6. 3D Scanning and printing¶

Objectives :¶

Group assignment :

- Test the design rules for your 3D printer(s)

Individual assignment :

- Design and 3D print an object (small, few cm3, limited by printer time) that could not be made subtractively

- 3D scan an object (and optionally print it)

Group assignment¶

Link to ULB Group : link

Design and 3D Print¶

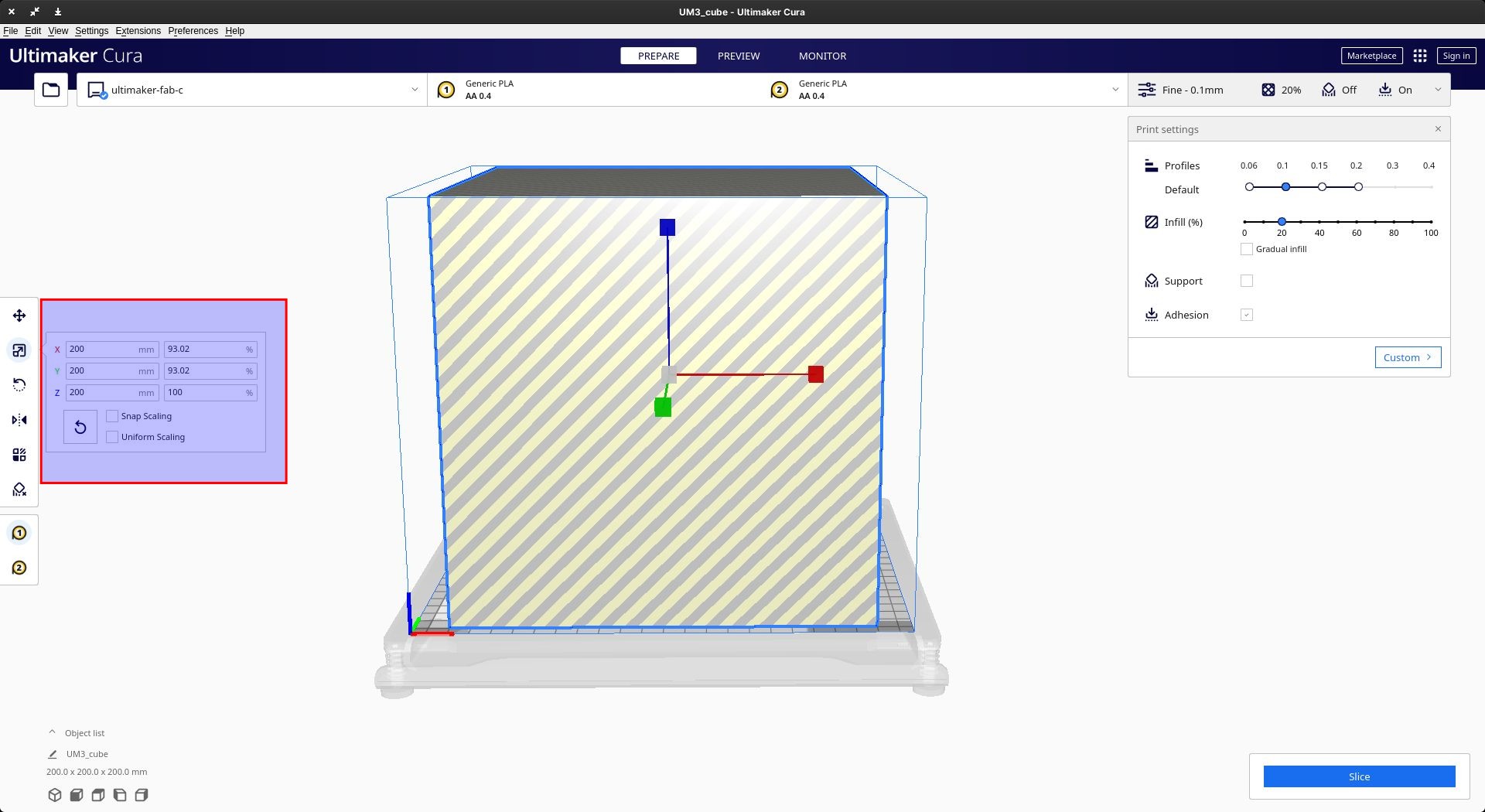

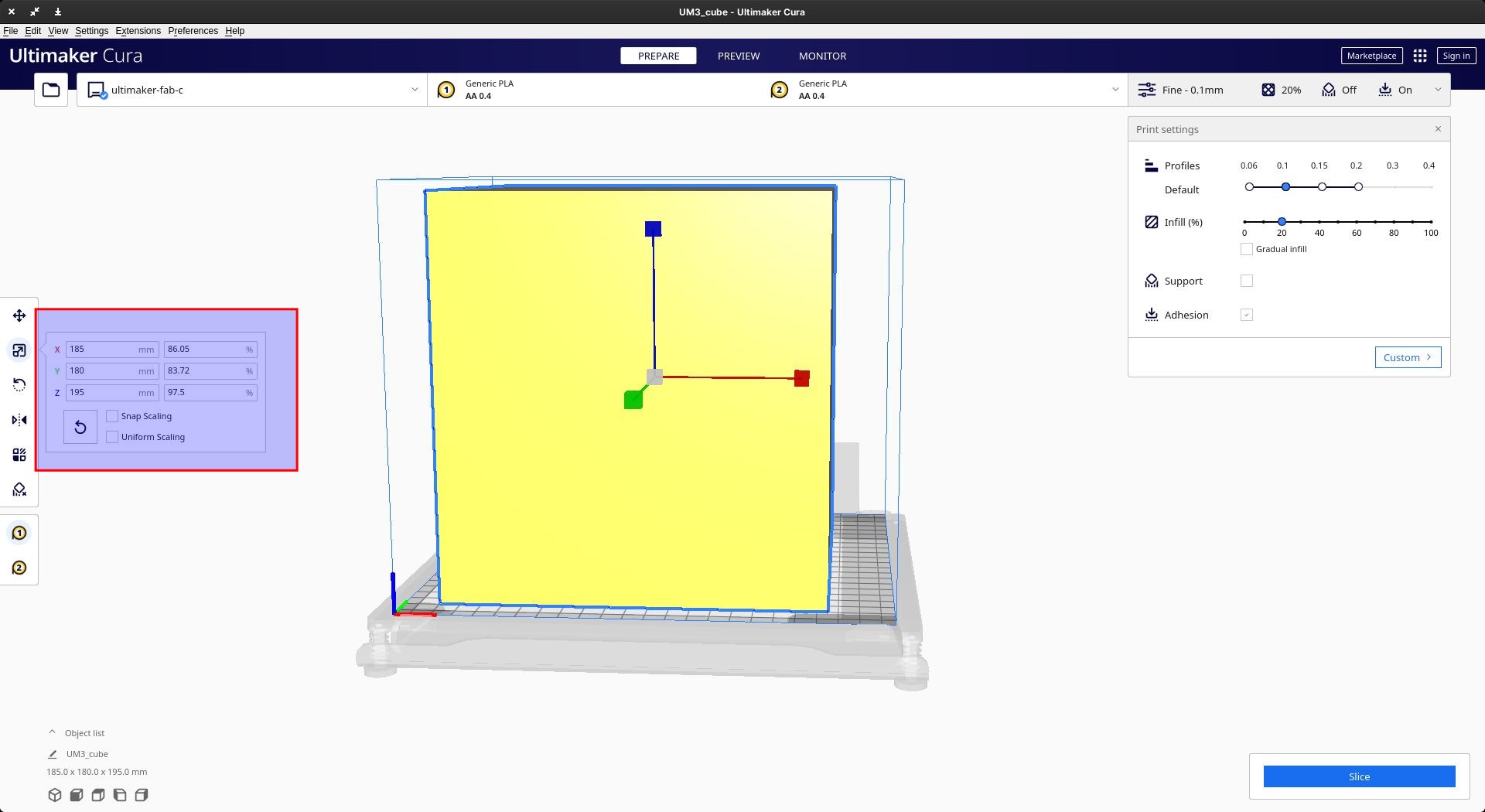

We are currently using an Ultimaker 3 3D printer in the fablab. The dimensions proposed by the manufacturer are 215x215x200mm, but as it is a double head, we lose in real dimensions in x and y (there are also safety margins).

with a cube, the maximum real size managed by the printer is determined

The X,Y,Z dimensions are adjusted until the cube fits completely into the printer

When testing with a cube that is 200x200x200mm, it is clear that the machine cannot handle this dimension.

The real dimensions are 185x180x195mm.

The main characteristic of this brand is the use of 2.85mm filament.

I was able to carry out the various test files proposed. No special adjustment. 0.2mm layer height.

Here are the results:

With support¶

Overhang¶

Clearance¶

without support¶

Angle¶

Overhang¶

Bridging¶

Wall thickness¶

Anisotropy¶

Surface finish¶

Individual assignment¶

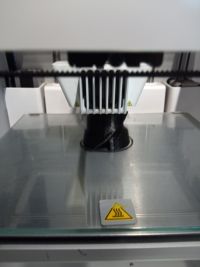

Maxwell Wheel¶

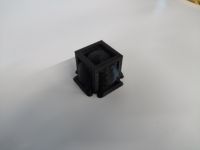

For individual work, I took advantage of a request from a physics teacher who wanted to improve a classroom experiment.

This is the Maxwell wheel experiment. The aim of the piece is to stabilise the whole thing to facilitate the various measurements.

Indeed, the wire can wrap around itself and make the movement unstable, hence the creation of the following part in collaboration with the teacher.

As part of the exercise, there are also measurements taken on the same wheel as it descends on rails

Design¶

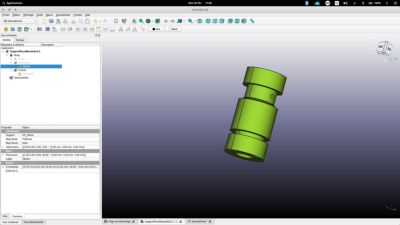

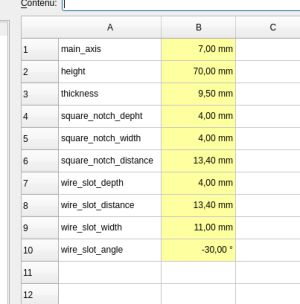

To make the missing part, which allows the two experiments to be carried out without adding or dismantling anything, I used Freecad with a table to make the maximum parametric

file : MaxwellWheel

Export to STL

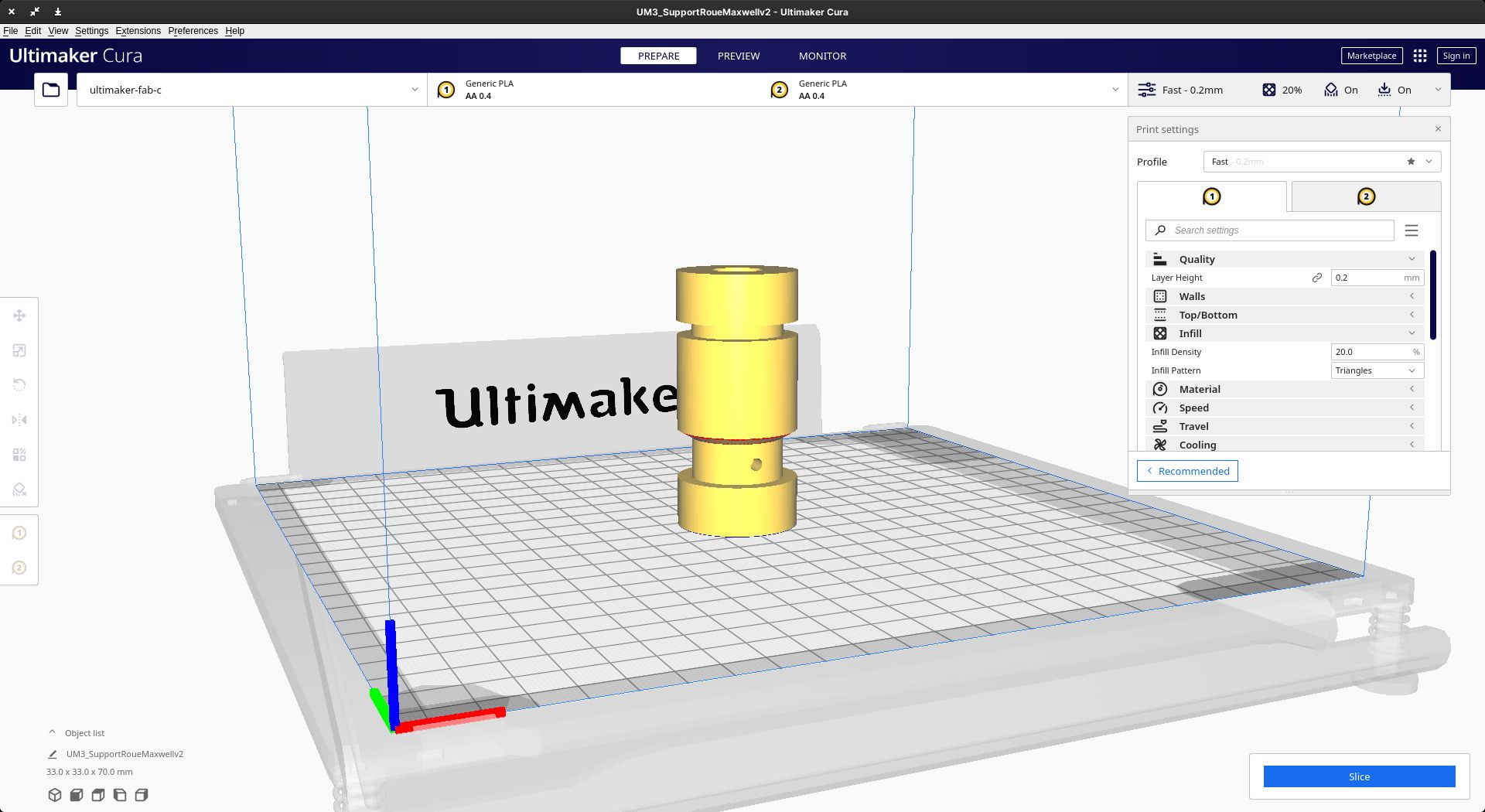

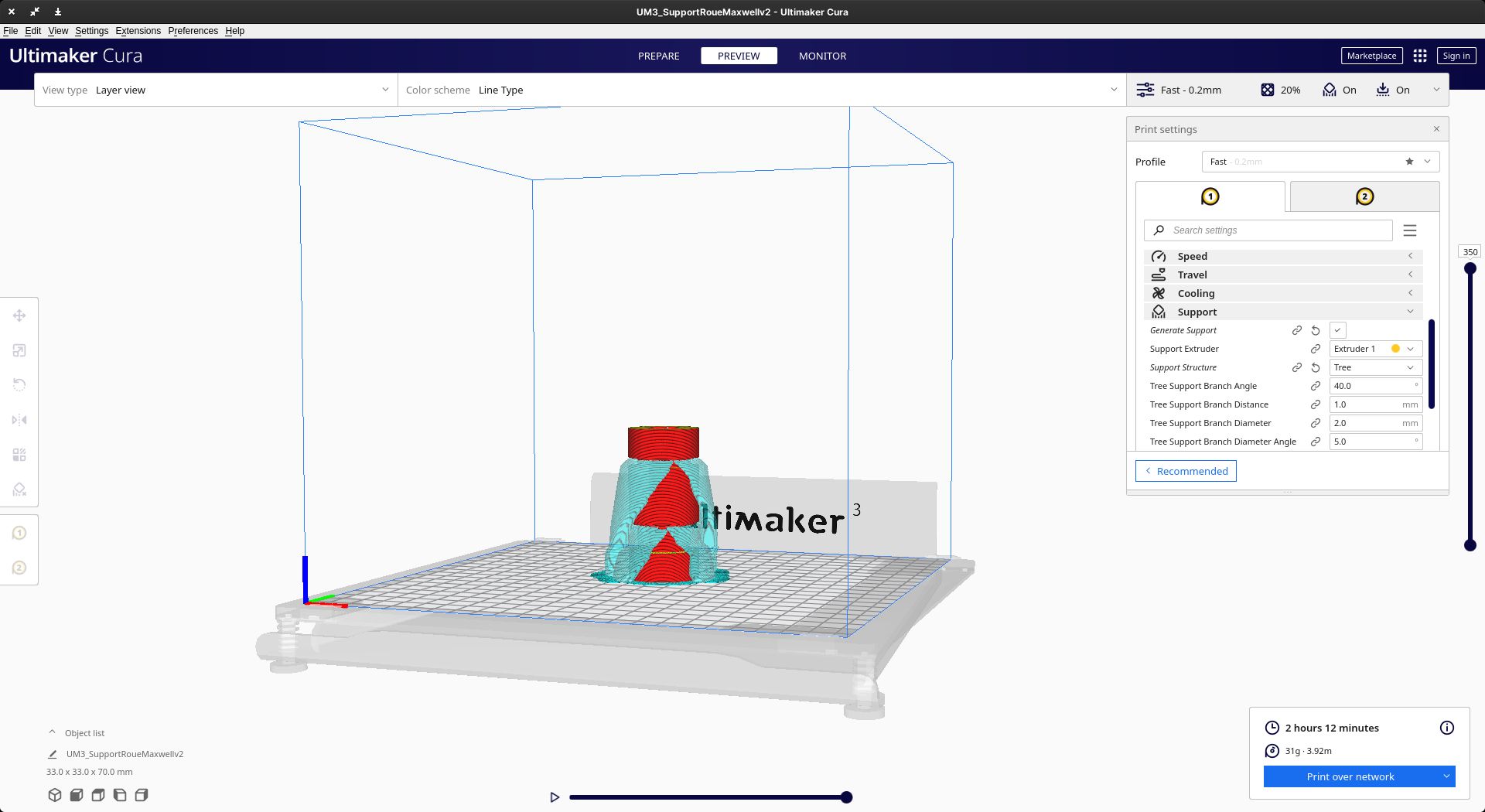

Open Cura¶

Import file

we add the supports (here in tree structure)

Print¶

Exercice in method additive¶

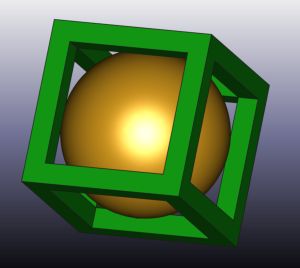

For the exercise, we had to create an object that required 3D printing, i.e. an additive method.

Freecad¶

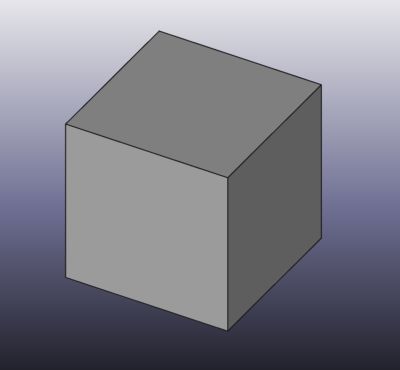

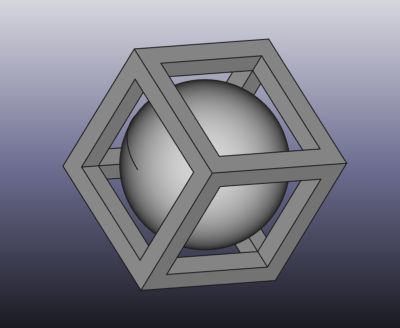

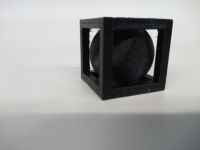

I made a quite common object which is a sphere in a cube (still in Freecad)

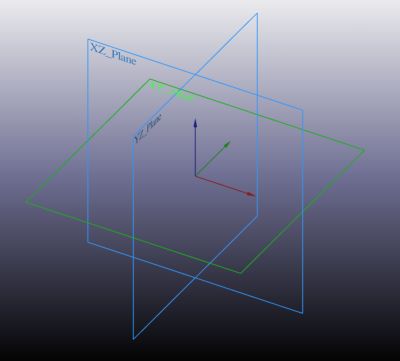

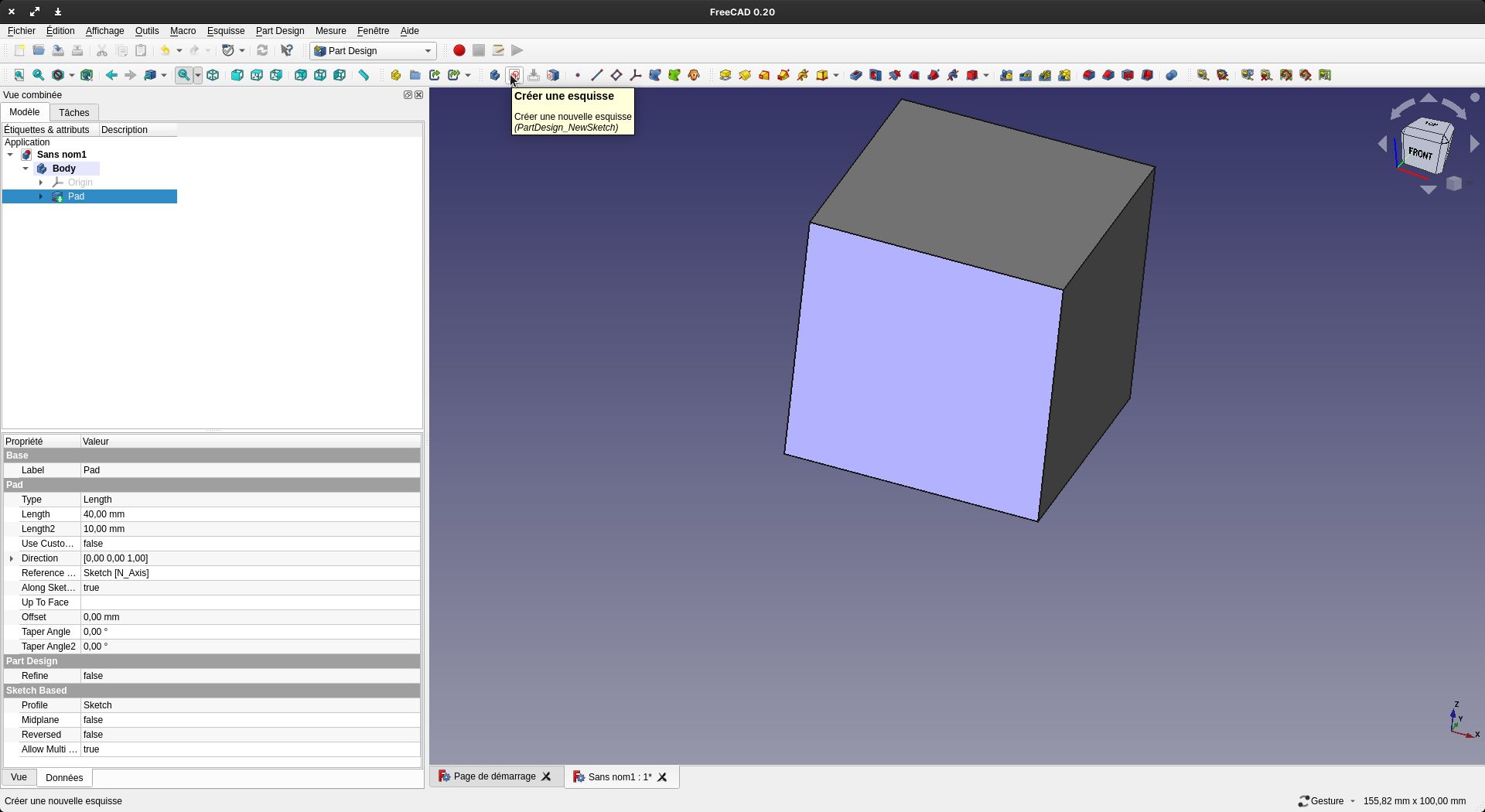

Open a new project in freecad, select a plan to start. Here I select the xy plane

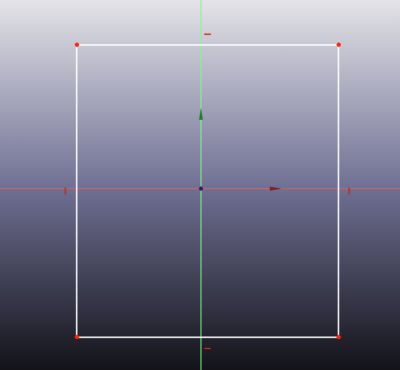

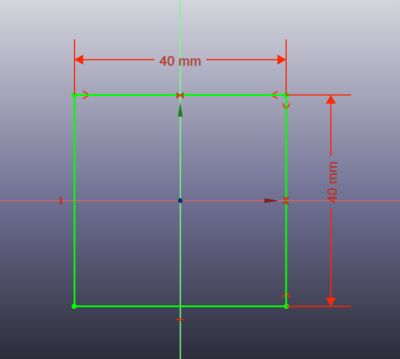

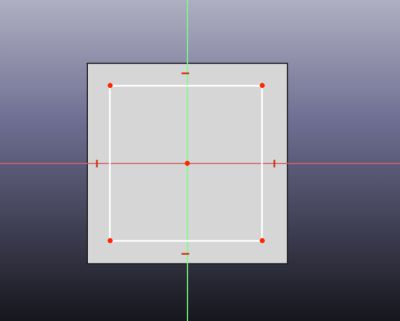

I draw a rectangle. I give the desired dimensions (here 40 mm square) - I also put a symmetry constraint to have the object symmetrical on the axes. When I add the 40mm material, I make sure that it is also symmetrical.

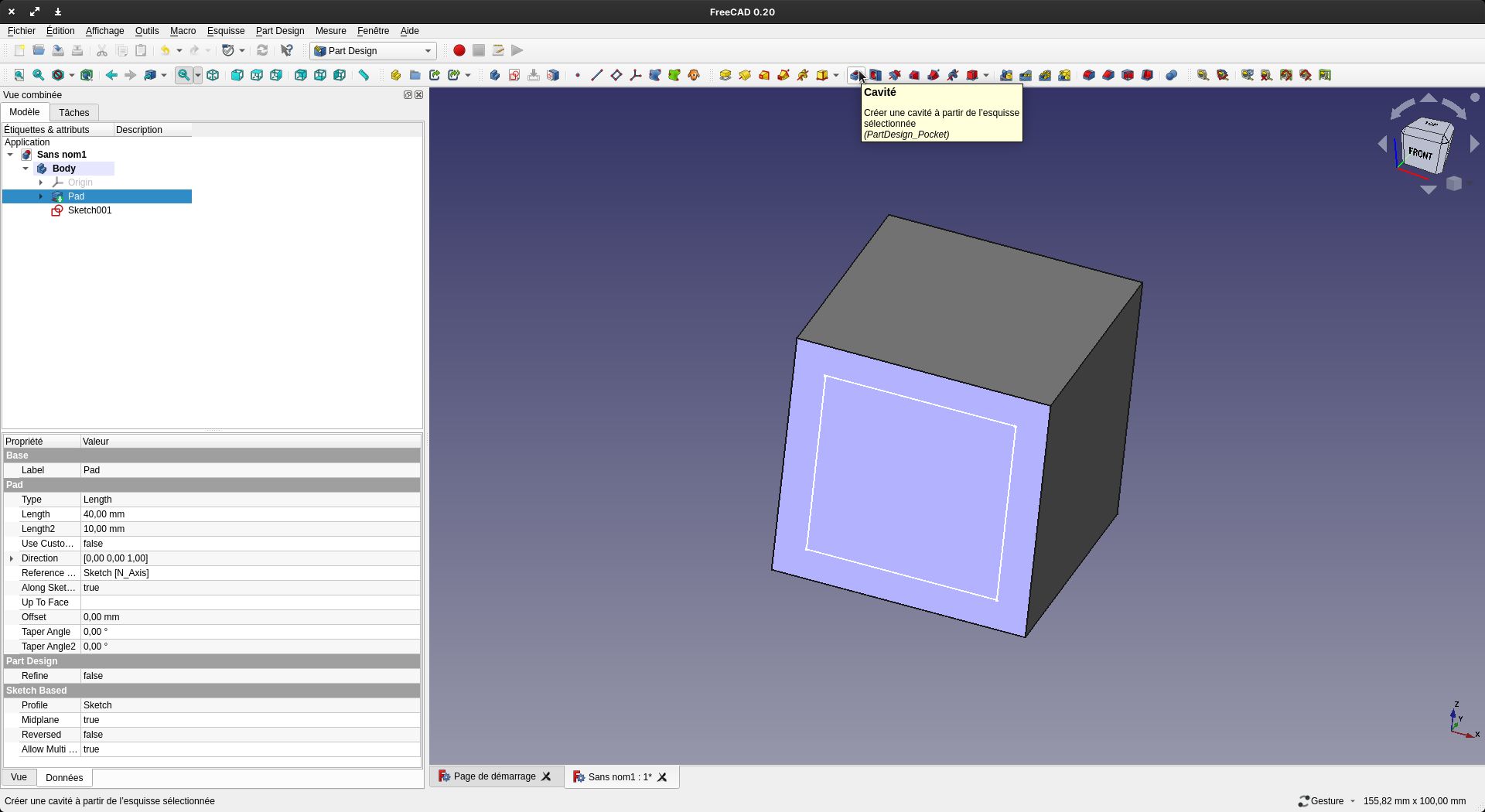

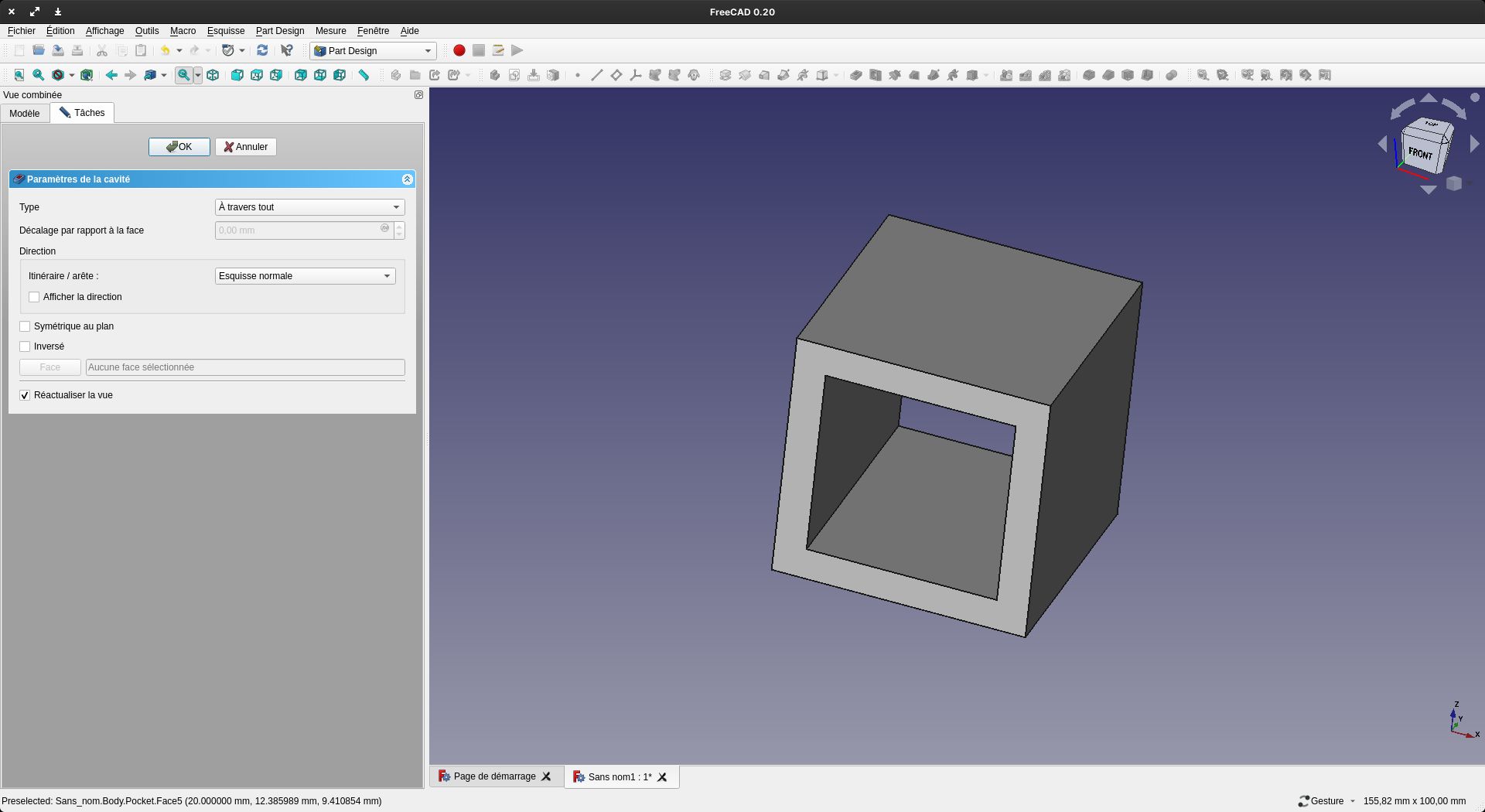

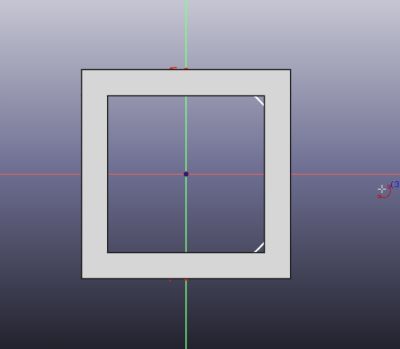

I select a face and draw a sketch that will be used to remove material throughout the object. I take the material out through everything

I repeat the operation on the other two sides.

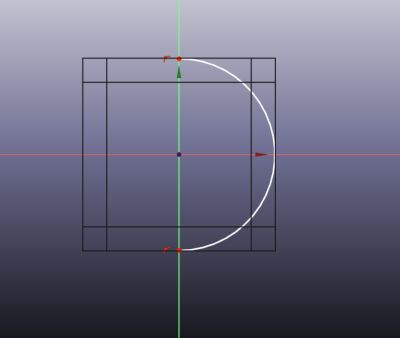

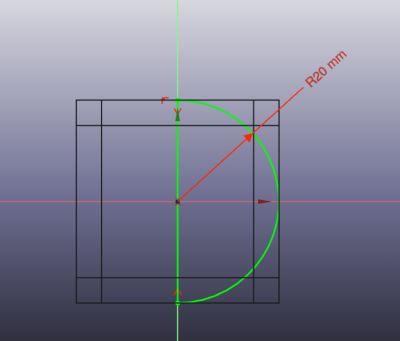

I decide to create a second object which will be a sphere. So I take a plane and draw a semi-circle. To get a better view, I either uncheck the cube object or choose the drawstyle display on wireframe mode (v+3). I give it the desired dimensions and make it make a revolution.

file : - cubesphere - cubeinsphere

Printing¶

3D scan an object¶

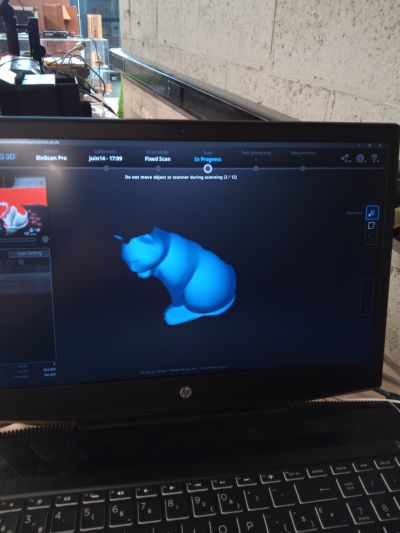

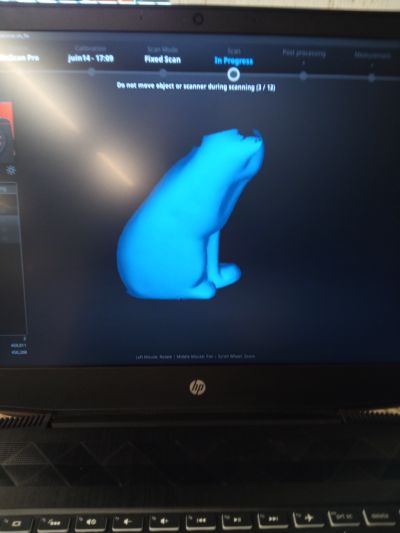

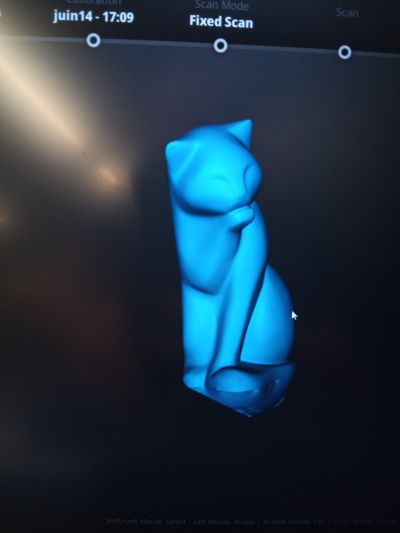

In the fablab, we have an Einscan-Pro scanner - https://www.einscan.com/handheld-3d-scanner/einscan-pro/

For the exercise, I took a cat statuette. It is black and shiny. (this is a frequent request from artists who want to scan their pieces and print them in different formats)

The scanner does not scan the black colour, nor the shiny one, nor the transparent one (in this last case, you have to put some pellets that the scanner will recognise).

What to do in this case, the part must be matted. There are several methods:

- Painting but it is destructive

- A special matting product for scanners which is quite expensive

- or in our case, we tested dry shampoo (less than 5 €)

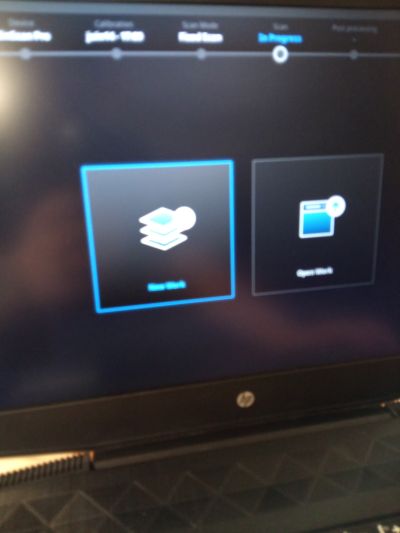

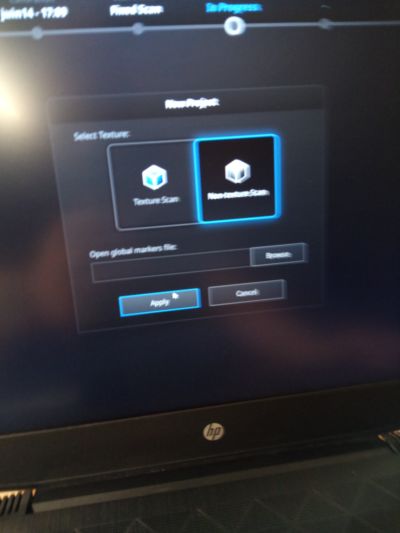

We start the scanner software

we choose the standing option. We will use the turntable

Here I have set to make 12 captures (360°/12)

Save the scan in the desired format (here you can save as .stl, .obj or .3mf)

Print it