- Home

- My Assignments

- Project Management - Complete

- Computer Aided Design - Complete

- Computer Controlled Cutting - Complete

- Electronics Production - Complete

- 3D Scanning and Printing - Complete

- Electronics Design - Complete

- Embedded Programming - Complete

- Computer-controlled Machining - Complete

- Molding and Casting - Complete

- Input Devices - Complete

- Output Devices - Complete

- Composites - Complete

- Networking and Communications - Complete

- Interface and Application Programming - Complete

- Applications and Implications - Complete

- Mechanical and Machine Design - Complete

- Invention, Intellectual Property, and Income - Complete

- Final Project

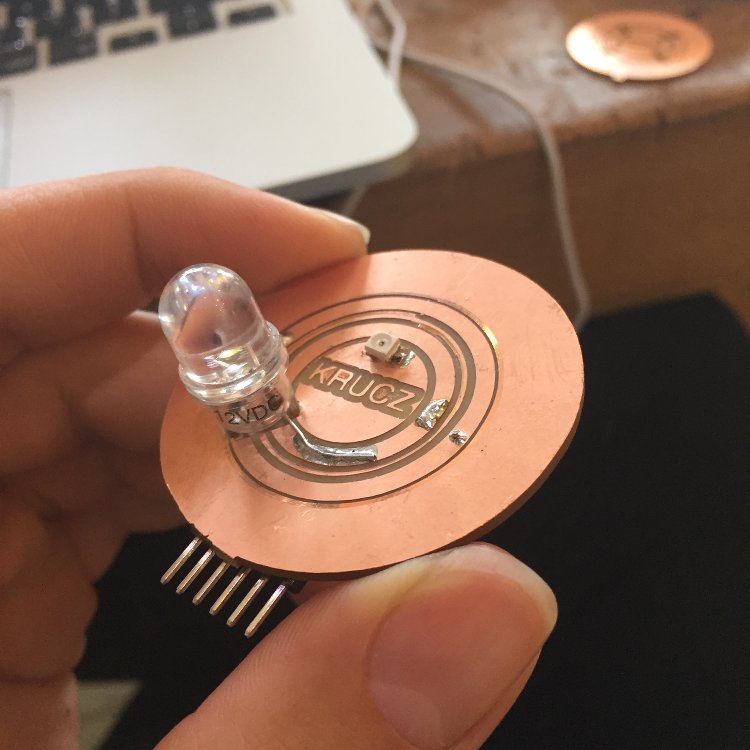

16th April 2015 - Bigger LEDs

I want to take this assignment as an opportunity to do something towards my final project. I made a light design which I could adapt into a bike light. I am thinking of making a secind version which is light sensitive. This would bring the design closer to being a functional bike light. My main priority though is to get a circuit design which is bug free. If that goes well I will look at designing a housing for it too.

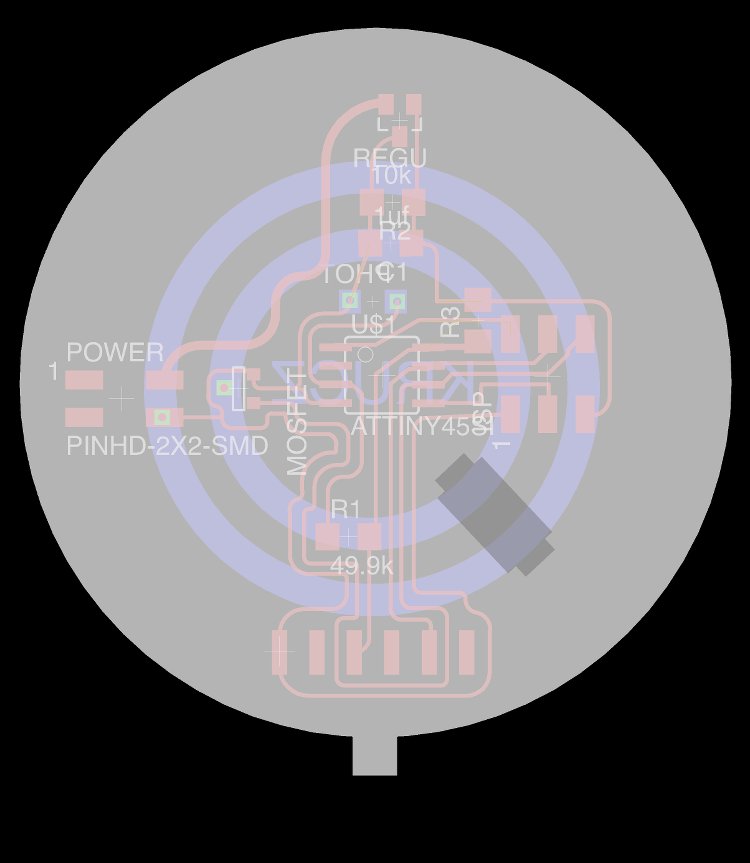

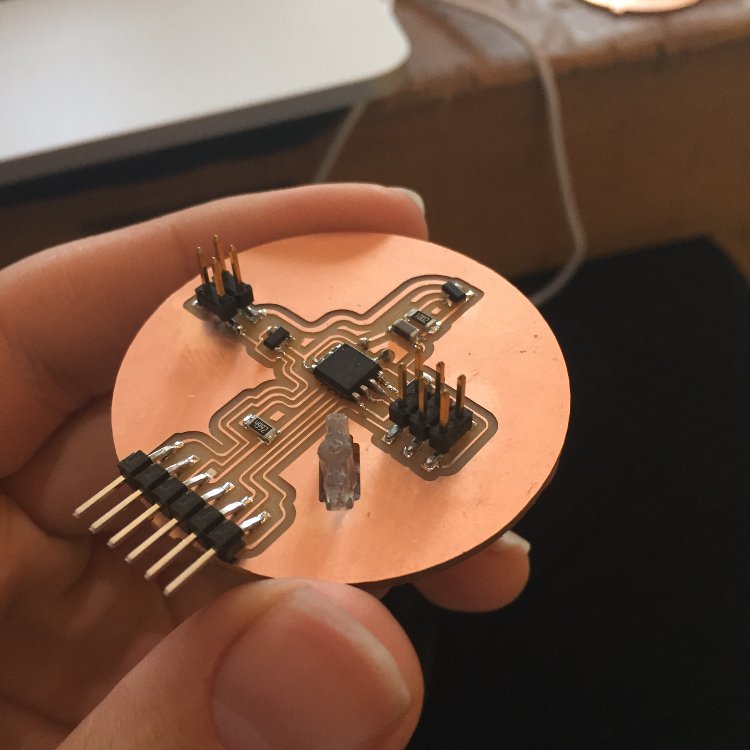

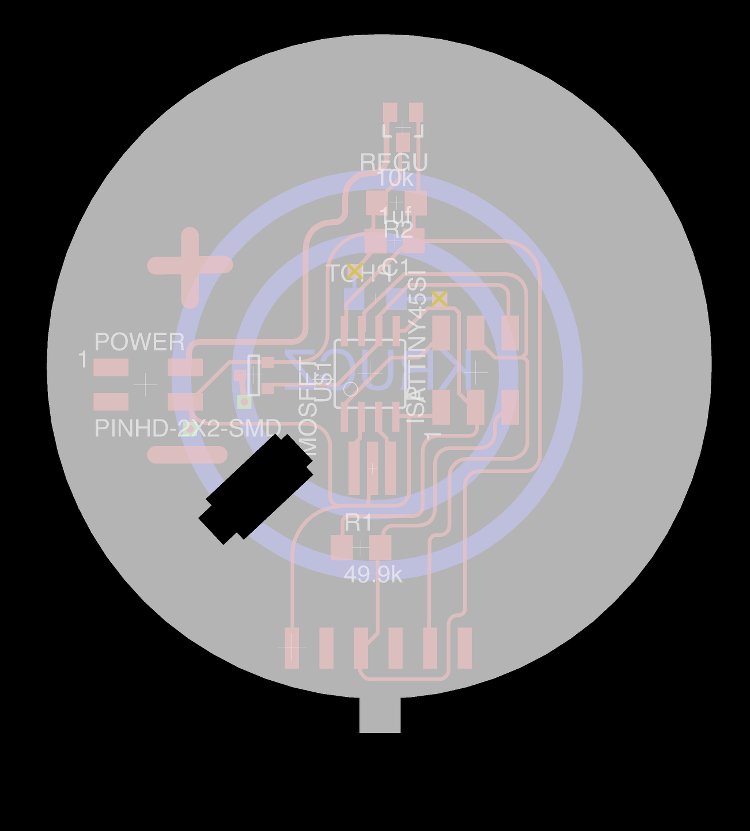

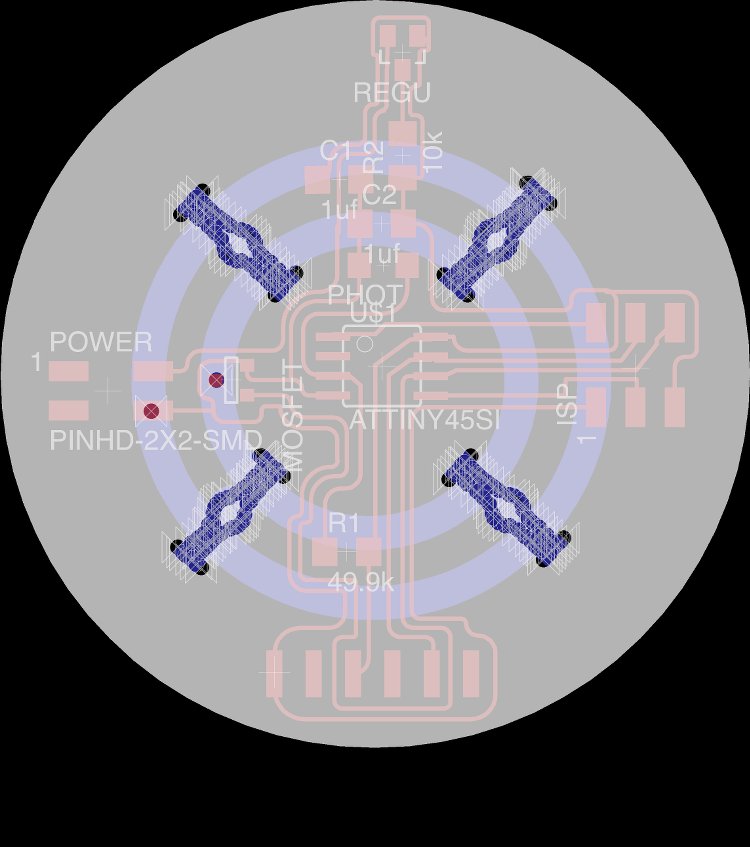

Below is the board I have designed:

The biggest difficulty I had with this was trying to make some though holes for the LEDs I would be using. I had to rather crudely use the hole funstion in eagle to make the shape and then tidy it up in GIMP. I will try to find a more accurate way of doing it. Unfortunately the modela isn't avaliable until sunday so all I will do between now and then is compile more research for my final project and watch out for any bugs in my design.