- Home

- My Assignments

- Project Management - Complete

- Computer Aided Design - Complete

- Computer Controlled Cutting - Complete

- Electronics Production - Complete

- 3D Scanning and Printing - Complete

- Electronics Design - Complete

- Embedded Programming - Complete

- Computer-controlled Machining - Complete

- Molding and Casting - Complete

- Input Devices - Complete

- Output Devices - Complete

- Composites - Complete

- Networking and Communications - Complete

- Interface and Application Programming - Complete

- Applications and Implications - Complete

- Mechanical and Machine Design - Complete

- Invention, Intellectual Property, and Income - Complete

- Final Project

A rethink!

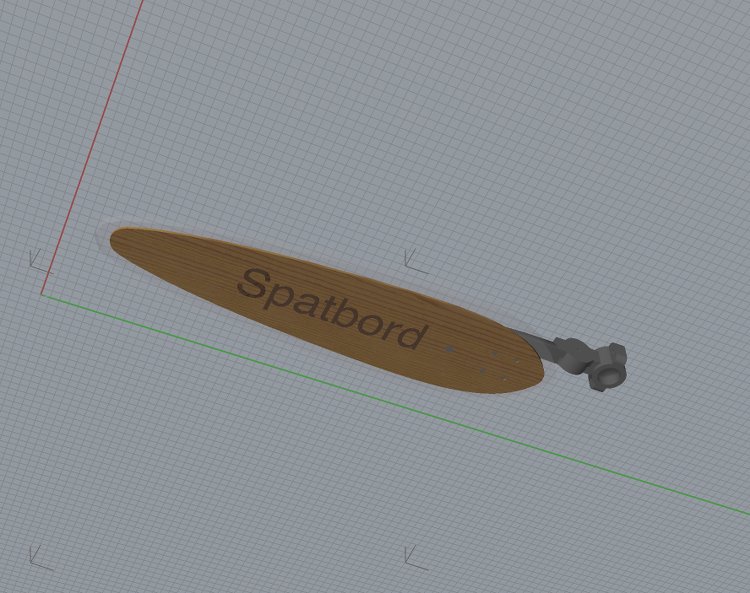

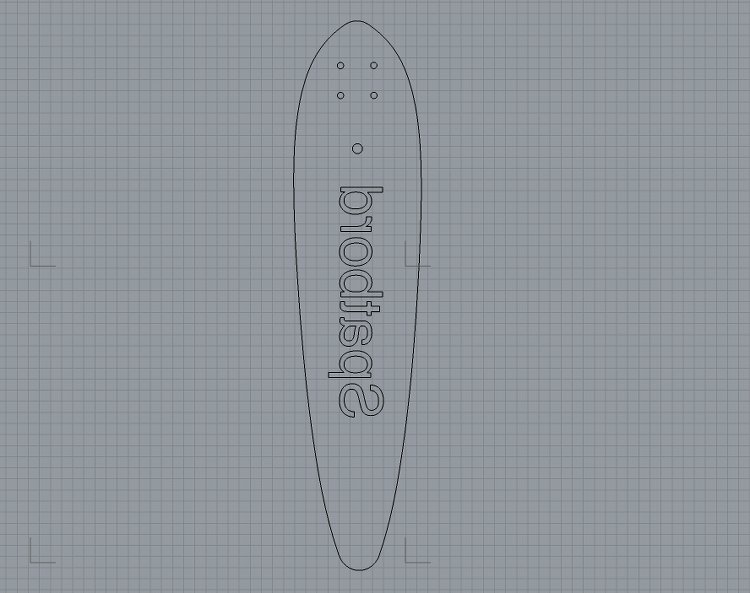

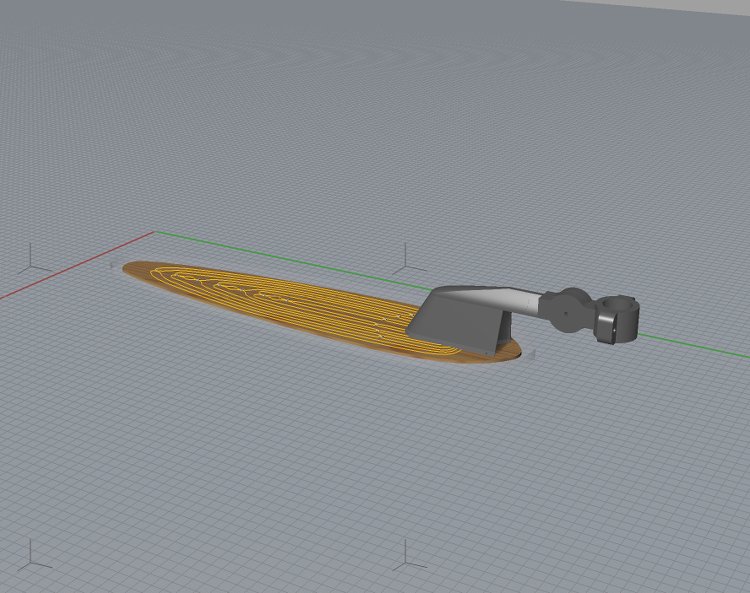

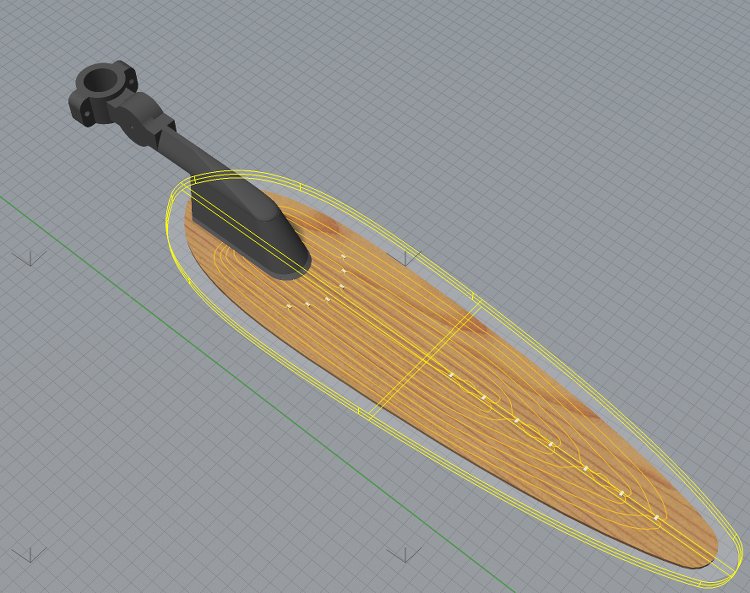

Over the weekend I had a small apiphany and throught to re-assess my goals regarding the project and to change the project but not the heart of it. The heart of it being to benefit cyclists. I have designed a mudguard/fender which incorporates all of the skills taught by the academy:

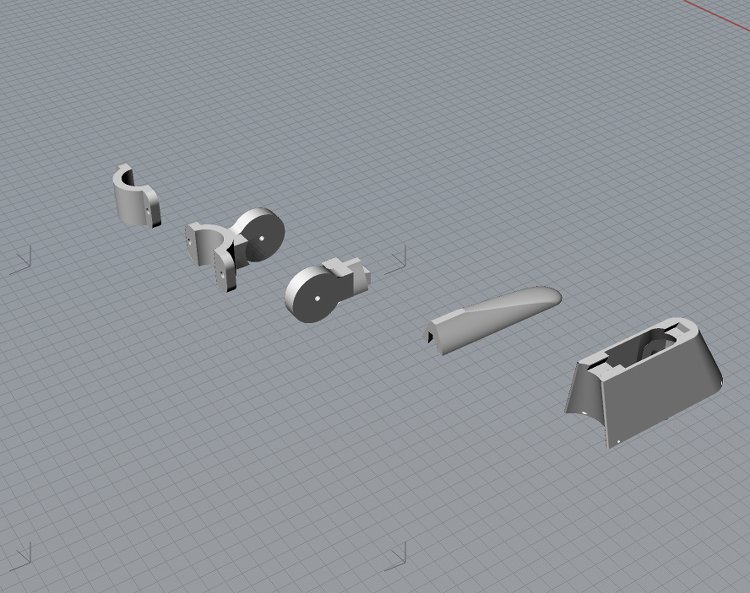

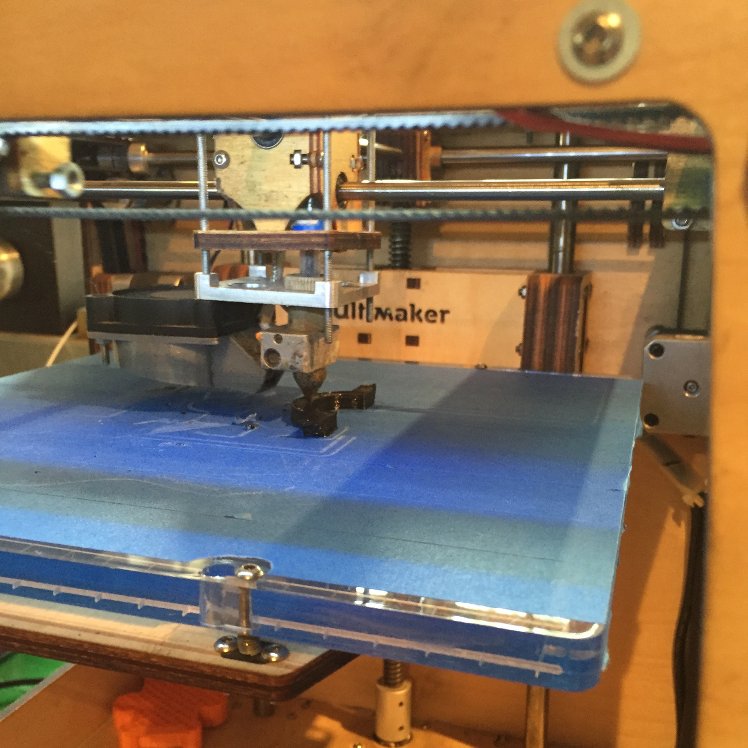

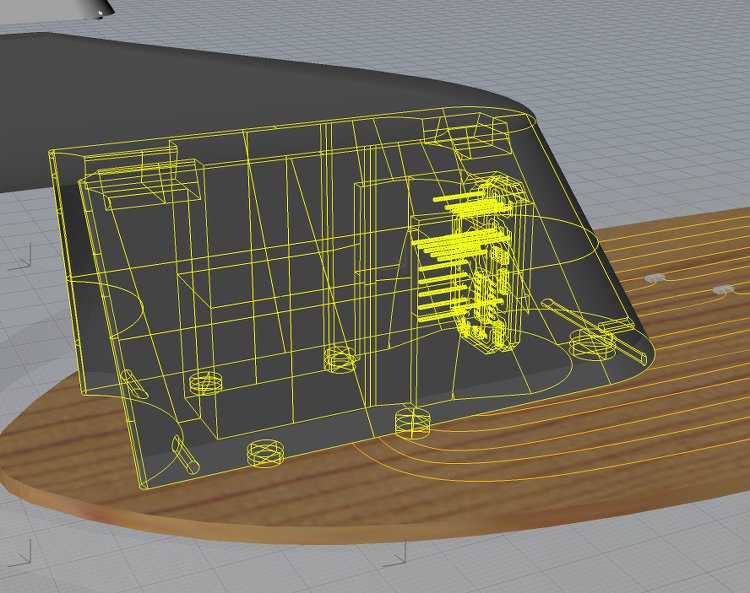

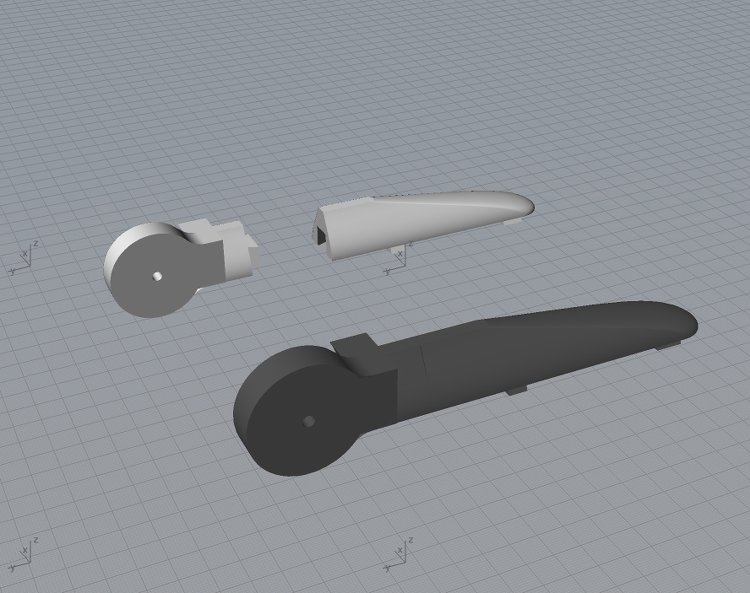

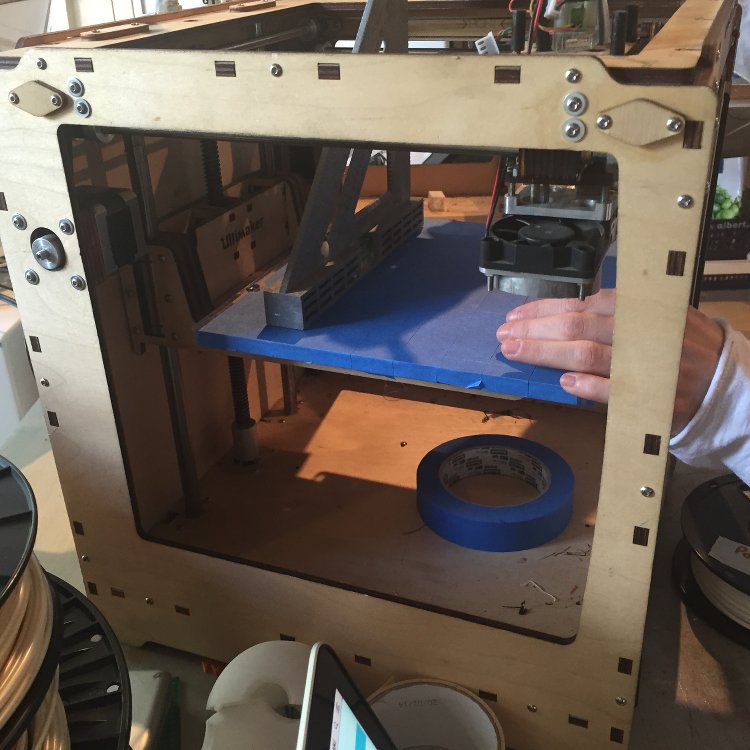

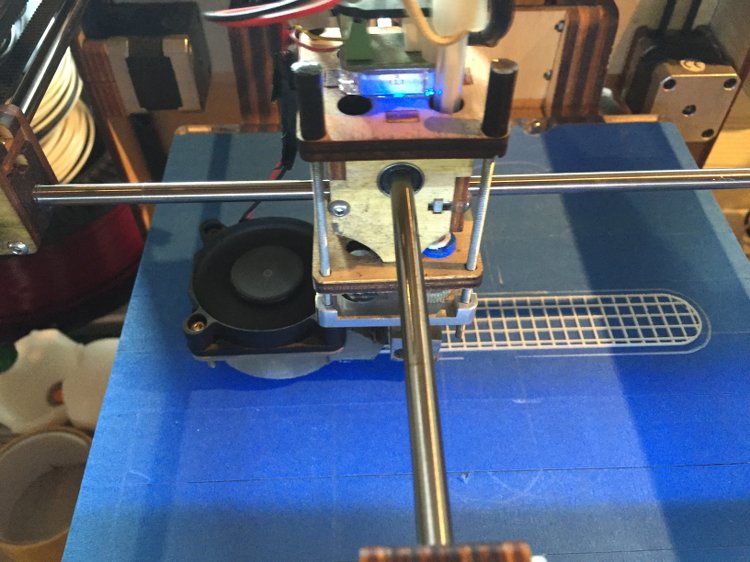

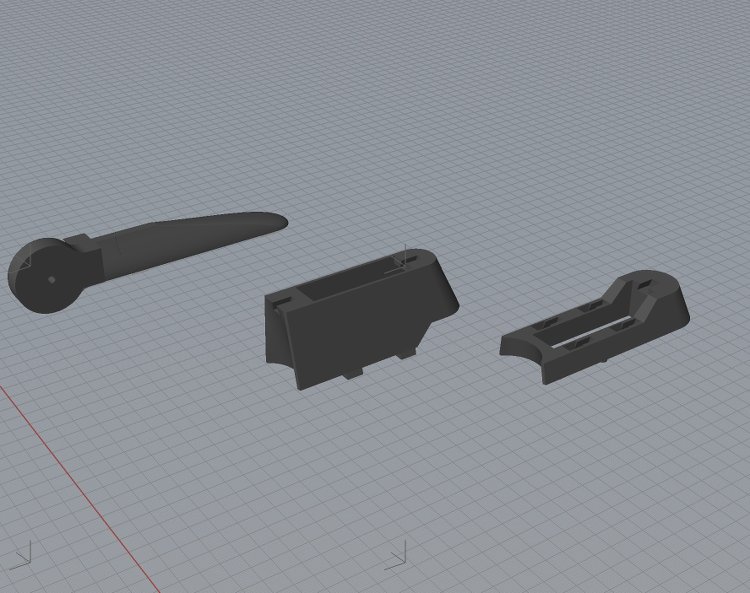

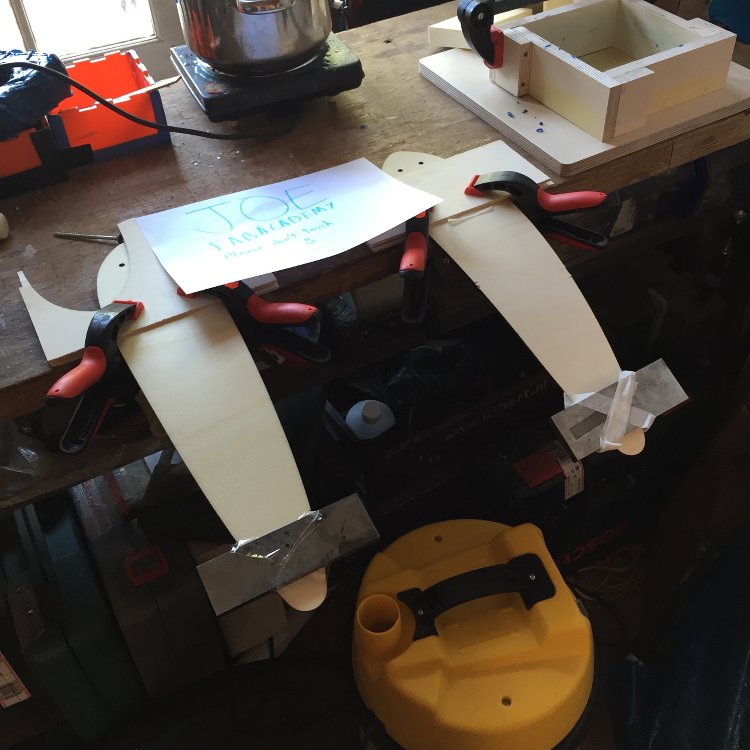

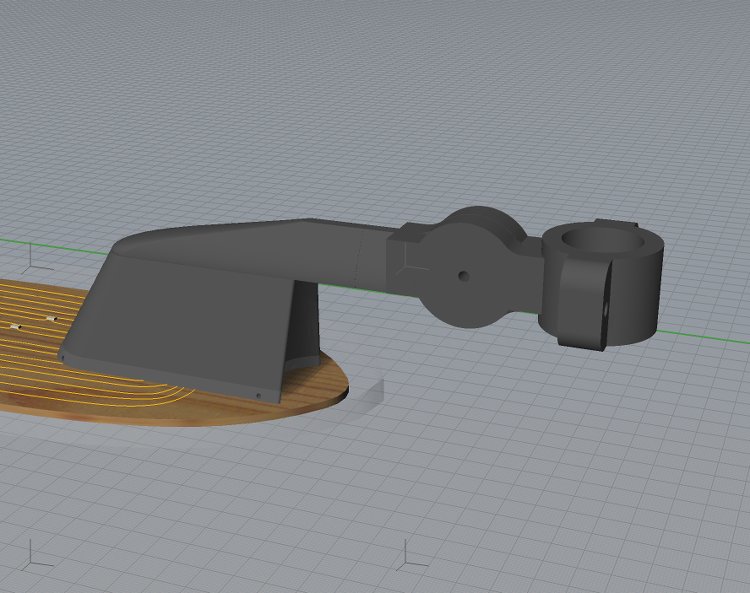

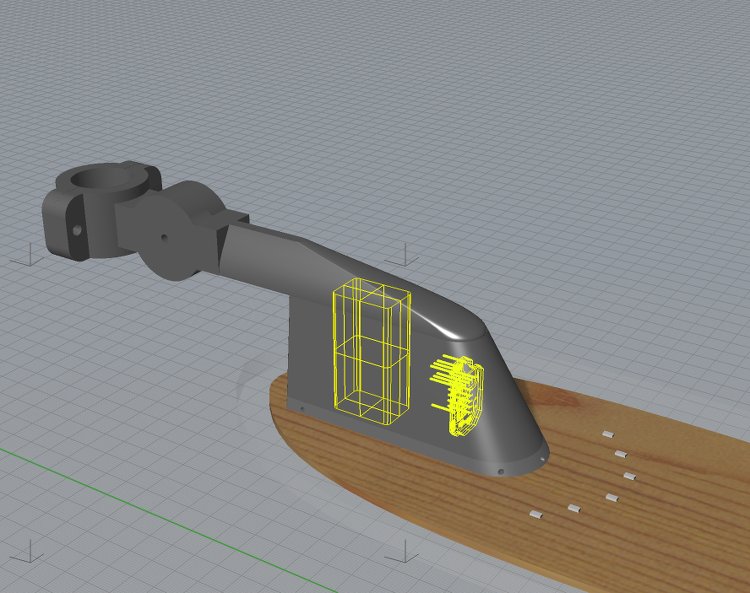

The mechanism to secure it to the bike will be 3D printed. It would be an opportunity for molding and casting but on this occasion I think it will be quicker and easier not to.

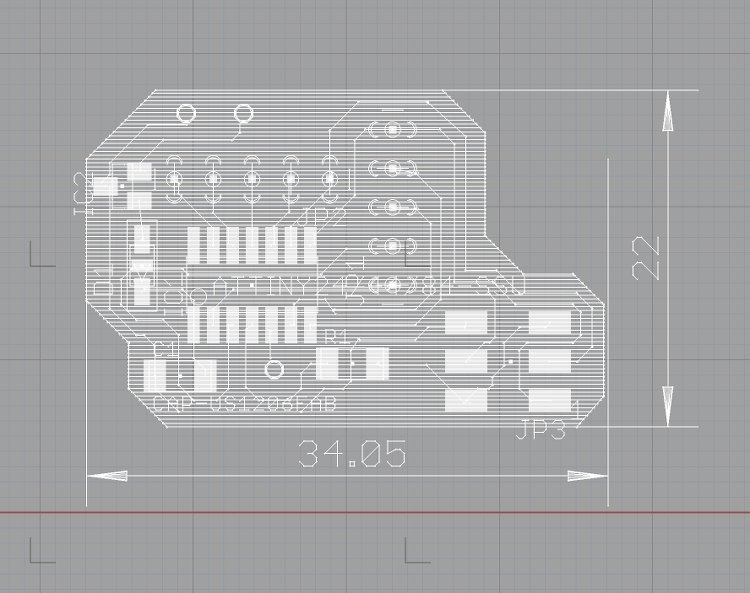

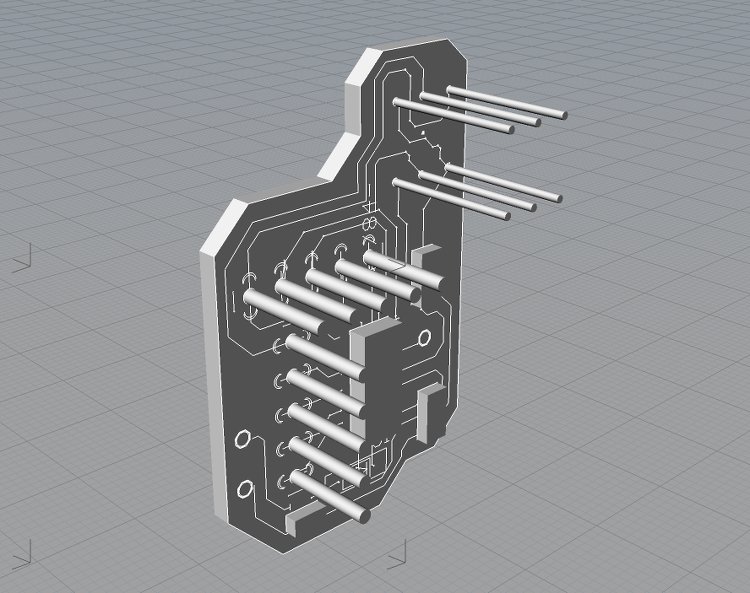

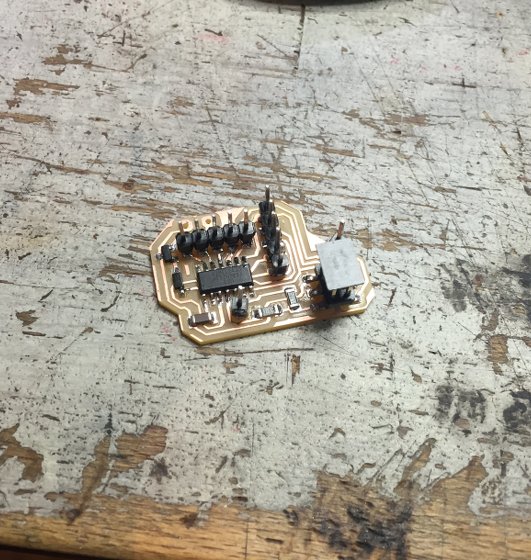

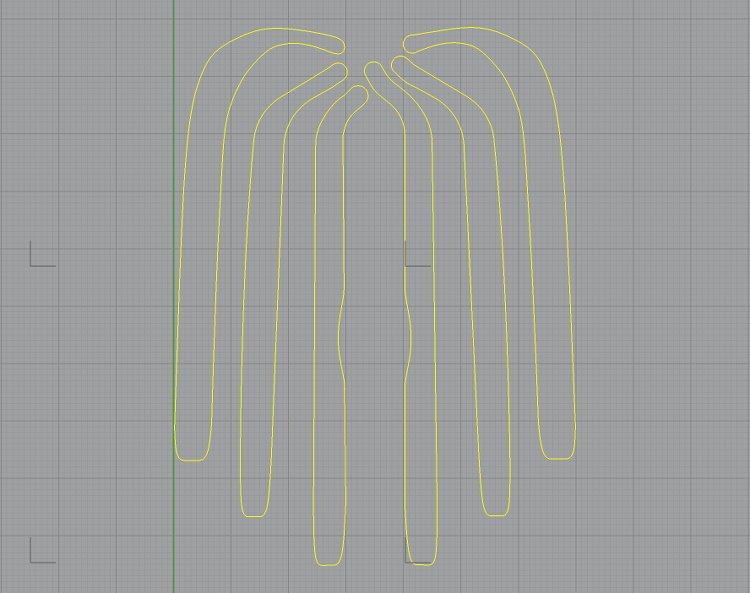

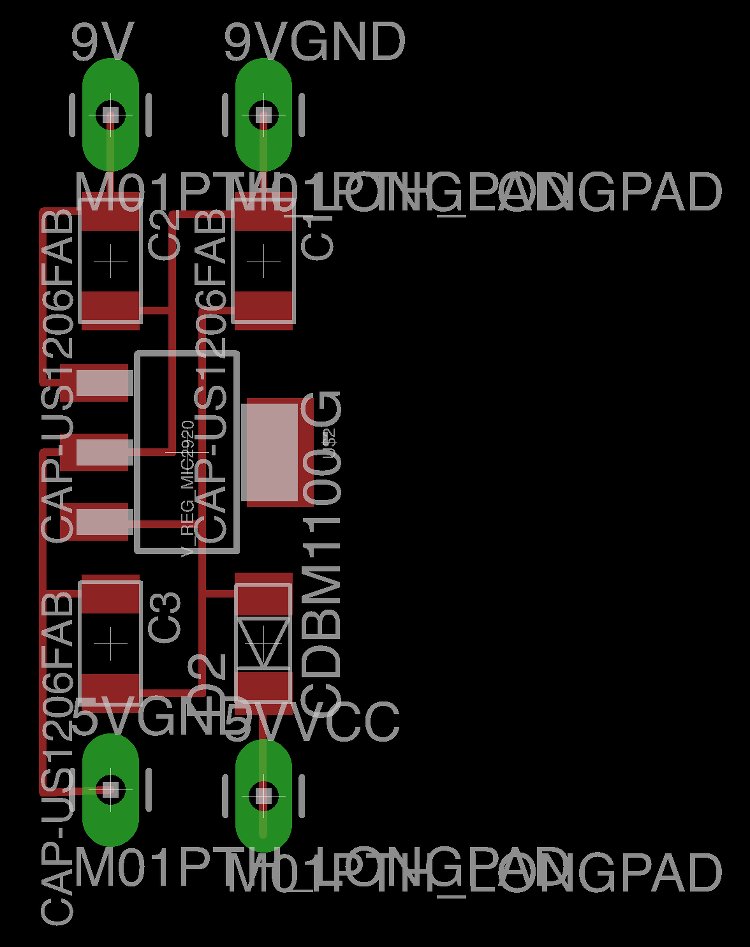

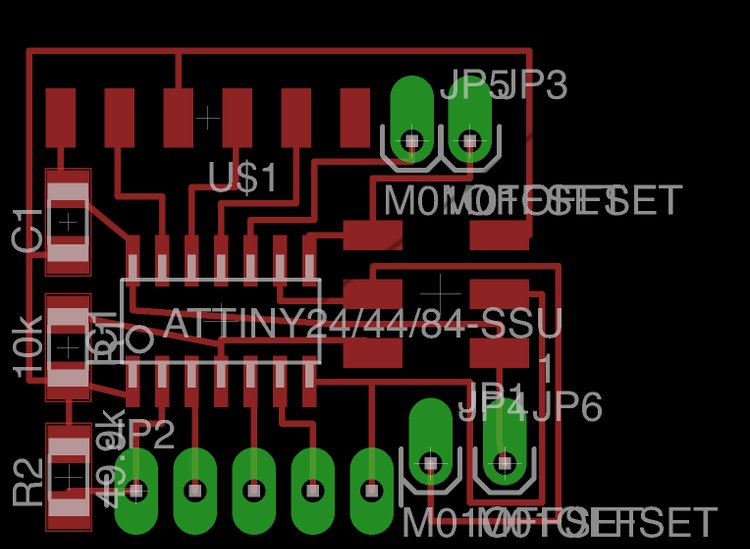

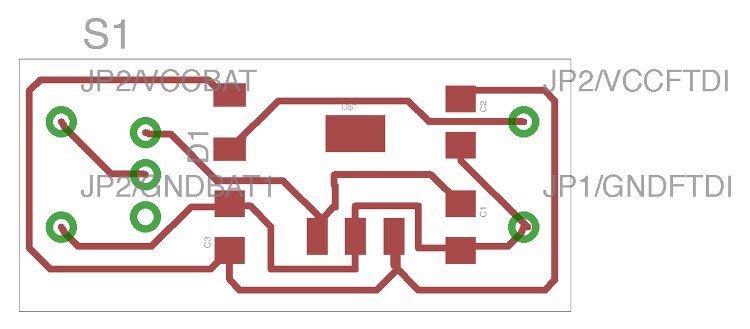

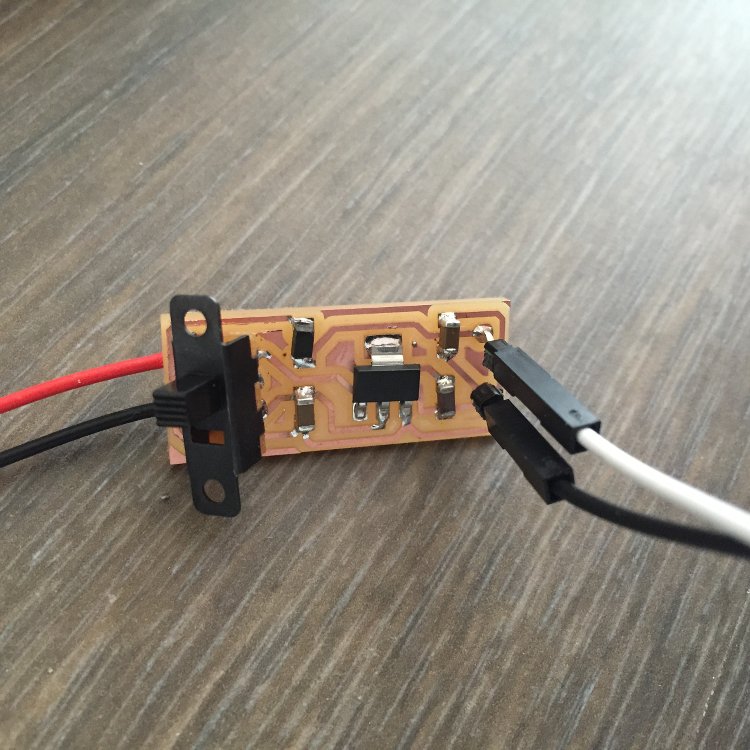

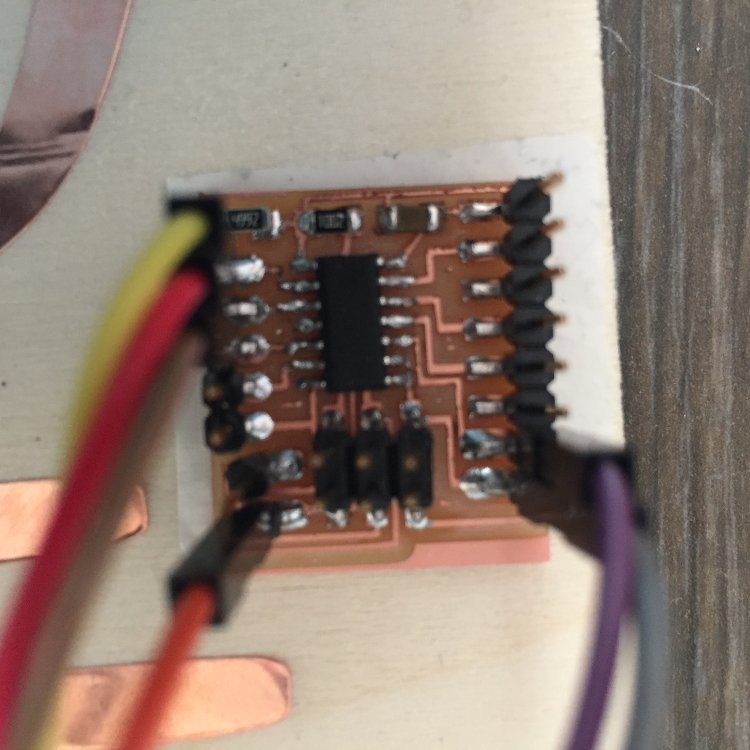

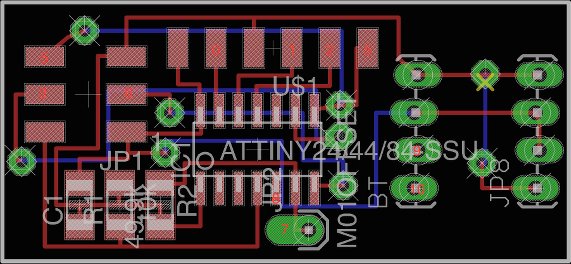

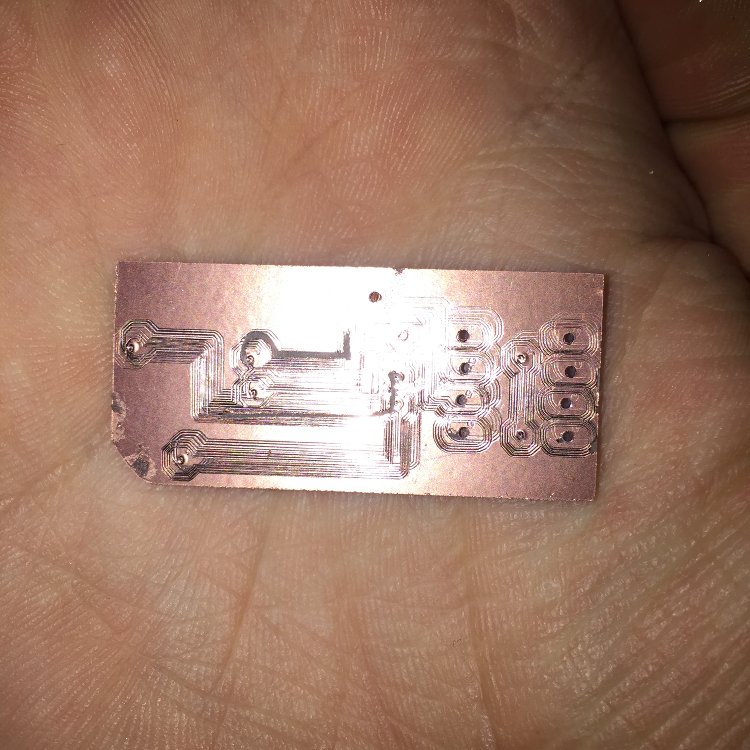

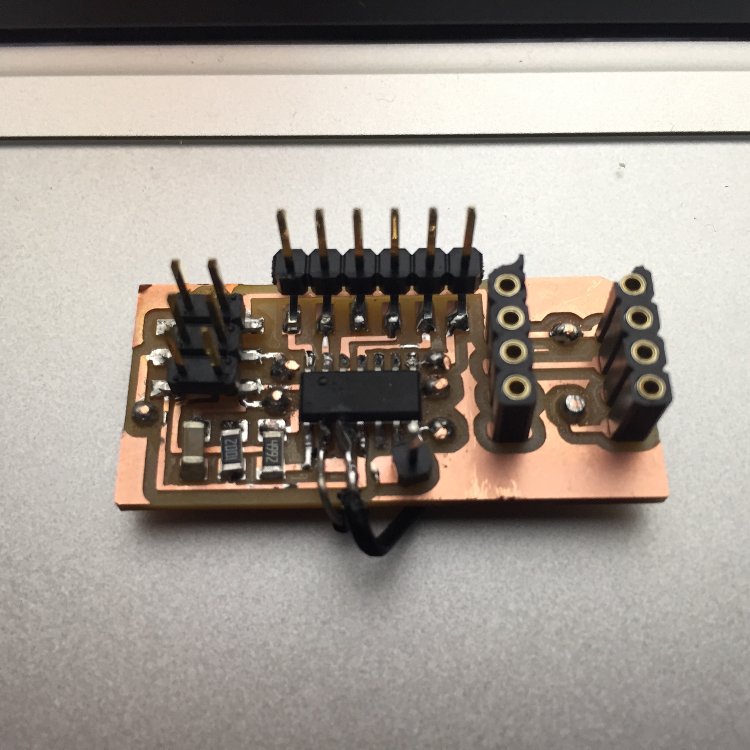

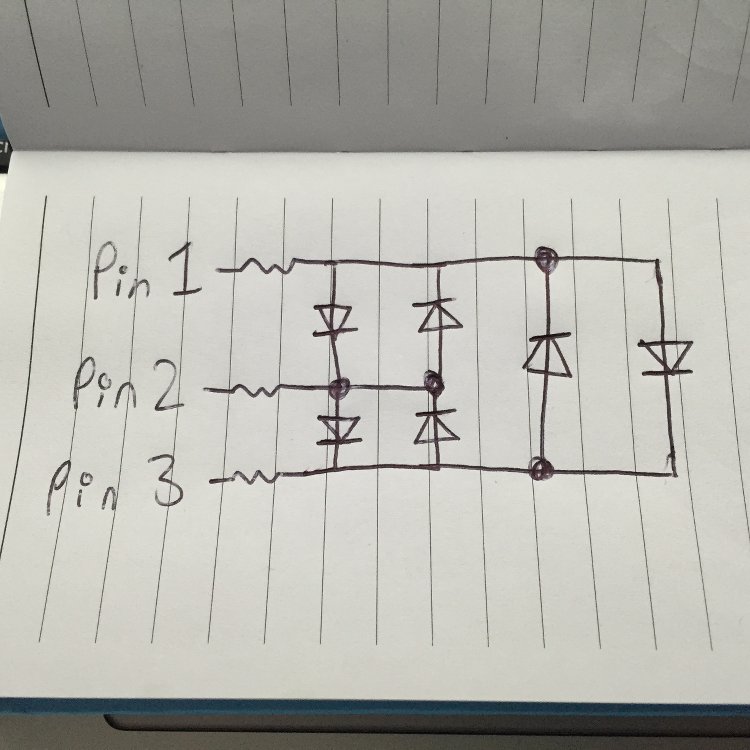

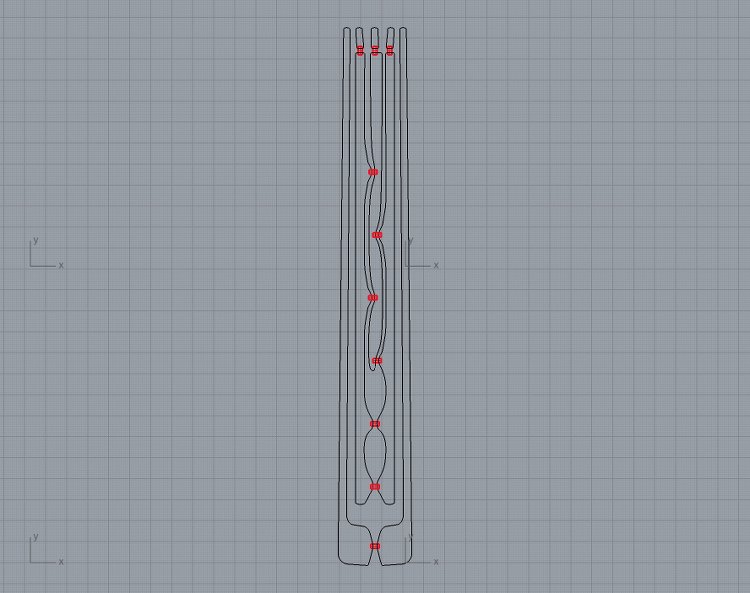

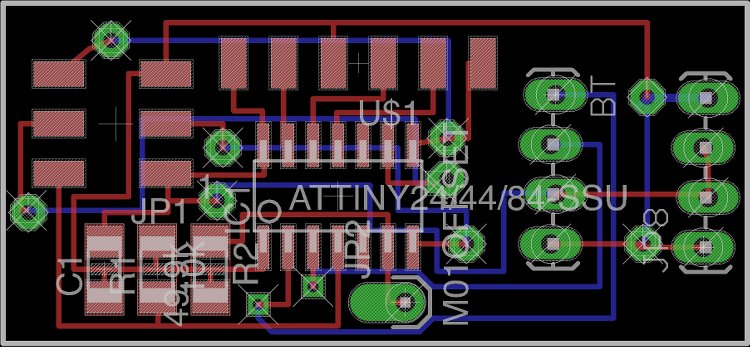

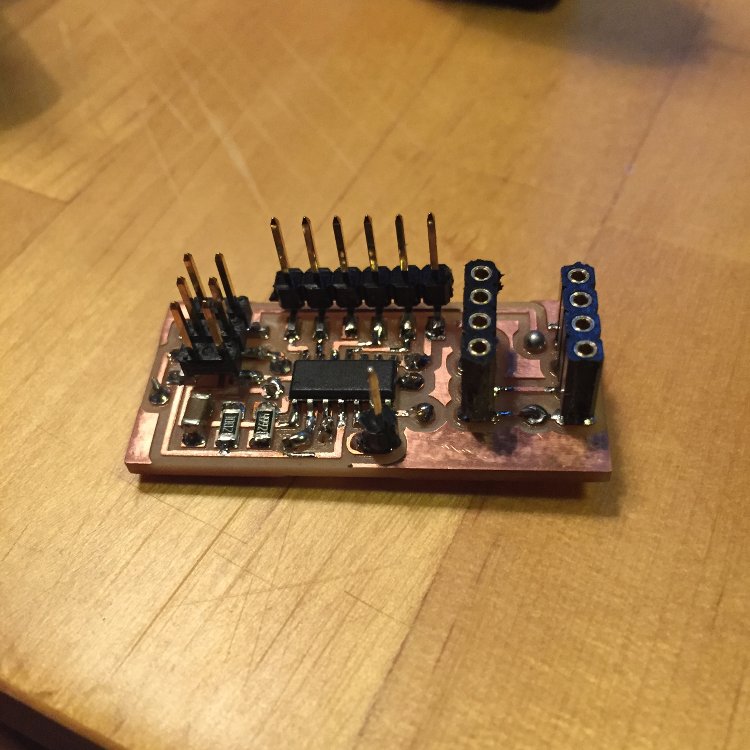

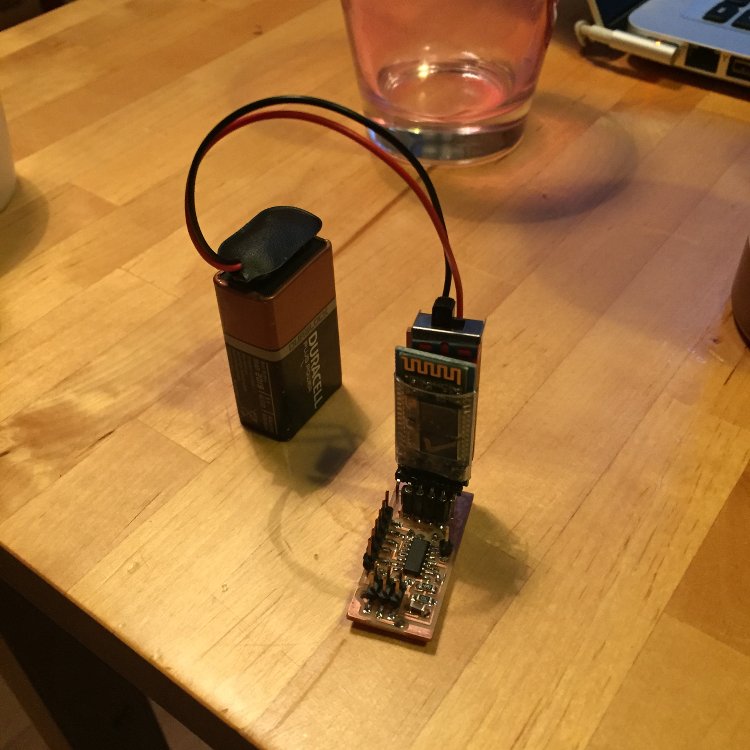

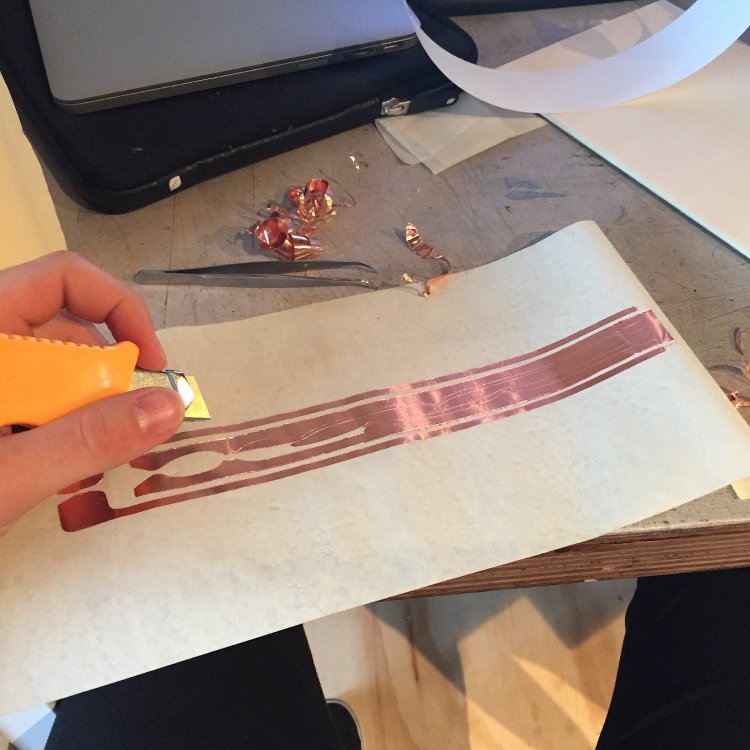

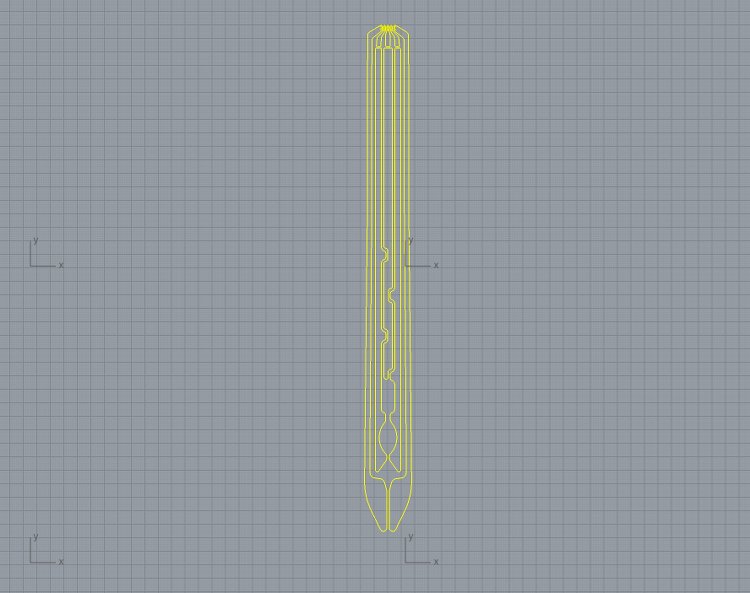

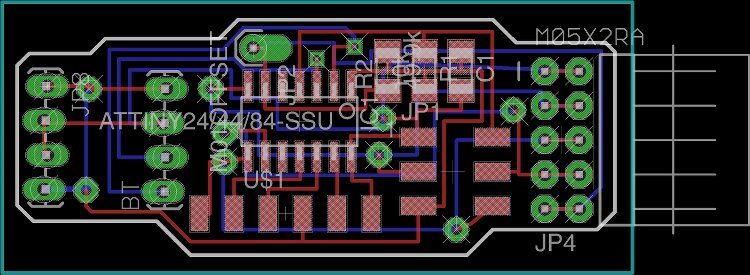

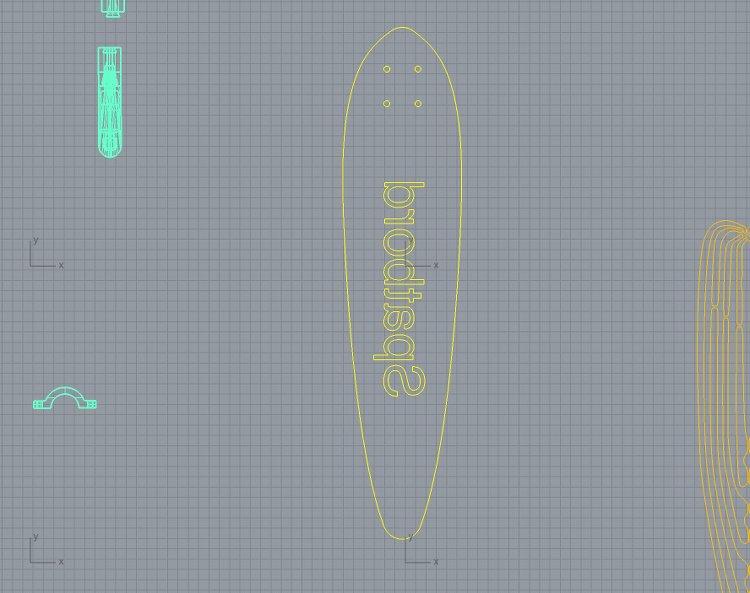

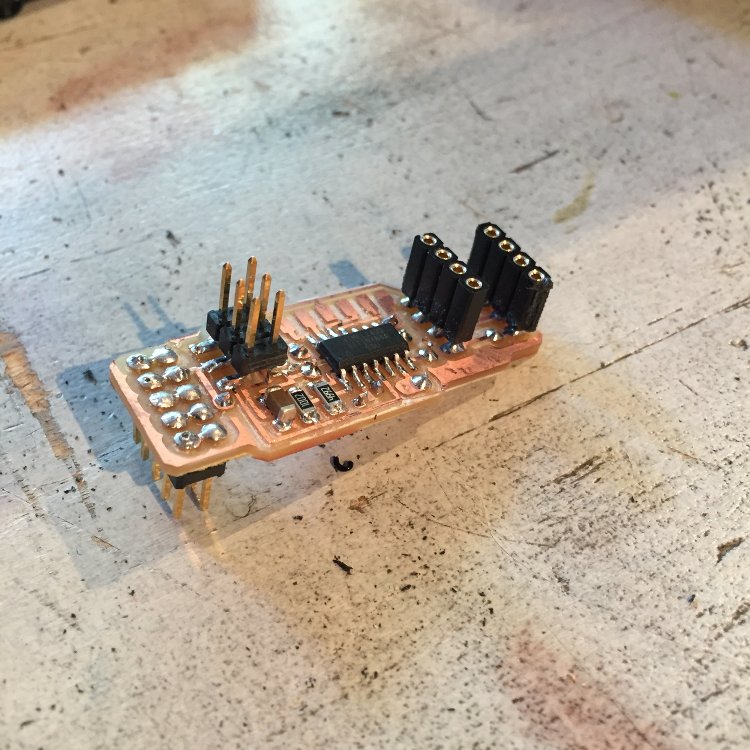

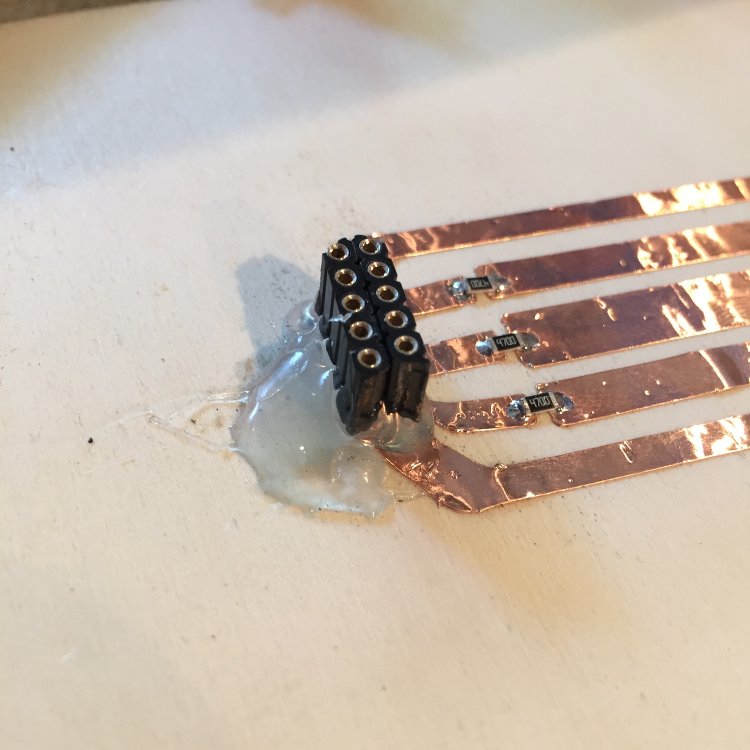

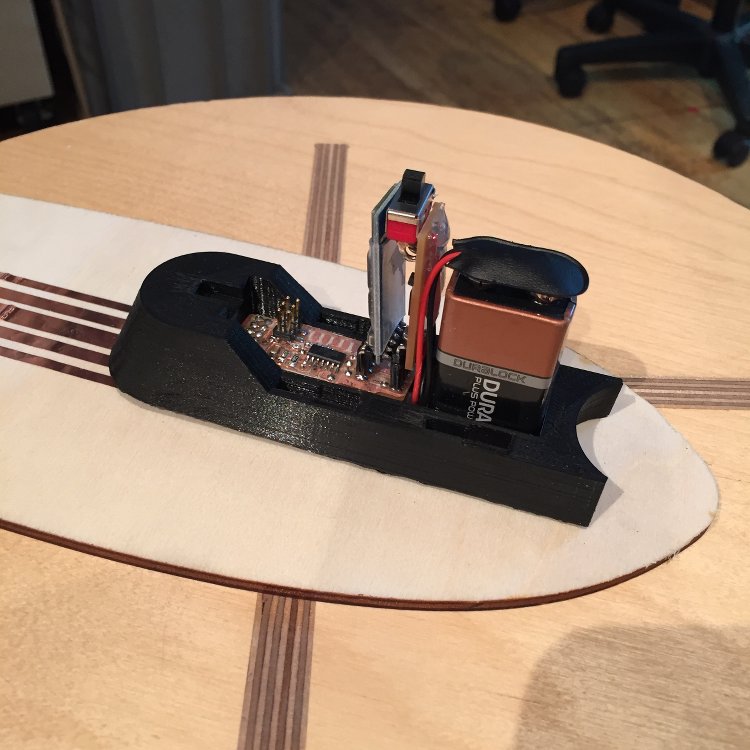

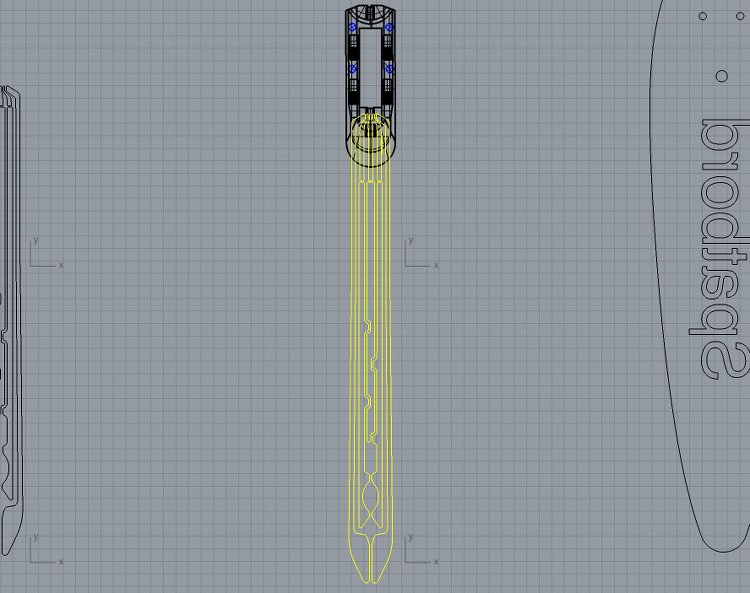

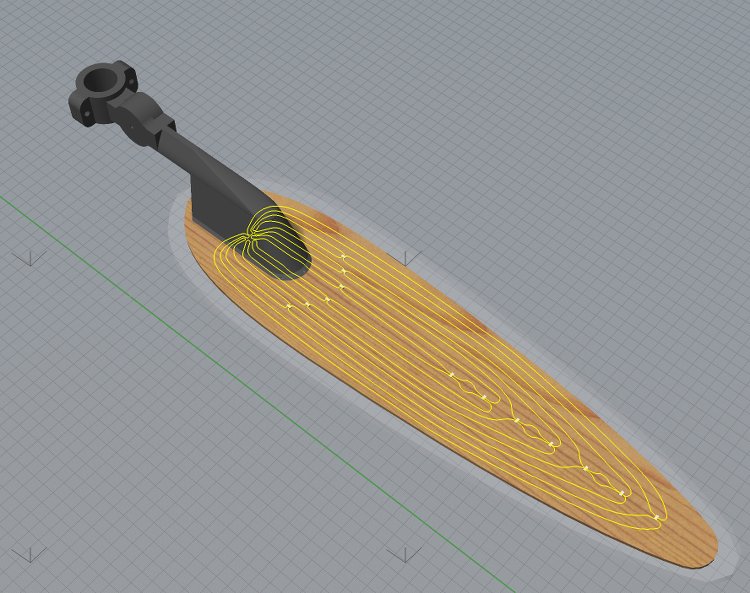

The body of the mudguard will be made of a few elements and include some electronics. A laser cut piece of plywood will provide the core of the mudguard. On the plywood will be a circuit producted in the vynil cutter and controlled by a board housed inside the holding mechanism. The circuit will be a charlieplex circuit to power and LED array and improve the safety of the biker. There will also be a phototransistor to activate it automatically.

Regarding powering the device, a simple 9V battery housed in holding mechanism will suffice for this prorotype. More advanced methods of powering a circuit can turn into another project all together! This is also where the board controlling the LED array wil be housed.

Weather proofing the fender is a challenge. My initial thought is to make a mold and cast the fender in epoxy resin. This will made it completely weather proof but impossible to repair if the LEDs or phototransistor fails. A further think may be required.

Another question was what to call this thing! As I am Brit doing the academy in Amsterdam, I thought it would be appropriate to call it the local name. The Spatbord!