Mechanical Design

Although the initial proposal for the project was to

develop a 3D printing head for clay/ceramics, there

have been some issues, particularly in terms of time

management/availability; therefore, I'll report here

another project that I have developed and where many

of the tools covered in the FabAcademy have been used:

A hexapod robot called Cyclops.

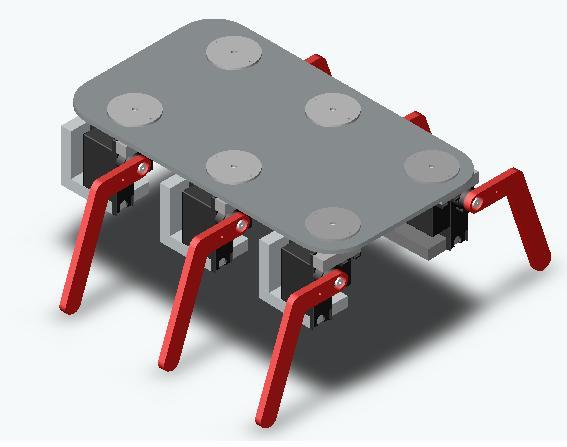

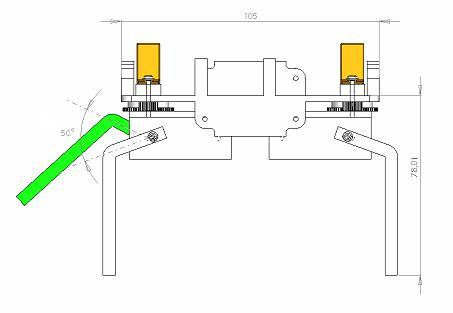

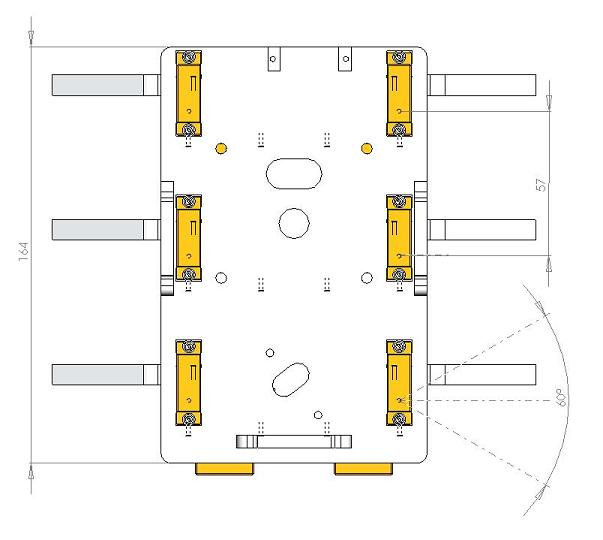

The design of its structure went through several

revisions but was always based on similar concepts:

1. each leg should have two degrees of freedom, and

2. the servomotors used should also play a

structural function, minimizing the overall size of

the hexapod.

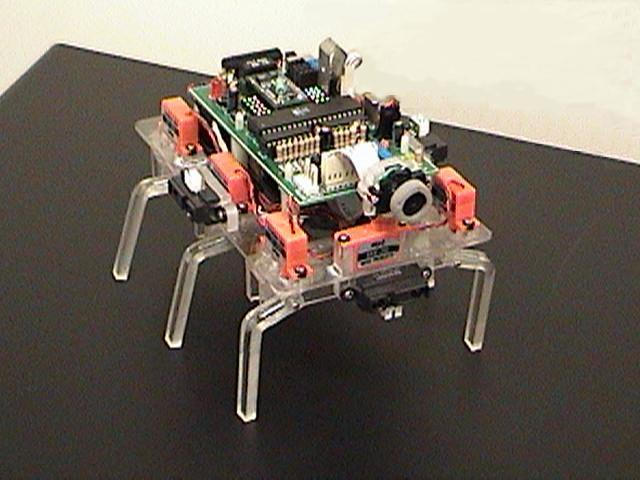

The first attempt achieved the simplicity and

compactness but the motors were inadequate for the

load that the robot required. A photo of the early

design can be seen below next to the model in Solid

works.

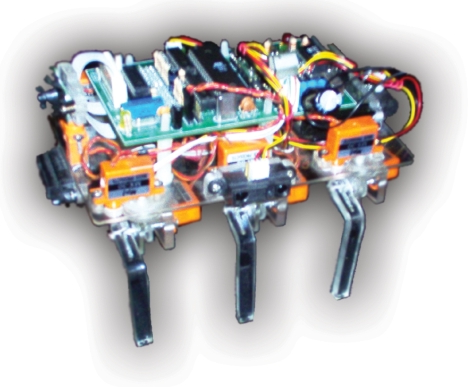

Despite having a fairly simple and compact design,

the motors had a lot of problems maintaining the

standing position, and it was noted that most of the

range of motion of each servo was being wasted

because each articulation of the leg did not move

the 180 degrees which is roughly the range of motion

of the servo. Gears were used to provide more force

in each leg while maintaining an acceptable range of

motion.

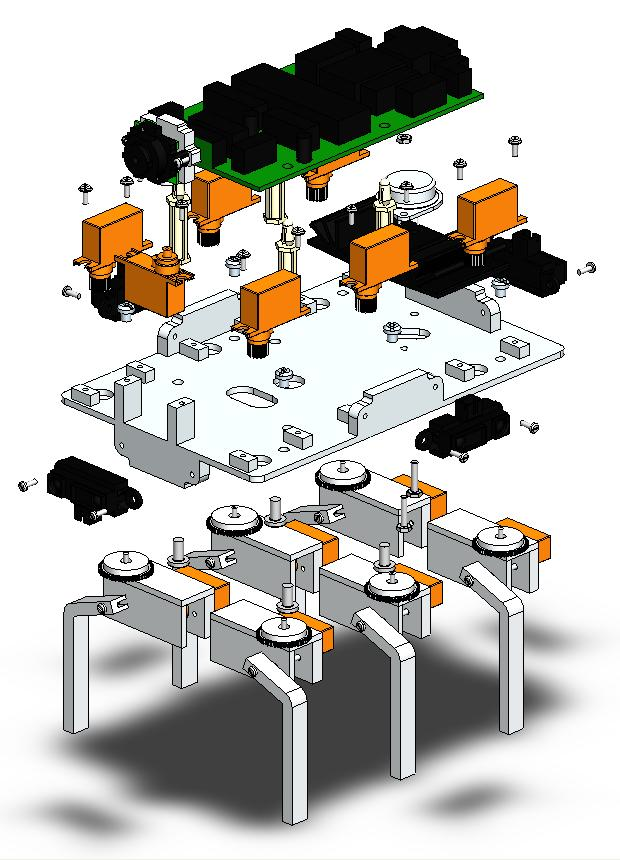

This new version was completed according to those

objectives chosen. An explosion view of the final

assembly can be seen below.

Progress

- Project Proposal

- 2D and 3D Model

- Laser Cut

- Circuit Making - FabISP

- 3D Scanning and Printing

- Electronics design

- Make Something Big

- Embedded Programming

- Molding and Casting

- Input Devices

- Composites

- Output Devices

- Networking

- Mechanical Design

- Interface

- Applications

- Invention

- Project Development

- Project Presentation

Alvaro J. Rojas Arciniegas, PhD

Assistant Professor Department of Automatics and Electronics - UAO

+57 (2) 318-8000 ext. 11384