10. Modeling and casting¶

TODO List¶

- Group assignment:

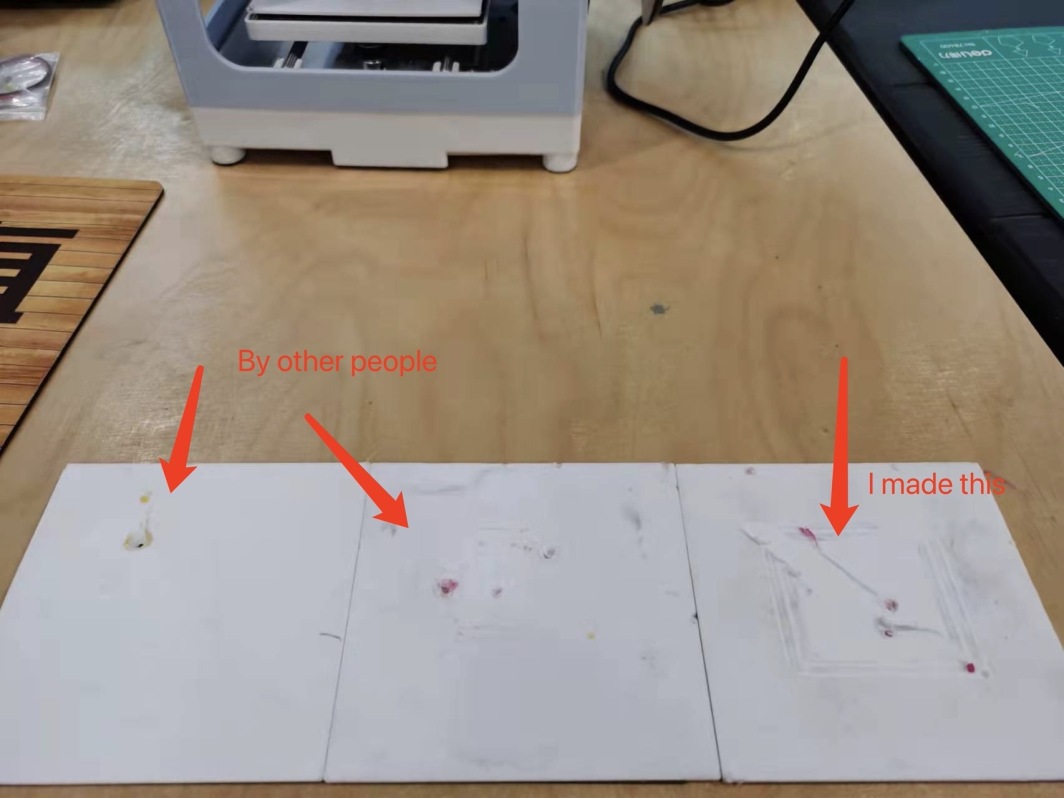

- Review the safety data sheets for each of your molding and casting materials

- Make and compare test casts with each of them

- Individual assignment:

- Design a 3D mould around the stock and tooling that you’ll be using, mill it (rough cut + (at least) three-axis finish cut), and use it to cast parts.

Bird house¶

Design¶

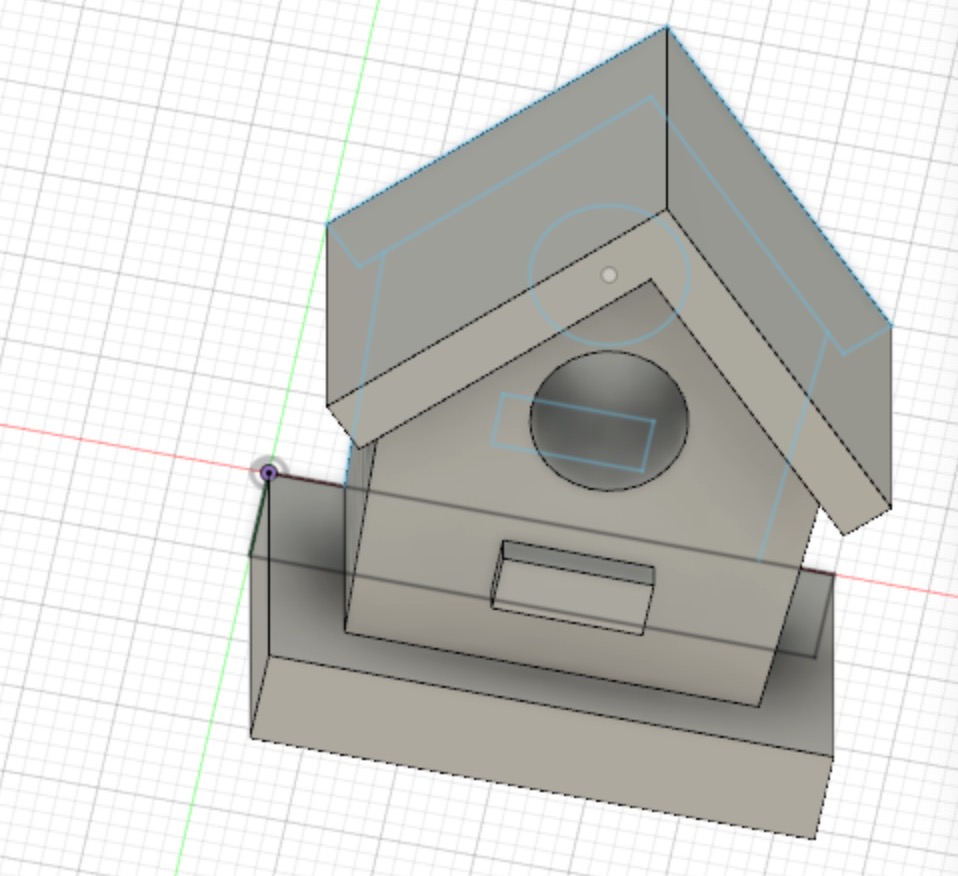

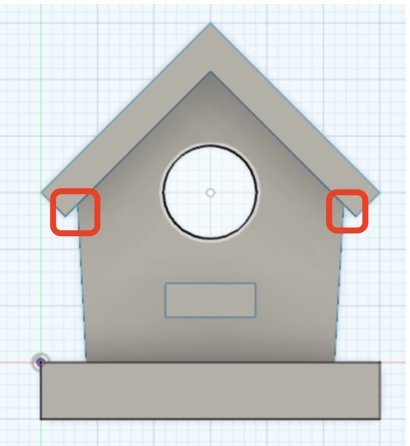

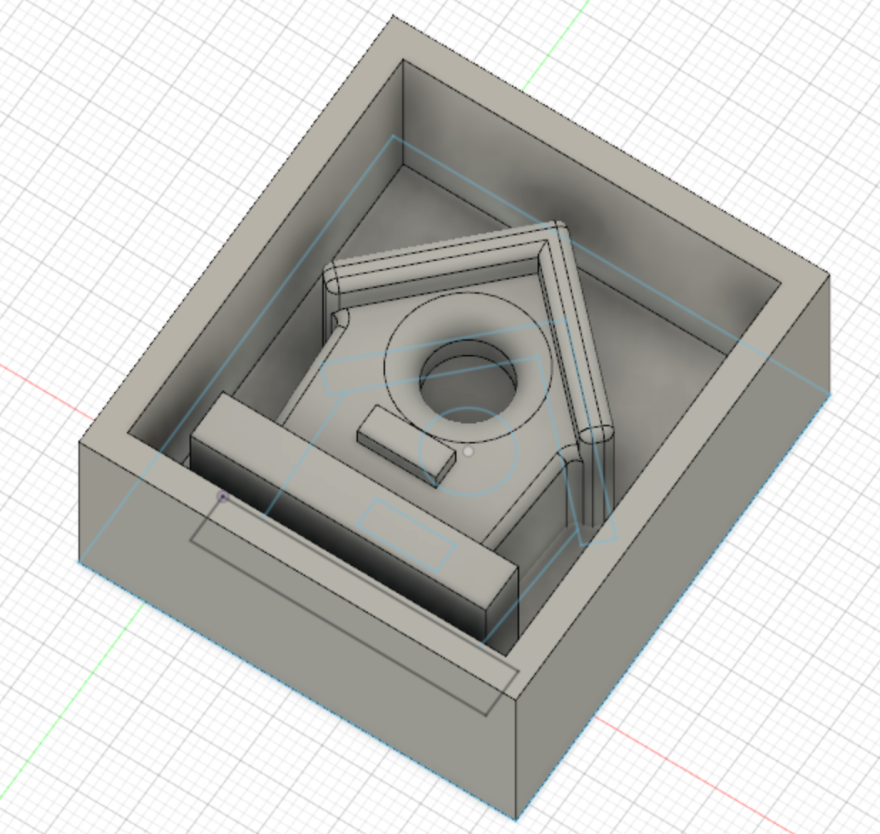

I use Fusion360 to make a bird house:

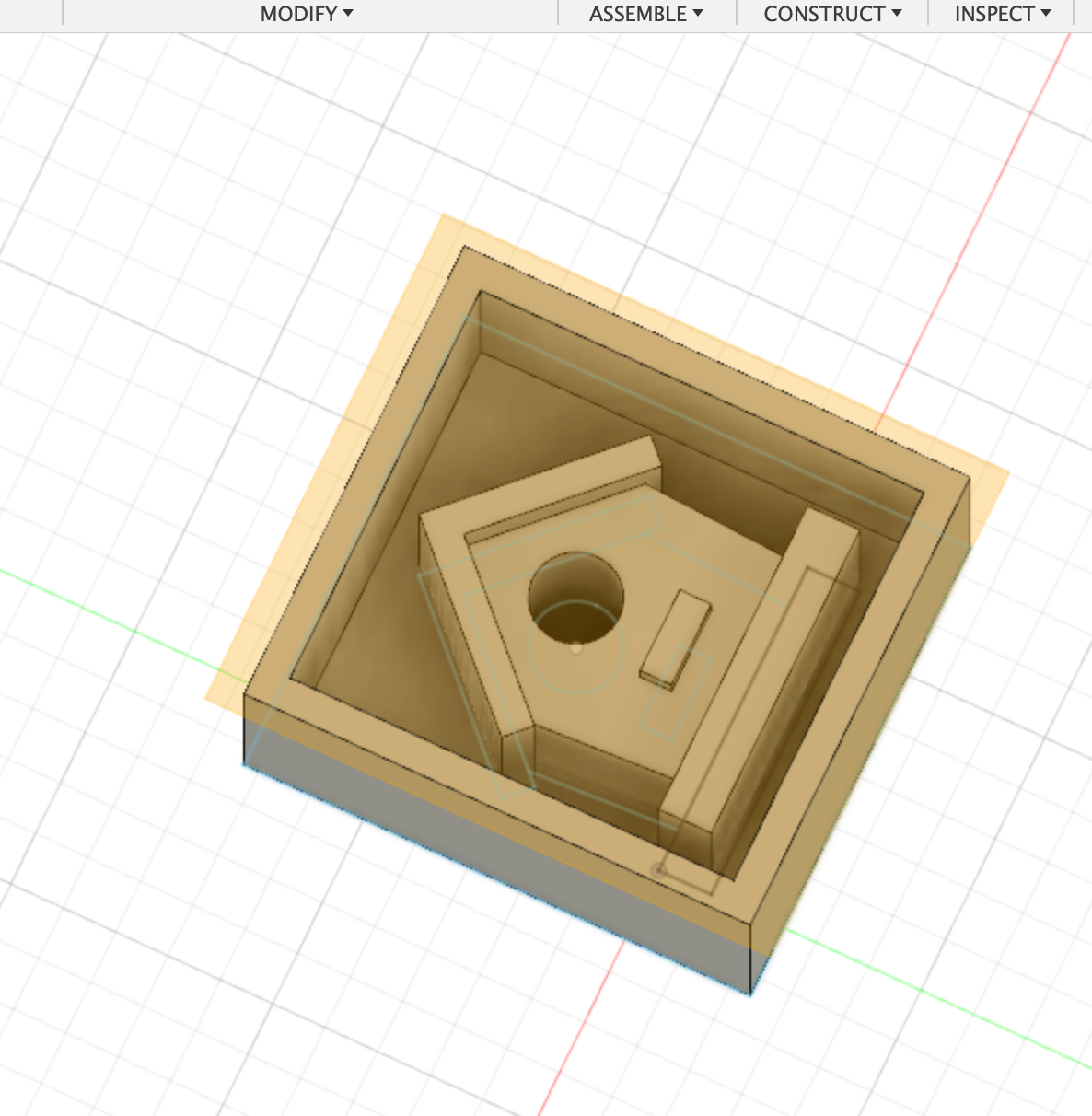

Add the outside holder to it :

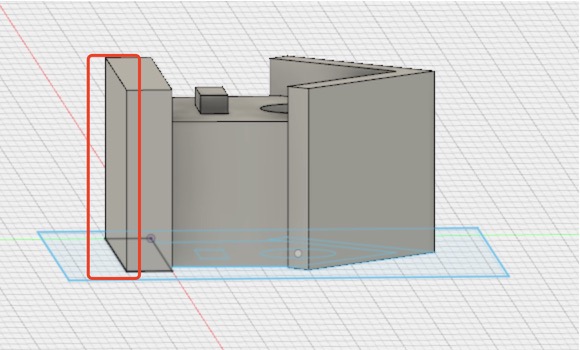

The problem of the model:

- All the surfaces goes straight down to the bottom.

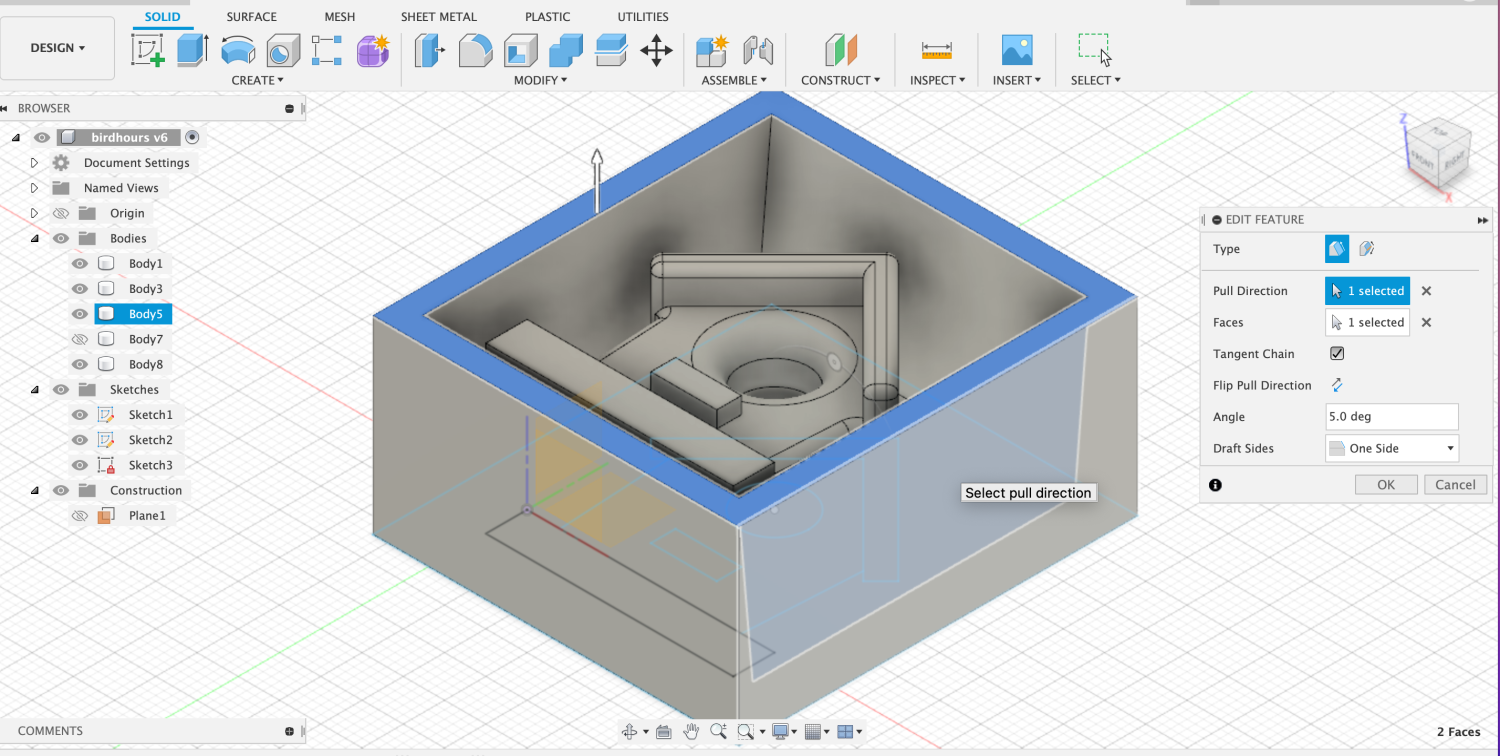

Use the new function called Draft(SOLID>MODIFY>DRAFT) to rotate the wall with a 5 degree angle.

- The under part of the roof might not cut well.

To fix this problem, I use the fillet to change the under roof angles into round.

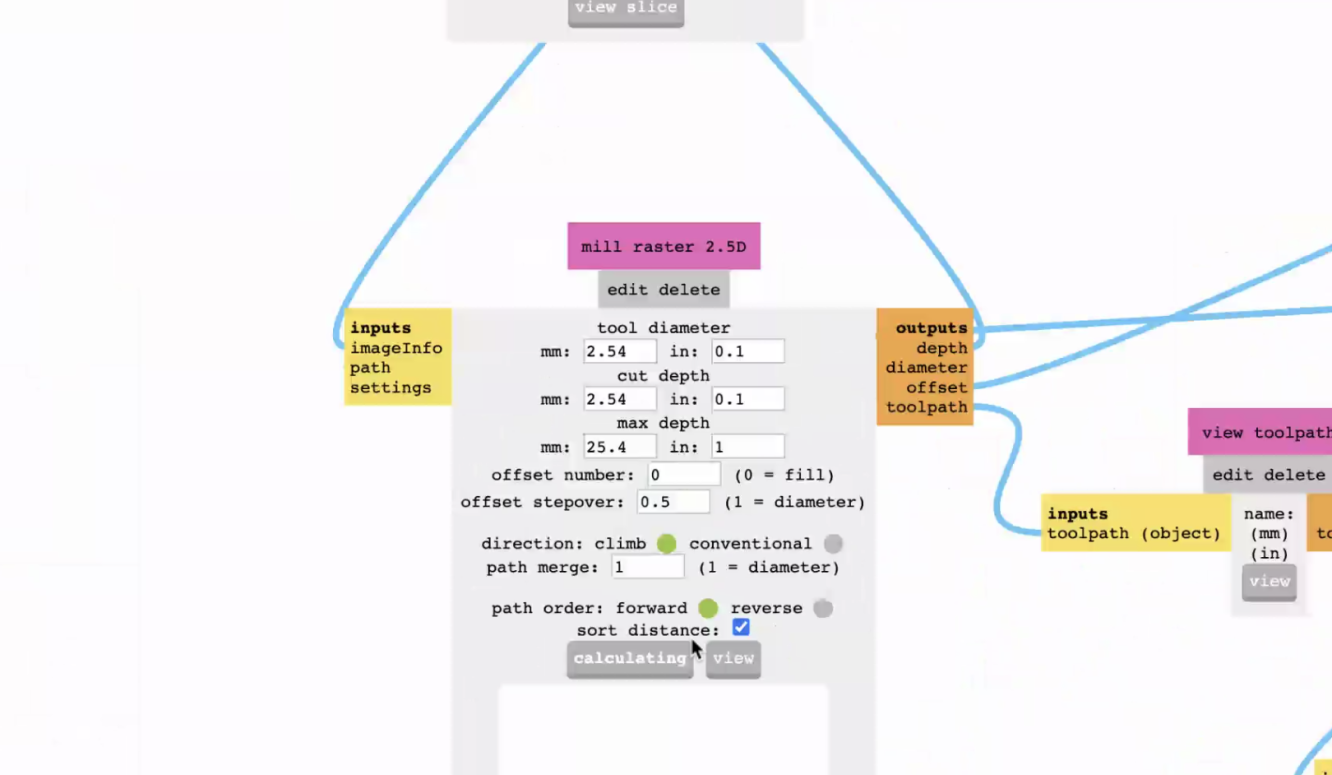

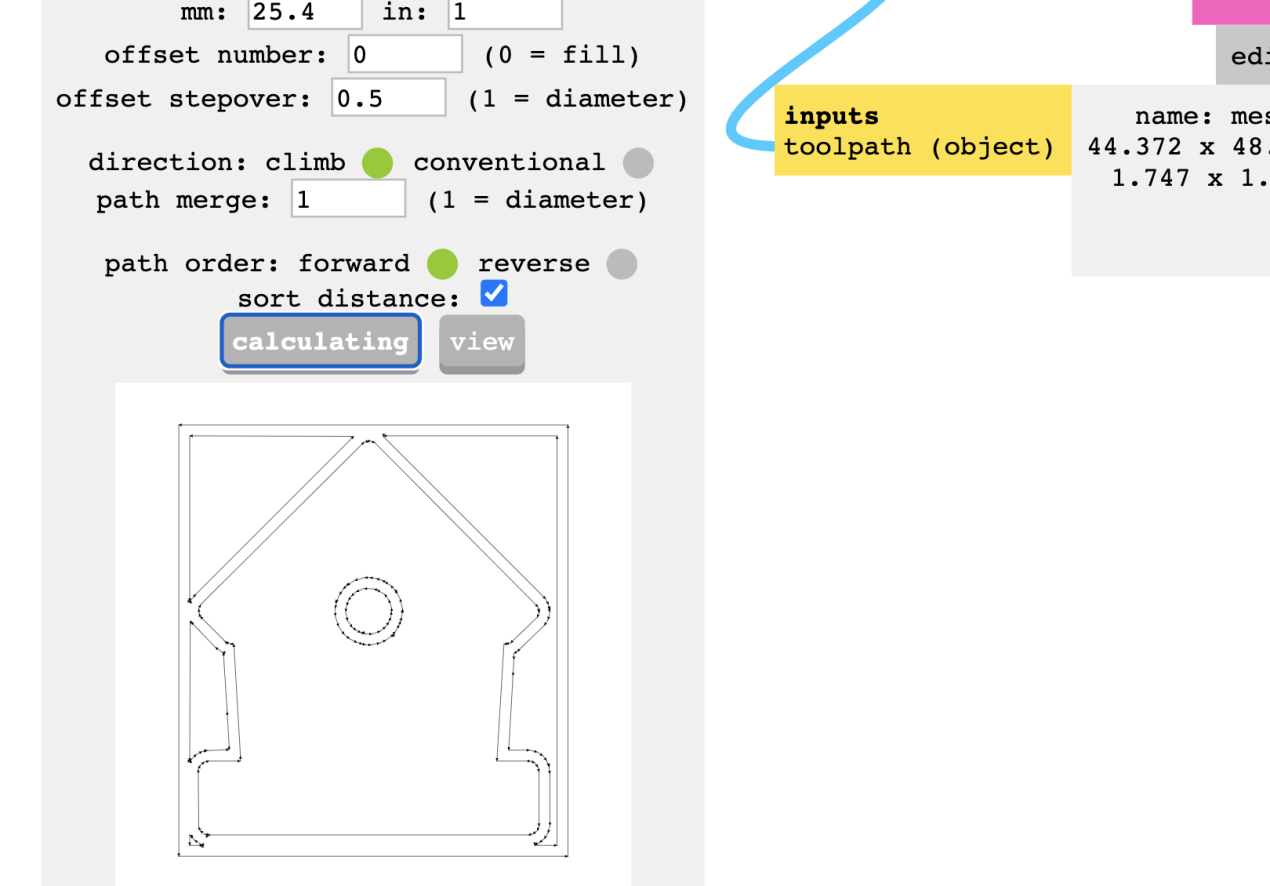

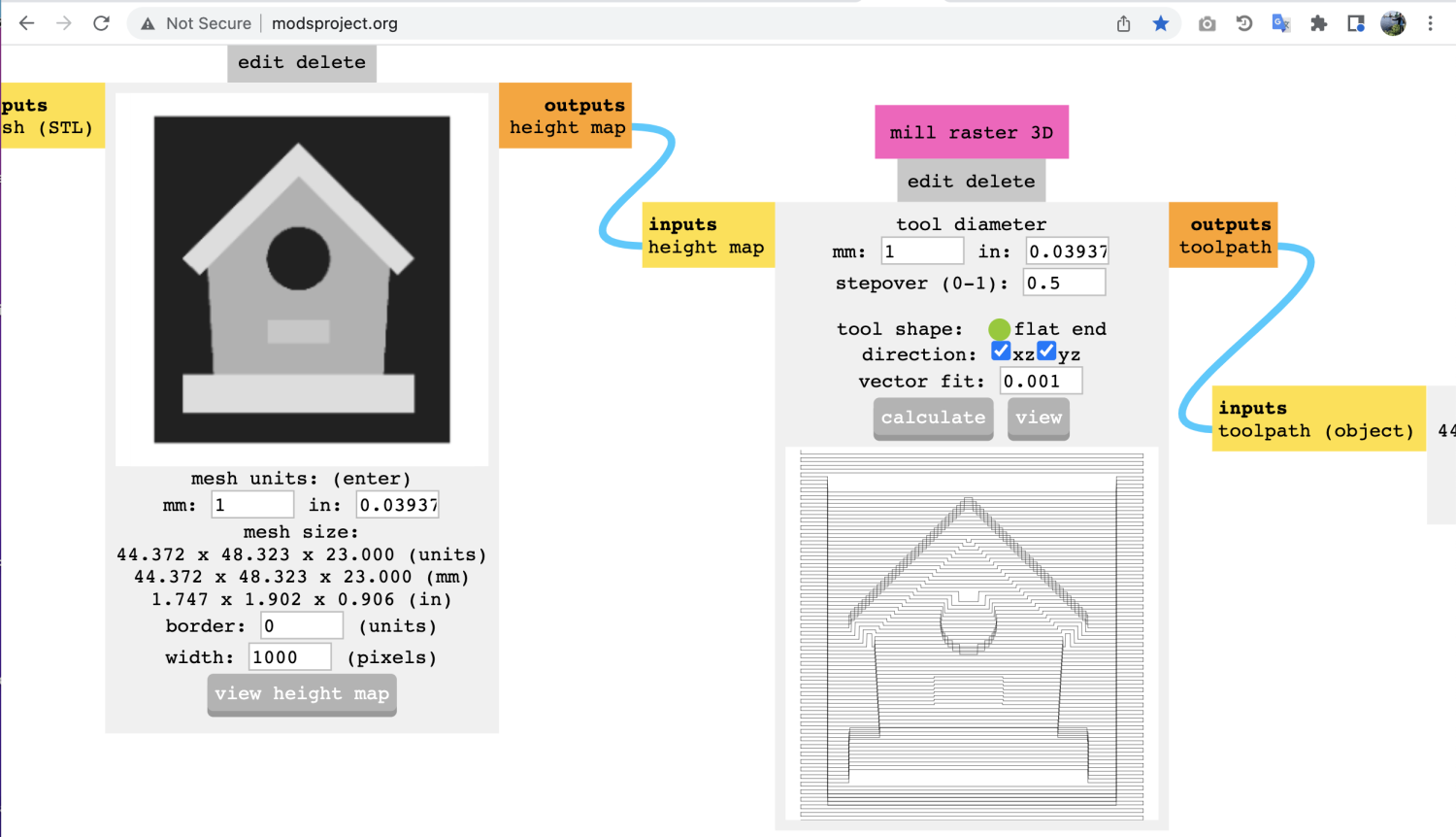

Mods¶

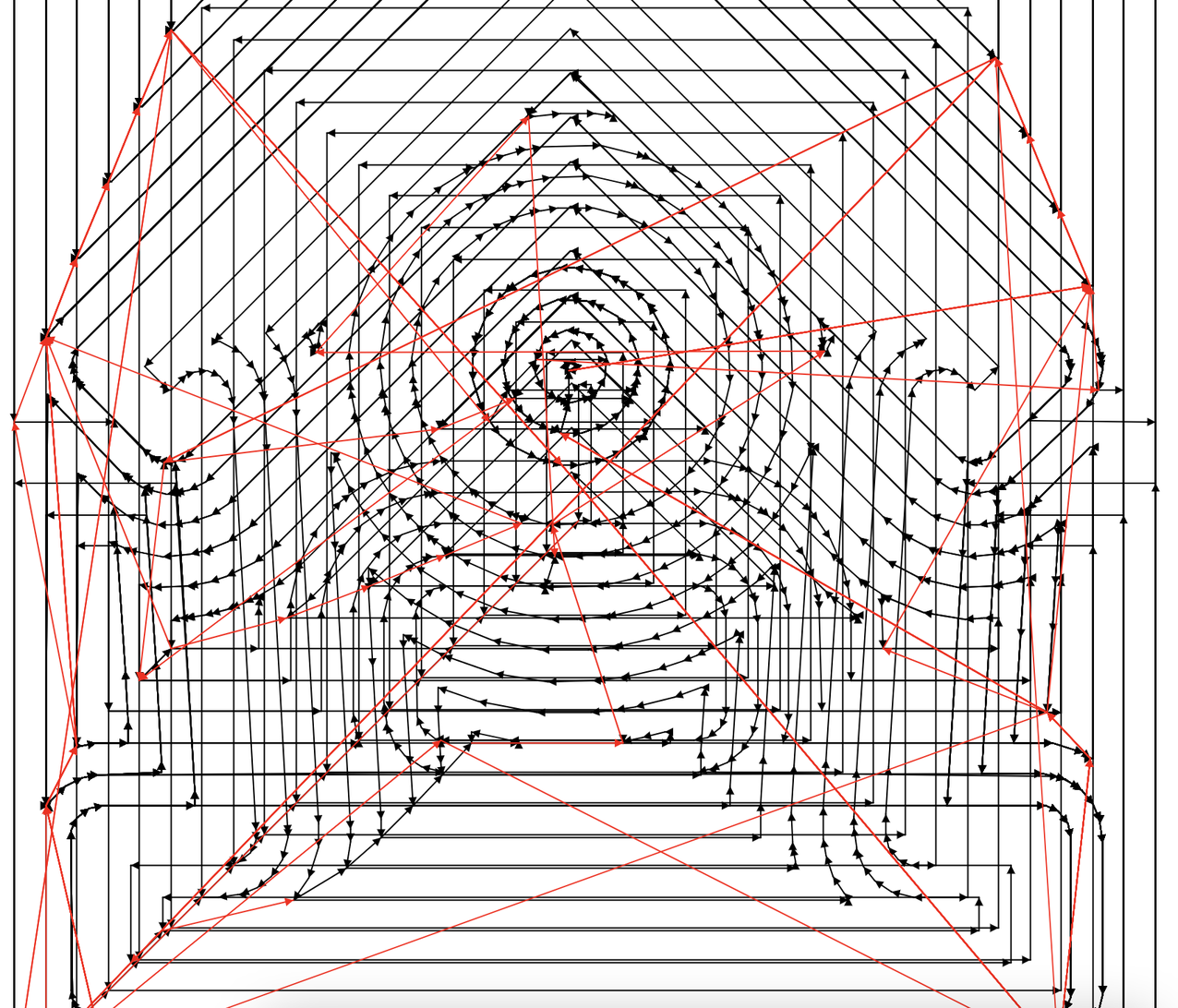

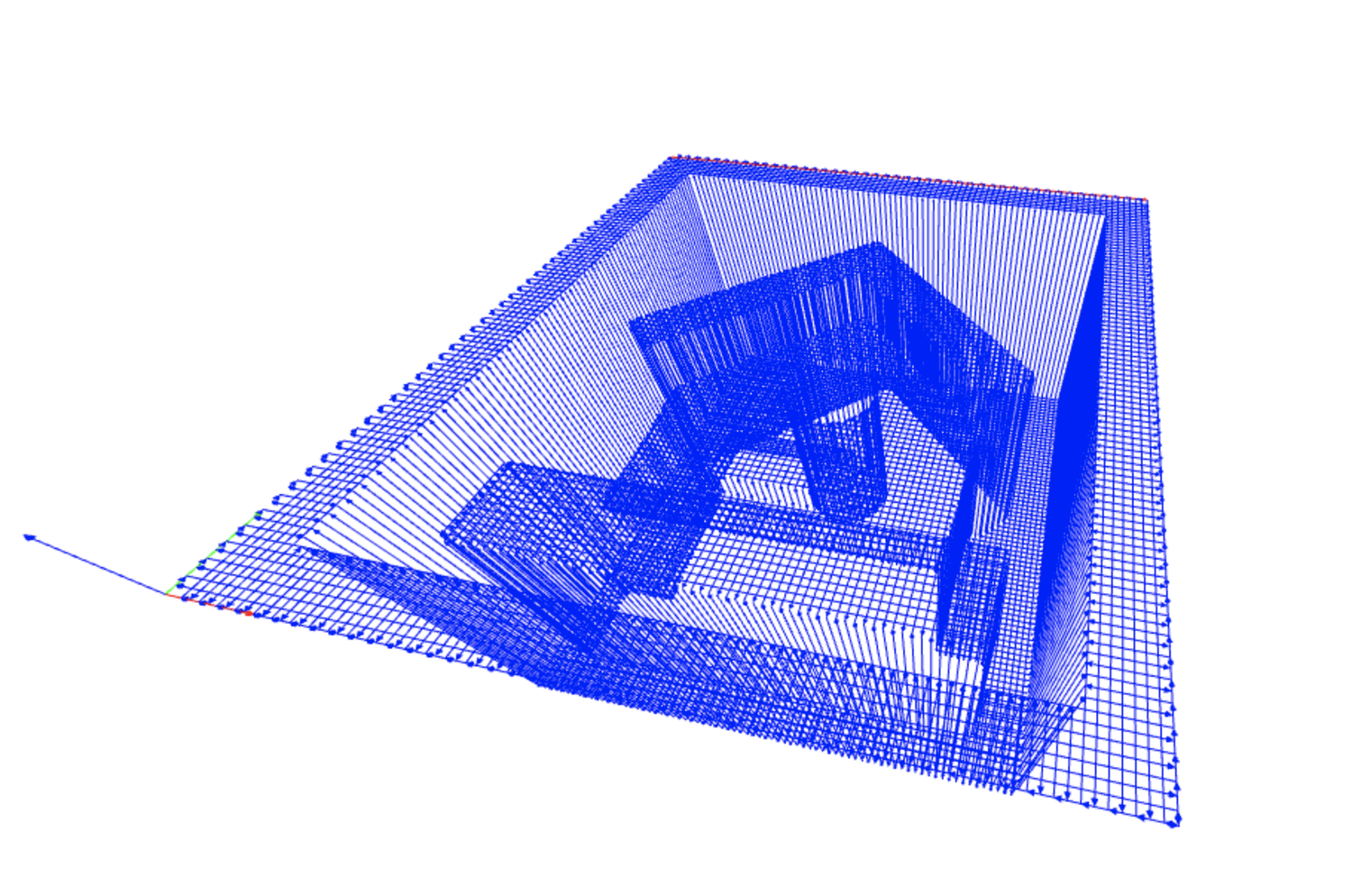

Use mods to simulate the cut process. The process will be too parts: rough cut and final cut.

Rough cut¶

Final Cut¶

https://fabacademy.org/2022/labs/kannai/Instruction/tips/wax_milling_mods/

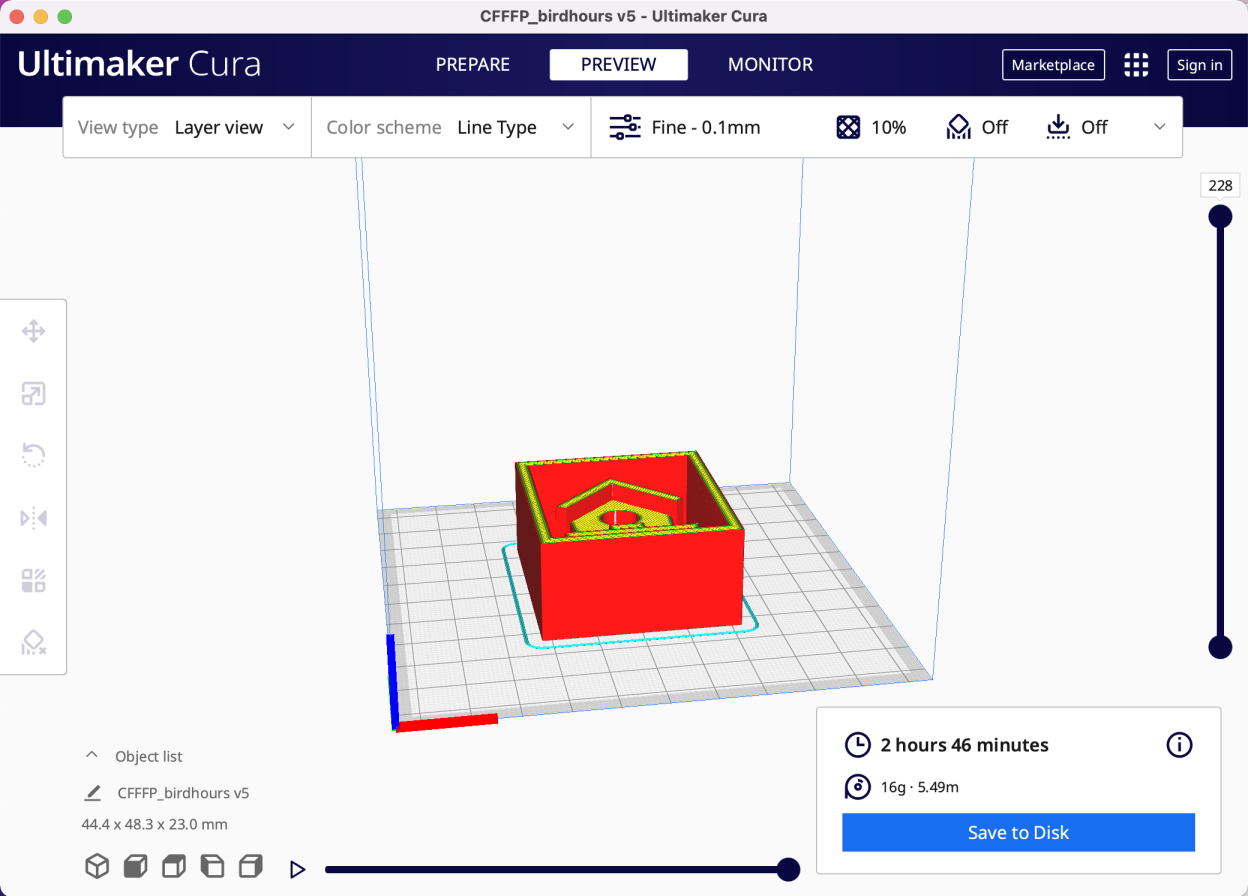

3D printer test¶

3D printer issue¶

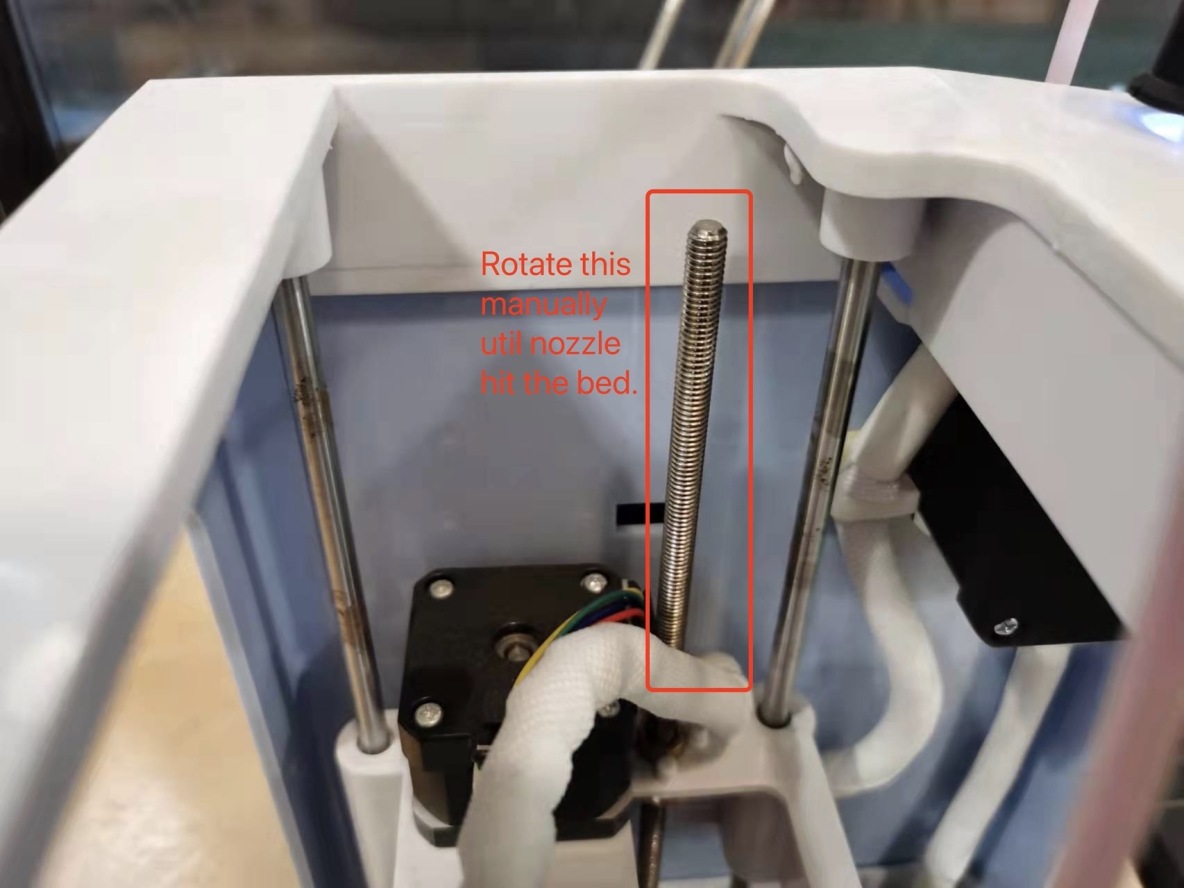

The Z-index is not set properly, so the first 10-20 layers will not come out. So every time when I try to stop or pause the printer, the 200 degree nozzle will hit the bed and leave a hole on it.

The fix is to adjust this screw a little up and rotate Z-axis until the nozzle hit the bed properly, not too much.

Brick¶

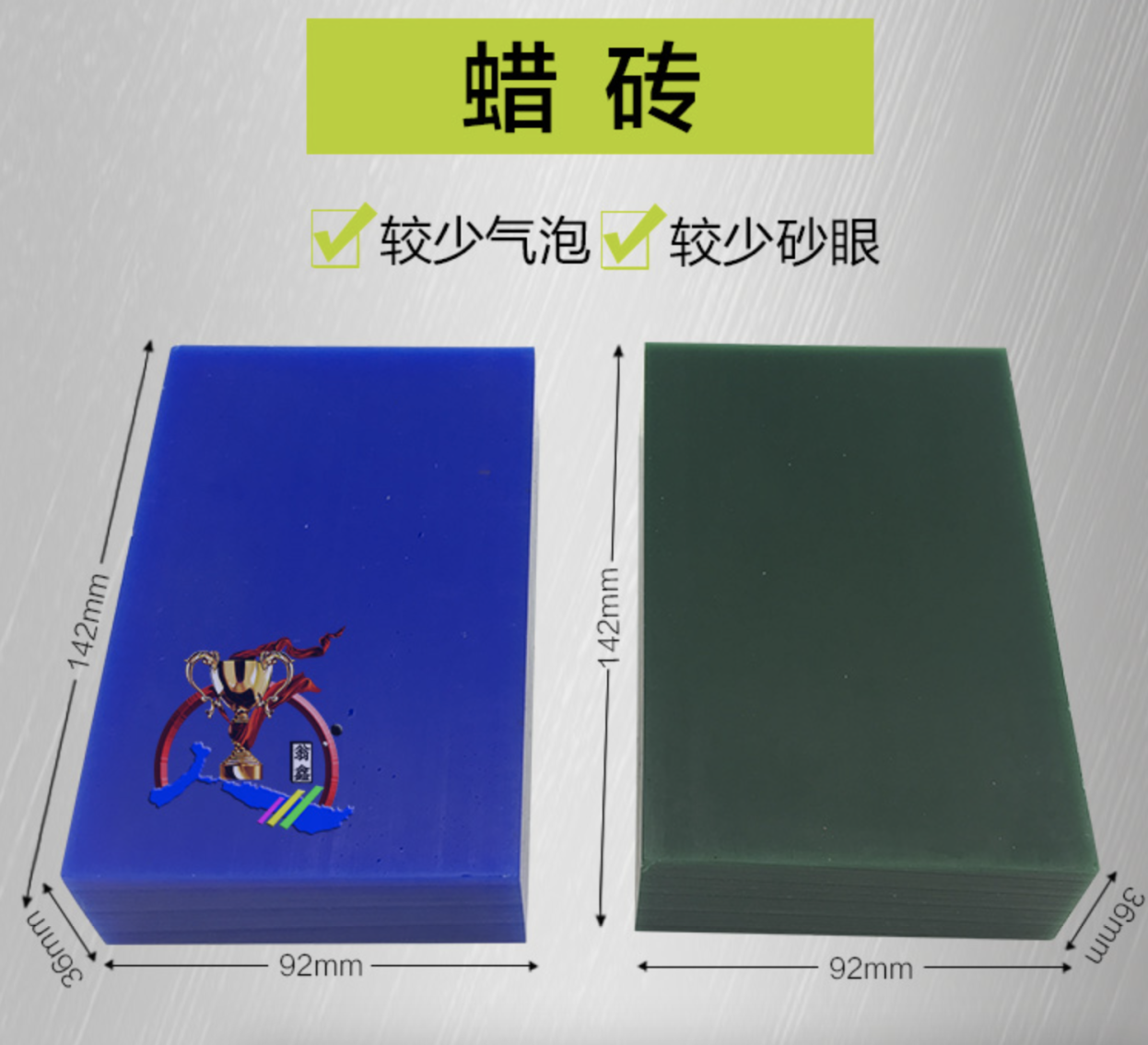

The bricks we will use is size: 36mm92mm142mm.

Endmill¶

Roughcut 3mm endmill Finishing cut 1mm endmill 1mm ball end