Electronic Production

Week 5 - Electronic Production - NOTES

General info

Things to do

Questions to ask

Useful resources

Assignment

Raw class notes

Weekly reviews :

- Saba ghole from USA BOS Earth FabLab

- eunice lee from seoul

- Dario from siena

- yousef alsenwar from Dhahran (nice project : troller)

-

Jacob Jose from Kochi

- Nicolas de COster (ULB) generates a openscad file using js, for pressfit and flexible kits. He also use HP-GL protocol to print directly to the plotter.

class : producing electronics

make an incircuit programmer

PCB boards

SDS is bad, ecthing could be usefull if you produce a lot of circuit in the same tank, but we are be more responsible

using milling machine

milling produce a small amout of wastes, just dust

precision milling machine really small tools will be used (0.01in is 19$ carbidedepot.com)

if you use weel making a board is less than 1$

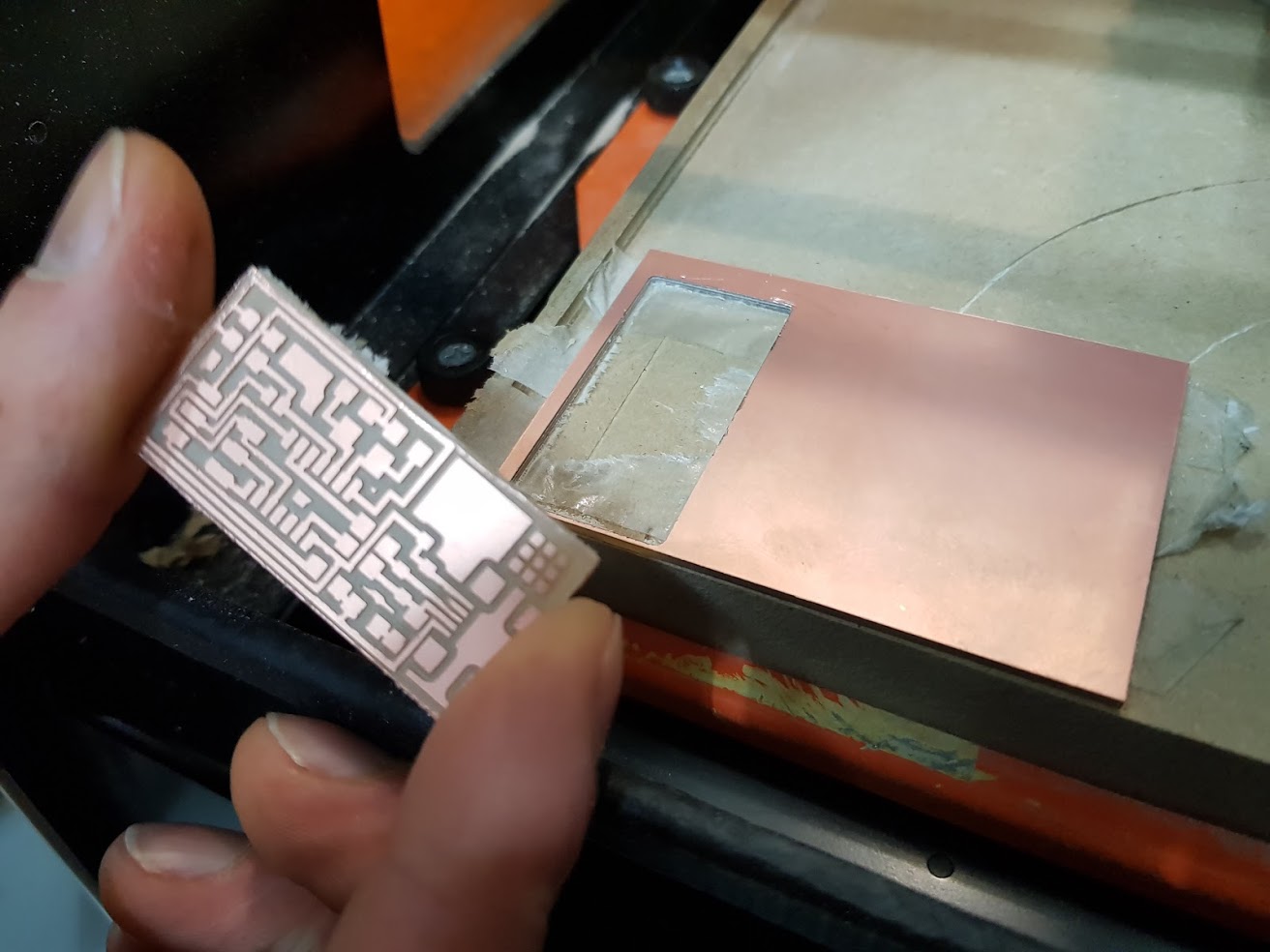

we use 2 sides tape to avoid board bending

sacrificial material (layer) under the board to cut the board, that has to be replaced

evrithing needs to be clean

zeroing is important because we will cut only 0.01 in don’t let if fall to the material hang it with your hand when you tighten be sure your tool is not broken clean with a stainless steel rule wash the board with clean water befor assembling the circuit

using vinyle cutter

honghao deng made a cube for fun and create e 3D circuit even multilayer flexible circuit see video bas add that we can use textile vinyle instaed of epoxy Neil doesn’t recommand to start with this but

using fiber laser

40k$ machine can remove the copper

using printer (special)

plating

rfid tags are usually print and ink

enbroidery/sewing

using conductive wire

boards

FR4 are the common ones (greeninsh color) but made using epoxy glass you can’t mill FR1 are the ones we use in fablab (phenolic)

boards are specified by height 1.0oz means 35um (micrometer)

pcb.ng is a online service for fabricating boards (board houses) http://aqs-inc.com/ looks interesting

think and tinker sells the machine that allows you to make your own pcb

seed studio is good

design rules spacing 1 mil = 0.01 in layers 1 side traces on 1.5 use zero resistor 2 sides 4 sides, power layers and ground layer

vias, to connect layers rivets are a clean way to make vias

Vendors https://octopart.com/ is the main provider ? (not sure)

Neil hate breadboards ;)

better mill a final form board

Soldering

they point is shiny and smooth joins (it’s hard to find the god temperature

remember to wash your hand before touching the solder

for smd use tweezers

Order matter, go to the bottom to the top

desoldering braid is usefull for desoldering or heat gun with special tip the point is to hold the piece you want to remove with the breezers and use the heat gun to let the board fall away on the table

pic and place machine is for at least 100 boards it make sense (will be common in labs)

encapsulation (silicon, nail polish)

go to bas (2012 student) molding and casting assignement

CAM

formats

the most common is Gerber we wille use images PNG (much cleaner than jpg) in high resulution (at least 500dpi better 1000dpi)

Mods is the new version of fabmodules

Jon dev his own tool

Have to try this tool too

there will be a recitation on it

Assignement

Group assignement

- caracterize your PCB process (cleaning, setup, underlayer, …)

- create a FabISP see Ali page for discovering what is happening on the programmer

See the brian’s page

practice your soldering until you have tiny shiny smooth joints

Don’t plug directly to your computer, use an extension cable

Extra : try to program the board, in 2 weeks we have to modify the board

Visual inpection this week

Stay in touch

Hi, I'm

Joris Navarro, from Perpignan (France), a proud dad, a fab director/manager, a teacher, a ceo, a FabAcademy student, but not only. Click here to know more about me.

Check my work for FabAcademy on FabCloud GitLab

@joris.navarro.

Want to say Hi ? Please send me a message.