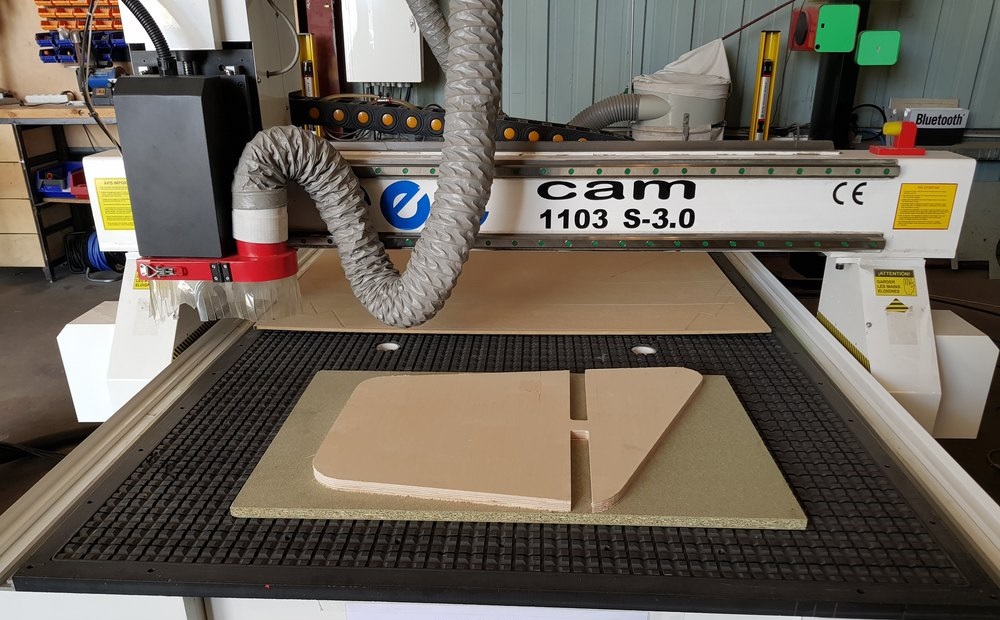

Computer Controlled Machining

Week 8 - Computer Controlled Machining NOTES

Here you will find my notes description during this eighth class

Things to do

Questions to ask

Useful resources

Assignments

Group assignment

- test runout, alignment, speeds, feeds, and toolpaths for your machine

Individual assignement

- make something big

Raw class notes

Weekly reviews :

class :

Make a Kickstarter startup with open furnitures

Shelters 2.0

Machines

The favorite tool for this assignement is Shopbot RS Alpha

Jens M2M machines

Materials

- rigid foam insulation

- veneer plywood (expensive but strong)

- medium density fiberboard (MDF)

- medium density overlay (MDO) (not recommanded cause of dust)

- oriented strand board (OSB) (like saucisse or hotdog of woods, cheap)

- HDPE (High density)

- Lexan, polycarbonate (harder than acrilic)

- Garolite (composite ?)

- aluminum (type of toolpath is essential)

Tooling

Use end mill, not drill bit

number of flutes

1 flute remove a lot of material quickly 4 flute leaves smoother surface behind

bottom cut makes leaves good edges on the top

the best is to use both, start with a bottom cut and finish with a upcut

be carefull some mills have not middle

speeds and feeds

machinery handbook is recommanded in each labs

a good guide is listening to your machine look and chip loads

V = Pi x d x n

cut depth = diameter of the tool step over = diameter of the tool / 2

lubricants

libricate & facilitate heat transfer not necessary for wood

other machining

for heavy metal use grinding machine for glass use abrasive machining

fixturing

for pcb use tape slinding c clamps / clamps (the middle can bow !) vaccum usefull for quick stock changing

sacrificial layers, squaring

squaring is to be shure X & Y axis are 90 degress

dust collection

depending of material you should need a mask Improve your dust collection

flexures, living hinges, kerfing

joinery

japanese joinery is beautifull

toolpaths

tool pathing is much complexe than laser cutting

kerf is the material that will be removed

we have to offset

kerf is greater that the diameter of the tool

climb or conventional ?

conventional for rought cutting and climb for finish cutting

adaptive clearing you cut deeper so you use more surface

trochoidal milling you do loops, it maintains chips thickness (thiner), but you can go faster

fusion is now able to generate this advanced tool path

sides

2 sides

N axis

2D 3 D all axis move together

! collisions spindle collet shank mill bit

The first thing you shoud do is cut air! use cheap material first protoype using laser cutter

V Carve Fusion has CAM Master CAM Mods less power full but easier

fromats

rml, gcode,

safety

glass, gloves, shoes, hair tied, clothes not too loose

focused, not alone

Master classe by

use straight flute

secret finger join

skect chair to have a look

U tweak ? Isaac Pierre

utweak.io customize your furniture

DEmo

Open rhino CAM go to mill processor

Stay in touch

Hi, I'm

Joris Navarro, from Perpignan (France), a proud dad, a fab director/manager, a teacher, a ceo, a FabAcademy student, but not only. Click here to know more about me.

Check my work for FabAcademy on FabCloud GitLab

@joris.navarro.

Want to say Hi ? Please send me a message.