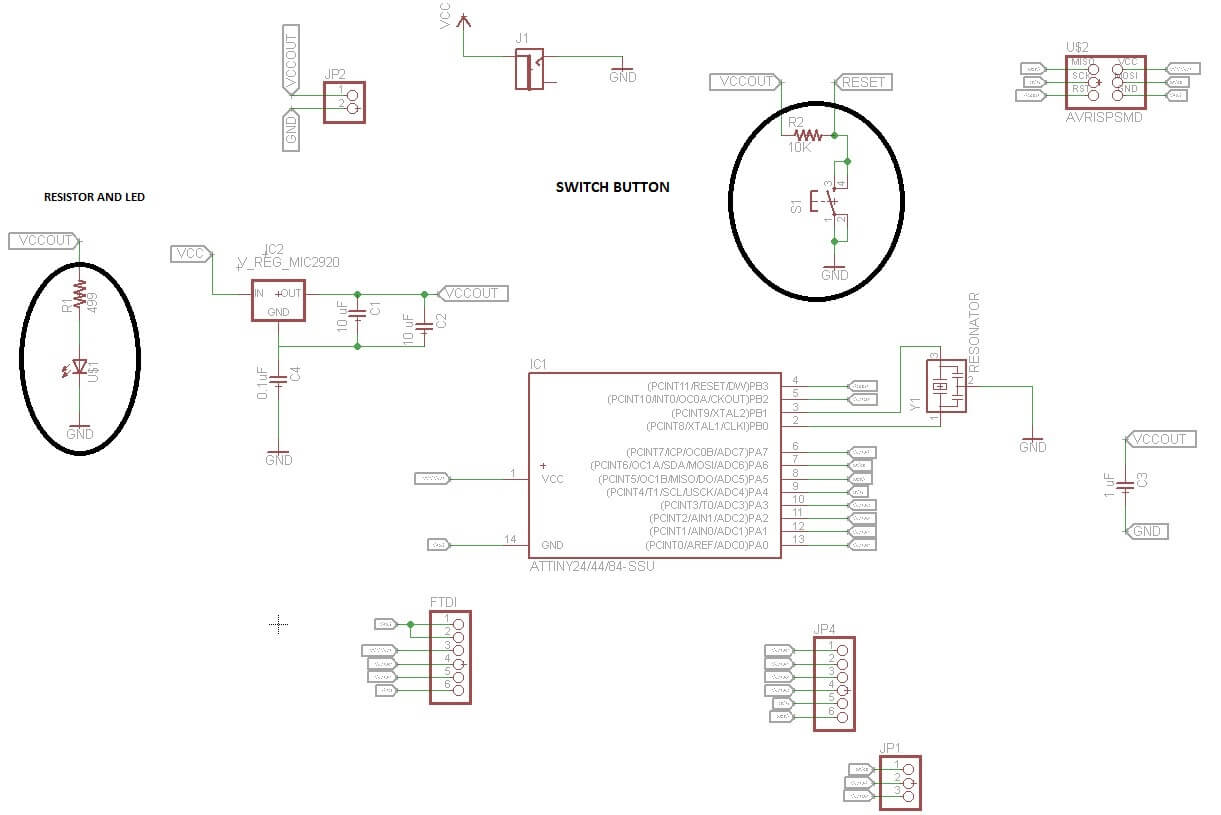

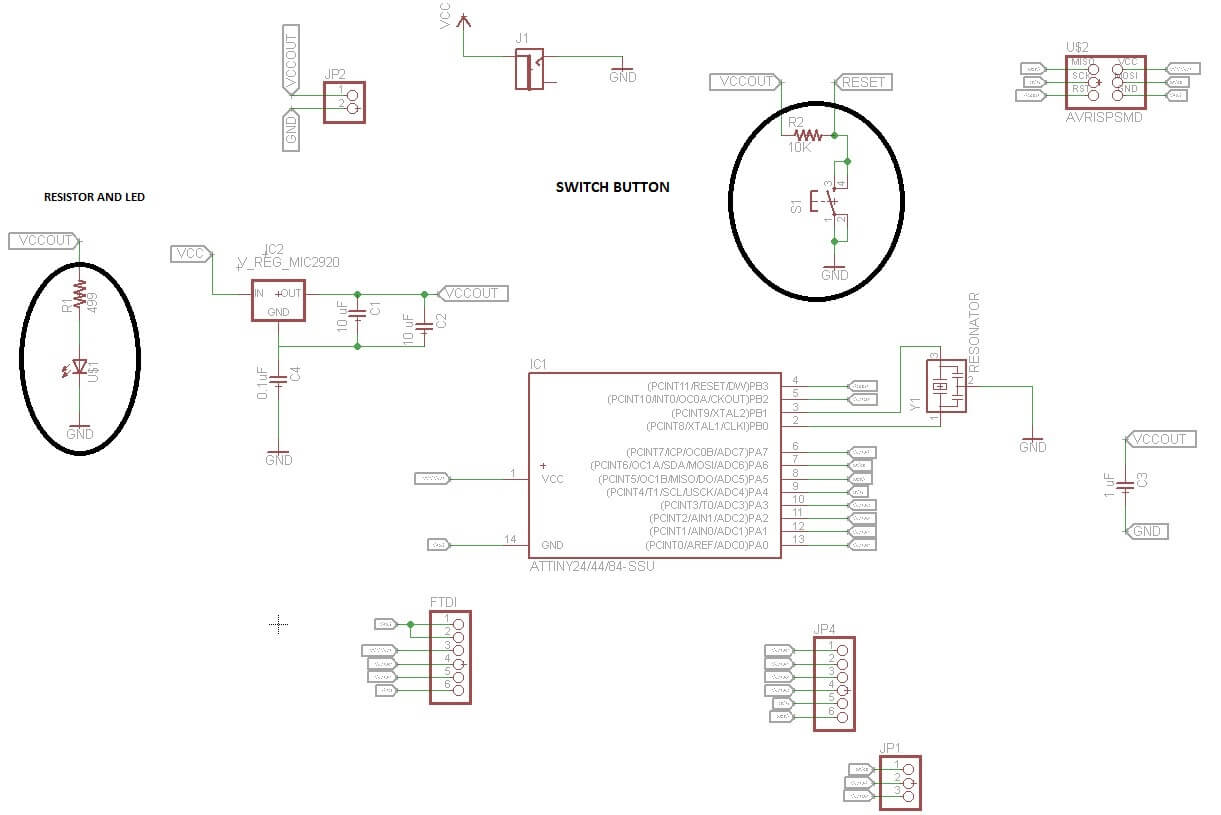

With the help of a tutorial about eagle, I made a new redesign, like I show below, I added a pulse switch, a led with its resistor, the value of resistor is 470 ohm.

At the schematic circuit, I modified it to insert a light emisor diode, resistor and a pulse switch, connecting the pulse sitch to the input pin of the microcontroller and led to the output pin, like I show below.

2. PROCESS

Fabmodules

STEP 1: enter the adress www.fabmodules.org into the search page.

STEP 2: click on the input format, you will see a menu, like i show below.

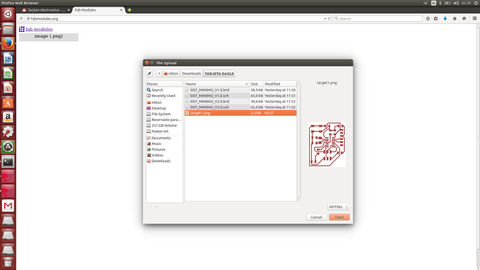

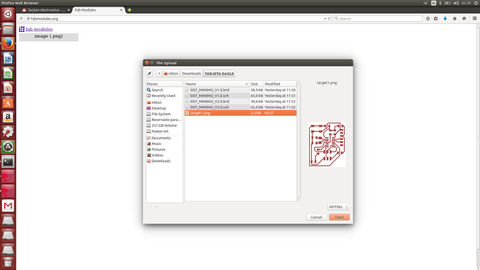

STEP 3: click on the image (.png) format, previously you export the circuit design make in eagle to png format, it will open a windows to search the png file, like i show below.

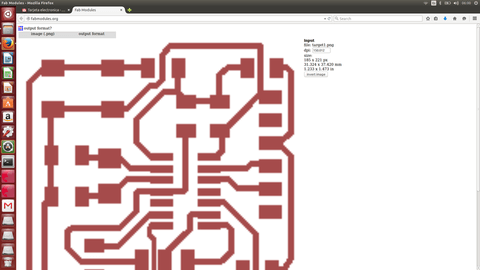

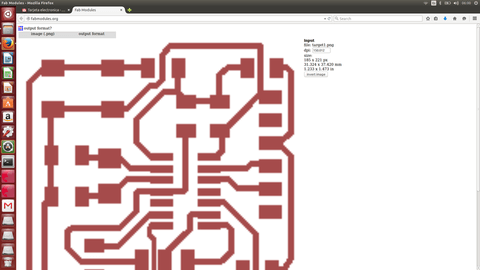

STEP 4: A window will show the circuit to print, like i show below.

STEP 5: click on the input format, you will see a menu, like i show below, where you have to choose the machine conected to your laptop, in my case I chose the Roland Mill (.rml).

STEP 6: Then choose the process, click on the input format, you will see a menu, like i show below, where you have to choose the machine conected to your laptop, in my case I chose the Roland Mill (.rml). Then click on the calculate button, and it show the trajectory of the mill machine to make a printed circuit board.

But when I tryed to work with the SRM-20 with the fabmodule I had troubles and I didn't get to work with the SRM-20.

There are some parameters:

tool diameter(mm) = 0.4

overlap(0-1) = 0.5

intensity(0-1) = 0.5

number offset= 1

image threshold (0-1) = 0.5

dut depth(mm) = 0.1

Speeds: plunge = 2.0 mm/s

feed = 2.0 mm/s

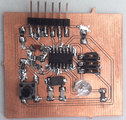

Finally I use the lpkf mill machine and use the software in windows, this was a bad experience. however I made the pcb, like I show below.

At the end, after learn soldering superficial electronic devices I show below the pcb with the electronics components.

The pcb is shown below, the dimension of this board is 45 mm x 40 mm.

I have any problems to mill the board, one of them was the board was not level and this meant that the router does not do a good machining depth and I did many boards until the routing was perfet.

Another problem was the soldering, because I worked with a tin soldering station, and it's really dificult.