16. Applications and implications¶

WEEK 16¶

This week’s assignments are:

- Propose a final project masterpiece that integrates the range of units covered, answering:

What will it do? Who’s done what beforehand? What will you design? What materials and components will be used? Where will come from? How much will they cost? What parts and systems will be made? What processes will be used? What questions need to be answered? How will it be evaluated? - Your project should incorporate 2D and 3D design, additive and subtractive fabrication processes, electronics design and production, embedded microcontroller interfacing and programming system integration and packaging

- Where possible, you should make rather than buy the parts of your project

- Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable

WHAT WILL IT DO?¶

The Table should be able to raise and lower its height upto 1100mm with a press of a button in order to accomodate the est comfortable height for the user…

Who’s done what beforehand?¶

Such a product is available in the market but is on the premium price range by bigger companies like Hafele so my idea is to try to make it as efficiently and make it into a DIY kit

This product comes in both manual and electric motor driven mechanisms

What will you design?¶

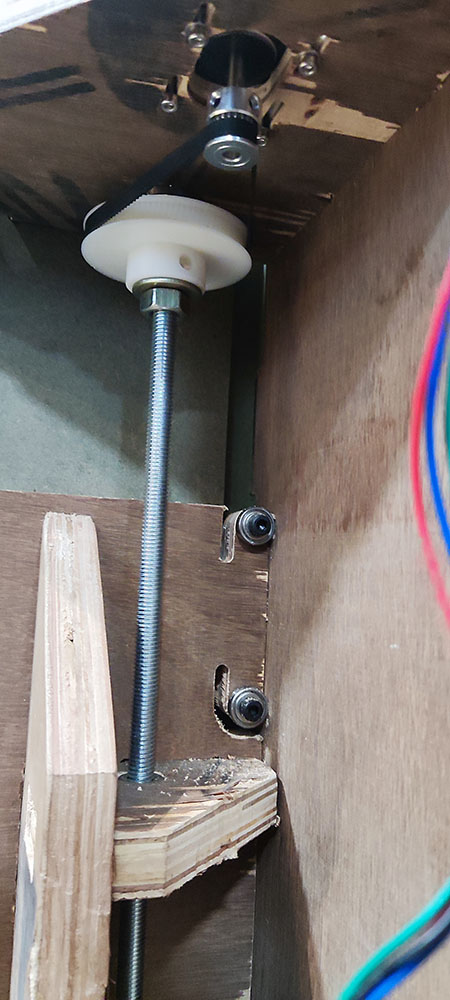

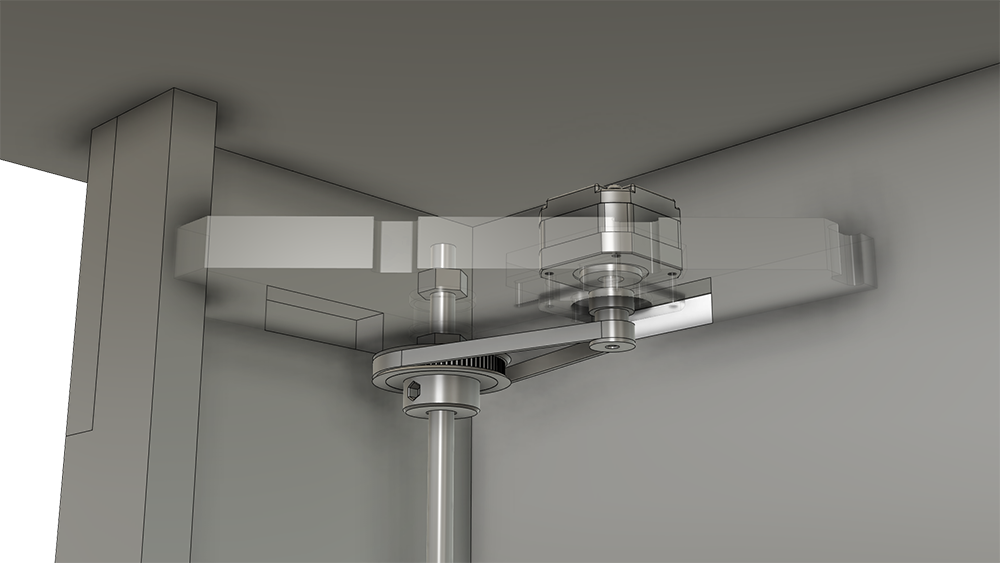

I have designed the table and I’m working on the mechanical design in order to actuate and be able to lift the weight using gear reduction pulleys

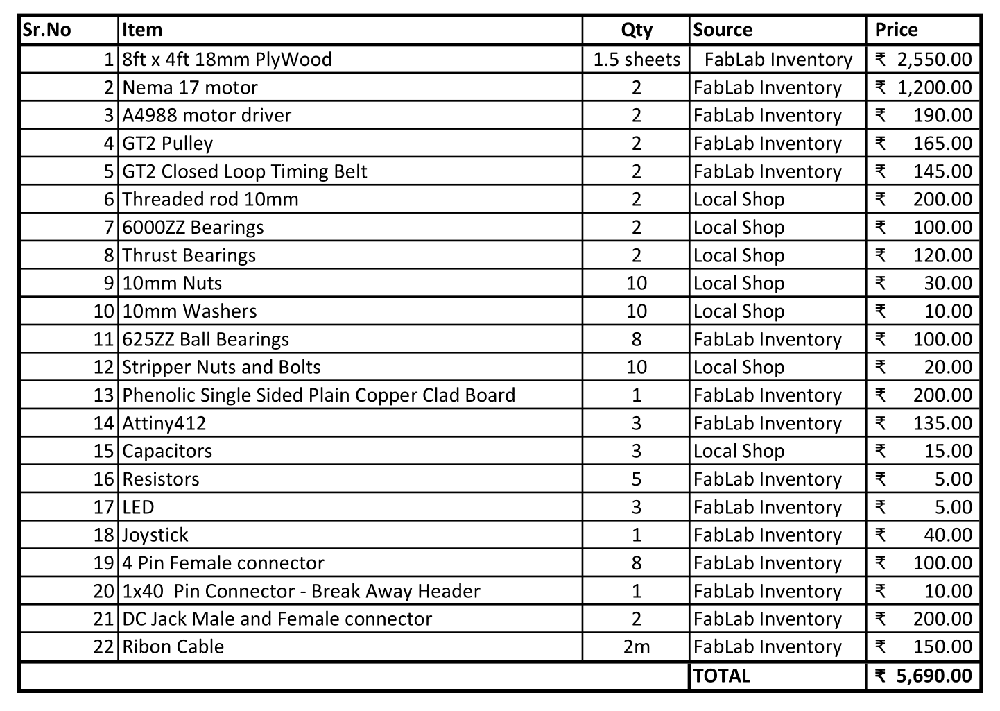

What materials and components will be used? How much will they cost?¶

As of now the main table parts will be made of plywood and use 2 stepper motors Nema 17 with a lead screw to raise and lower the height

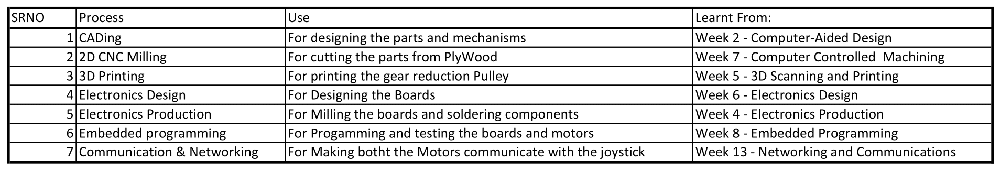

What processes will be used? What parts and systems will be made?¶

For making the table’s parts I am going to use the ShopBot for cutting the plywood, use the Roland MODELA MX-20 for milling the boards and if necessary use the Prusa 3D printer for making small parts for housing the motor. We can make all the necessary parts here at FabLab

What questions need to be answered?¶

One of the main question that came up was will the motor have enough torque to lift the weight of the table and so we used gear reduction in order to increase the torque but then the table was lifting much slower than it should have

Another question that came up was if the ball bearings would take this load and so we used thrust bearings so that we could use the whole surface for spreading the weight and use the bottom for acuating

<== Before====================================After==>

Thrust Bearing

Thrust Bearing

How will it be evaluated?¶

This project should be evaluated on the basis of the success rate in the actuation we have created for lifting and lowering the table using the NEMA17