5. Electronics production¶

Objectives :¶

Group assignment :

- characterize the design rules for your in-house PCB production process

- extra credit: send a PCB out to a board house

Individual assignment :

- make an in-circuit programmer that includes a microcontroller:

- mill and stuff the PCB

- test it to verify that it works

- extra credit: customize the design

- extra credit : try other PCB processes

Group assignment¶

Link to group work : Link

We had to test the brand new machine acquired for the fabacademy. Test of the machine and then test of the PCB creation.

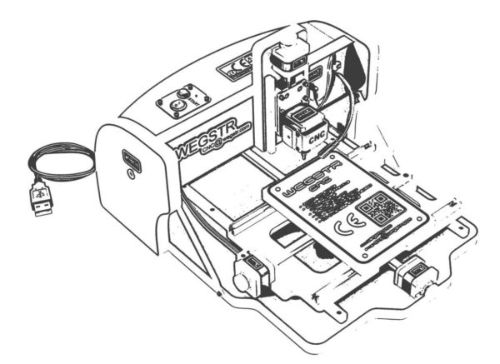

The CNC Wegstr

This the link fo website : https://wegstr.com

Here are the technical information of the machine

width - 380 mm

length - 460 mm

height - 290 mm

working area - 140 x 200 mm

spindle revolution - 11 000 rpm

maximal height under the spindle - 40 mm

maximal traverse speed :

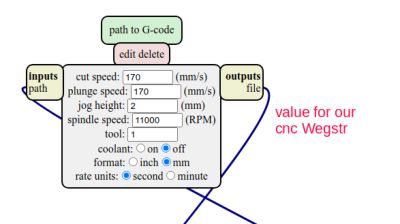

axis X – 170 mm/min

axis Y – 170 mm/min

axis Z – 170 mm/min

diameter of the spindle hole (for tool holding) - 3.175 mm

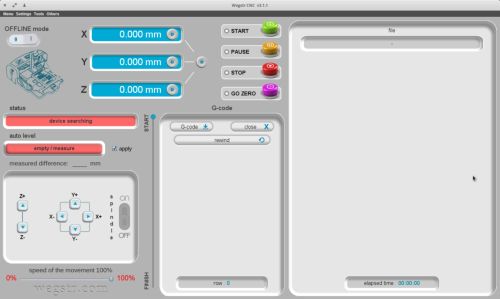

For information, the control software of the machine works under WIndows | MAC OS | Gnu/Linux. its name is : Wegstr CNC

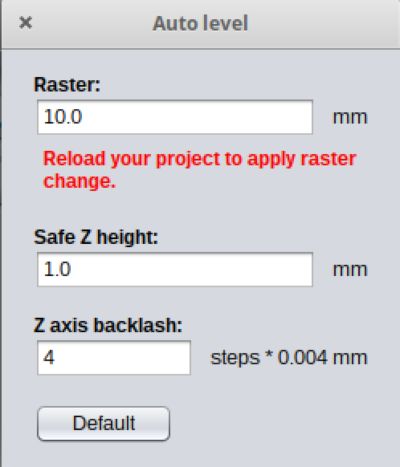

For self-levelling, the probing points can be set via the option provided in the software. You take the cut file for the probing and let the machine do it.

demonstration of auto-leveling

Practice CNC¶

We’re off to test the beast.

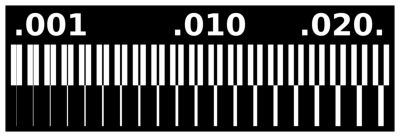

this is a test provided by our instructor to check the operation of the machine.

Exercice for group¶

for the purpose of the exercise, 3 drills (cnc cutter) are used

- V-mill (circuit)

- 0.6mm (clean-up)

- 1mm (cut)

We then carried out the requested group exercise with the following files:

Preparation of files¶

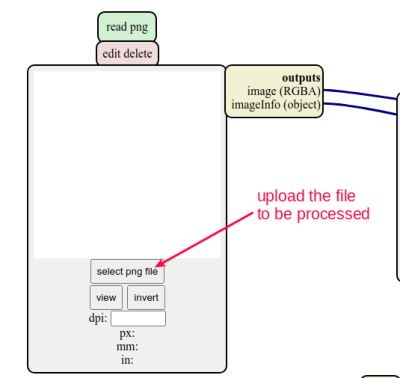

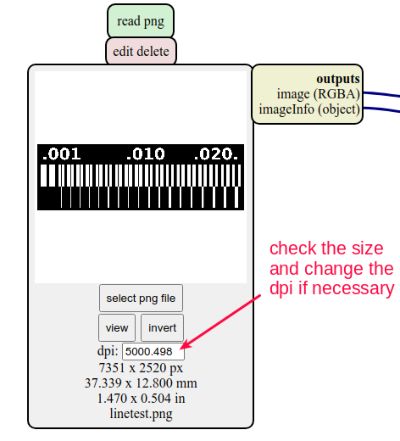

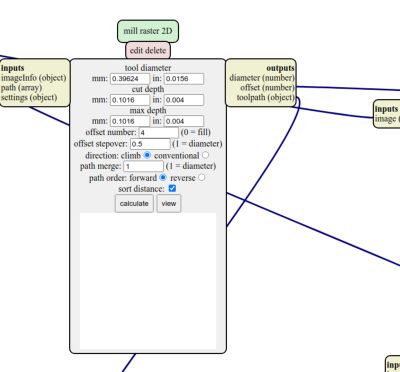

Preparation of engraving files, cleaning and cutting via mods

programs / open server program / Gcode / mill 2D PCB png

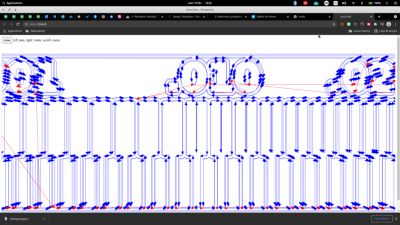

result after calculation

First Result, not satisfied with the result

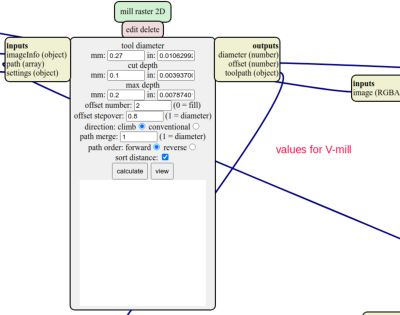

It’s better

Different values for engraving, cleaning and cutting¶

Circuit (engrave)¶

- V-bit

- tool diam : 0.27

- cut depht : 0.1

- max depht : 0.2

- offset : 2

- step over 0.8

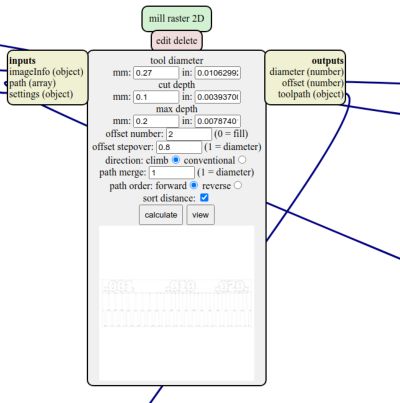

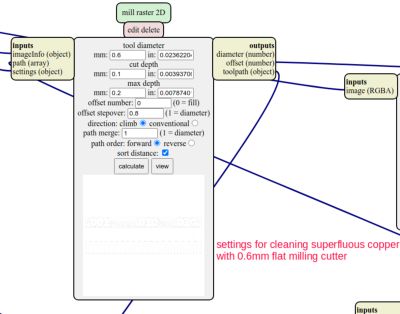

Copper cleaning¶

- tool 0.6mm

- tool diam : 0.6

- cut depht : 0.1

- mac depht : 0.2

- offset : 0 (fill)

- offset step over 1(0)

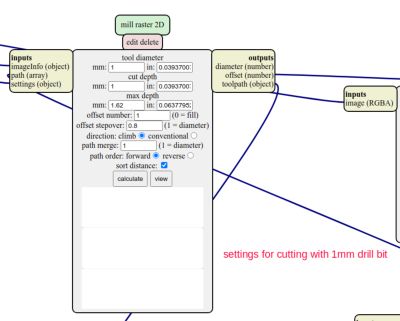

Cut¶

- die 1mm

- tool diam : 1mm

- cut depht : 1mm

- mac depht: 1.62 (copper plate measure)

- offset : 1

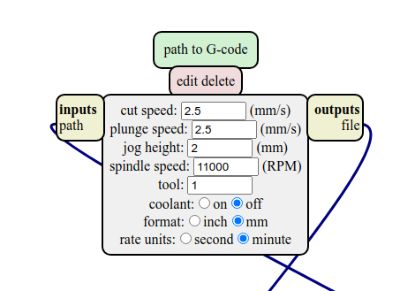

Speed milling¶

- speed 175

- rpm 11000

Individual assignment¶

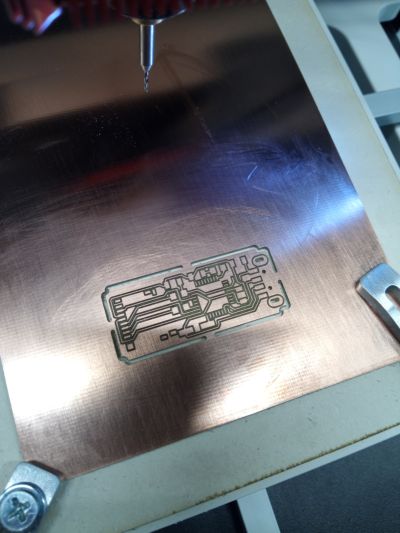

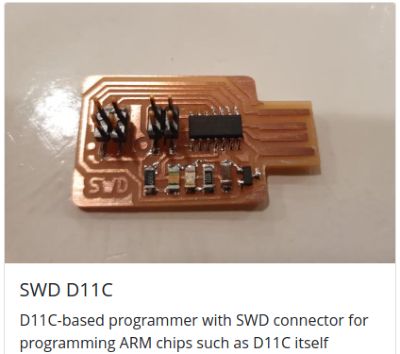

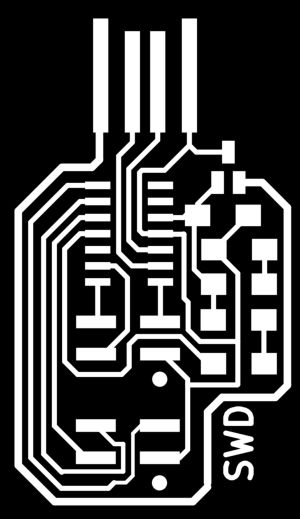

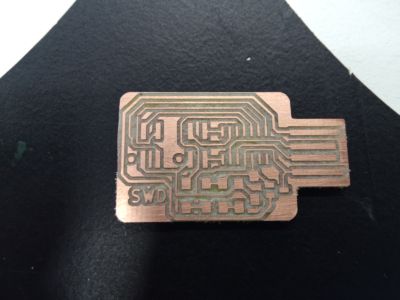

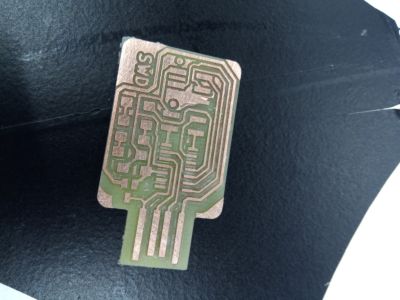

For our individual work, we had to make the printed circuit of the SWD D11C

These are the two files we need to process.

Step 1 : set up with mods¶

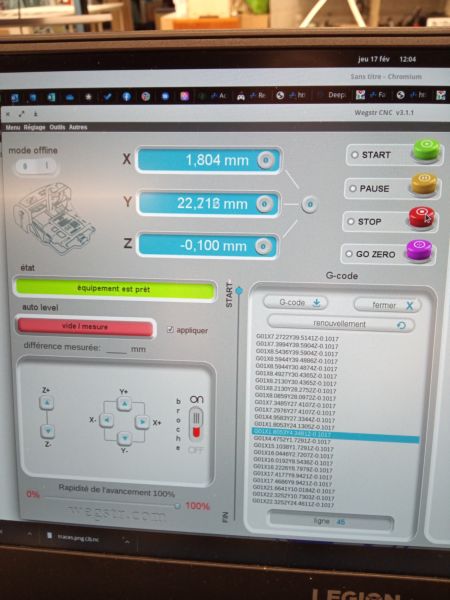

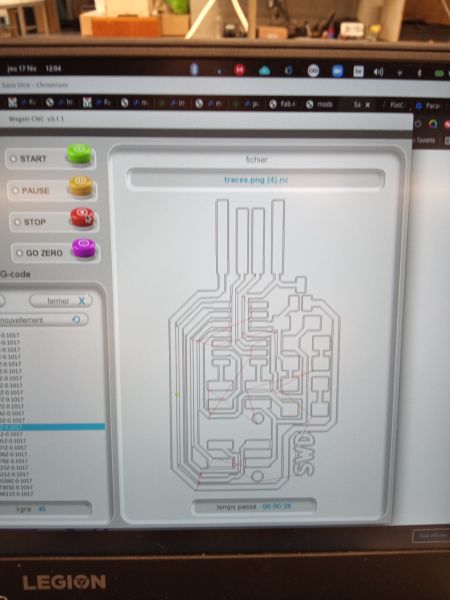

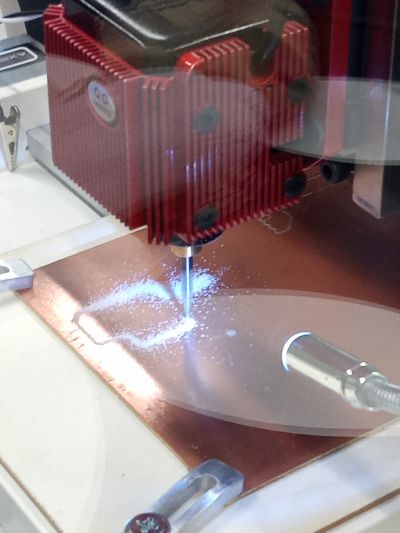

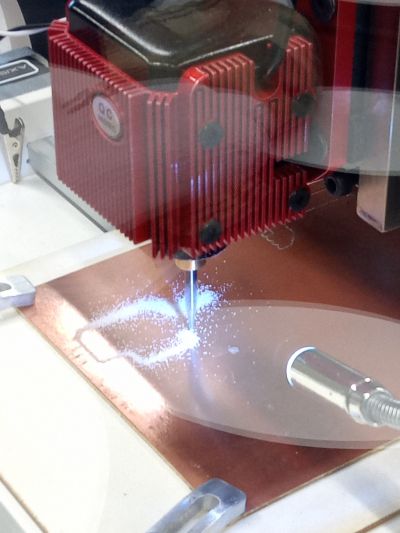

Step 2 : run CNC¶

Take the .nc file, generated by mods to open it in webgstr (with the “Gcode” option).

Then check the position of the tool with X,Y and Z.

When all this is done, put the tool that will be used for the job.

There are still the functions, START, PAUSE and STOP.

Warning

Attention STOP, stops the work and therefore, if you click on START, the work starts again from the beginning, while PAUSE, START will restart where it is.

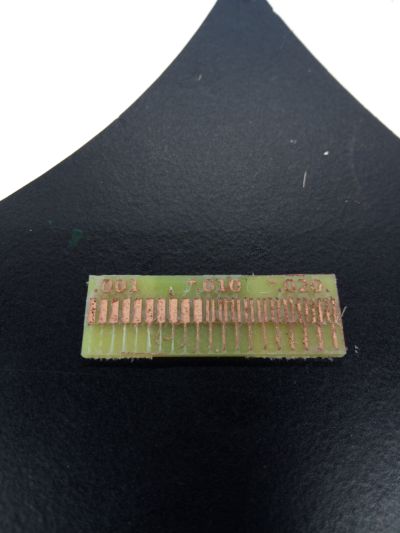

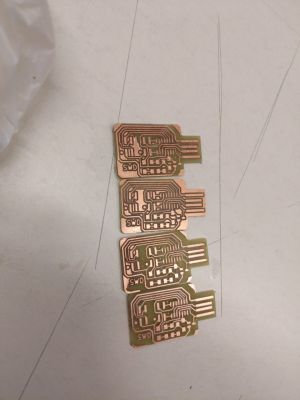

Result :¶

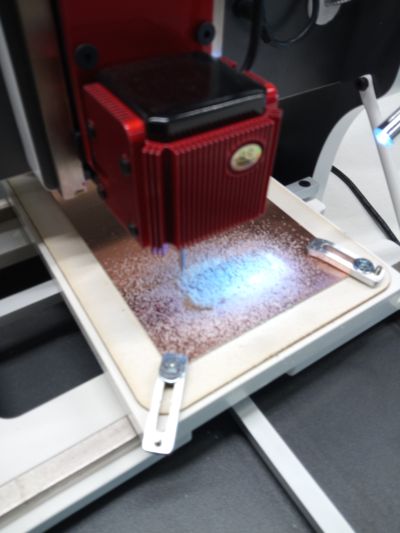

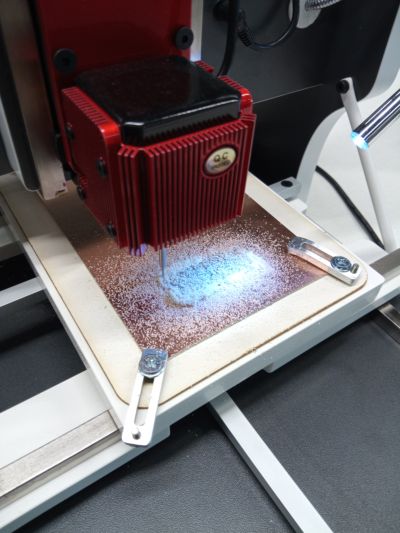

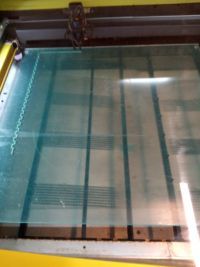

Mineral oil is used to avoid material splashing from the milling machine

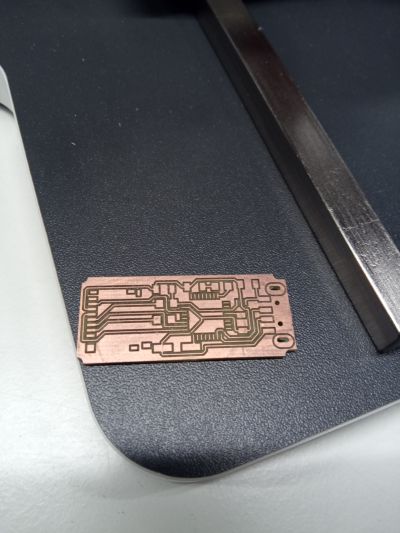

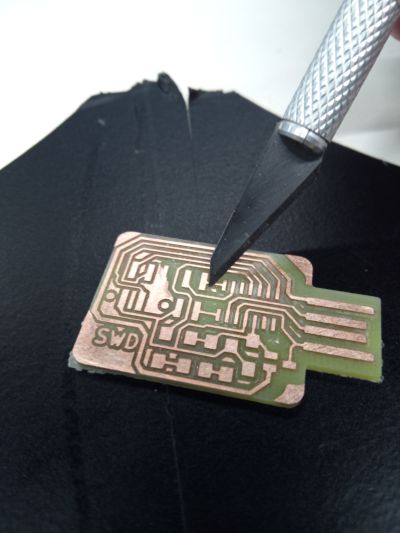

Step 3 : cleanup via cutter¶

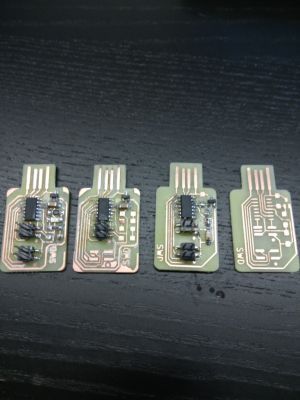

Step 4 : welding¶

with microscope, its more easy

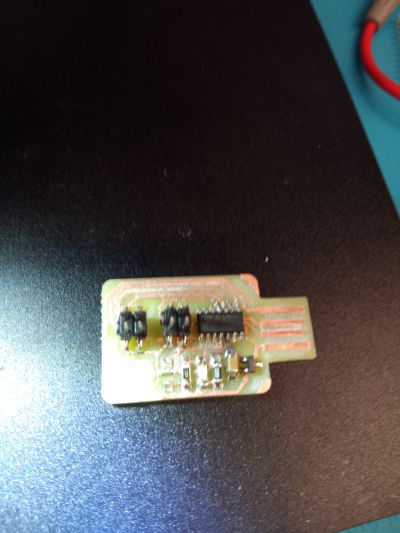

Step 5 : programming¶

Flashing firmware¶

This board must be flashed with the free dap binary from Alex Taradov, which can be downloaded here .

For flashing, edbg can be used with the following command, in the terminal:

edbg -ebpv -t samd11 -f free_dap_d11c_mini.bin

Normally, after successful flashing, your board should show up as a USB device named “CMSIS-DAP”.

Problem : with our instructor, we had a problem. The programming works (no error message), but then no way to be detected by the PC. Our instructor thinks that there is a technical problem with the main component. We will meet again next week to fix the problem.

correction We found a difference in the SAMD11C14 . There was a letter difference at the end. There was an M. With the correct version, there were no more problems, the programming went smoothly.

Bonus¶

transformation of an old piece of furniture to dedicate it to the CNC PCB

Plexiglas protection :

files :

- drawer : drawer.svg

- plexiglass protection : plexiglasprotection.vsg

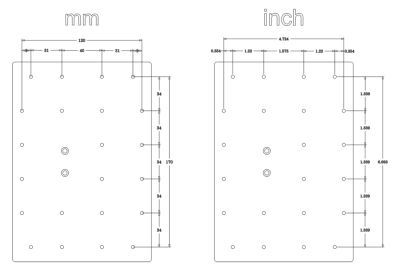

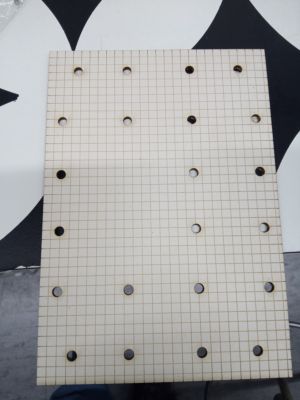

As i had the cnc datasheet, i redrew in freecad the martyr and i took the opportunity to create a grid to align the sheets more easily for pcb

files :