Final Project

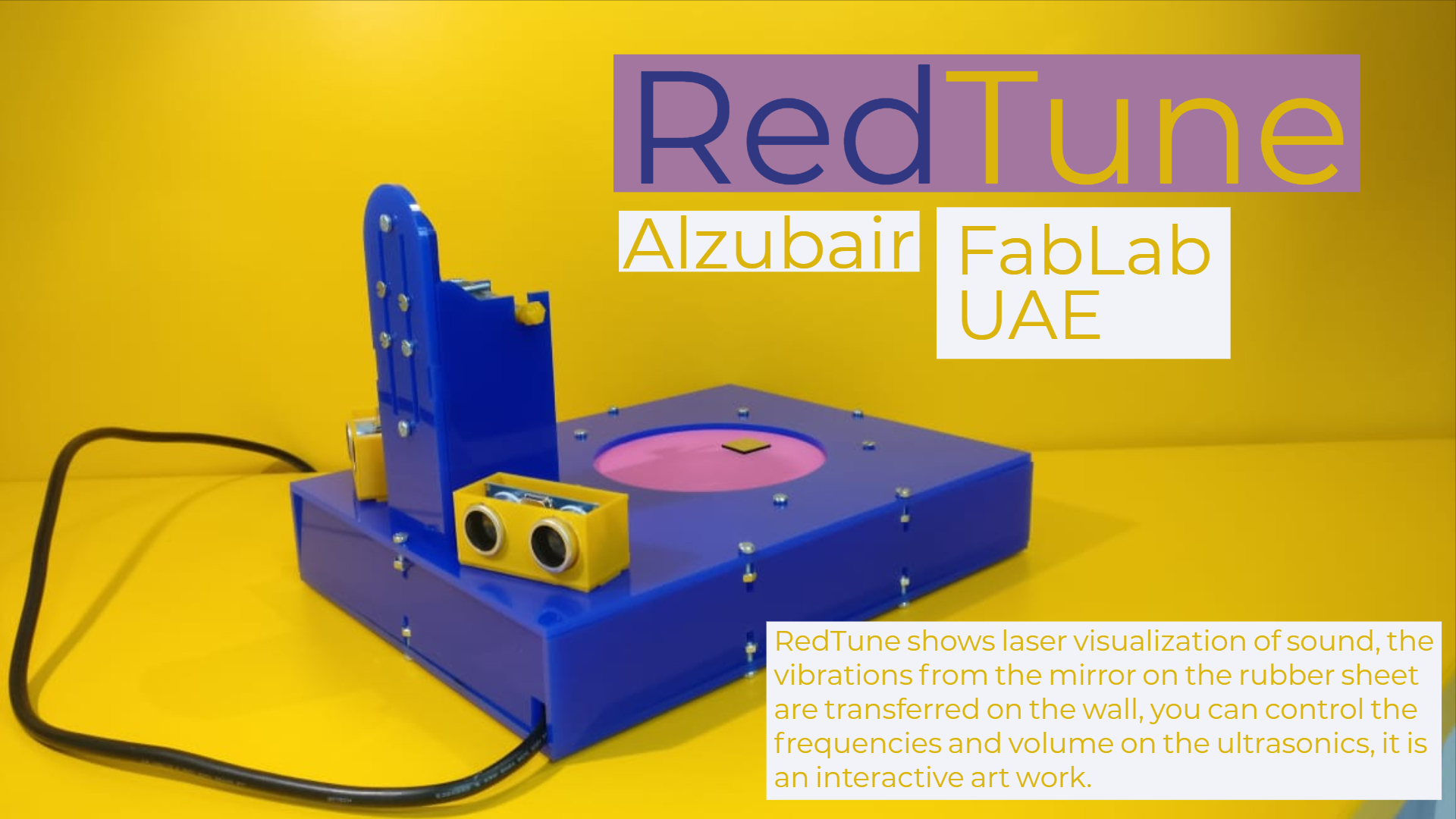

RedTuneThis project is a visualizing kit, an art piece or maybe even a kit to experiment with laser visualization of sound, my first intention was to use it to experiment production of shapes by the laser projection on the wall, there wasnt enough time for that, so i simply made a visualizing project of the laser, you change the frequencies by one ultrasonic sensor, the other should've controled the Volume(This failed) so instead i added frequency pulsing on the other ultrasonic. Slide

VideoBill of MaterialsImportant LinksThese links of weeks either have a component of the final, or helped me make a componenet of the final project. Week01 - Principles and Practice. ComponentsThis section is to divide the project into components and give a brief description on each. **Ultrasonic Sensor 3D prints**Used ultimaker 3 Extended, PLA material on recomended settins with a brim, supports, gradual infil and 0.15 layer heigh. Used Fusion360 to design it. The files in the Zip folder for this components are AcrylicCaseAndUltrasonicCaseAndLaserAngler.f3d and UltrasonicCase.stl. Laser ClampThe same printer settins as above, except for the screws you actually have to scale them down to 85% of their original scale, i explained why this step is necesary on week6. This component is used to hold the clamp on the case. The files are LaserClampScrews.stl and LaserClamp.stl and LaserClampAndScrewFinal v1.f3d. **Laser Angle Adjuster**Same printer settings, this component is a special achievement for me, it is used to adjust the angle of the laser using screws, i am proud of this. The files are LaserAngler.stl and AcrylicCaseAndUltrasonicCaseAndLaserAngler.f3d. BoardI really pushed the limits of the pins available on the attiny84, I used Eagle to design the board and fabmodules to convert the type of the file for the SRM-20 milling machine on a one sided FR1 copper plate. The files are RedTune.brd and RedTune.sch **Acrylic Case**The case was entirely made on fusion 360 exported to DXF and used a Universal Laser Systems machine, the material was acrylic blue 3mm thickness. The files are AllAcrylicCuts.dxf and AcrylicCaseAndUltrasonicCaseAndLaserAngler.f3d. CodeI used arduino code for this entirely, tried to add a volume changing library but that failed, due to the use of attiny84 i believe, anyway the volume change wasn't used for this. The file is RedTuneCode.ino. --Note--Everything with ** next to it, actually used the same Fusion file, that is why they share the same file name, i thought it might be better to combine them together at this point, the bodies in fusion are named accordingly, the sketches as well. License

AcknowledgementsThis couldn't have been done without my mentos Wendy and Hashim, they helped a lot, my friends in FabLabUAE, Hamdan Bin Rashed Award for sponsoring and support. This experience was amazing, my physical limits were changed, I will not forget the great teachers and our program chair that helped me squeez my schedule so that i can attend the lab more! My friends Mohammed for letting me stay at his place, Maitha for psychological support, other friends for understanding my commitment. I am sorry if i forgot anyone else. Download the project files here. |