Make Something BIG!!!!

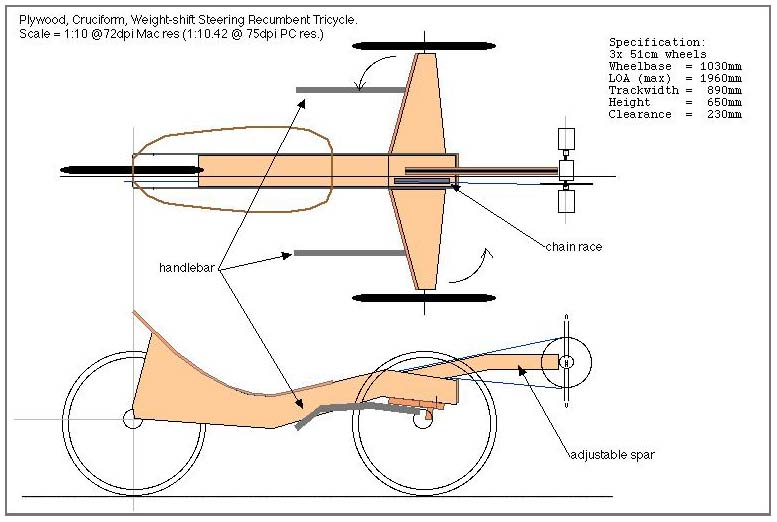

For this assignment the intent was to make an object that was significantly larger than previous attempts. A tricycle bike was selected as the object of choice and the work was developed in conjunction with my colleague Oscar Campo.

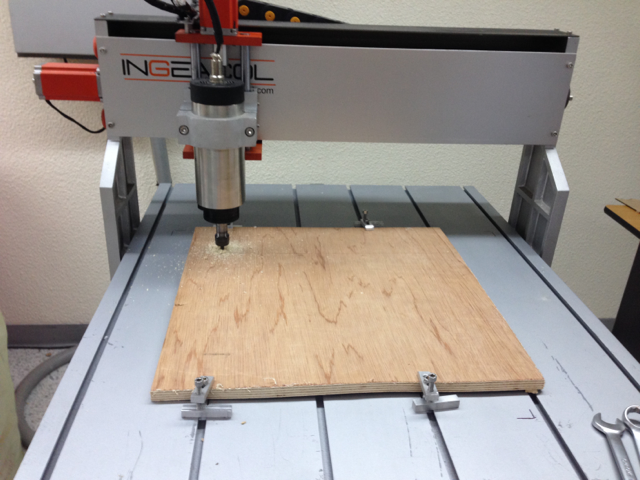

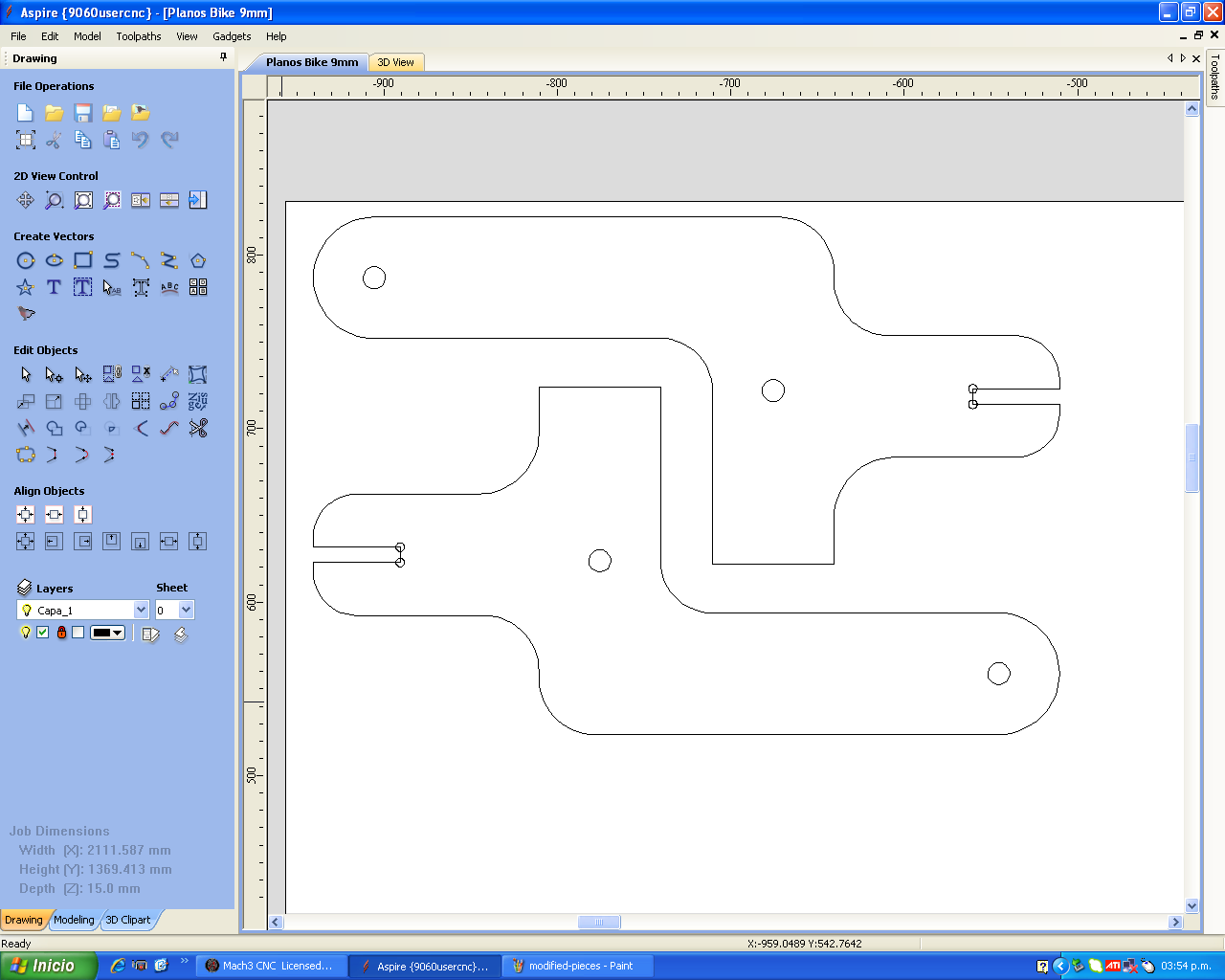

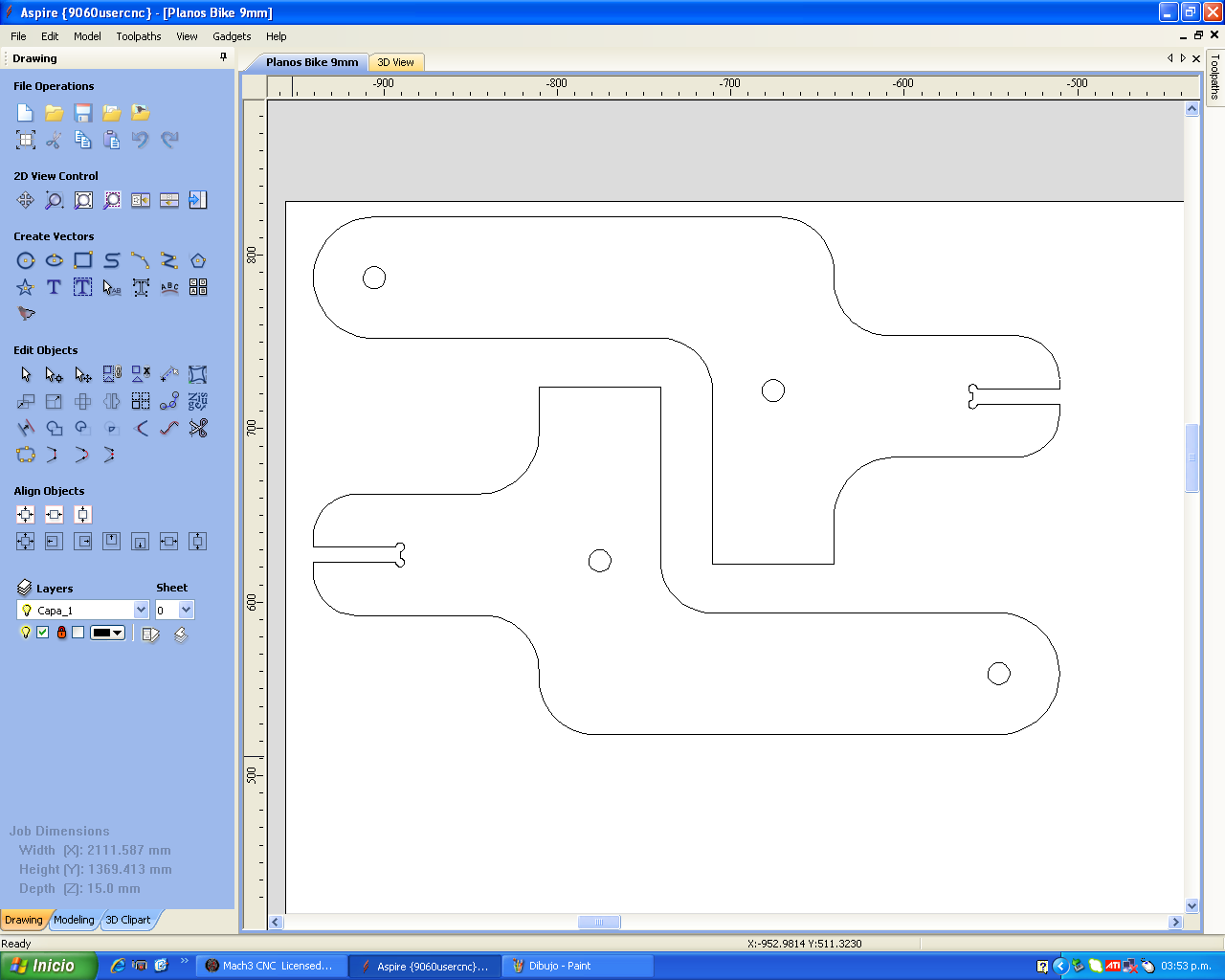

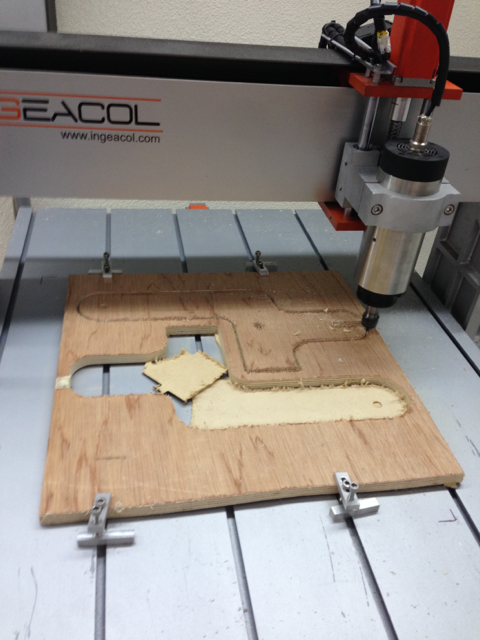

The initial intent of the design was to do all pieces in 15 mm plywood using a large router that we have access to; however, that router was damaged and we had to rely on a smaller router. Two pieces were selected as critical components and were done in the small router.

The geometry of the piece had a slot to fit in another piece, in order to obtain a proper fit, the slot was modified in the corners allowing the other piece to go in all the way. The result was much more satisfying but unimpressive for being such a simple geometry.

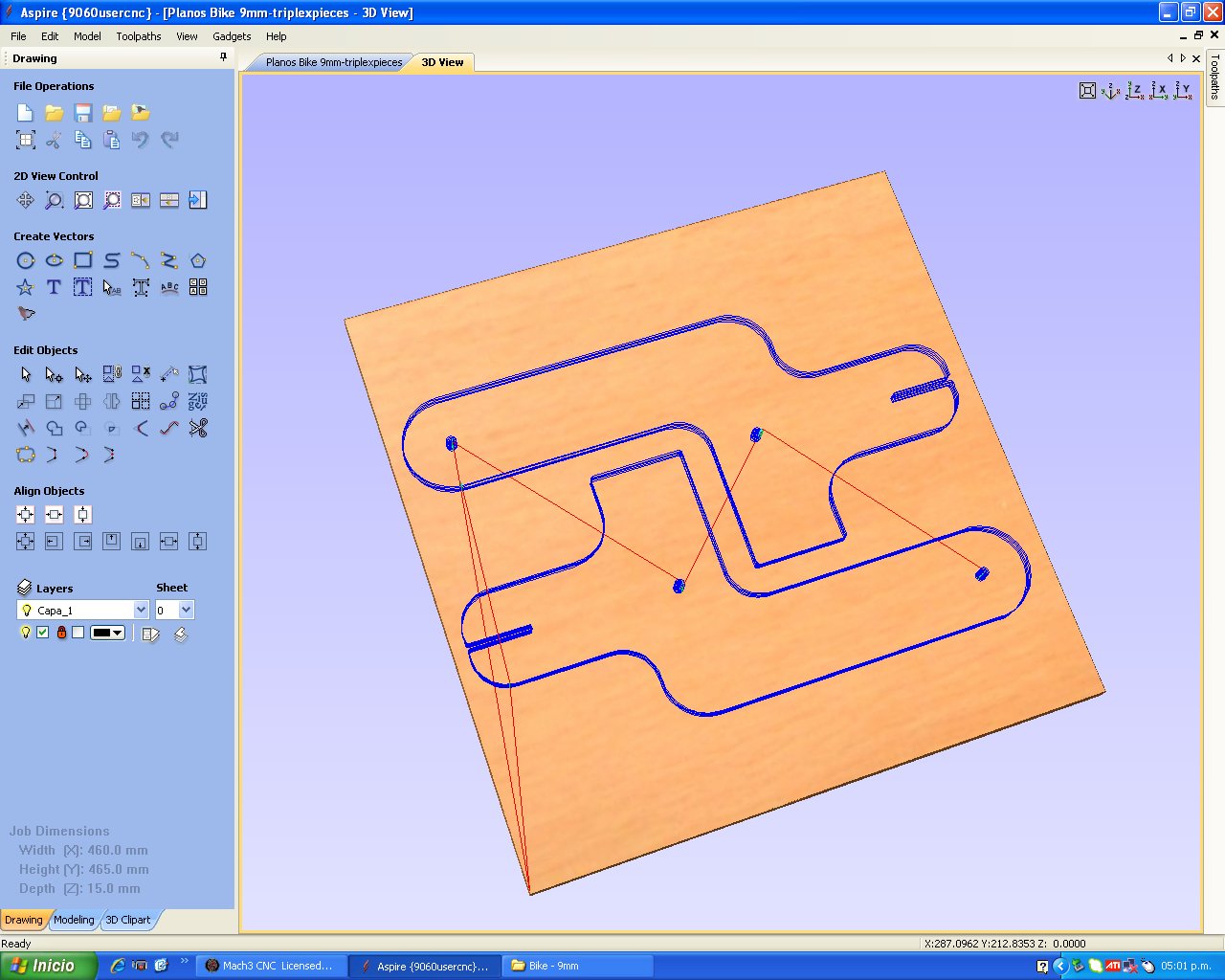

The cut was simulated before sending the router to cut; this allowed for verification of the settings, cutting path, compensation options, etc.

The result was fairly good and straightforward to do.

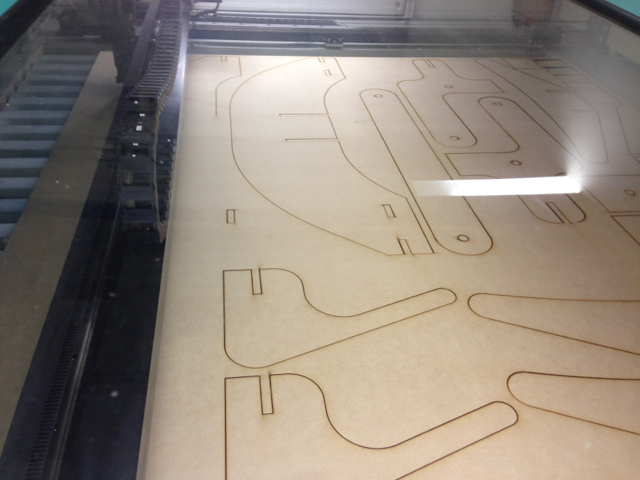

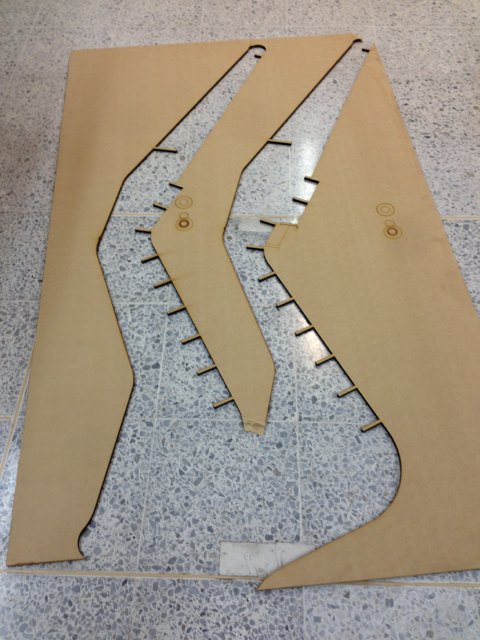

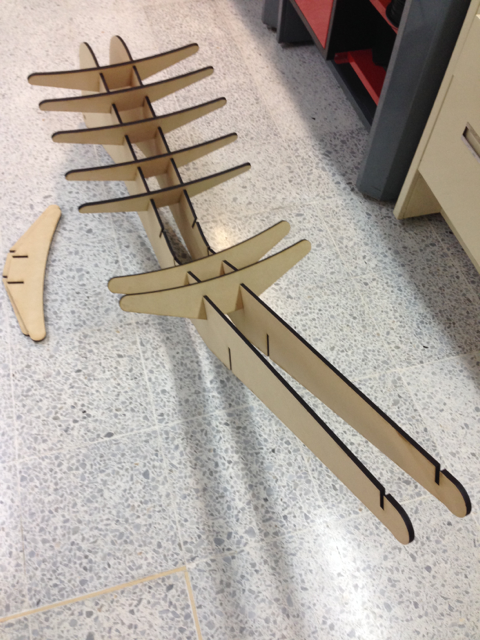

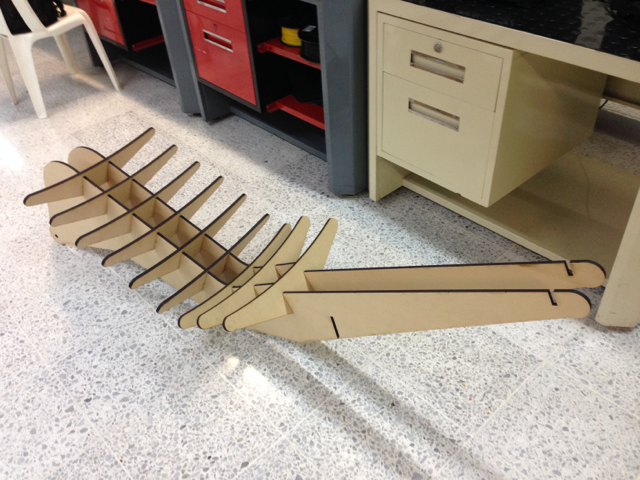

The remaining parts were done in 9 mm MDF. The geometry of the pieces had to be updated so the slots would fit, and they were cut in the laser cutter.

The two central pieces of the structure were too big to fit on the laser cutter; therefore, the cut had to be done in two passes: bottom half, then moving the material forward, and then cutting the top half. Matching the right location of the cut such that the end of the bottom half would coincide with the end of the top half prove to be difficult. Registration marks were added so we could compare the desired location of the material relative to the machine. In the end the strategy worked and the pieces were cut.

Assembly

Having all the structure the next step was to put all the pieces together.

The bike is still under construction. The structure is ready but other components like the wheels are being acquired. Stay tuned for further developments.

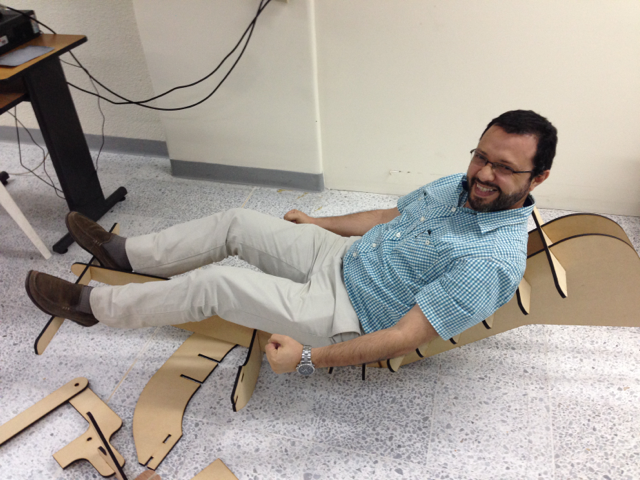

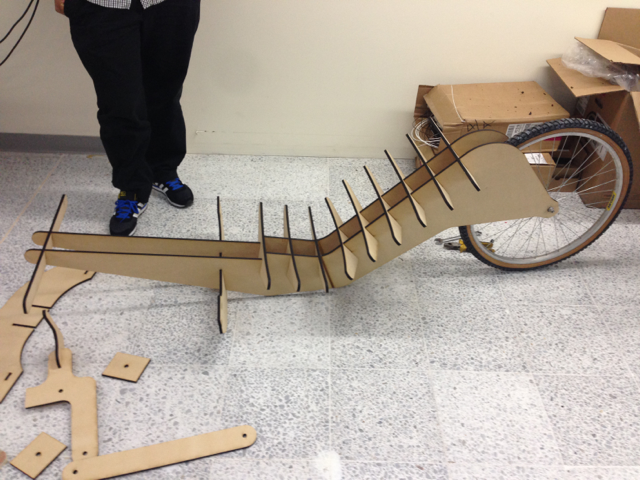

Update 03/25/2014... we got the wheels and we are

in the process of machining the axes so they can be

mounted on the tricycle. Here you can see Oscar

testing it out...

Update 04/23/2014... after a few issues with the

axes, the mounting brackets that support the wheels

and the direction, the bike is finally ready...

Progress

- Project Proposal

- 2D and 3D Model

- Laser Cut

- Circuit Making - FabISP

- 3D Scanning and Printing

- Electronics design

- Make Something Big

- Embedded Programming

- Molding and Casting

- Input Devices

- Composites

- Output Devices

- Networking

- Mechanical Design

- Interface

- Applications

- Invention

- Project Development

- Project Presentation

Alvaro J. Rojas Arciniegas, PhD

Assistant Professor Department of Automatics and Electronics - UAO

+57 (2) 318-8000 ext. 11384