Composites (and 3D printing)

In this assignment we decided to explore the benefits of composites associated with 3D printing by analyzing the improvement in tensile strength of a hollow probe of ABS filaments (printed in a makerbot replicator 2X) filled with clear silicone sealing. In this case the filaments of ABS printed on the makerbot create the fibers of the composite while the silicone acts as the matrix.

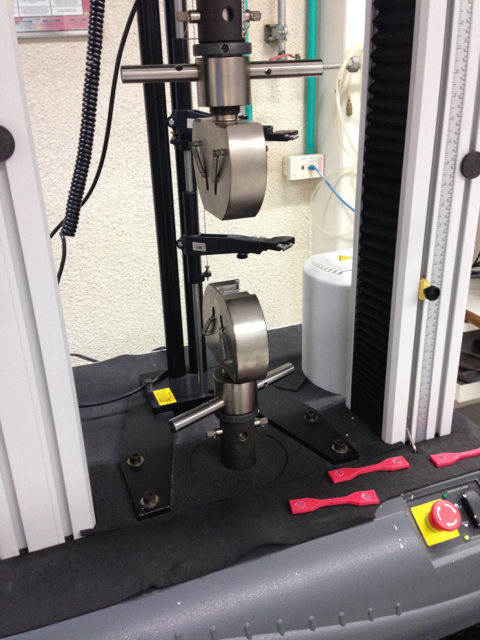

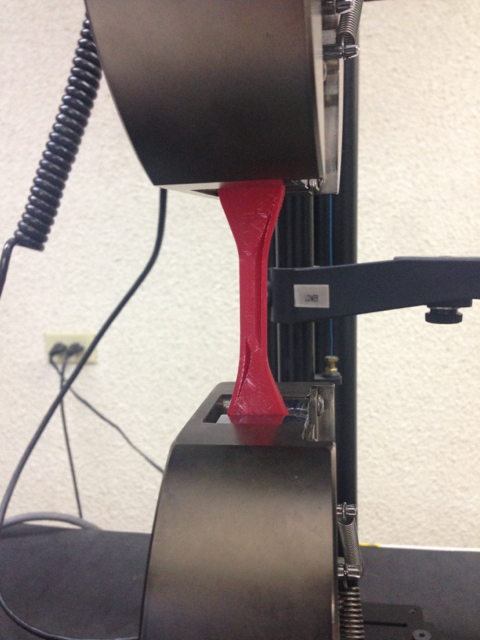

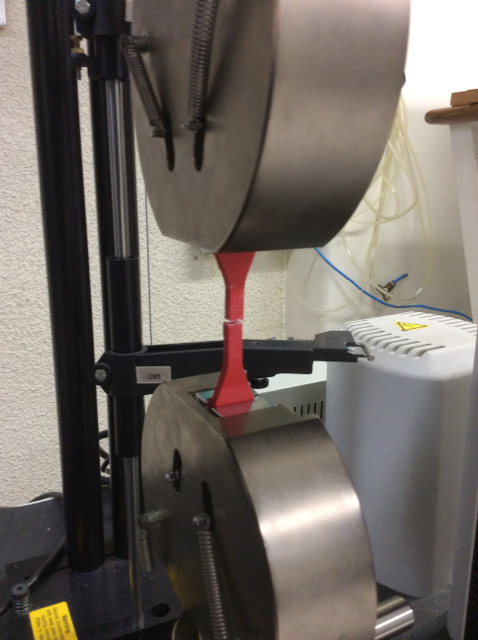

The probes were taken to a universal testing

machine that allowed us to examine the tensile

strengh of the material by pulling the probe until

braking point and recording the load applied.

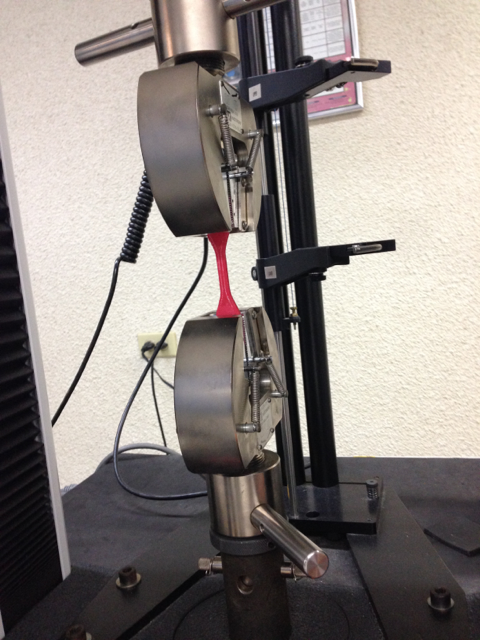

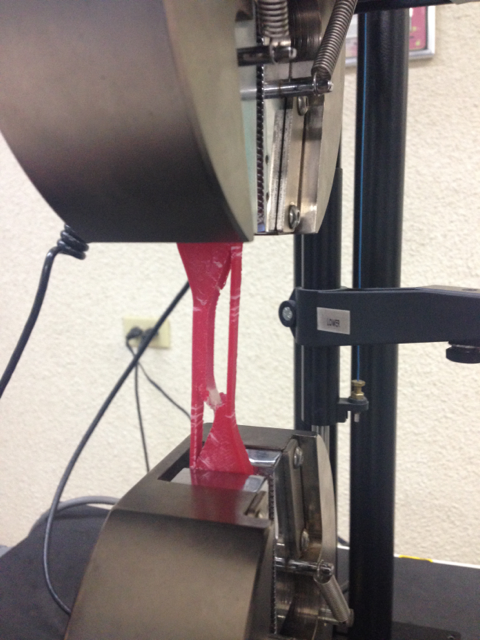

The way the probes were printed led to interesting

behaviors during the test. The filaments on the

edges tend to stay together and separate from the

top and bottom faces fairly quickly.

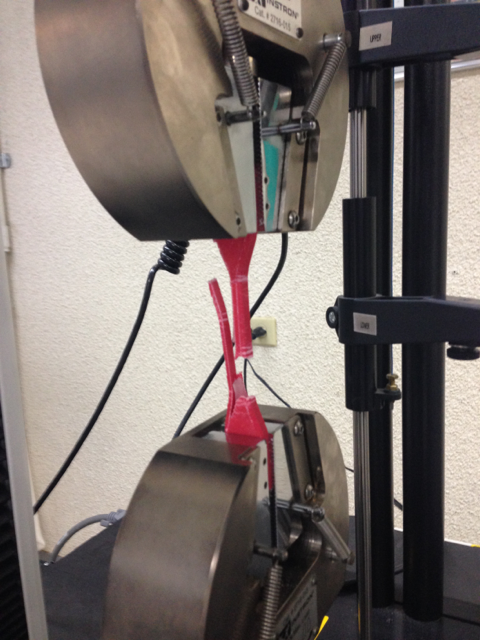

3 probes were made and notice that in all cases the

ABS failed first on the top and bottom faces that on

the sides and the clear silicone is still expanding

until the breaking point for it is reached.

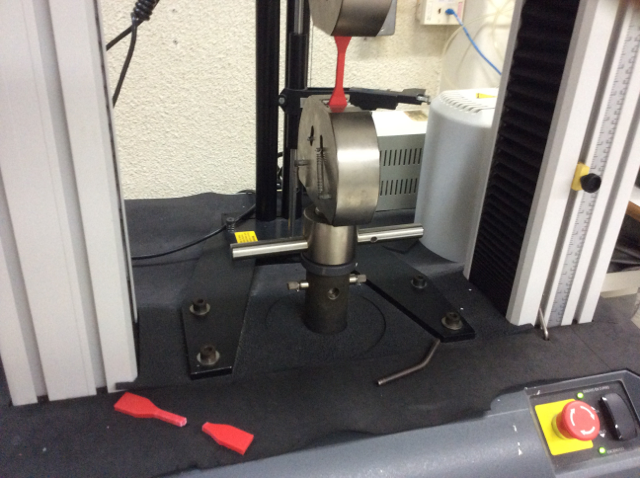

To compare the performance 3 solid probes were

printed and put to the test. These probes behaved

different; the sides did not separate from the body

because of the pattern used to print the part was

constant all along. However, the probe broke quickly

without much deformation.

The maximum load supported by the probes was

registered as follow:

Composite Probes

#1: 0.70004 kN

#2: 0.70232 kN

#3: 0.65122 kN

Average: 0.68452 kN

Solid Probes

#1: 0.72271 kN

#2: 0.70877 kN

#3: 0.74304 kN

Average: 0.72484 kN

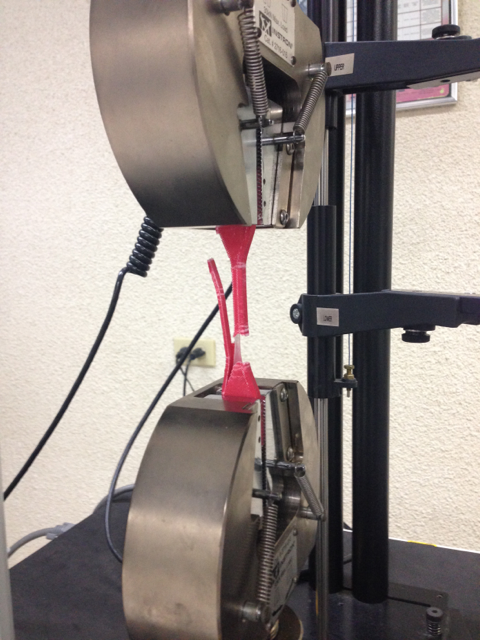

showing a similar performance for both cases, with

a slight advantage from the solid probes. More

elongation was observed in the composite probes due

to the side walls separating from the top and bottom

faces, straightening and finally breaking, while the

solid probes simply broke after certain elongation.

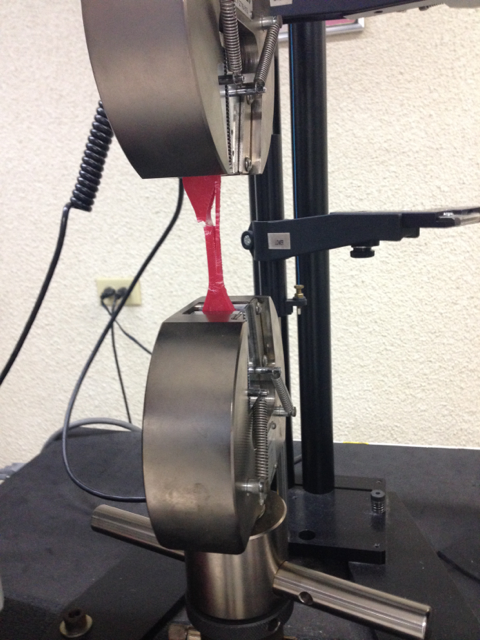

This is representative of the observations where the

solid probes had better structure while the

composites separated easily by faces. Looking

further into the structure of the composite probes

one finds how only a few filaments were really

surrounded by the clear silicone and those provided

a true composite behavior.

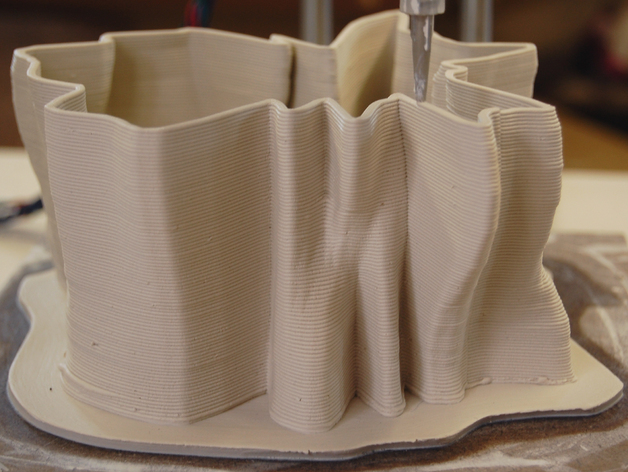

Two conclusions can be extracted from this

experiment. First, in order to create composites

with 3D printed filaments one needs to print an

internal structure that would allow for filling it

up with the matrix while providing enough fibers to

allow for good interaction between fibers and

matrix. Second, 3D printing may be an alternative

for creating molds that can be filled with resins

and later peel off the printed case since the walls

and faces are fairly uniform and separate cleanly

from the clear silicone.

Progress

- Project Proposal

- 2D and 3D Model

- Laser Cut

- Circuit Making - FabISP

- 3D Scanning and Printing

- Electronics design

- Make Something Big

- Embedded Programming

- Molding and Casting

- Input Devices

- Composites

- Output Devices

- Networking

- Mechanical Design

- Interface

- Applications

- Invention

- Project Development

- Project Presentation

Alvaro J. Rojas Arciniegas, PhD

Assistant Professor Department of Automatics and Electronics - UAO

+57 (2) 318-8000 ext. 11384