Final Project Presentation

The final project has been successful achieving

control over the six legs of the hexapod. Take a look

at this video

recorded during the presentations of the FabAcademy.Here is the image shown that day during presentation.

Final Project

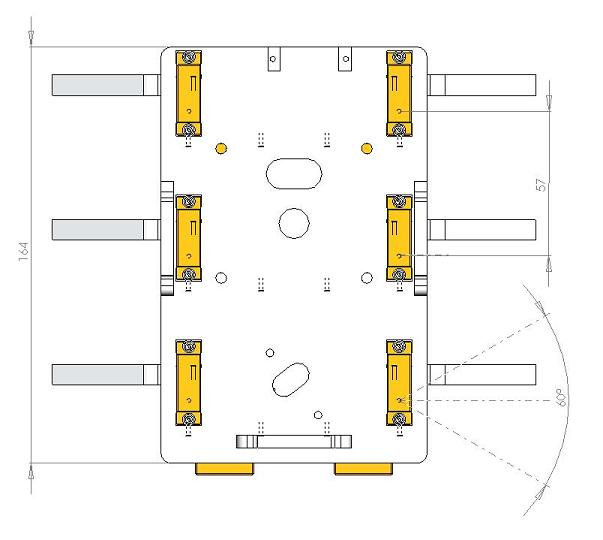

As it was reported in the mechanical design assignment, the final project has switched to a hexapod robot. The intent of the robot is to be able to walk through various terrains or surfaces by having six legs, each one with two degrees of freedom: one to move it up or down, and one to move it forward or backwards.

Actuators and sensors selected

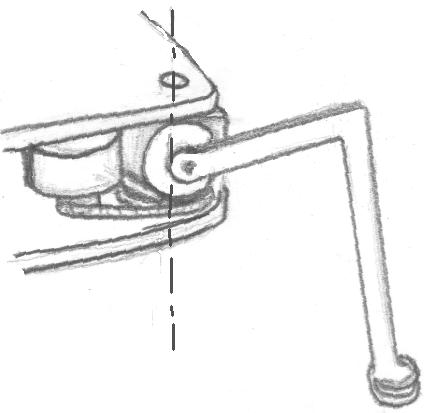

The first selection was the type of actuator to

use. Multiple alternatives were considered but

looking for ease of driving and compactness the

pico-servos were selected. Driving them with a micro

controller was shown in the output devices homework

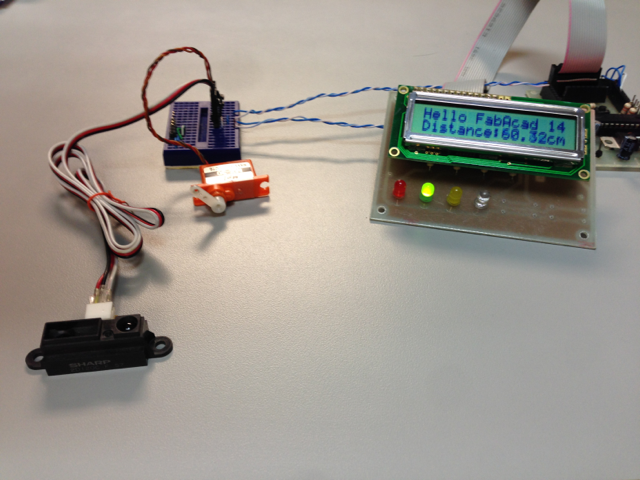

(see image below). Similarly it was important to

select some way to sense the environment in order to

facilitate navigation. Infrared sensors were

selected based on the range they covered (10-80 cm)

and the direct output of 0-5V making it easy to

interface with a micro controller. One was also

tested in the input devices and output devices

homework (see image below).

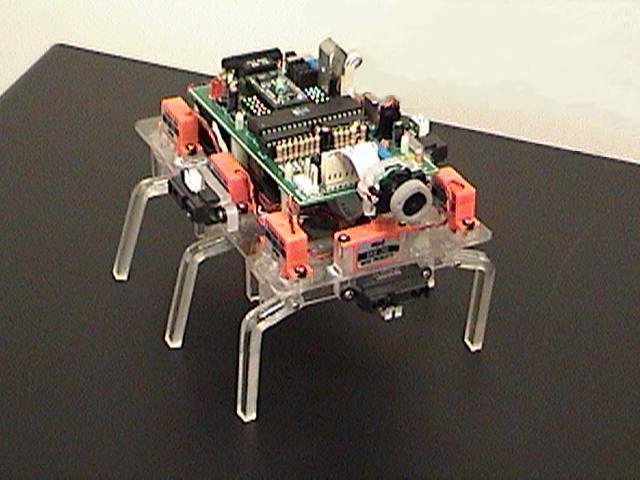

First Attempt

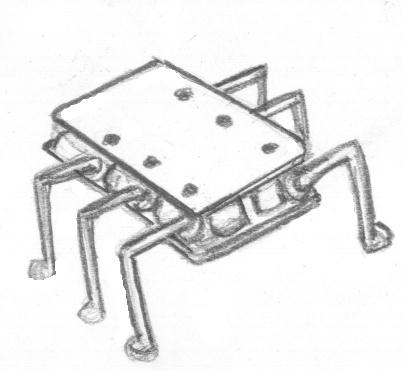

The first attempt achieved the simplicity and

compactness but the motors were inadequate for the

load that the robot required. All the pieces that

made the body of the hexapod, the legs, and the

structure to connect two servos in place were made

in acrylic cut with the laser cutter. A photo of the

early design can be seen below next to the model in

Solid works. The main flaw was not to consider the

weight of batteries which ended up being

significant.

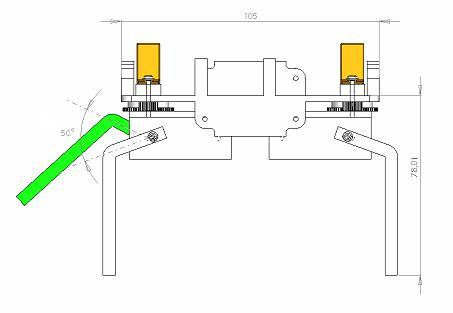

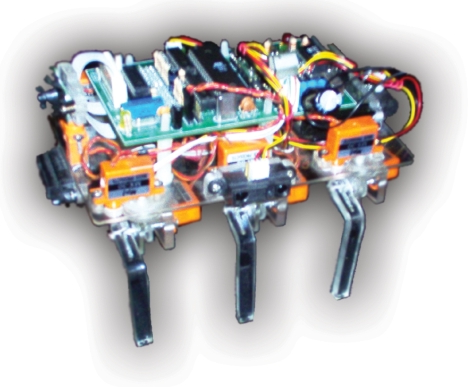

Second Attempt

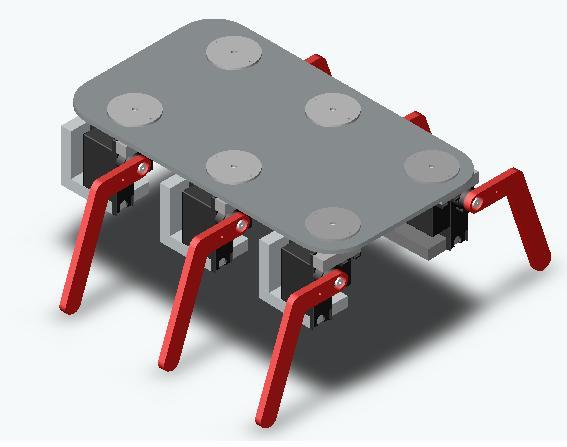

Despite having a fairly simple and compact design,

the motors had a lot of problems maintaining the

standing position, and it was noted that most of the

range of motion of each servo was being wasted

because each articulation of the leg did not move

the 180 degrees which is roughly the range of motion

of the servo. Gears were used to provide more force

in each leg while maintaining an acceptable range of

motion.

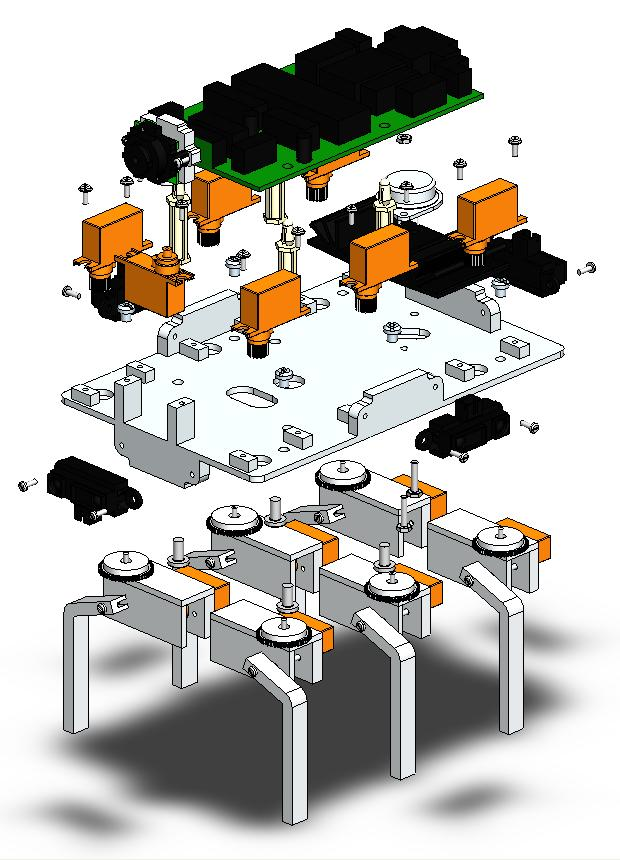

This new version was done similarly, in acrylic cut

with the laser cutter, small pieces to mount the

sensors were cut separately and glued into the base

with crazy-glue. An exploded view of the final

assembly can be seen below.

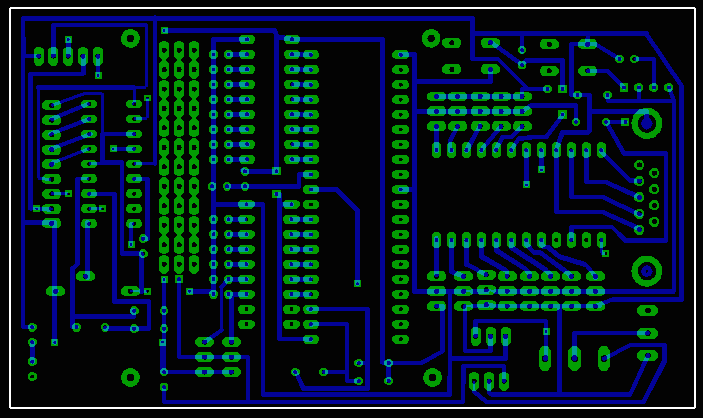

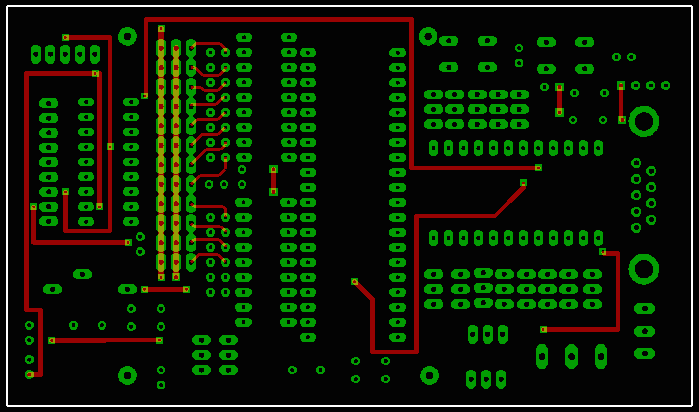

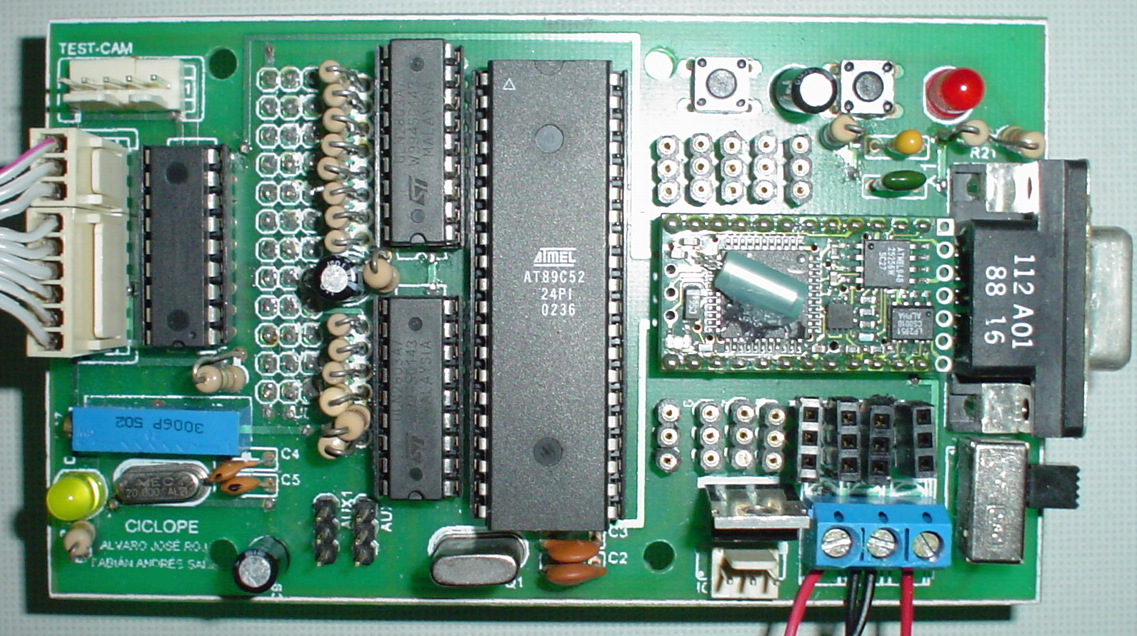

Electronics Design

Part of the intent of the electronics was to have a

single board as compact as possible. Single layer

designs resulted in too many bridges and connections

so a 2 layer design was done which allowed for a

much compact PCB. The design of the board was made

and then it was sent to a local shop that had more

experience with multiple layer PCBs.

As you may notice in the printout of the board the design was made jointly with my friend Fabian A. Salazar who is not participating of the FabAcademy.

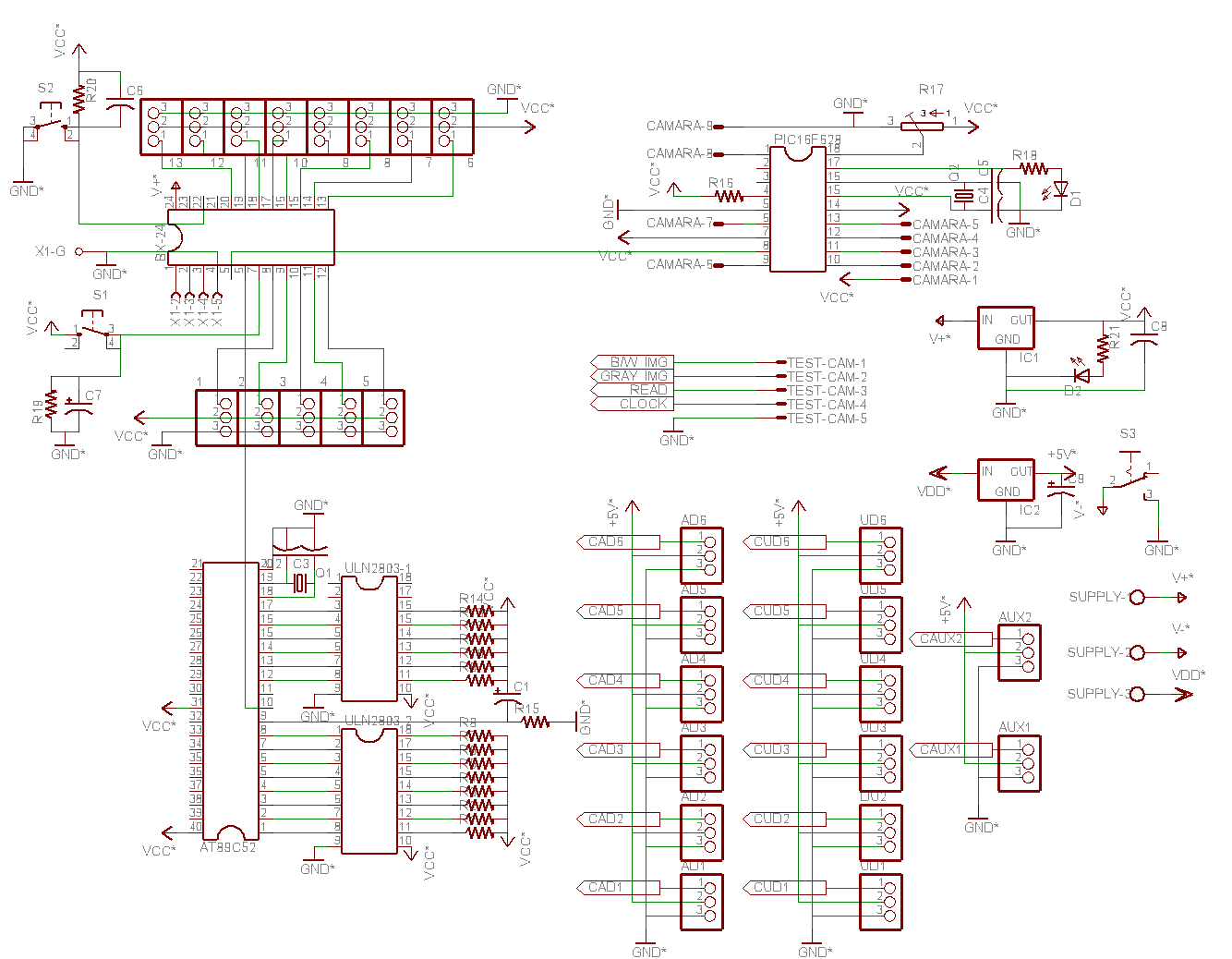

To control the movement of the legs there is a

master microcontroller basic stamp BX-24 that is

programmed in basic and an Atmel AT89C52 that was

programmed in assembler to generate the PWM for the

servos. The two microcontrollers are connected

through serial communication in which the master

indicates which step to take: forward, backwards,

turn left, or turn right, and the slave does the

generation of PWMs to produce the step.

Progress

- Project Proposal

- 2D and 3D Model

- Laser Cut

- Circuit Making - FabISP

- 3D Scanning and Printing

- Electronics design

- Make Something Big

- Embedded Programming

- Molding and Casting

- Input Devices

- Composites

- Output Devices

- Networking

- Mechanical Design

- Interface

- Applications

- Invention

- Project Development

- Project Presentation

Alvaro J. Rojas Arciniegas, PhD

Assistant Professor Department of Automatics and Electronics - UAO

+57 (2) 318-8000 ext. 11384