2D and 3D Model

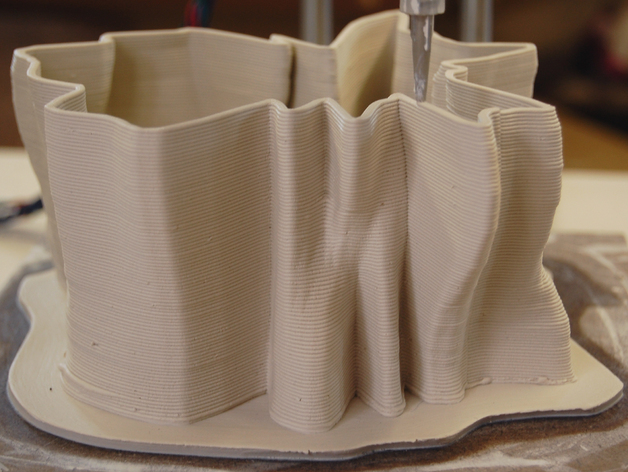

Ceramics 3D printer

The assignment for this week was to model the final project using different softwares, ranging from pure sketching tools to more sophisticated CADs.

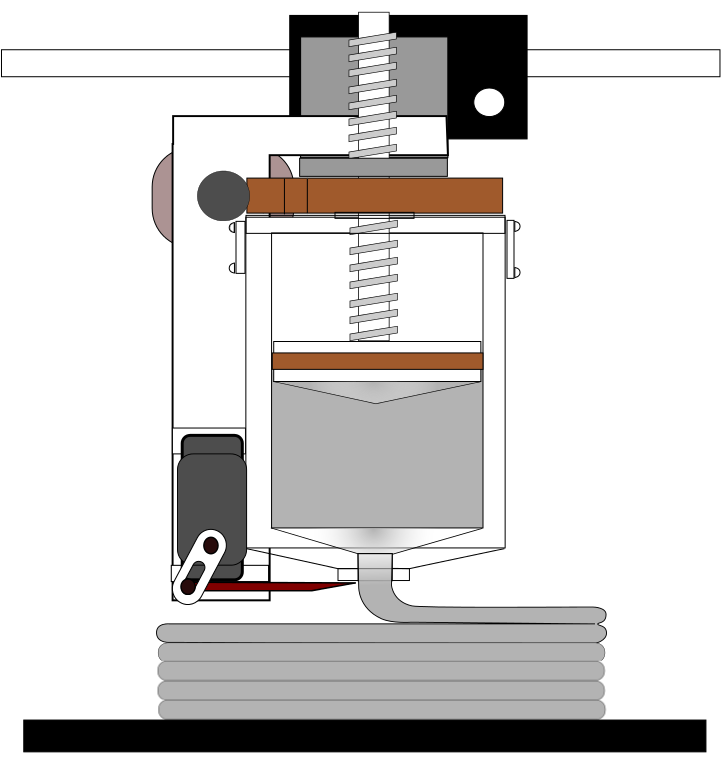

In my case, I used the tool Inkscape to create a vector image of the ceramics printer. It was fairly easy to use and powerfull in the sense that is able to handle layers, modify the number of nodes to each object, much more that one can get through tools like paint.

This was the first detailed version of the concept. The intent of the project shifted from building the entire machine to develop a new printhead that can be used to print ceramics on one of the existing 3D printers of the FabLab Cali, likely the Markerbot. A more robust version may be developed further to be used with the CNC Router to get larger pieces.

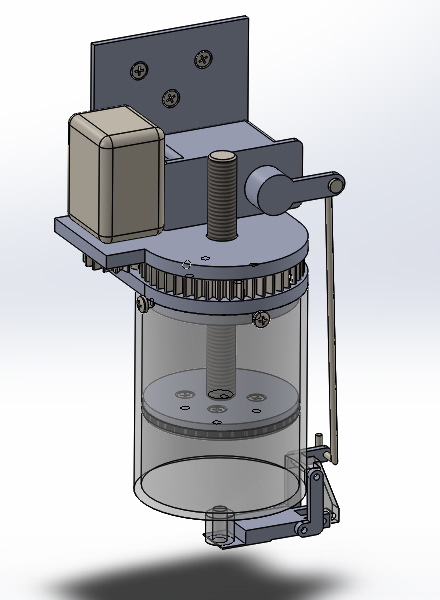

The next step was to use a 3D CAD package, in this case Solid Works 2012 was used to model individual pieces that would constitute the system and the assembly of the printhead. The software proved very useful to determine geometric interferences, assembly methods and facilitated the use of standard elements like screws or gears through their library of components.

The process of modelling the system in Solid Works lead me to some changes in the design; instead of using a screw and a gear to drive the extruder, two straight gears were selected which makes the mounting of the motor much easier and compact. Similarly, the servo driving the closing mechanism of the nozzle was moved up to the printhead clamp which makes it compact too.

Overall the experience was very positive, somewhat frustrating at times since every program has their own way of doing things. Comparing both experiences, Inkscape and Gimp (which I tried but got frustrated and decided not to include the results) were good to draw sketches but I'm hesitant to use them heavily at the time to design parts and systems. On the other hand Solid Works is a very complete package for parametric design, it is easy to create parts based on actual measurements but can be a bit restrictive at the moment of starting from a white canvas.

Progress

- Project Proposal

- 2D and 3D Model

- Laser Cut

- Circuit Making - FabISP

- 3D Scanning and Printing

- Electronics design

- Make Something Big

- Embedded Programming

- Molding and Casting

- Input Devices

- Composites

- Output Devices

- Networking

- Mechanical Design

- Interface

- Applications

- Invention

- Project Development

- Project Presentation

Alvaro J. Rojas Arciniegas, PhD

Assistant Professor Department of Automatics and Electronics - UAO

+57 (2) 318-8000 ext. 11384