Applications and implications

Week 18 - Application and implications

Here you will find my work description during this eightteenth week

General info

Assignment

Propose a final project that integrates the range of units covered, answering: What will it do? Who’s done what beforehand? What will you design? What materials and components will be used? Where will come from? How much will they cost? What parts and systems will be made? What processes will be used? What questions need to be answered? How will it be evaluated? Your project should incorporate 2D and 3D design, additive and subtractive fabrication processes, electronics design and production, microcontroller interfacing and programming, system integration and packaging Where possible, you should make rather than buy the parts of your project Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable

Class notes

Final project

My final project is to fabrication a Mood tracker device.

What will it do?

The devide will used your smartphone, for connectivity and position. The smartphone application will send a mood level you can set using the capacitive sensor. Then a visual animation will be displayed using the LED matrix.

Who’s done what beforehand?

Some student have made lamps using those neopixels. But as far as I kwnow no device like this one. Today we can track our mood using smartphone or connected wristbans.

What will you design?

The whole device, except (for now) the LED matrix, and the power adapter.

What materials and components will be used?

- PMMA

- Wood

- ABS

- (optionnaly aluminium, if I find some)

- (Other kind of plastic)

- basically Everything I can mill

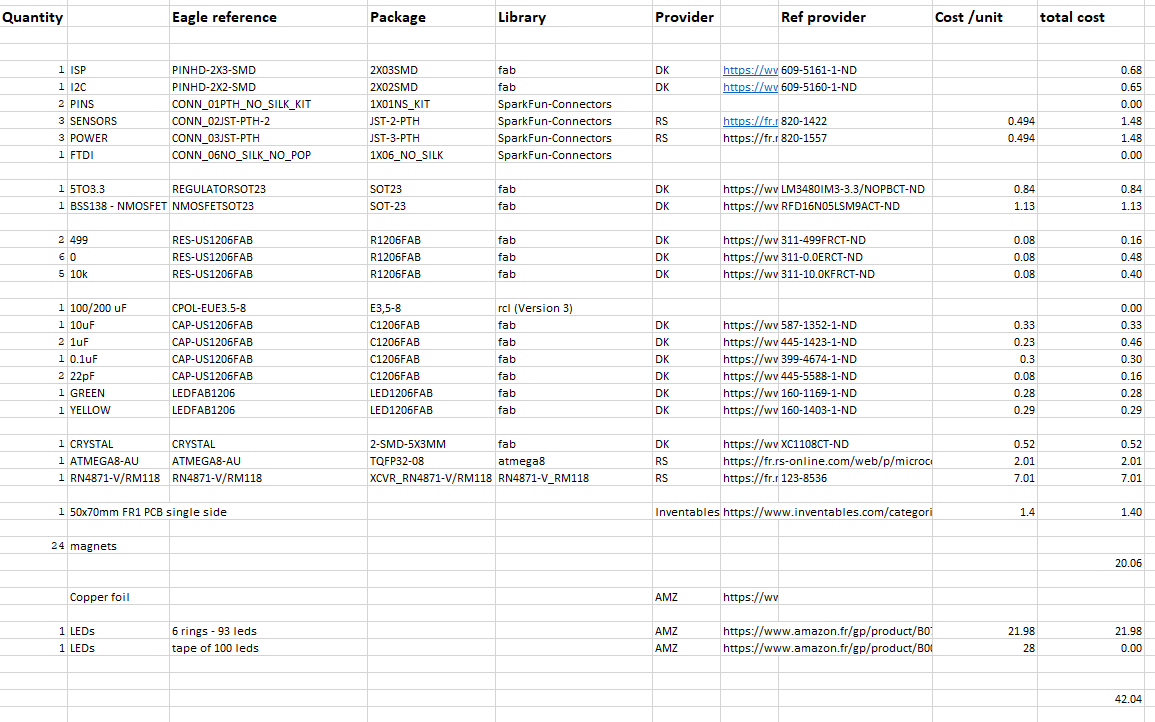

Where will come from? How much will they cost?

Download the electronic BOM Excel format

Download the electronic BOM CSV format

The cost should be around 60 €

What parts and systems will be made?

- the electronics

- the rings

- the mobile application

- The rest and frontend server

The only thing I cannot do because of the time, (and will probably be done later) is the LED matrix.

ALso, depending on the time, I will do the mobile application and the server later.

What processes will be used?

As much as possible !

- 3D Printing

- Milling

- Molding and casting

- Computer controlled cutting (laser and plotter)

Unfornutately no composite

What questions need to be answered?

How will it be evaluated?

I dream I can run a kickstarter campaign.

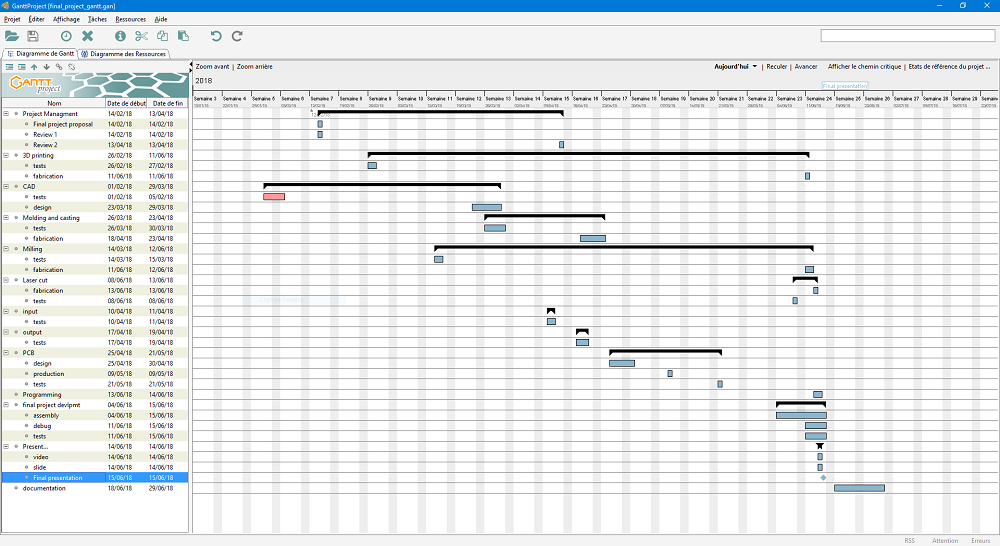

Schedule

I tried to work on final project each week during assignments. Each week has been used to try technics, and as you probably read previous assignments you seen my work on each part on the final project.

In paralell, since the network and communication week I worked on the main electronic board. Since this assignement I knew that I will going to use that BLE chip. So I started designing the main board using rn4871 and atmega 328p.

Why this MCU. basically because, as an open source project, I want people who want to do their own lamp using an arduino uno (that has the same MCU).

So people who want o build their own, they will have several choices:

- make their own board following the how-to tutorial

- Use arduino with provided code

- Buy a manufactured board

During the last week, project developpement, I put all things together. There was one point thas has not been clear, wich input sensor to use. I had to mill, laser cut, 3D print more rings.

The last weeks has been a commando week, I know this was not a regular well planned project managment but regarding the few amount of time I had to show something.

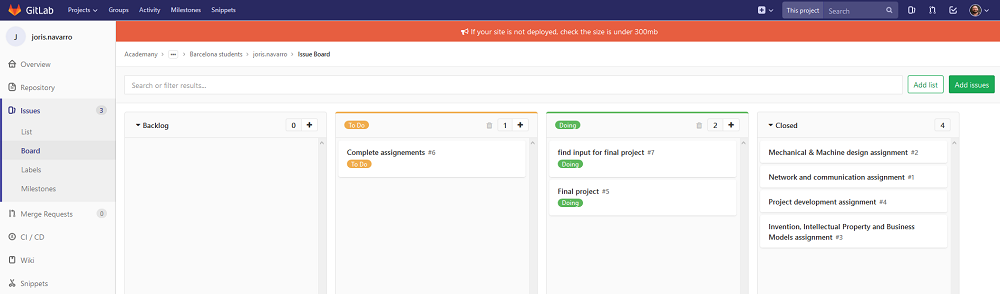

Project managment of the last week

As you can see in the image bellow for the last week I used Gitlab Issue and then Kanban board to follow the task I had to do.

What the schedule was ?

- 01/06 : PCB soldering

- 02/06 : test and choose inputs

- 03/06 : programming

- 04/06 : Part fabrication milling / laser / 3D

- 05/06 : integration tests

- 06/06 : slide

- 07/06 : video

The last four days are buffer, to finish what has not been finished.

What really happened

- 01/06 : solder PCB

- 02/06 : FAB14

- 03/06 : debug PCB - level shifter

- 04/06 : debug PCB - level shifter

- 05/06 : assignement documenation

- 06/06 : test input 1/2 rotary encoder -> need to design new parts

- 07/06 : programming output

- 08/06 : debug PCB - BLE

- 09/06 : documenting behind assignemnts + fabricating parts 3D

- 10/06 : documenting behind assignemnts

- 11/06 : test input 2/2 capacitive -> no need to design new parts

- 12/06 : change input to capacitive sensor, engraving + fabricating parts milling laser

- 13/06 : programming + integration + tests

- 14/06 : slide + video

You knwow that Murphy’s law

Anything that can possibly go wrong, will go wrong.

I felt like everything went wrong, that made me prouder to succeed to fix it until it works.

At the end here is a chart showing how it was done.

Extra

You might be interested by reading an Incomplete Manifesto for growth by Bruce Mau

Extracts I liked:

- Process is more important than outcome

- Love your experiments (as you would an ugly child)

- Collaborate

- Strange things happen when you’ve gone too far, been up too long, worked too hard

- Make your own tools

- Don’t enter awards competitions

- Make mistakes faster

- Laugh

- … and so many others

Stay in touch

Hi, I'm

Joris Navarro, from Perpignan (France), a proud dad, a fab director/manager, a teacher, a ceo, a FabAcademy student, but not only. Click here to know more about me.

Check my work for FabAcademy on FabCloud GitLab

@joris.navarro.

Want to say Hi ? Please send me a message.