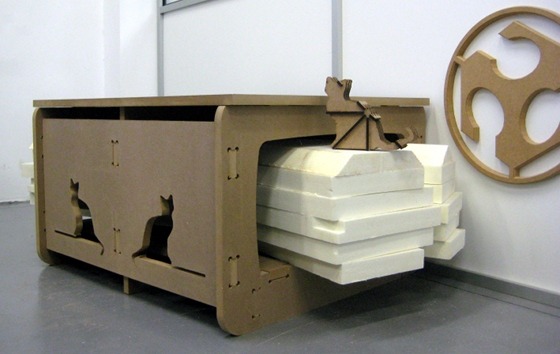

Computer Controlled Machining (I): A cat friendly bench

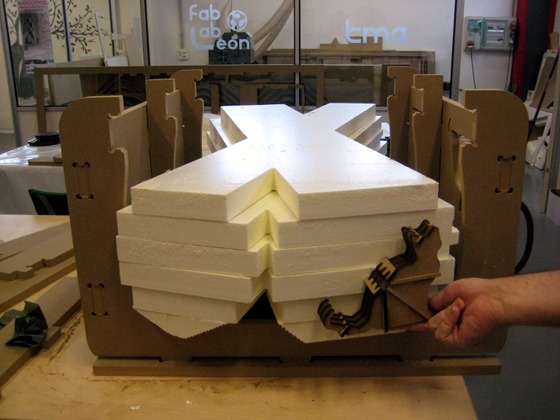

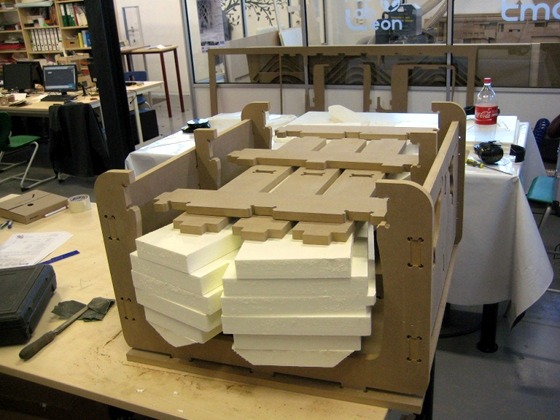

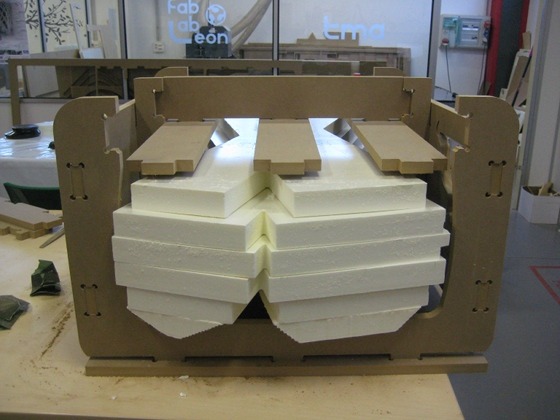

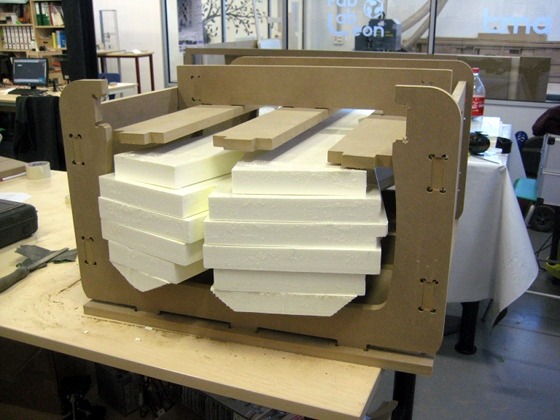

I have designed a cat friendly bench that is going to be made on DM and a X tube molde that is going to be made on FOAM. It is very important to have in mind the bed size of the machine and the size of the material one is machining. In this case the bed size is 2440x1220 mm, and the size of the materials are 2440x1220 mm for DM and 1220x660 for FOAM.

The documentation is here:

* CNC Machining (I) DM: A cat friendly bench (Below)

* CNC Machining (II) FOAM: An X tube mold (Click here)

A cat friendly bench

Designing

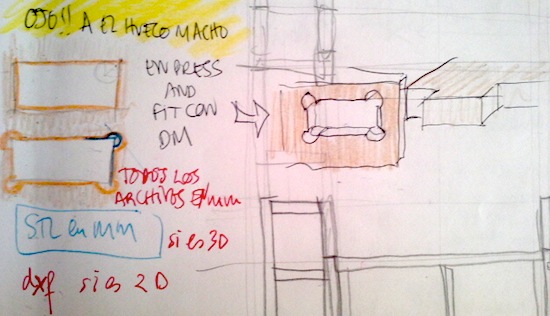

- Material: 2440x1220 mm DM .It is important to measure the thickness of your material with calipers => 19 mm

- Files to download:

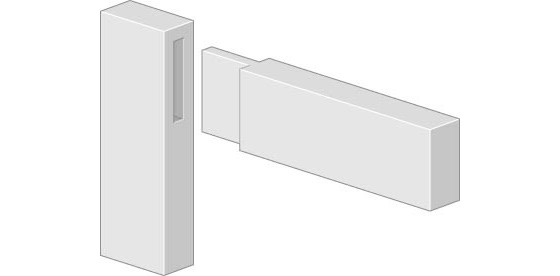

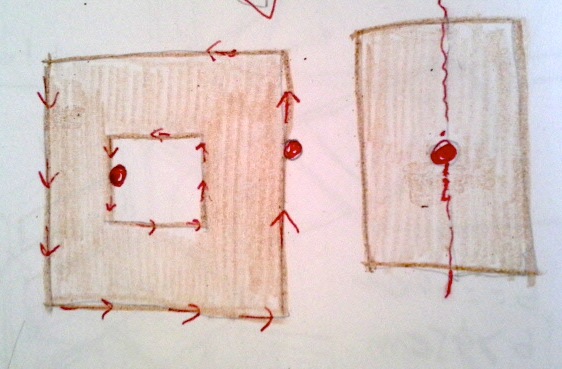

- Joints: joint among panels is a tenon joint. The image below shows how this joint works.

However as the machining is not able to do a perfect 90°, the design of the joints is like in the image below, allowing easy press and fit of parts:

*DXF File of the cat friendly bench

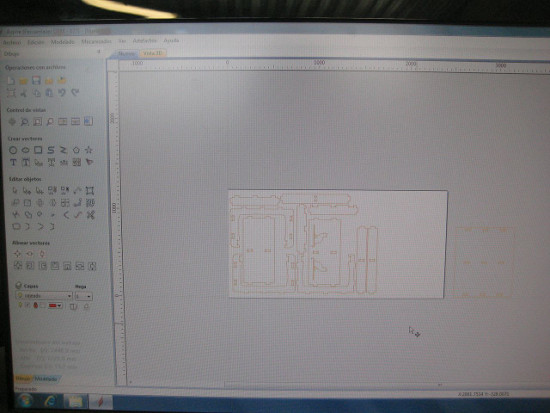

2D DM MACHINING: configuration of the "Aspire" Software for CNC Machining (I)

Aspire is the software we use at Fab Lab Leon. It is neccesary to follow these steps and fill all gaps on the Aspire:

* "Material dimensions" ---> "Dimensiones del material" (what is the size of the material we are machining)

* "Material thickness" ---> "Espesor del material". For DM, we add 0.2 mm to the thinckness measured with calipers. If it is a 19mm DM, this data on the software "Material thickness" will be 19.2mm.

* "Cero Z". Always "up"/"arriba"

* "X, Y". Place the (0,0) where your machine will start working.

*"Units" --->"Unidades". Set units, in this case mm.

*Click "Ok" and go to "3D view".

2D DM MACHINING: configuration of the "Aspire" Software for CNC Machining (II). "Trayectorias de herramientas".

Next is time to select paths on the Aspire and set the cutting parameters:

- "Cutting Parameters"--->"Parámetros de corte" (2D dimension DM machining)

- Feeds and Speeds for DM--->2D dimension machining

- "Ramps". Click on "Agregar rampa" -> "suave" ->"ángulo 30º"

- "Compensación herramienta". Chose from an image similar to this one below, which schema represents how is the tool cutting.

* How deep you cut--->"Profundidad de pasada" 19mm/5 = 3.5 mm

*Step--->"Paso" = 2.4 mm 40%

*"Spindle Speed"---> "Velocidad del husillo" = 18,000 RPM

*"Feed Rate"--->"Velocidad de avance" = 750 mm/min

*"Plunge Rate"--->"Velocidad de bajada"= 400mm/min

Security:

*Listening to the machine, if it sounds like if it is in pain, something is wrong, how the cuts sounds is a good feedback. Normally if it is making a too much hight sound it is because of the feed rate, probably is too hight.

*Keep next to the machine for the first 10 minutes, if something is wrong or the material starts burning you would notice it in time.

CNC tooling & Calibration

The tool we are using for the 2Dimensions 19mm DM cutting is an "End mill 6mm". As we can see at the picture below our CNC has a small piece of metal, that detects where is the Z=0, measuring the Z and making the Z alignement automatically.

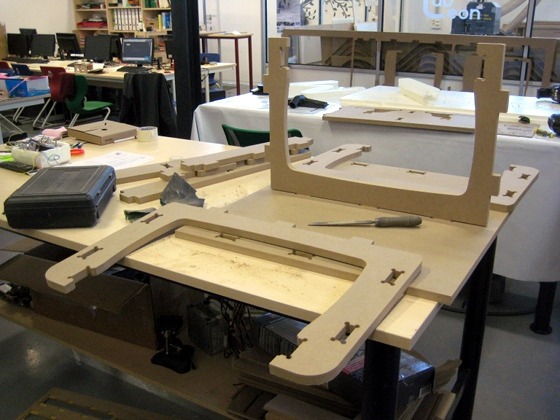

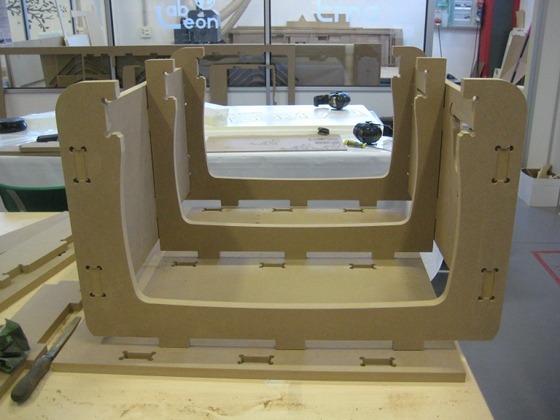

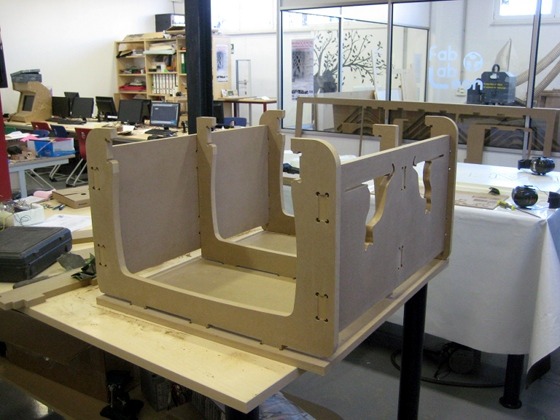

Assembly

To do not forget

*If your tool is 6mm diameter, the distances between cutting paths should be broader than 6 mm.

*Always make a simulation of how long is the work going to take. At Fab Lab Leon is the half of the time the simulation is showing.