03. computer-controlled cutting¶

Class Week 03¶

Lesson03 computer-controlled cutting

Review02 computer-aided design

Recitation02: projects

Laser Cutting¶

Assignment¶

GROUP ASSIGNMENT - Characterize your lasercutter, making lasercutter test part(s), making test part(s) that vary cutting settings and dimensions(group project)

INDIVIDUAL ASSIGNMENT - Cut something on the vinylcutter - Design, make, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways

Learning outcomes¶

- Demonstrate and describe parametric 2D modelling processes.

- Identify and explain processes involved in using the laser cutter.

- Develop, evaluate and construct the final prototype.

Student should have¶

- Explained how you parametrically designed your files.

- Shown how you made your press-fit kit.

- Included your design files and photos of your finished project.

Vinyl Cutting

There is no specific project that is focussed on this very useful tool. There are a range of ways you might utilise it throughout the programme, or your local instructor may set a specific project. You might make:

- stickers

- flexible circuit boards

- a textured surface/relief pattern

- screenprint resists/stencils

Ensure that you have used it in some way during this time and met the objectives below.

Learning outcomes¶

- Identify and explain processes involved in using this machine.

- Design and create the final object.

Student should have¶

- Explained how you drew your files.

- Shown how you made your vinyl project

- Included your design files and photos of your finished project

FAQ¶

What does ‘characterise’ mean?

- describe/understand the nature and features (of your particular laser cutter)

Can I use the Inkscape clone tool for my pressfit kit?

- No. The clone tool is not a real parametric software.

Is it compulsory to design my own file in Vinyl cutting?

- Yes. Or modify existing one, and acknowledge where you found it.

FAB LAB BCN classes¶

Computer-control Laser Overview¶

Materials¶

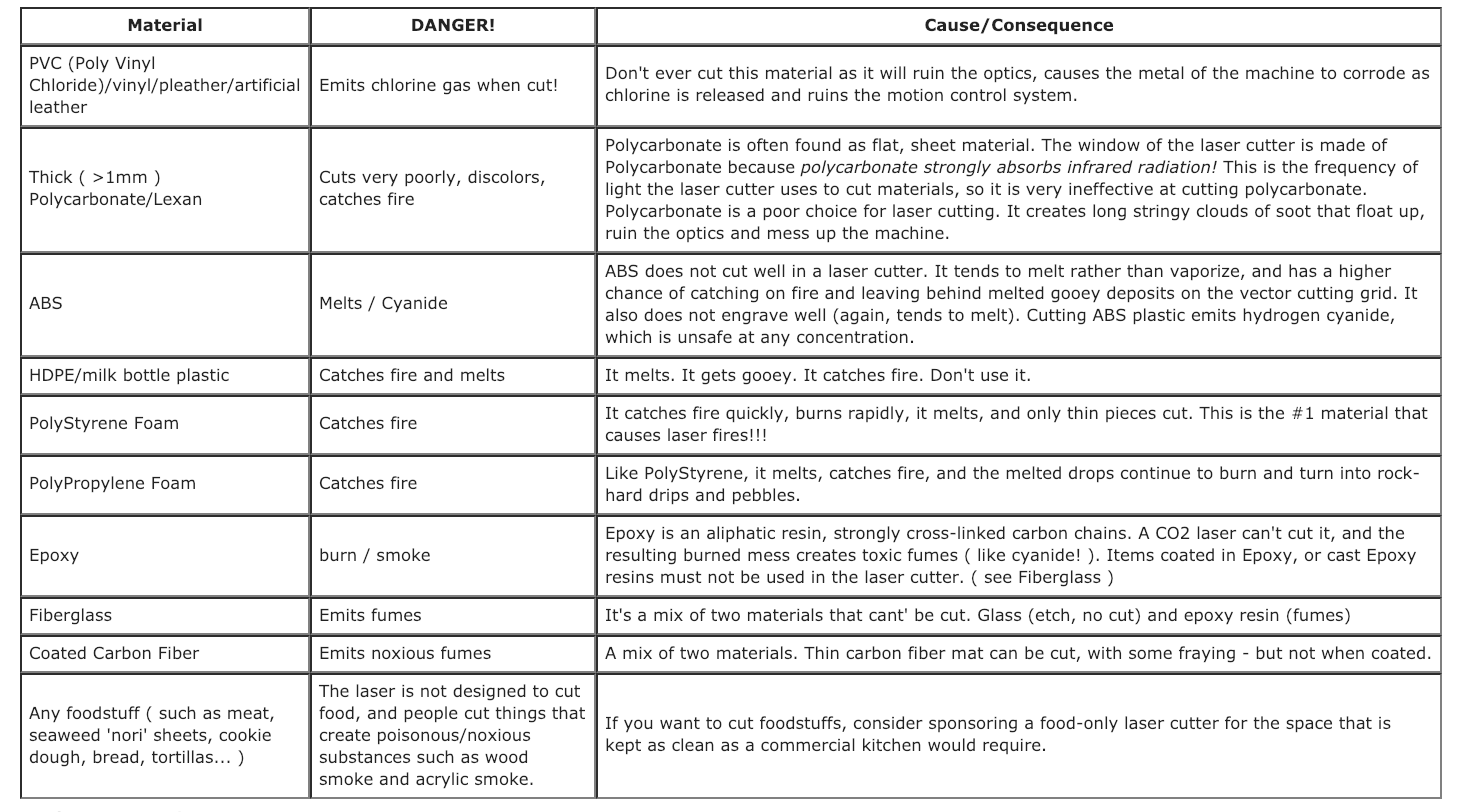

NEVER CUT THESE MATERIALS

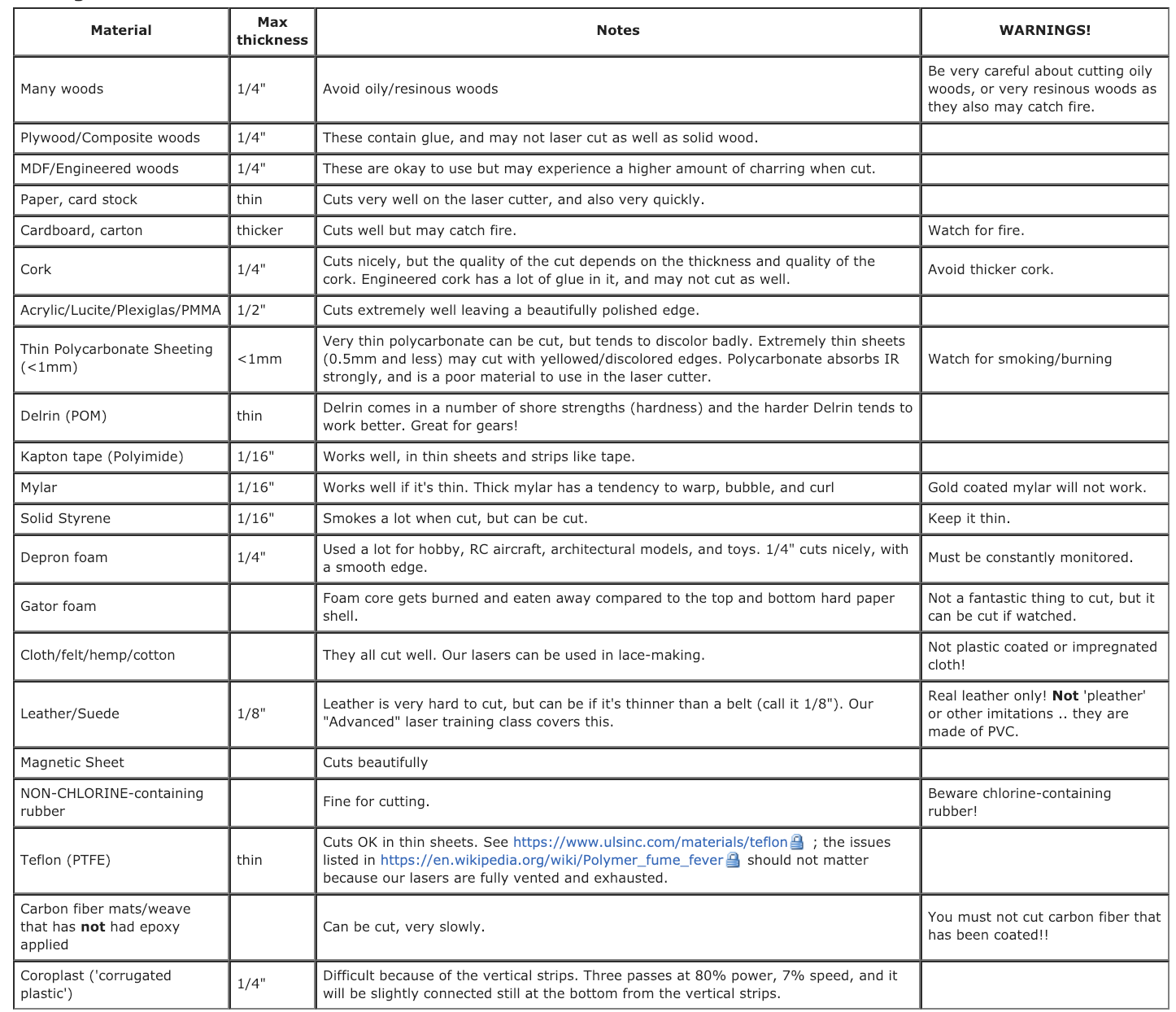

Safe Materials

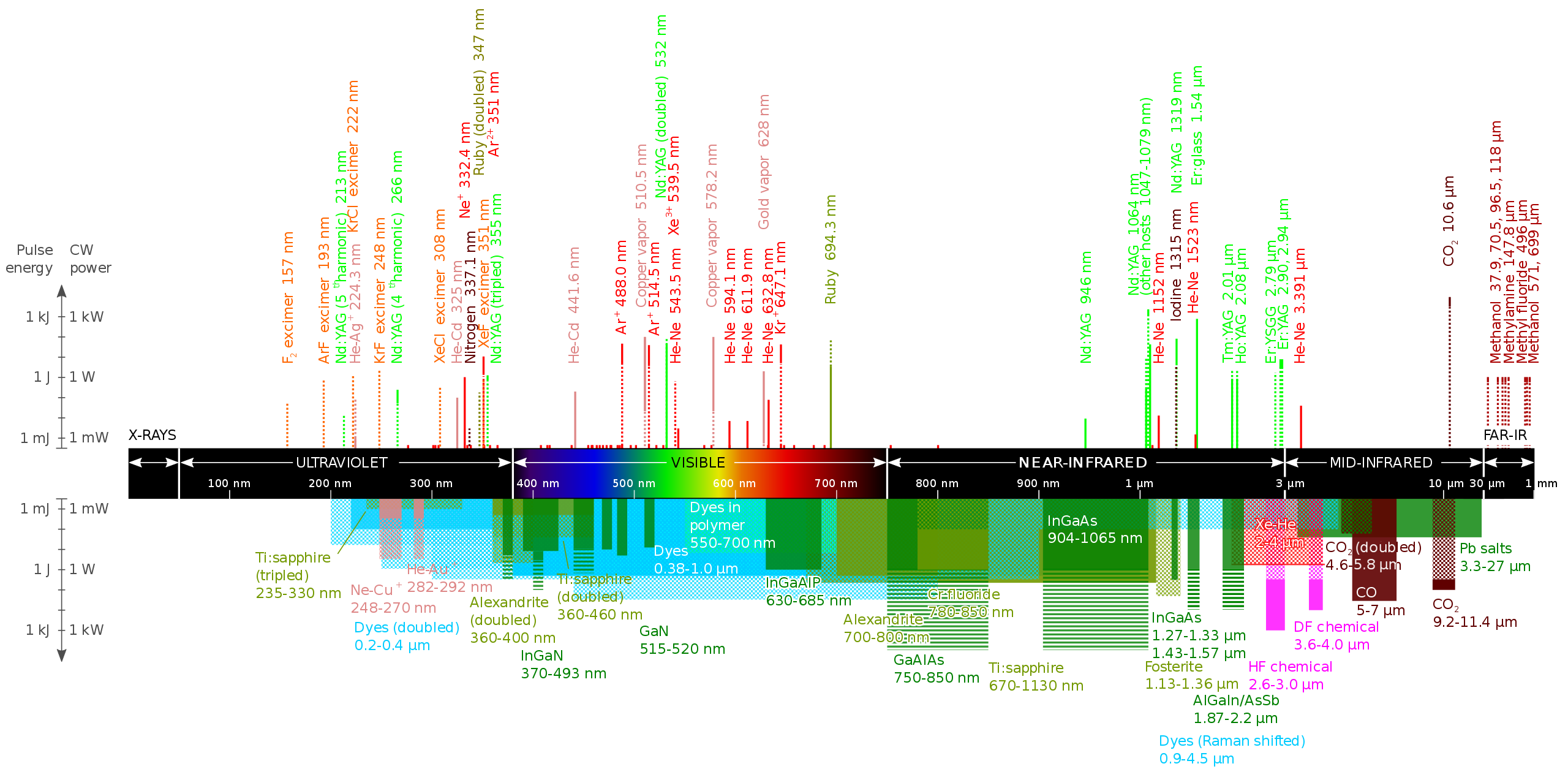

Laser types¶

Tutorials¶

Vinyl Cutter¶

- How to use a vinyl cutter

- How to use vinyl cutter for PCB - how to use SILHOUETTE CAMEO

- How to use Roland GX-24 vinyl cutter - short guide

- How to use Roland GX-24 vinyl cutter - extended guide

MULTICAM 2000 Laser Cutter (2D CAM)¶

Please, visit - FAB LAB BCN Wiki : - LASERCUT STEP BY STEP -PROTOCOL GUIDE

-

technical specifications

-

materials and configuration ( wood, playwood, cardboard… )

-

how to prepare and send files

-

how to turn on the machine

-

how to cut

-

what not to do

EnRoute Software

- Learn EnRoute: Youtube EnRoute Channel

Downloads

-

Multicam Material Settings only suggestions!!!!

Trotec Speedy 400 (2D CAM)¶

Please, visit FAB LAB BCN Wiki for:

-

technical specifications

-

materials and configuration ( wood, playwood, cardboard… )

-

CAM

-

machine workflow (how to cut)

-

commands

Spirit GE Laser Cutter¶

Spirit GE Laser Cutter - Menual

Please, visit FAB LAB BCN Wiki for:

-

technical specifications

-

materials and configuration ( wood, playwood, cardboard… )

-

CAM

-

machine workflow (how to cut)

-

commands

Resources¶

Example Documentation¶

Studnet’s documentation:

Other Resources:

- Massimo Menichinelli - Laser Cutting lecture

- HOW TO LASERCUT LIKE A BOSS

- Paper Models

- How to use a caliper

Softwares:¶

- Sketchair is a free, open-source software tool that allows anyone to easily design and build their own digitally fabricated furniture.

- Pepakura

Origami:

Multiple Tools -Machine Software

- Fabmodules

- Visicut

- inkcut

- INKCUT

- flatfab

- BoxMaker: A free tool for creating boxes using tabbed construction

- Inkscape living hinge plugin

- Inkscape SILHOUETTE CAMEO plugin

- svgnest

- deepnest

Inspirational Ideas¶

- Lasersaur, an open source laser cutter

- Monsters

- Straw Bees

- Open Source straw bees

- Rubik’s Snake

- cardboard-surfboard

- Karton

- 20-creative-cardboard-lamp-ideas

- FAB MIT

- Thingiverse

- Laser origami

- Press-fit construction

- Flat Fab

- Obrary

- Paper Sculptures