Week 1

Principles & Practices

We started on 17th January 2018 at 19.00 Hours (IST). It began with an introductory lecture by Prof. Neil Gershenfeld, Director of the Fab Academy Program. We were introduced into the field of Digital Fabrication which is set to revolutionise the world just like the Personal Computers did. With the expansion of Fab Lab network, the culture of Personal fabrication is set to spiral out, enabling people to embrace technology on a more personal level and thus dissolving the boundaries set by the state's and the current economic order. Just as life reproducing itself, the ultimate vision of Fab Lab is "FabLab making a Fablab".

The Fab Academy Course structure was introduced and the lecture gave a clear idea of what is expected from a student for the satisfactory completion of the course. It will be an intense learning experience across multiple disciplines which will result in a final project, where in the student will integrate the skills developed over 20 weeks. The students are to build a website and document the progress on the website which will be reviewed weekly by local and regional evaluators, followed by the final global evaluation.

This week's assignment was to plan and sketch a potential final project.

The Final Project!

We were introduced into the different machines and facilities available at Fab Lab Trivandrum. Based upon the facilities available, the potential final project was to be decided.

I find joy in riding motorcycle and had felt the need to mount my smartphone over the motorcyle to shoot onboard footage. To make the resulting footage free of jerks and shakes associated with the ride, a smart phone mount that will be gyro stabilised was the initial project idea.

However, after learning about different sensors during the input week assignment, it was decided to change the final project to a digital speedometer. Owing to mechanical wear and tear, the analog speedometer on my 1973 make motorcycle frequently runs into trouble and is left broken. The thought of replacing it with a digital speedometer is my final project.

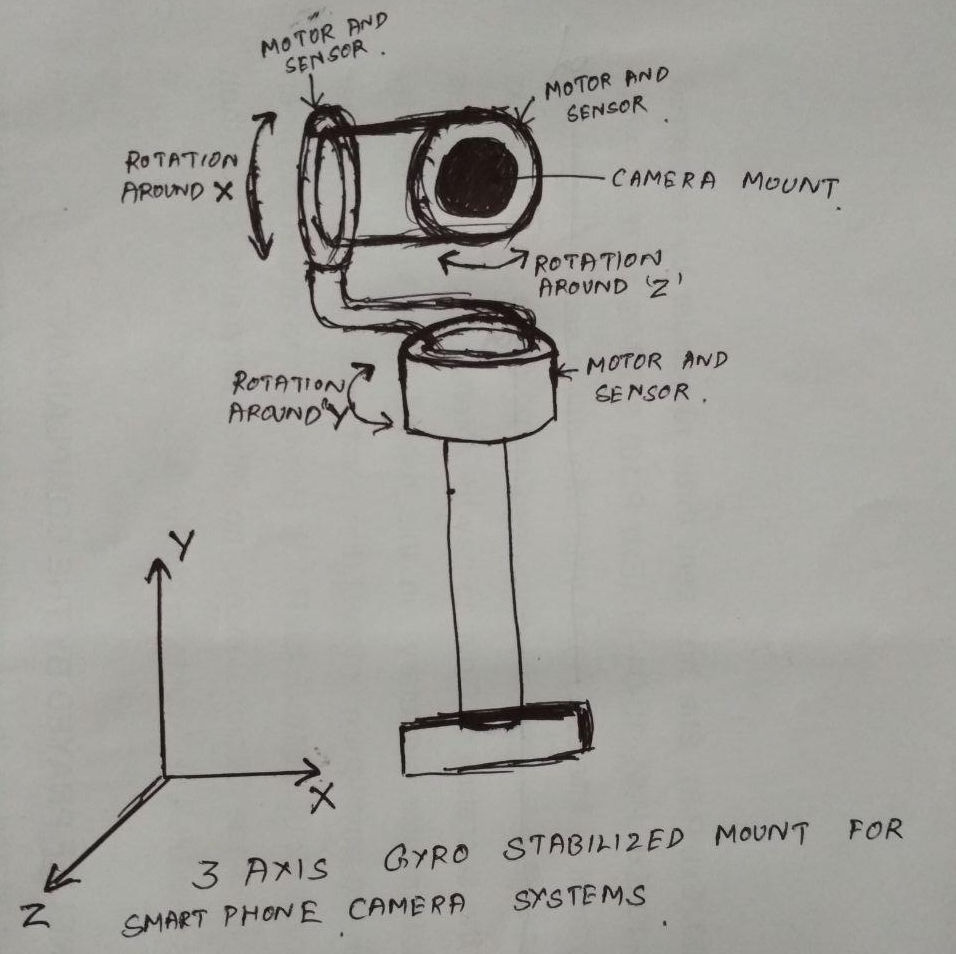

Gyro stabilised mount for smartphones.

The mount will be having three axis stabilisation. The stabilisation is made possible by using gyroscope sensors, accelerometer sensors and three motors which are electronically controlled. The sensors will provide the instantaneous data regarding the tilt of the mount, which will be processsed and used to drive the 3 motors. The gyroscope sensor will give the amount and direction of tilt and the accelerometer sensor will give the rate of tilting. The combined data from these sensors will be used by the microcontroller to control the speed and direction of the 3 motors so as to make the mount stable in 3 axis.

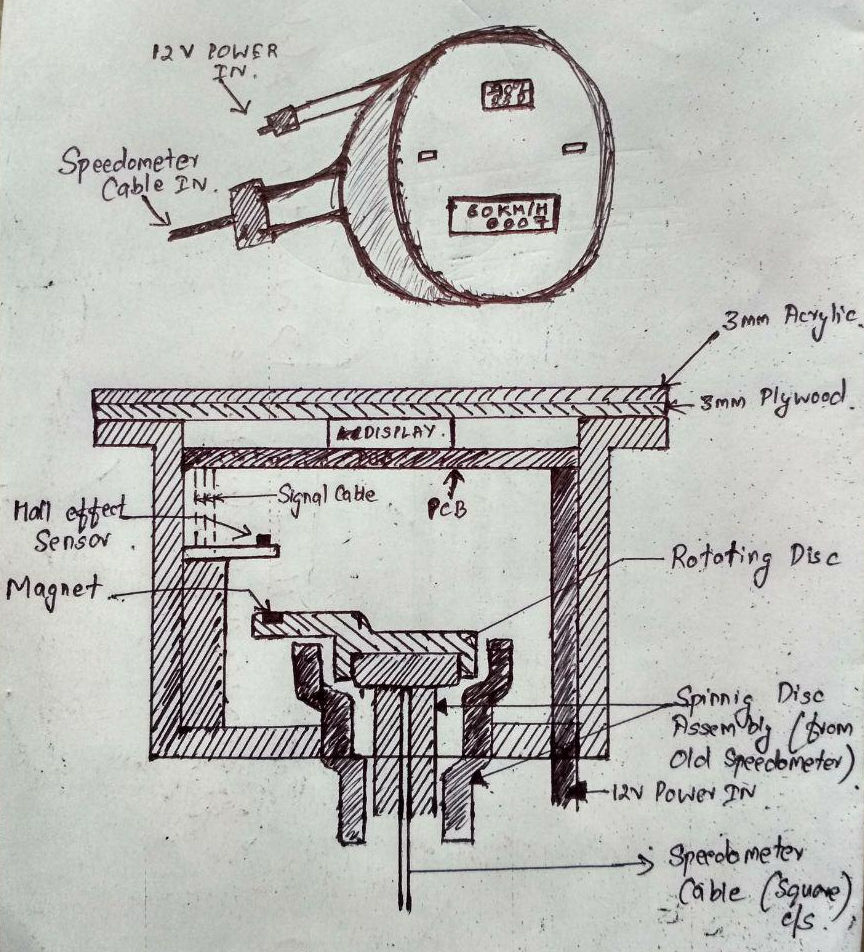

Digital Speedometer

The rotation of the wheel is transferred to the speedometer casing through a cable which is free to rotate. The spinning disc assembly from the old analog speedometer which spins along with the cable will be reused. On top of the rotating part of the assembly, a 3D printed disc carrying a magnet will be mounted. The magnet will be rotated along with the wheel and a hall effect sensor will detect the magnet each time it completes a revolution. The microcontroller will take the input from the sensor and compute the speed and will then display it onto an LCD. Im also planning to add magnetometer sensor and temperature sensor to display the direction of movement and temperature onto another LCD.