1. Principles and practices¶

This week we had two tasks: 1) learn documentation and 2) plan and sketch a potential final project. This document is for sketcing a potential final project

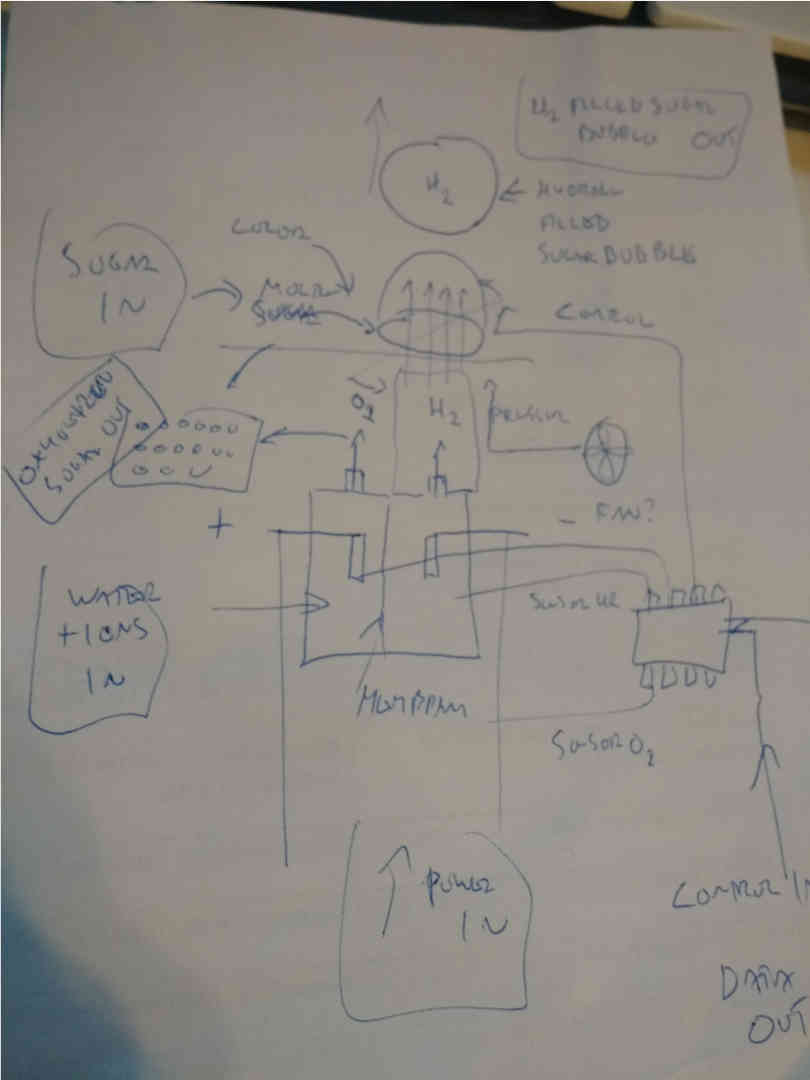

My potential final project is to break water to hydrogen and oxygen. At the first phase, my idea was to create hydrogen and perhaps make hydrogen-filled sugar bubbles. Howerver, my imnstructors told me, that just making hydrogen is enough. There were also security concerns, and I got instructions to do electrolysis only outside the building. Here is the initial description of my original idea and the research and links to support it.

Research¶

Hydrogen is the lightest of all the gases. It is used for its lift generating properties in balloons. Liquid hydrogen has a very good specific impulse and it would be ideal for rocket engines. However, it would require very large and therefore heavy tanks. Keeping the hydrogen in liquid state is also problematic because of its very low boiling temperature of −252,9 °C in the normal pressure. However, hydrogen is an ideal gas for burning, because the resulting waste is more or less pure water, depending on the impurities. The water itself is a very potent greenhouse gas, but the amount of water in the atmosphere is naturally regulated.

Ways of creating hydrogen¶

Hydrogen is seen as the best possible fuel alternative for cars. It has a potential to become even more environment friendly than electricity. The easiest way to create hydrogen is electrolysis of water. However, there are lot of chemical reactions producing hydrogen as well. During the World War 2 there were a lot of cars converted to woodgas. Heating dry wood to the right temperature results breaking up of the structure of the wood. Because of the moisture reducing to hydrogen in the high temperature coal layer the resulting burning gas has 20% hydrogen content. Hydrogen can also be produced by adding Group 1 and Group 2 metals to water.

Storage of hydrogen¶

Hydrogen is usually stored in gas containers in 150 bar pressure. The pressure is high compared to LPG tanks 8 bar pressure. There is no comparable safe and cheap low pressure storing technology available for the consumers yet.

Electrolysis of Water¶

Because the sun is not readily available here in the north for breaking the water by using the directed sun beam breaking method, the easiest and probably safest idea for producing hydrogen is by electrolysis. Electrolysis is the electrochimical breaking of the water by directing at least over 1.23V potential difference over water. The optimal potential difference, current, electrolyte materials, catalytic materials and additives required must be considered.

Proposed idea for the final project¶

The idea for the final project would be creating an electrolytic hydrogen bubble foam generator. The secondary objective, if viable, would be making the generator modular, so that small units could be combined in order to produce larger quantities of hydrogen. If modular design is not necessary, it would make the project a lot easier.

The combined units would share water lines, power lines and oxygen and hydrogen foam lines. The primary reason for producing the hydrogen foam would be trying to generate lift by storing foam in very lightweight net. The future expansion for the idea would be adding the net waving device in the foam generator array for generating lift.

Bubble foam¶

The hydrogen is produced in foam form, like the foam forming when washing the dishes. The foam behaves more like liquid. It still burns and perhaps even explodes, depending on the type of the foam. The soap would be the easiest alternative, but I believe there are some more interesting alternatives also forming foam available to experiment. There are also ways to remove hydrogen from the foam, if pure hydrogen gas is required for the application.

The interesting thing in bubbles is that the pressure inside small bubbles is actually higher than in larger bubbles. So, if the right liquid is selected, the bubble size kept small enough, it might actually be possible to increase the energy density of the foam considerably.

Mechanical design¶

The mechanical desing part of the project would include designing the modular but safe container for the process. This is quite tricky, because there are two power lines, hydrogen and oxygen(?) foam lines, water for both electrolysis and foam formation and line for foam producing material. If modular desing is implemented there are lot of things to consider. For example, if hot swapping is possible to implement?

Electronics design¶

The electrical designg part of the project would be making the system for monitoring the effectiveness and safety of the electrolysis process. If modular design is implemented, this means that there should be a common wired or wireless bus for for monitoring and controlling the process. For example, any overvoltage over 1.23V needed for breaking the bonds in water is waste. There also should be some kind of fuse design in case there is malfunction or extra power drain in a single module. There should be visible signals showing the status of the electrolyse process. I wonder if there are suitable sensors available for monitoring oxygen and hydrogen content?

Software design¶

Every module should have a controller running for management software for and there should be a way to turn a single unit on or off. The total amount of gas produced should be monitored. If the process fails, there should be clear and visible signal. The water level should be monitored. If there are sensors available, the amount of gases produced should be monitoried. The remote control software can control and monitor the status of the modules.

Safety considerations¶

Because of the modular desing, the amount of hydrogen foam produced in a single generator would be small and therefore it should not pose a threat for anyone working in the lab. The amount of free hydrogen gas inside the device before foam production should be minimized, perhaps by adding an food grade oil layer over the electrolytic chamber. Also, the mixing of pure oxygen and hydrogen is not allowed to happen in this design. The mixture (HHO) is explosive by itself. Note that HHO behaves differently, more violently than clear hydrogen, as shown in the linked videos below.

In production mode the process should be ran only if commanded. There must be a way to turn electrolysis off even if the device is powered.

A Crazy idea to consider¶

The autoignition point of hydrogen gas is 585°C and ~570°C for HHO. Regular sugar melts at 186°C, so there is quite wide marigin, where the sugar is liquid but where the hydrogen won’t ignite. So, in theory it is possible to make really large sugar bubbles filled with hydrogen or oxygen for storing the gas? Hydrogen bubbles would probably float too.

The autoignition point of hydrogen gas is 585°C and ~570°C for HHO. Regular sugar melts at 186°C, so there is quite wide marigin, where the sugar is liquid but where the hydrogen won’t ignite. So, in theory it is possible to make really large sugar bubbles filled with hydrogen or oxygen for storing the gas? Hydrogen bubbles would probably float too.

Sugar is available basically everywhere. Depending of the surface tension and if the hydrogen gas has time to warm up, the energy density of frozen sugar bar filled with really small hydrogen bubbles might be worth testing. I couldn’t easily find the surface tension of molten sugar for pressure calculations, but it seems to be able to form very large bubbles.

Helium filled candy balloons do exist. Perhaps the generator could make very large floating sugar bubbles filled with hydrogen or low tech power bars filled with closed small bubbles of hydrogen or oxygen? If there is enough uplift, the machine could create floating, perhaps even colored, maybe fluorecent hydrogen filled sugar bubbles out of water and sugar. It would be just totally awesome!

Pulled Sugar¶

There is a form of sugar called pulled sugar. There is a good video made by Victorian Institute of Technology VIT Open Learning, how to make pulled sugar, which seems easy to follow.

The basic recipe for making pulled sugar seems to be 1 kg sugar + 400 grams of water + 2.5 grams of Cream of Tartar (potassium bitartrate). These should be heated in a stainless steel pot, aluminium can’t be used. Water must be added to the middle carefully in order to avoid splattering the sugar at sides.It must not be stirred in order to avoid crystallization.

The target temperature for heating is 160°C. Silpat mat can be used under the sugar. A Ceramic heat lamp keeps the sugar hot.

Pulled sugar seems to be the form of sugar that is used in making structures, like sugar domes and decorative objects like flowers. There are also other recipes, including for example corn syrup. These may produce more fluid materials. Isomalt is also used.

“Unpoppable” bubbles¶

There is a video about Making Bubbles that are Unpoppable. Corn syrup is added to soap water in order to create more durable soap bubbles. Glycerin is also used for the same purpose.

On week four we experienced with laser cutter and vinyl cutter. It might be possible to use laser cutter in order to create the electrolysis box instead of 3D printing. I also have an idea to use perforated two-sided and tin plated circuit boards as electrodes. The electrodes would be cheap to manufacture by traditional circuit-board manufacturing techniques. If done periodically, tin (or whatever they use in soldering today) layer in the circuit boards could be renewed by applying the soldering paste and dipping the circuit boards to molten soldering tin. The distance and current flow between electrodes could be adjusted to optimal by perforation size and distance between hole edges and copper.

Summary¶

- There should be + and - power lines for the cell.

- There should be common wired or wireless data bus for control and monitoring data. -There should be physical conducts at least for hydrogen bubble foam, oxygen (bubble foam), water for electrolysis, foam material and if needed, water for foam material.

- Embedded sofware is required for controlling the electrolysis.

- Control software is required for monitoring / controlling the array.

- Selection of the bubble forming material is a very interesting subject. A lot of very small bubbles with very high surface tension could perhaps mean high energy density for the foam. On the other hand, large bubbles with as low as possible density would probably have the best upthrust.

- Pulled sugar would be a really interesting choice. There are also other less durable bubble options.

Videos¶

- Helium filled candy balloons

- Hydrogen Bubbles.

- Exploding Hydrogen Bubbles.

- DIY Hydrogen/Oxygen Generators From Grocery Store Items.

- HHO 49 plates Hydrogen Generator.

- Making a Simple HHO Generator under 5$.

- Wire HHO. Hydrogen Generator 316L Wire. Fuel from Water.

- How to Make Pulled Sugar | Cook With VIT.

- Making Bubbles that are Unpoppable. Make your own unpoppable bubbles