Laser Cut

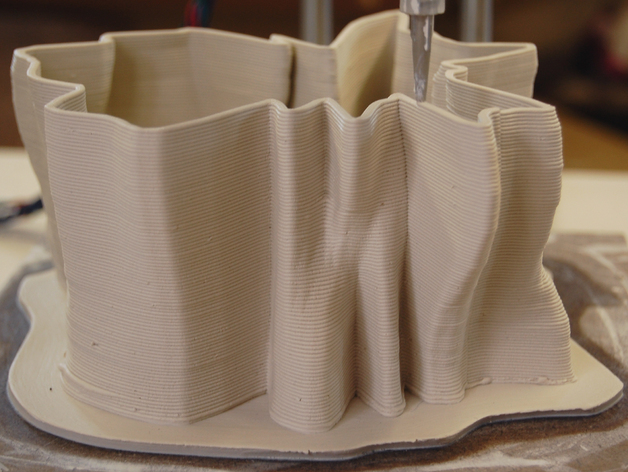

Ceramics 3D printer

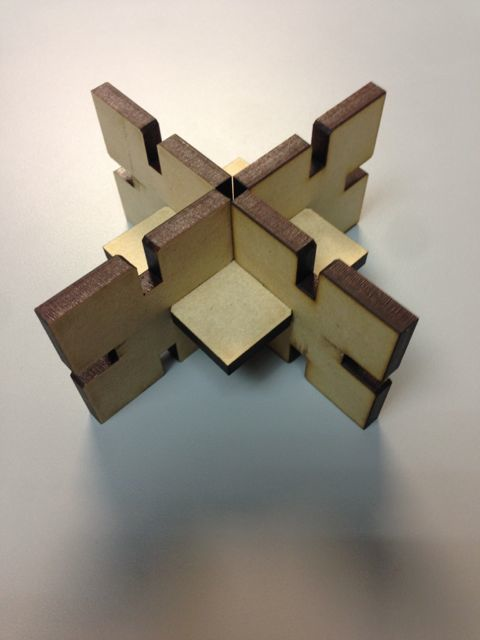

The assignment for this week was to experiment with laser cut and getting the tolerances right for a construction kit that would assemble without the need for glue.

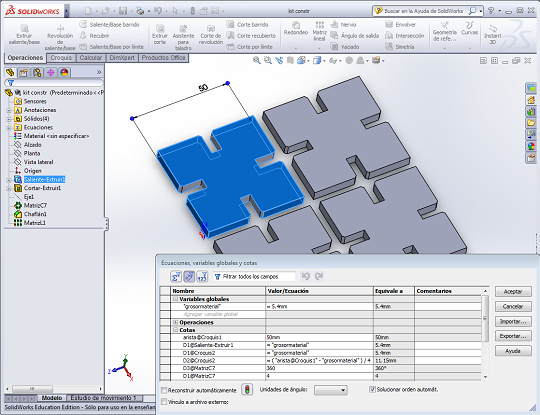

Towards that end, I decided to experiment with a very simple piece design, similar to the one proposed in class. I used solidworks to create the parametric design that would adjust the slot size as the material thickness changed.

The material selected was MDF due to availability in the lab. In the first attempt, the pieces wouldn't fit in the slots despite having the nominal thickness of the material (5 mm). The second attempt increased the slot by 1/10th of a milimeter, however the pieces still wouldn't go through.

At this point it occurs to me that the material might have been thicker than anticipated. Sure enough, after checking with a caliper the thickness of the material was 5.4 mm. The slot was adjusted accordingly and voila!! pieces fit together quite nicely!

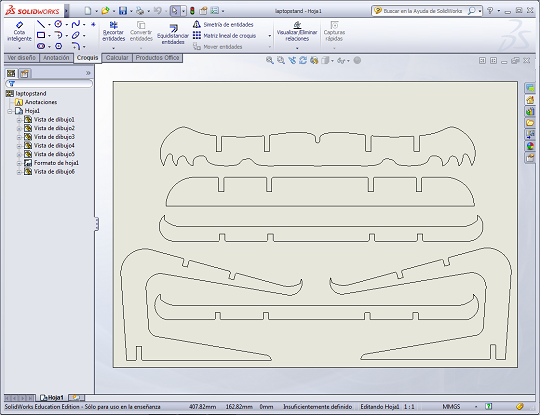

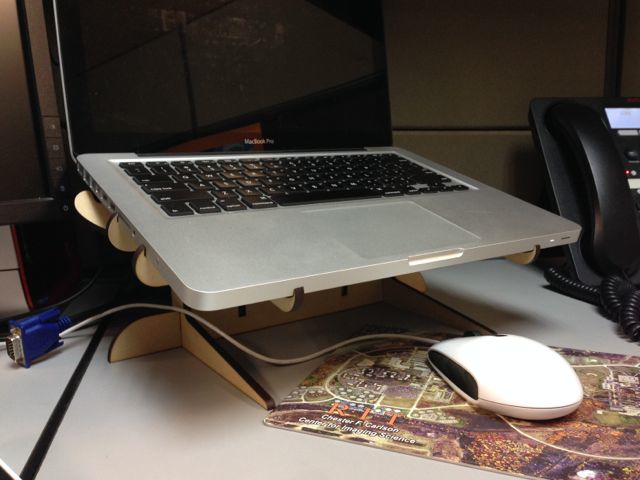

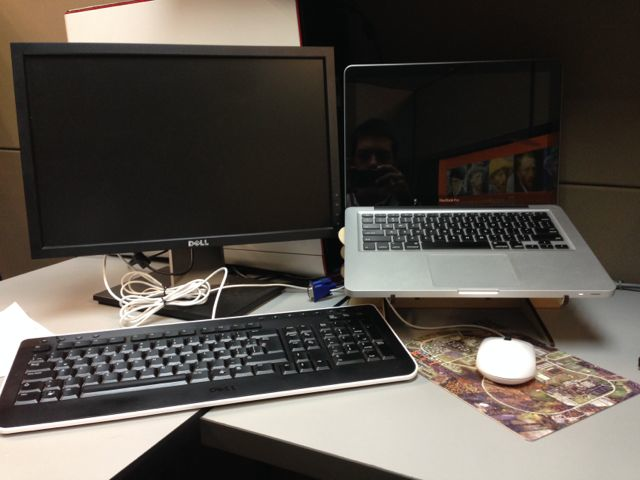

Having experimented with the construction kit, I wanted to do something more... At my desk I had my laptop on top of books to achieve the arrangement that I wanted when I plugged it to the desktop monitor. I decided to create a stand for it using the laser cutting machine. I measured the laptop and designed a set of simple, quite straight pieces that would fit togeter allowing for some reconfiguration (having the legs of the stand closer together or far apart), I also wanted to experiment with splines and more complex curves so I created one of the pieces with multiple curves to evaluate how it would behave. You can see the end result below.

Overall I was extremely happy with the results, I was able to get a useful structure that looks nice and it was all built in a couple of hours without the need for anything else than the materials and the FabLab! :)

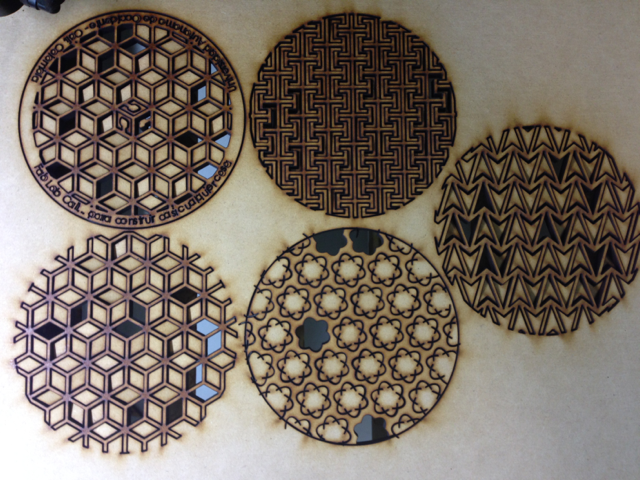

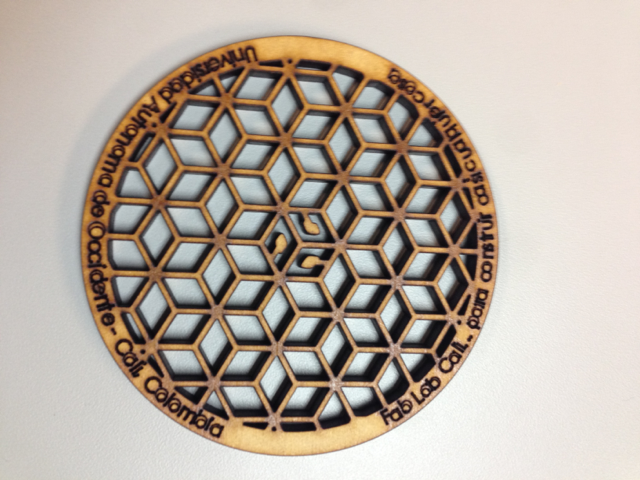

Update 03/25/2014: I decided to try to cut more complex forms to see how it behaved. I designed some coasters, one of them with the FabLab logo and for the most part it was very successful; however, some of the curves appeared different from what was intended, it is particularly noticeable in the letters and the pattern of one of the coasters that resemble a flower.

Progress

- Project Proposal

- 2D and 3D Model

- Laser Cut

- Circuit Making - FabISP

- 3D Scanning and Printing

- Electronics design

- Make Something Big

- Embedded Programming

- Molding and Casting

- Input Devices

- Composites

- Output Devices

- Networking

- Mechanical Design

- Interface

- Applications

- Invention

- Project Development

- Project Presentation

Alvaro J. Rojas Arciniegas, PhD

Assistant Professor Department of Automatics and Electronics - UAO

+57 (2) 318-8000 ext. 11384