Molding and Casting

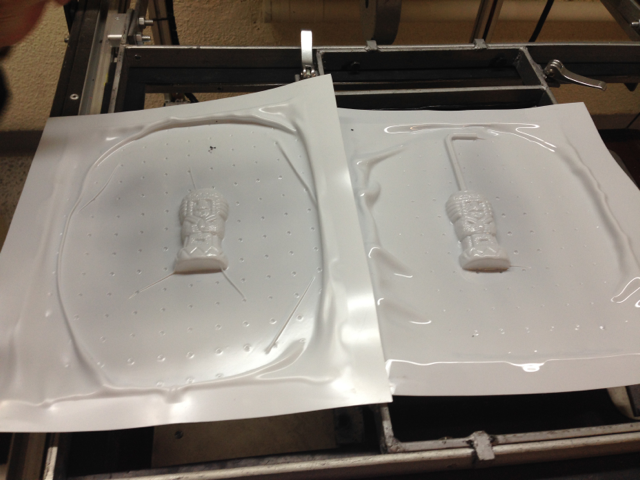

For this assignment the task was to create a mold and cast an object. Instead of using the CNC router, we decided to create the mold by thermo-forming using a machine that was done at the University and using polystyrene for the mold.

The machine works by heating the material until it becomes maleable, then the platform with the object of interest is raised and suction is applied making the material to conform to the object, creating the mold.

A second mold was created with the intention of

closing the mold. A channel was included to vert the

material into the mold.

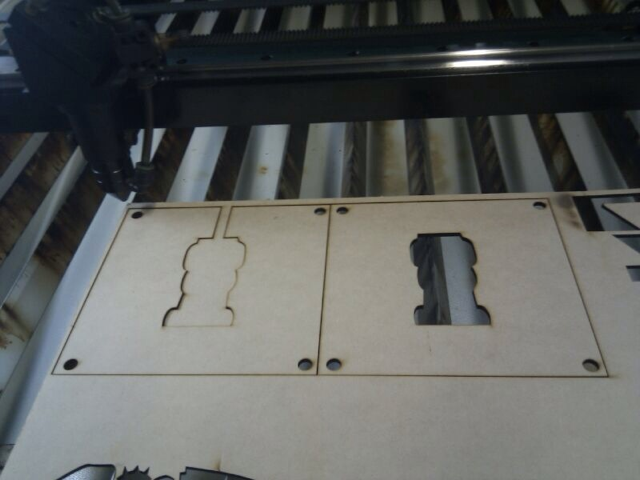

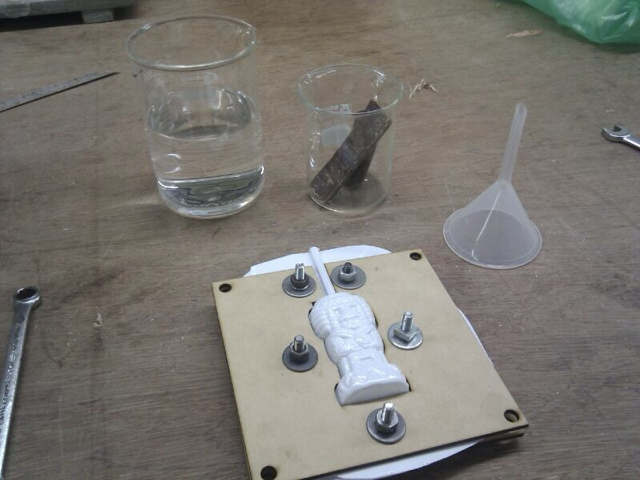

After analyzing the options of materials to cast we decided to use chocolate but to use a roto-molding machine to create the outer shell and leave room for filling it with jelly or fudge. A template was done in MDF with the laser cutter to create a better seal at the time of pouring the chocolate. The chocolate was heated indirectly by putting a jar with the chocolate in boiling water until it melted.

The first trial was not successful, the chocolate

reached the walls of the mold but it did not

solidify.

A second attempt was done but after removing the mold from the machine it was taken to the frezzer hoping to preserve the geometry of the shell.

The result was not as successful as we had imagined but served as a proof of concept. The chocolate resemble the geometry of the intended object but in some regions it did not follow the mold and did not reproduced the details correctly.

Progress

- Project Proposal

- 2D and 3D Model

- Laser Cut

- Circuit Making - FabISP

- 3D Scanning and Printing

- Electronics design

- Make Something Big

- Embedded Programming

- Molding and Casting

- Input Devices

- Composites

- Output Devices

- Networking

- Mechanical Design

- Interface

- Applications

- Invention

- Project Development

- Project Presentation

Alvaro J. Rojas Arciniegas, PhD

Assistant Professor Department of Automatics and Electronics - UAO

+57 (2) 318-8000 ext. 11384