18. Wildcard week¶

Research 1: Production of a composite¶

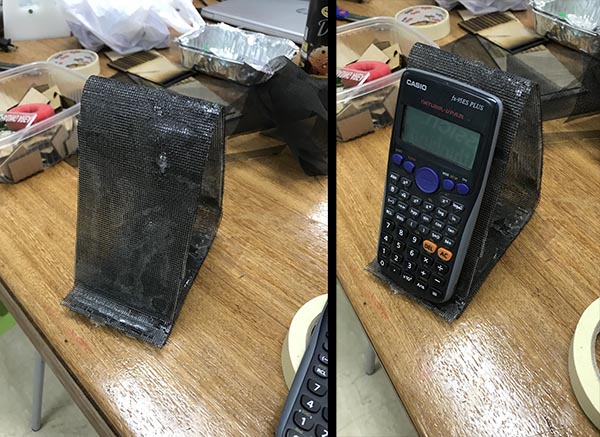

It was done by using Resisn with the adding of Raschel mesh that gives flexibility to the composite.

I am going to prepare a composite made of fiber Raschel messh with Resin

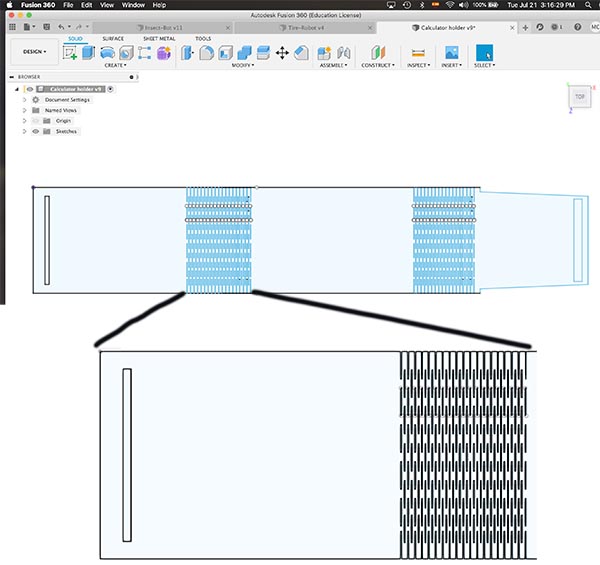

I start designing the calculator holder in Fusion 360. I use lines with small distance in between to make them movable. It is done to hold the Raschel mesh and the have the shape of it.

Once i finished i cut it in the laser cutter Boss Laser LS 1630

Cutting in laser the Calculator Holder as a mold from Manuel Corrales Arana on Vimeo.

Then i assemble the calculator model.

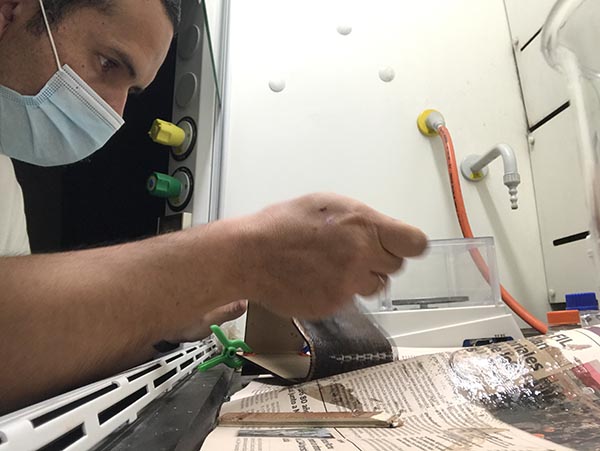

I need to use vaseline to facilitate the take of the composite from my mold.

I covered the mdf model with vaseline.

I use the Fume Hood of my School to cover the Raschel mesh with Resin to form the composite. According to the indications of the fabricant, i used 40 drops per 100g of resin. I dilute the catalizer and use inmediately before it start solidifying.

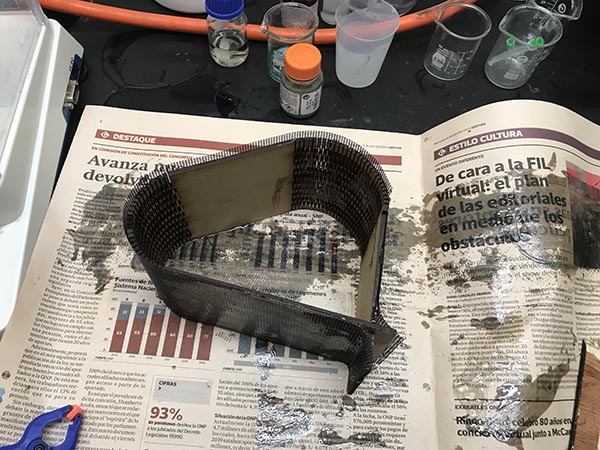

Here i left to dry for 24 hours. At the beginning it was a little sticky but then is starts drying after 20 minutes aproximately.

In the first trial the pores of the Raschel mess are too wide so the resin doesn´t cover it well.

I solve it by using two layers of Raschel mesh and repeat the process. I works better.

This assignment was a little difficult since i need to figure out what to do. I did it twice because in the first trial the resin sticks too much to the MDF mold so it turned dificult to take it out. Then i added more vaseline and it worked.