Invention, Intellectual Property, and Income

The assignment for this week is to develop a plan for dissemination of our final project, prepare drafts of our summary slide and a video clip and put them in our root directory.

At the beginning of the week I mainly worked on the motorization of my X axis.

I noticed that the motor was making quiet a lot of noise and tried to understand why.

I tried with with a different power supply and with a different stepper motor (NEMA17 instead of NEMA14).

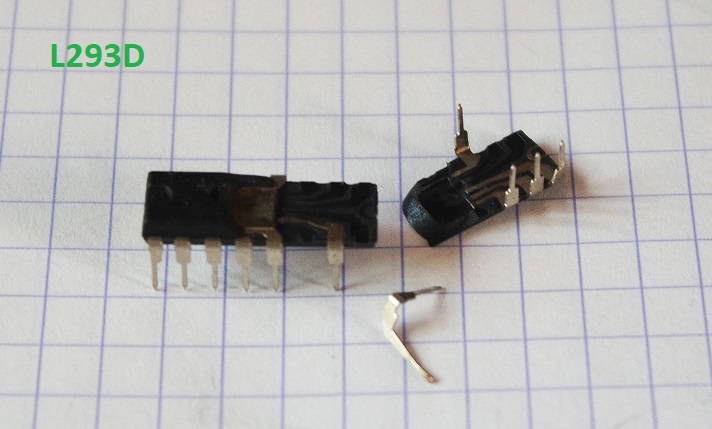

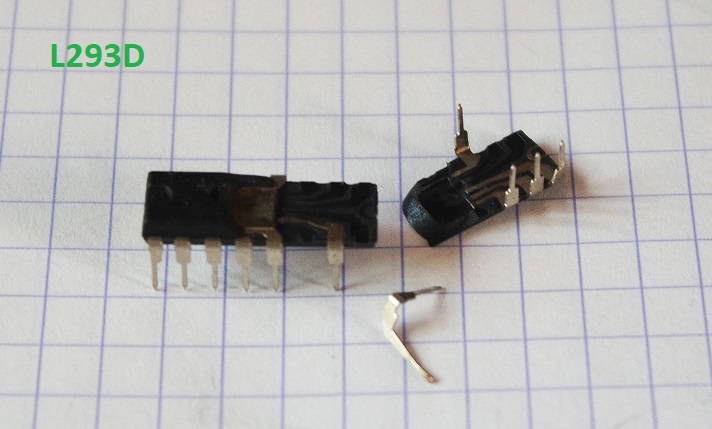

Probably because I was in a hurry and because I was too confident, I made a mistake in my wireing which resulted in a short circuit that distroyed my L293D H-bridge.

It made a big noise and the l293D just broke in two parts. Very impressive!

As I had no L293D replacing part (being at home for the week-end when it happened) I used a A4988 stepper driver instead.

Here is the datasheet for the A4988.

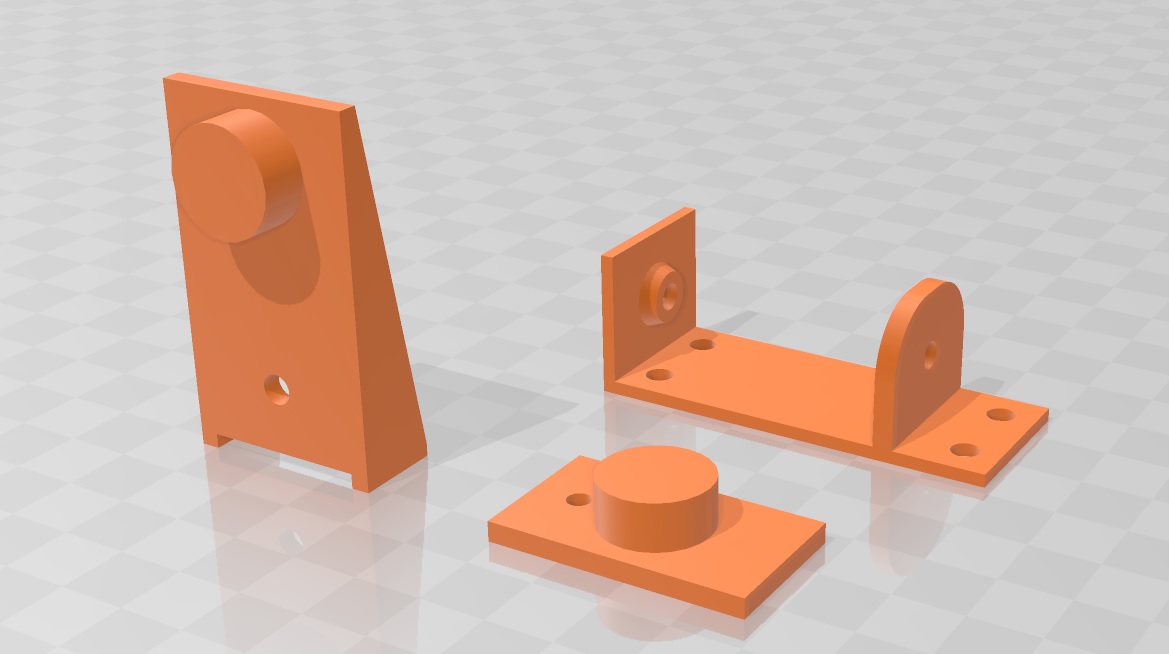

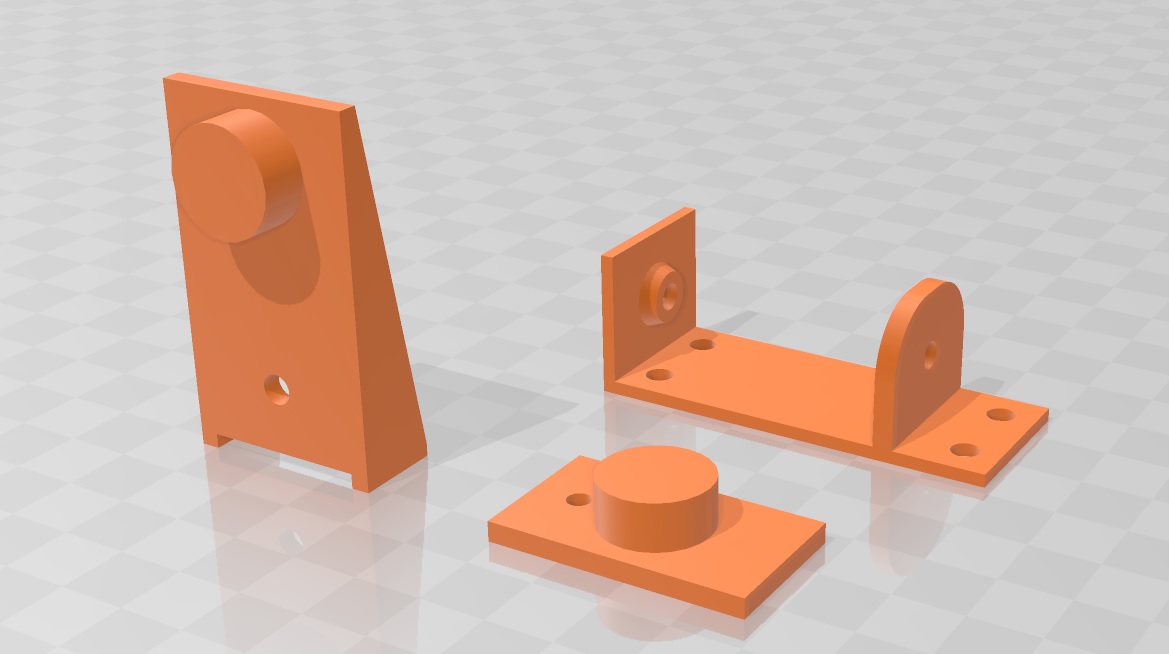

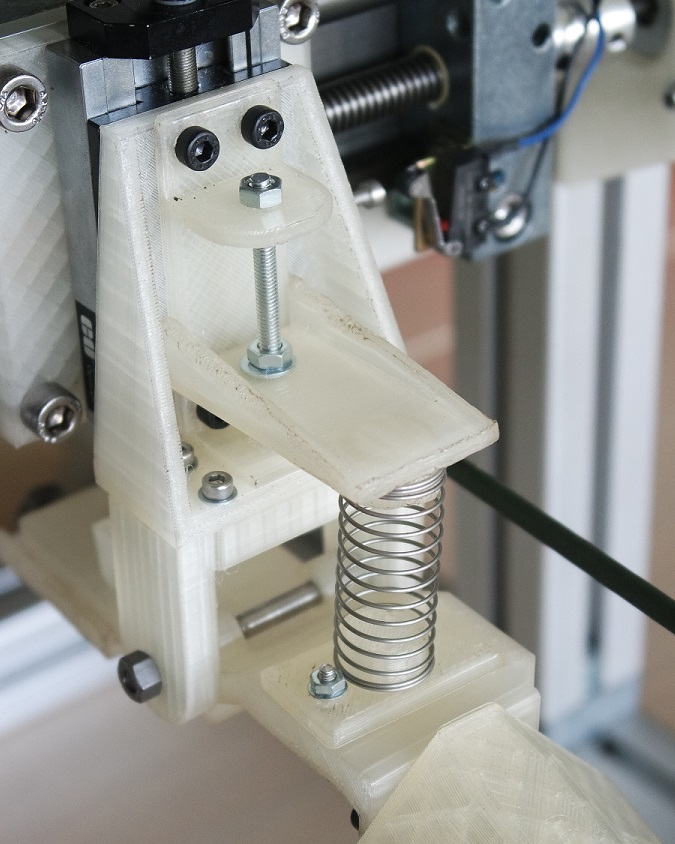

I also designed a stylus pressure fine tuning system that uses a spring and 3D printed it:

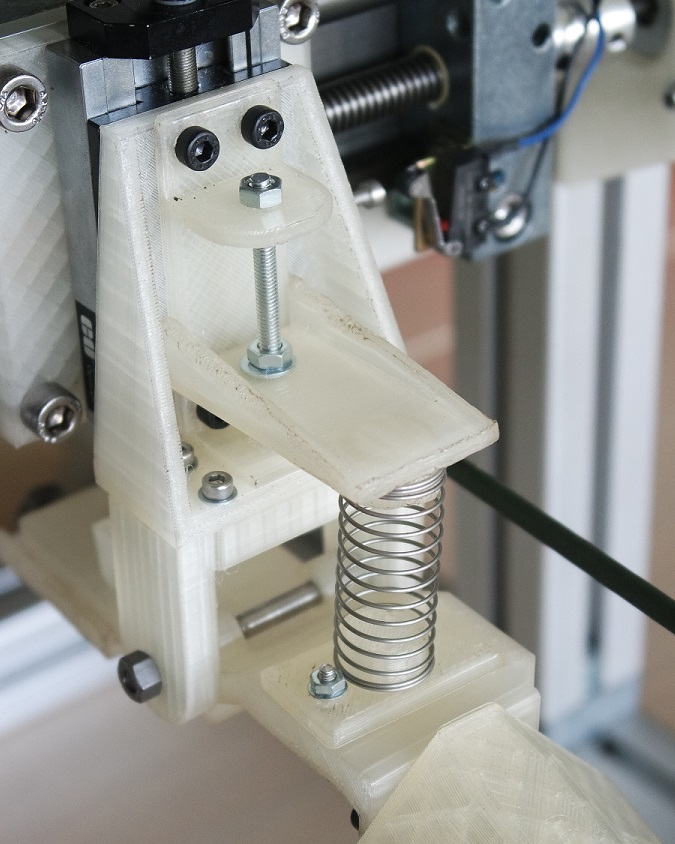

And here it is mounted between the arm holder and the arm:

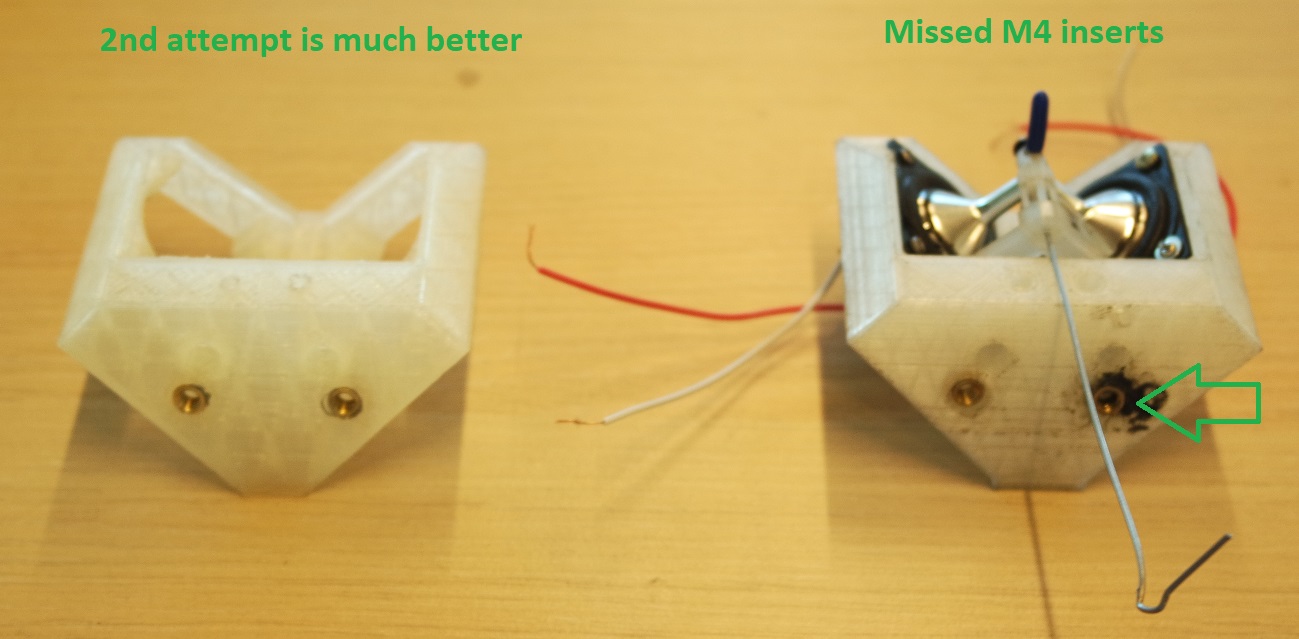

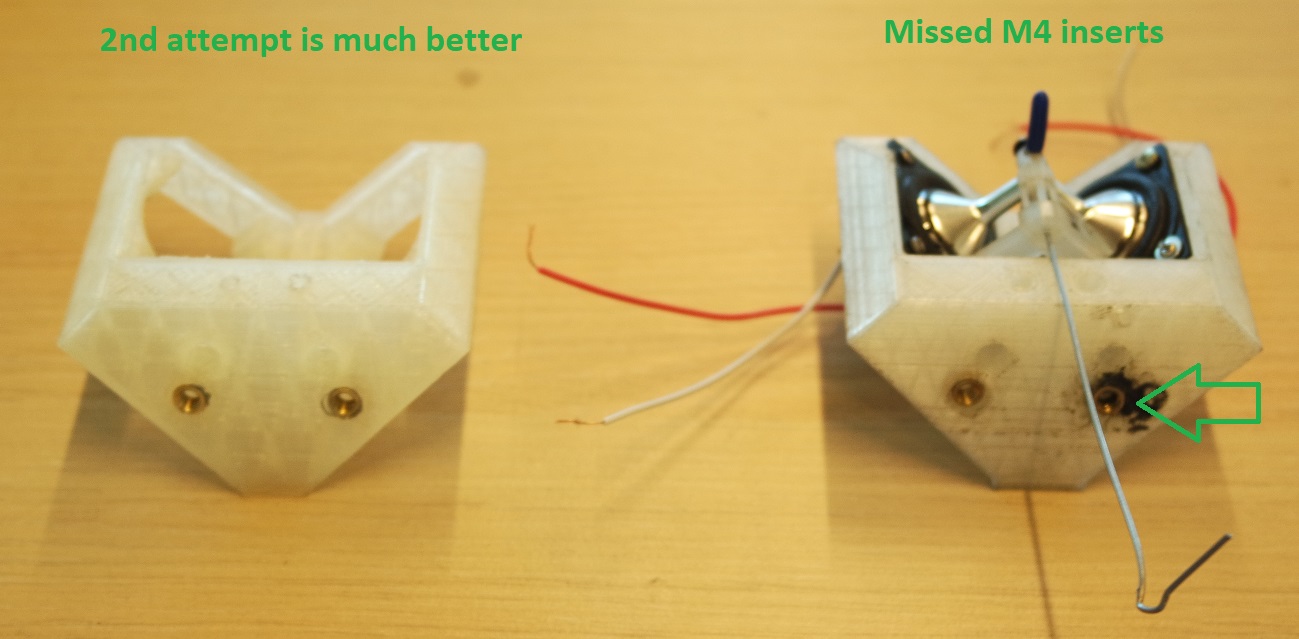

And I also needed to print the main part of my engraving head again because when I made the 1st one I missed the position of one of the two M4 inserts at the back of it.

Here are the 1st and 2nd one showing the M4 inserts:

But the demand seems to be here, so I guess a machine like this could probably find its public.

1) It could be sold along with a formation on how to use it, and could also generate future incomes from selling spare parts and consumables.

2) All the necessary parts could also be sold as a DIY kit for those who would like to learn on building it. Once again selling spare parts could also generate future incomes.

3) It also could be used in a recording studio to generate incomes by engraving short runs for musicians that would like to have their music engraved on vinyls

But none of these possibilities are on my plans...

So my idea, if the machine works well, would be to publish it as the very 1st complete open-source DIY project, with complete instructions on how to build and use it, and without the intention to generate any incomes.

If I decide to go this route, I intend to publish it with a Creative Commons Attribution-ShareAlike 4.0 International License:

So all in all I lost some precious time before being able to produce a video clip...

I produced my draft video clip on wednesday morning before the review in a hurry. I used OpenShot Video Editor to produce it.

Here is the link to my draft embedded video page.

At the beginning of the week I mainly worked on the motorization of my X axis.

I noticed that the motor was making quiet a lot of noise and tried to understand why.

I tried with with a different power supply and with a different stepper motor (NEMA17 instead of NEMA14).

Probably because I was in a hurry and because I was too confident, I made a mistake in my wireing which resulted in a short circuit that distroyed my L293D H-bridge.

It made a big noise and the l293D just broke in two parts. Very impressive!

As I had no L293D replacing part (being at home for the week-end when it happened) I used a A4988 stepper driver instead.

Here is the datasheet for the A4988.

I also designed a stylus pressure fine tuning system that uses a spring and 3D printed it:

And here it is mounted between the arm holder and the arm:

And I also needed to print the main part of my engraving head again because when I made the 1st one I missed the position of one of the two M4 inserts at the back of it.

Here are the 1st and 2nd one showing the M4 inserts:

Final project dissemination plan

Vinyl Record Cutting Lathes are very expensive machines, even when they are old second-hand and incomplete machines because they are hard to find, and I couldn't find any open-source projects that have been completed.But the demand seems to be here, so I guess a machine like this could probably find its public.

Possible incomes

Such a machine could generate incomes in several ways:1) It could be sold along with a formation on how to use it, and could also generate future incomes from selling spare parts and consumables.

2) All the necessary parts could also be sold as a DIY kit for those who would like to learn on building it. Once again selling spare parts could also generate future incomes.

3) It also could be used in a recording studio to generate incomes by engraving short runs for musicians that would like to have their music engraved on vinyls

But none of these possibilities are on my plans...

Going open-source

As I previously mentioned, I haven't been able to find any complete open-source DIY projects.So my idea, if the machine works well, would be to publish it as the very 1st complete open-source DIY project, with complete instructions on how to build and use it, and without the intention to generate any incomes.

If I decide to go this route, I intend to publish it with a Creative Commons Attribution-ShareAlike 4.0 International License:

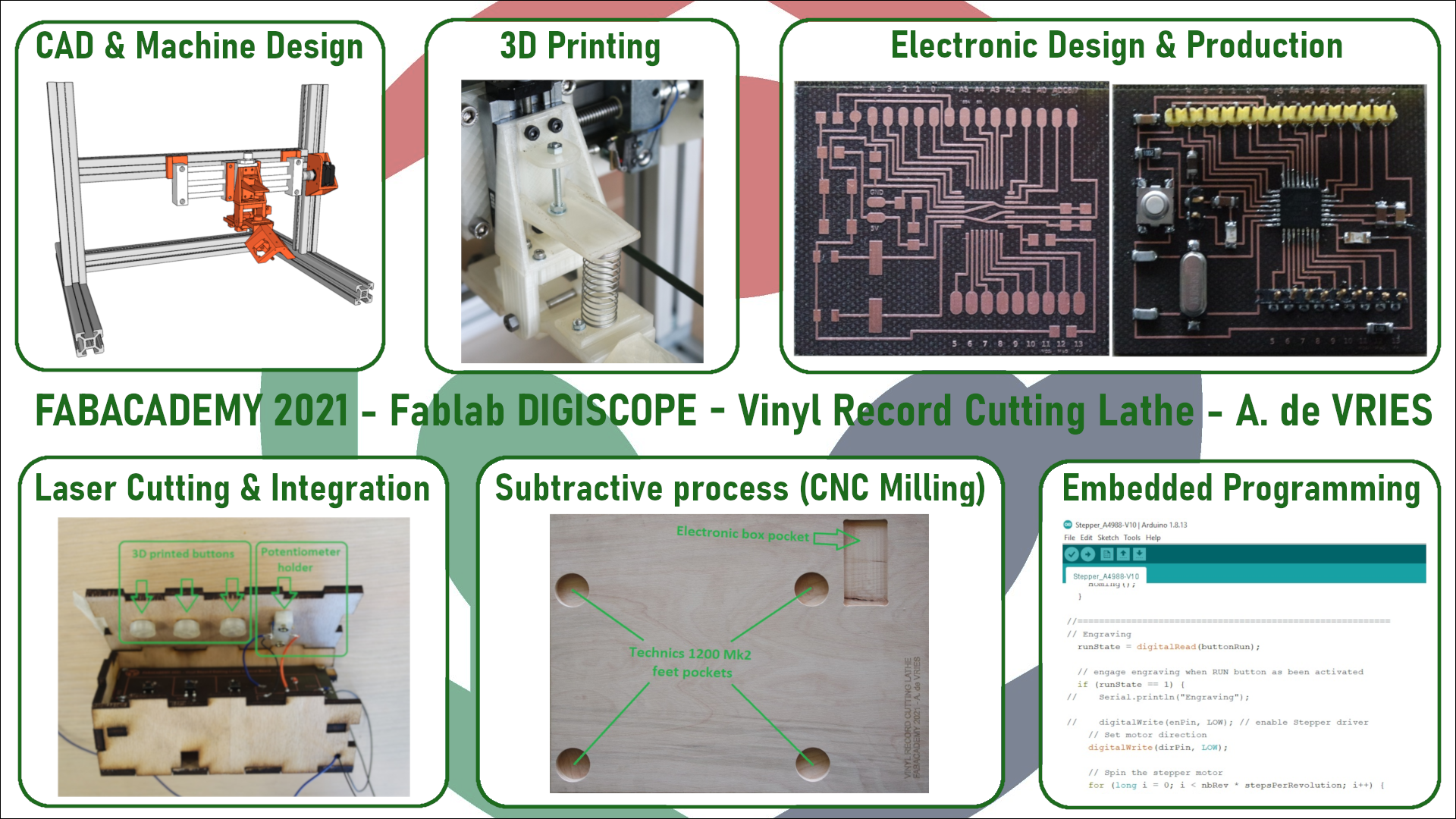

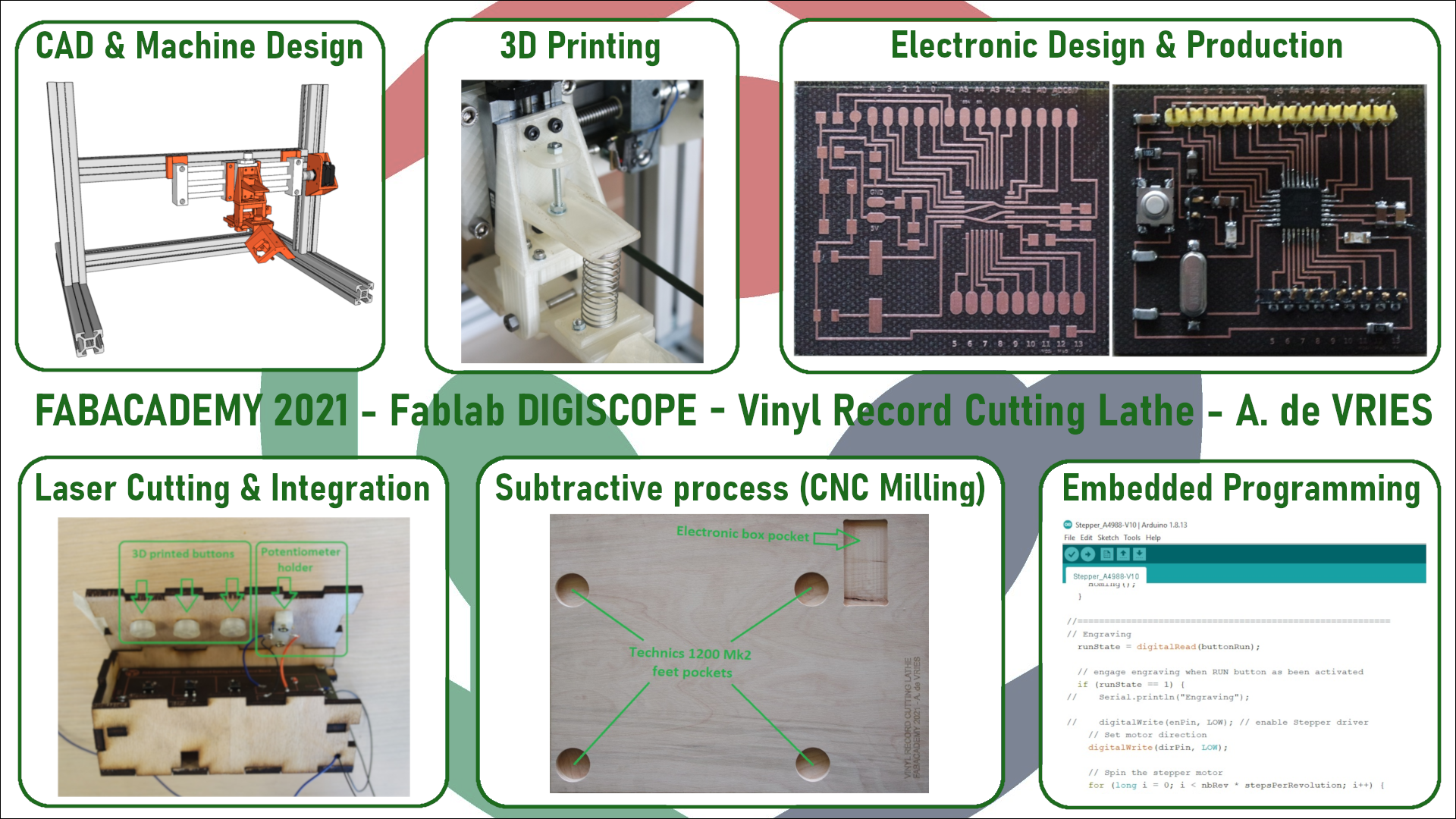

Summary slide

Here is the draft summary slide for my final project:

Video clip

Unfortunately I didn't shoot any video when I assembled my machine so I had to completely disassemble it to be able to shoot it back.So all in all I lost some precious time before being able to produce a video clip...

I produced my draft video clip on wednesday morning before the review in a hurry. I used OpenShot Video Editor to produce it.

Here is the link to my draft embedded video page.