8. Computer-controlled machining¶

TODO List¶

- Group assignment:

- Complete your lab’s safety training

- Test runout, alignment, speeds, feeds, and toolpaths for your machine

- Document your work to the group work page and reflect on your individual page what you learned

- Individual project

- Make (design+mill+assemble) something big

Flowershelf¶

I want to make a flowershelf for the small graden in our lab.

Some other ideas¶

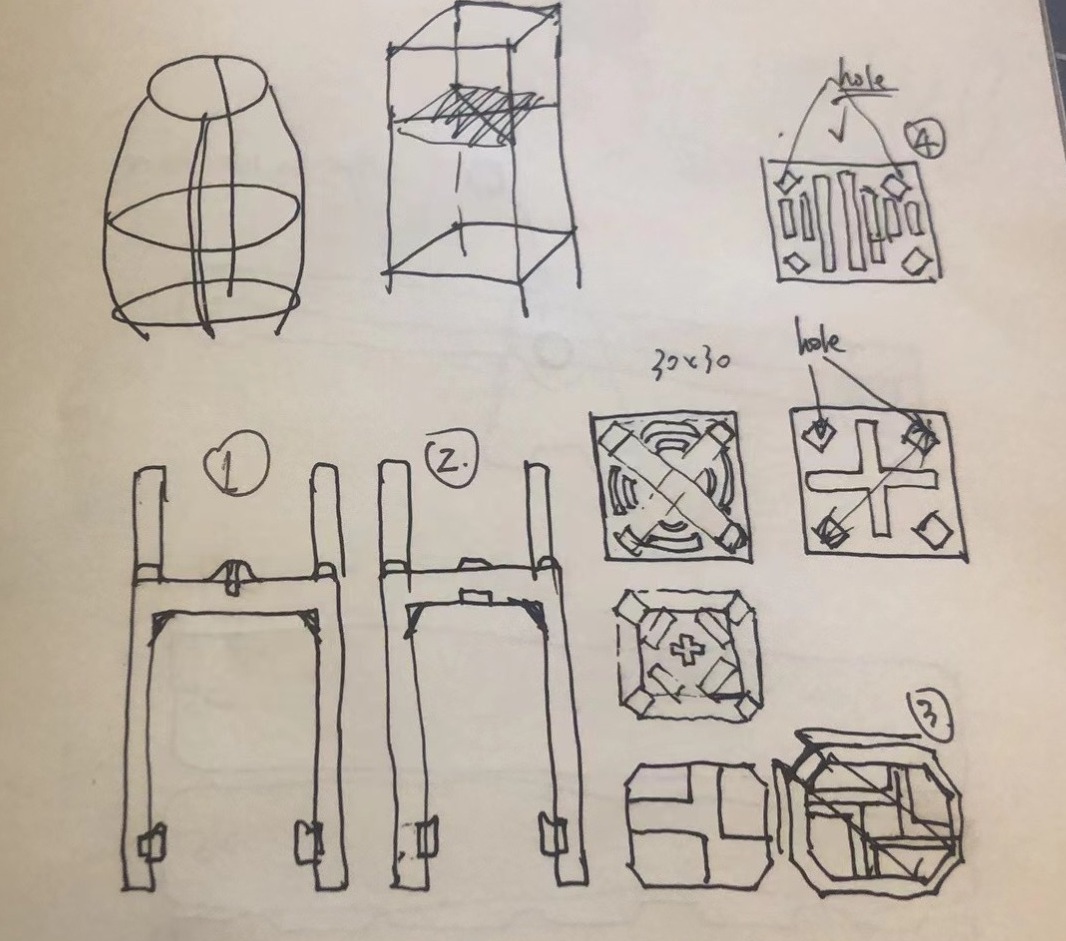

I was also thinking of making a seesaw or a floor lamp like these:

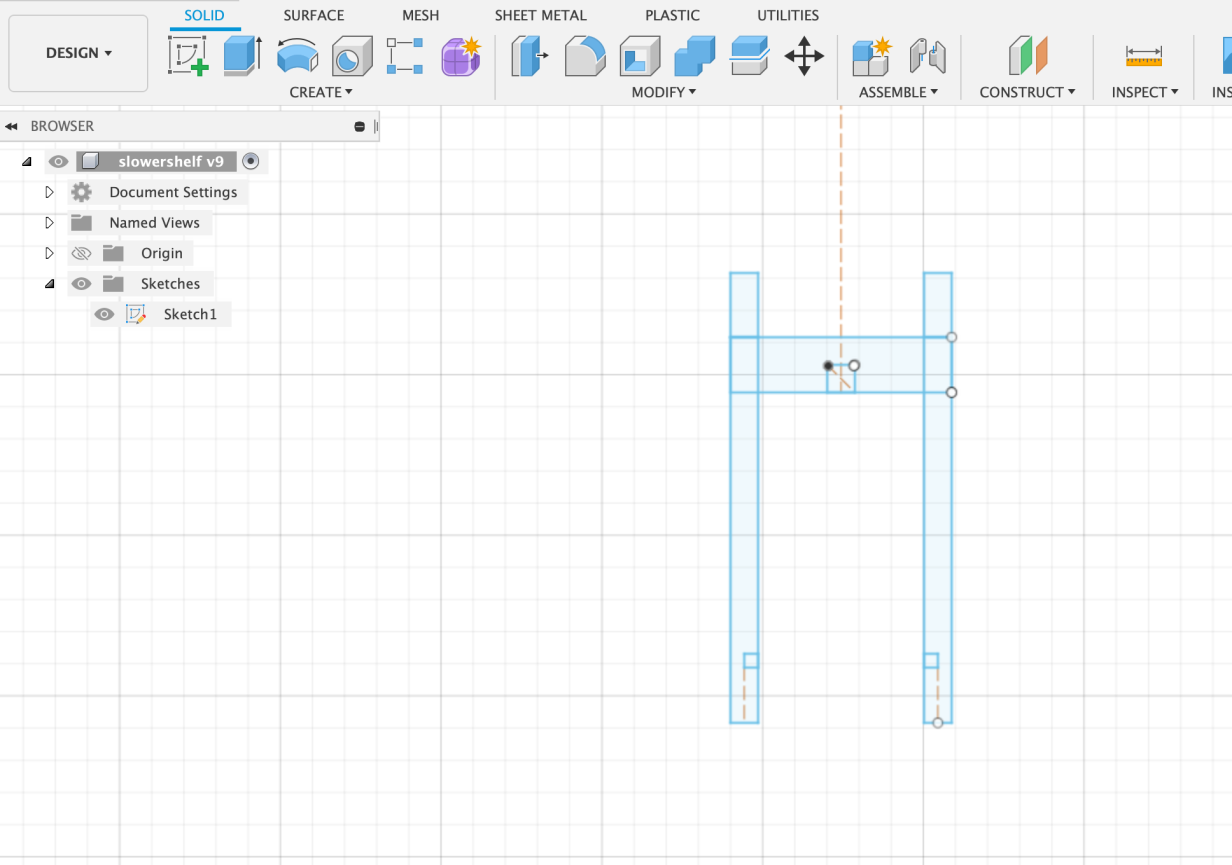

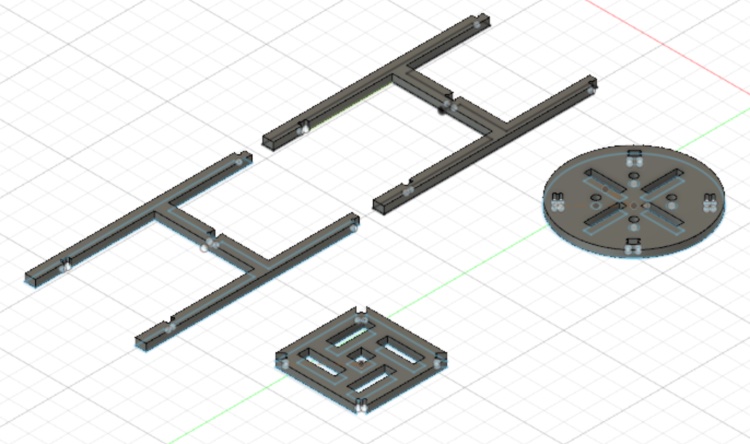

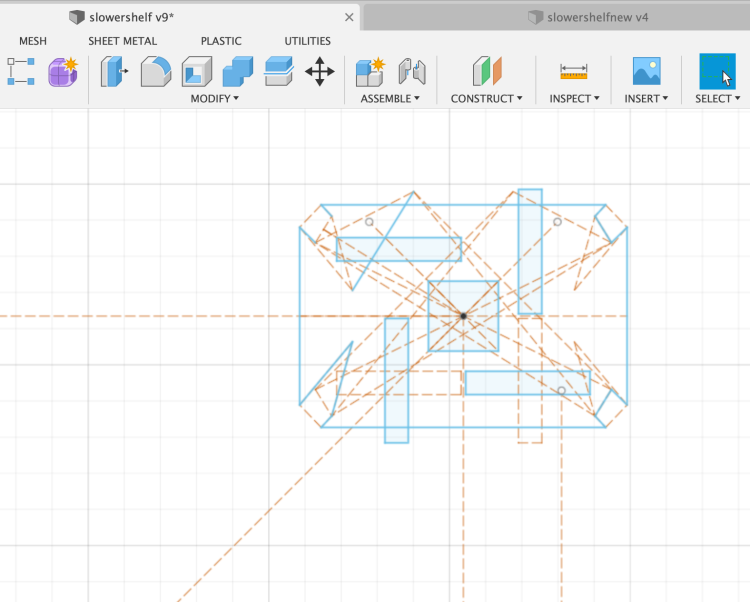

Design in Fusion360¶

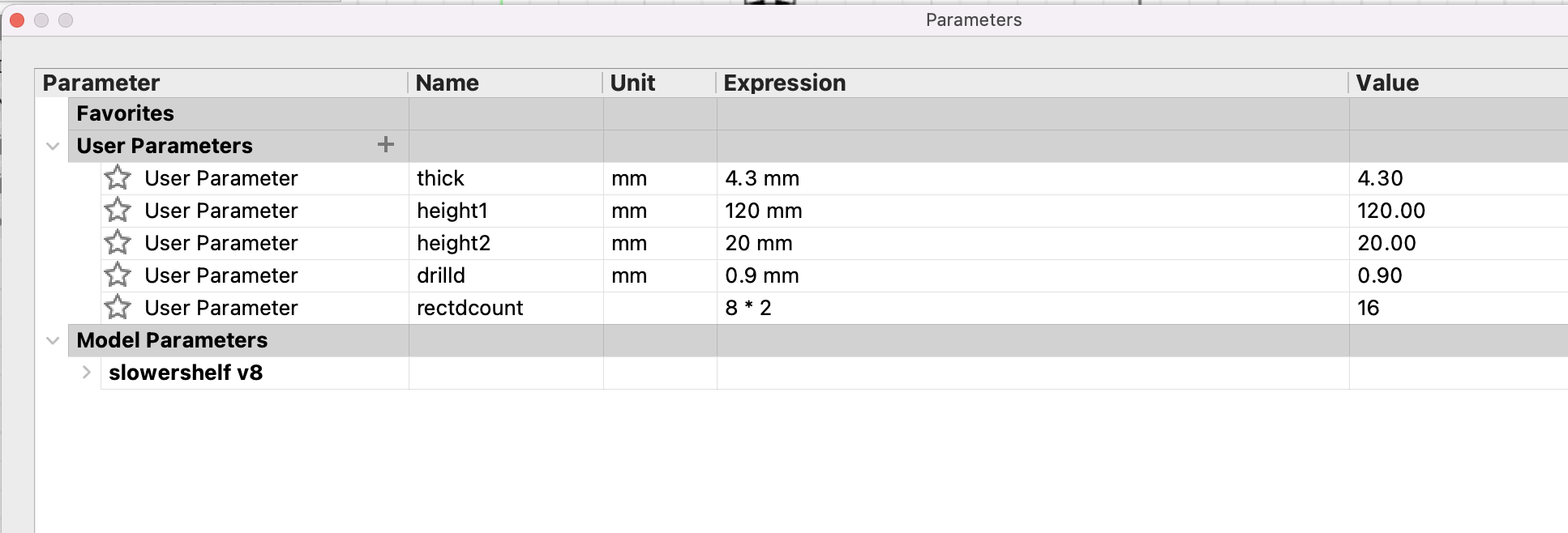

Define parameters¶

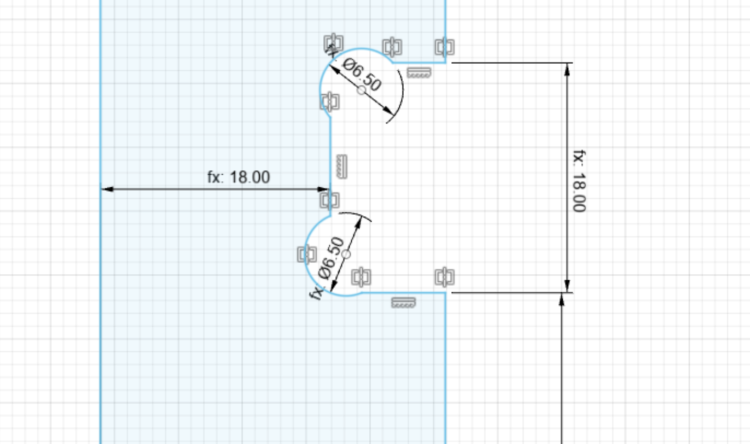

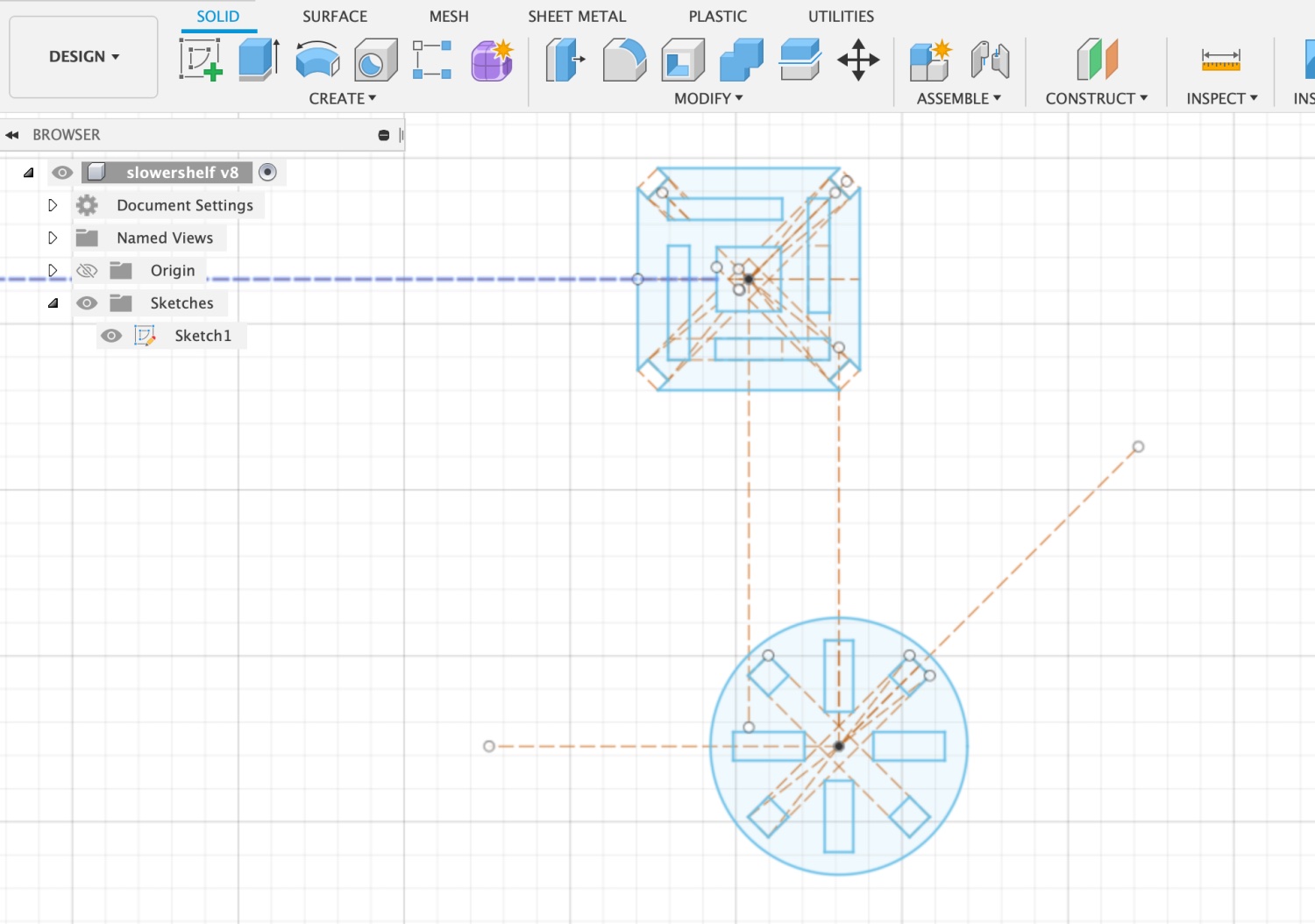

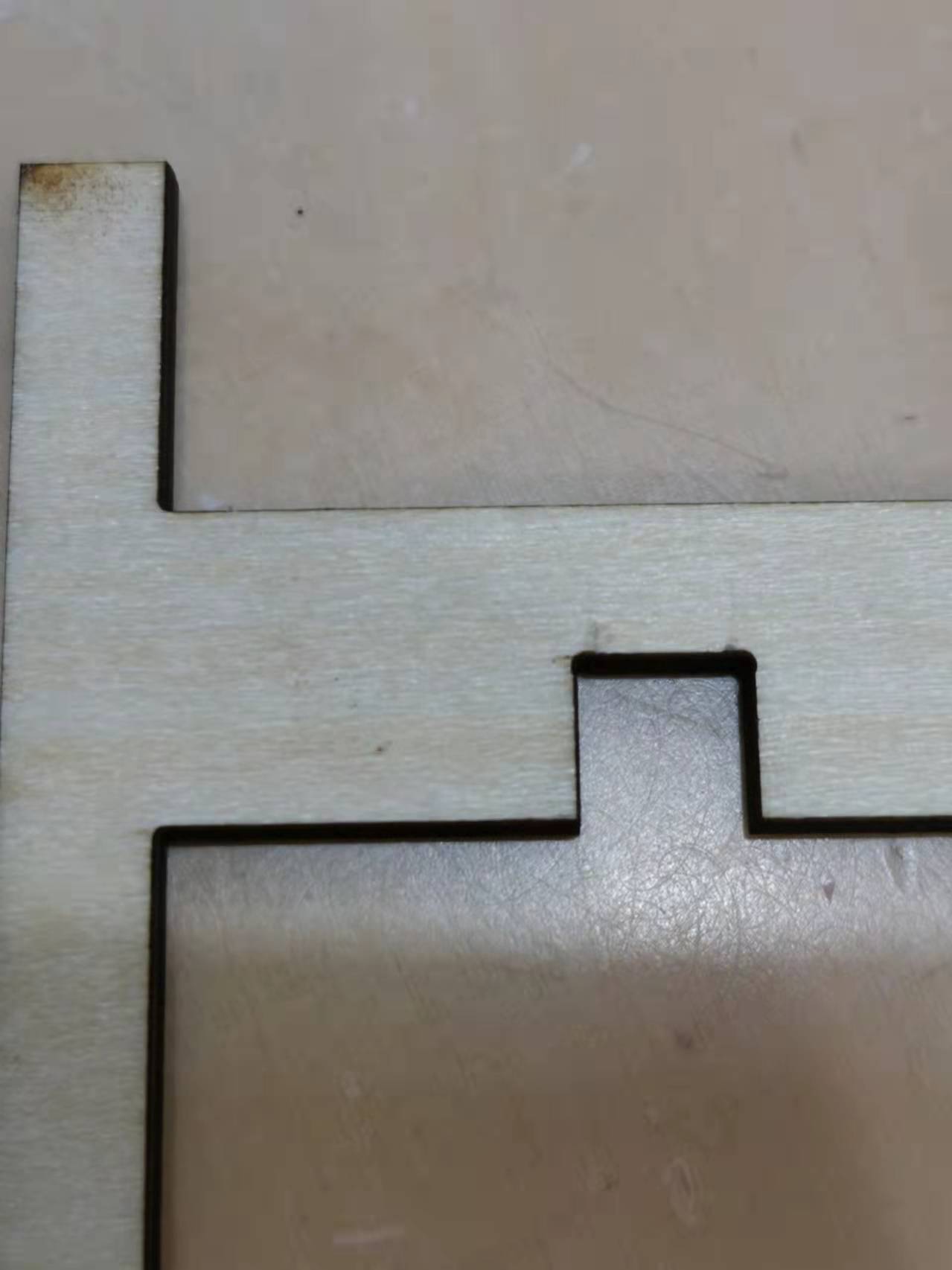

Joint¶

Use dog bone for the joint:

Layers¶

Model¶

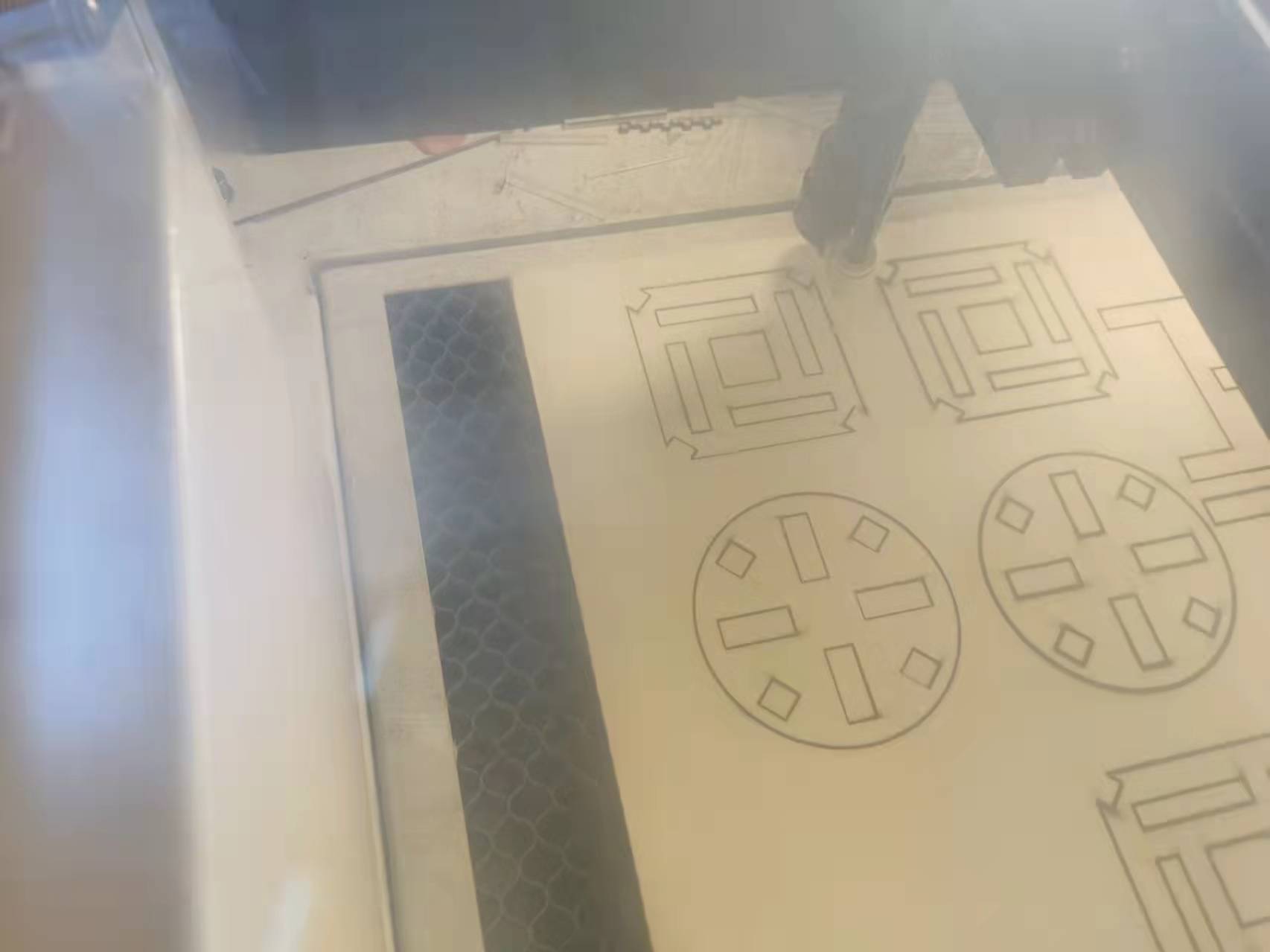

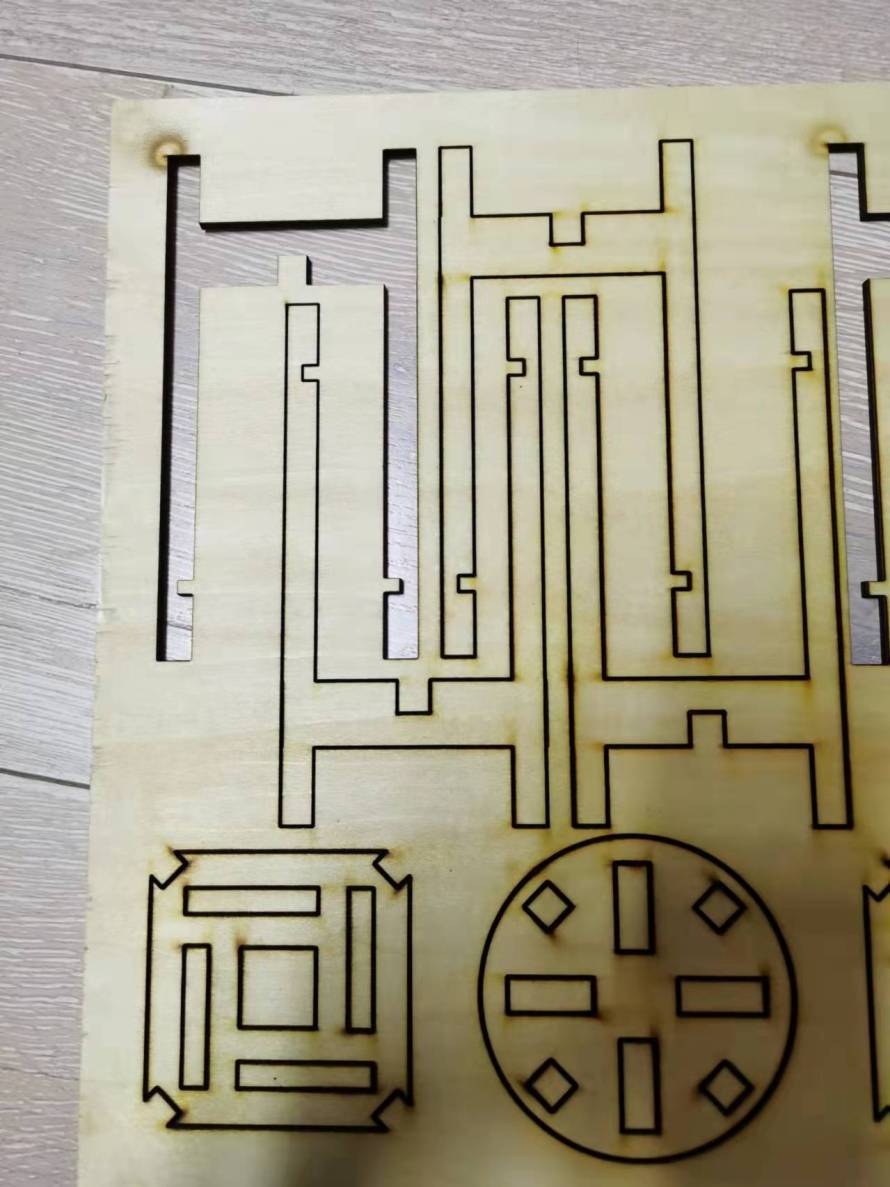

Laser cut model¶

Dogbone¶

Although in lazer cut the dog bone joint is not necessary, but it is good opportunity to observe the cut details.

Issue¶

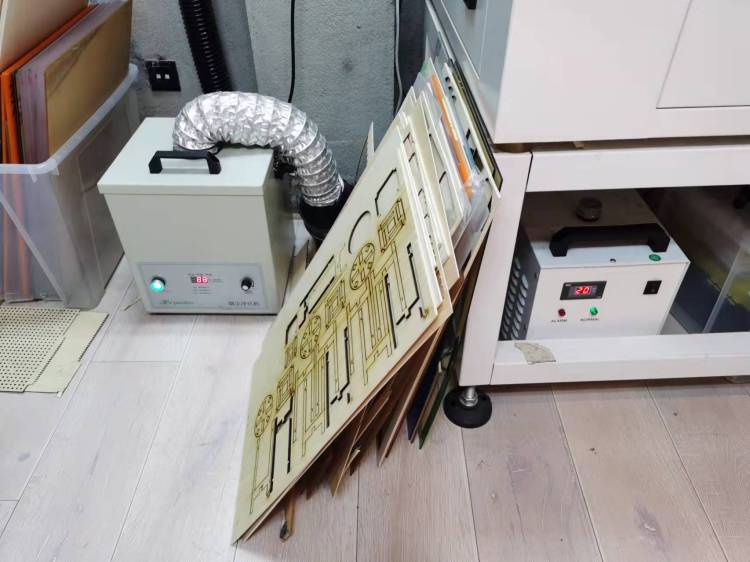

Laser cut smoke¶

When I was cutting the small size model, the lazer cutter machine inside get a lot smoke like this:

The result become a problem. Only the first piece can come off from the board. And the others can not get off.

I was thinking of may be the power and speed is not set correctly. So I did another two test with higher power, but the result is still the same. During the third time, the smoke even trigger the alrm!

That is when I start to check around the machine.

With the helper of our instructor Saverio, we found the problem. The issue comes from the smoke filter and it shows it was 90% full.

It is time to seal it before we change the filter!

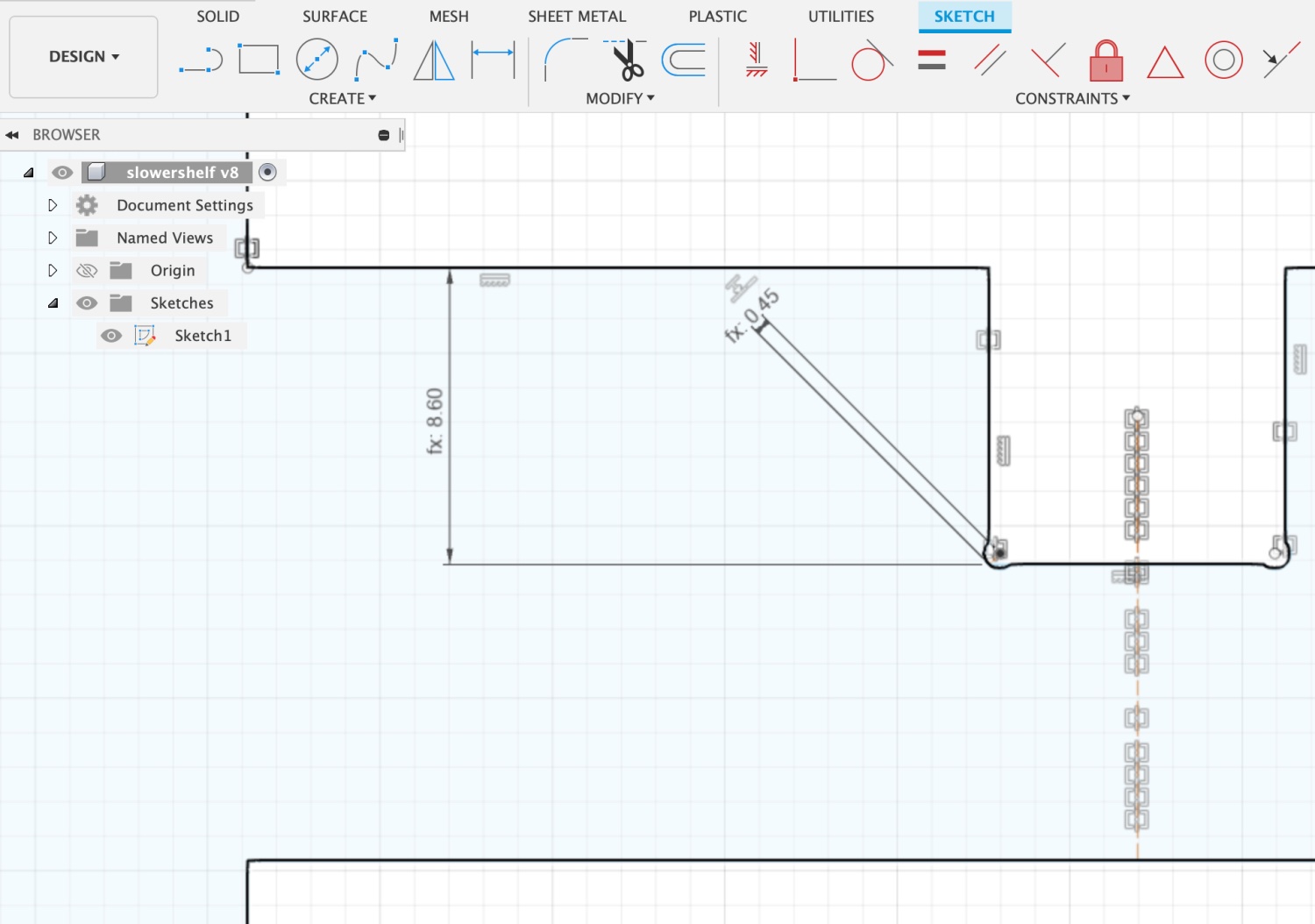

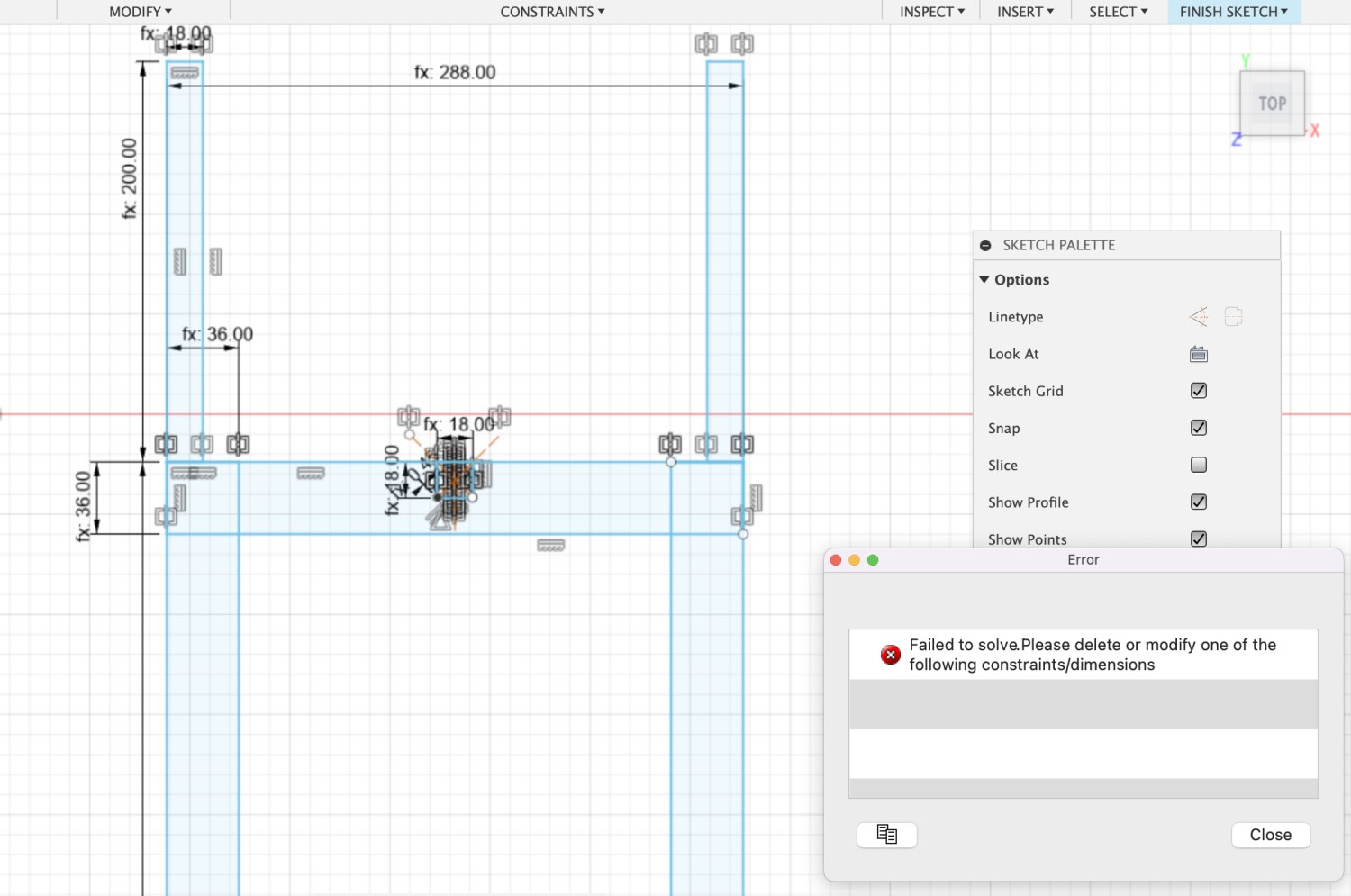

Can not update parameter value in sketch¶

The Fusion360 engineer told me it is because there are too many restrictions in the sketch. Most of them are generated from the mirror function. Some of them become confict and cause the problem. They suggest me better use the mirror function in solid not in sketch.

Parametic design¶

Watch this video for parametic design https://www.youtube.com/watch?v=3GQHaYdmULs

I am using paramtic design in Fusion360. Actually it took me the most time in getting used to this. Because every time when I try to modify the param values, the sketch always get into like chaos.

I found the best way to test if the sketch is OK is to drag some line or point in the sketch. If the sketch stays the same and do not reform, it means this will mostly work when params are changed.

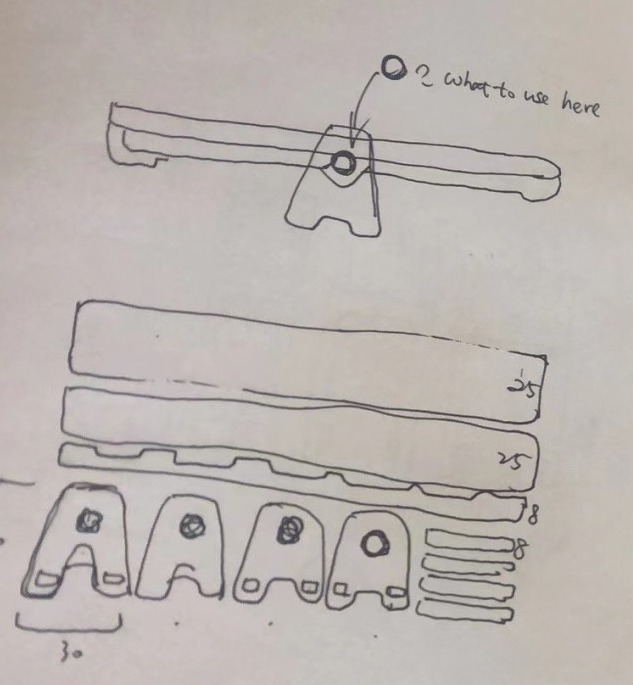

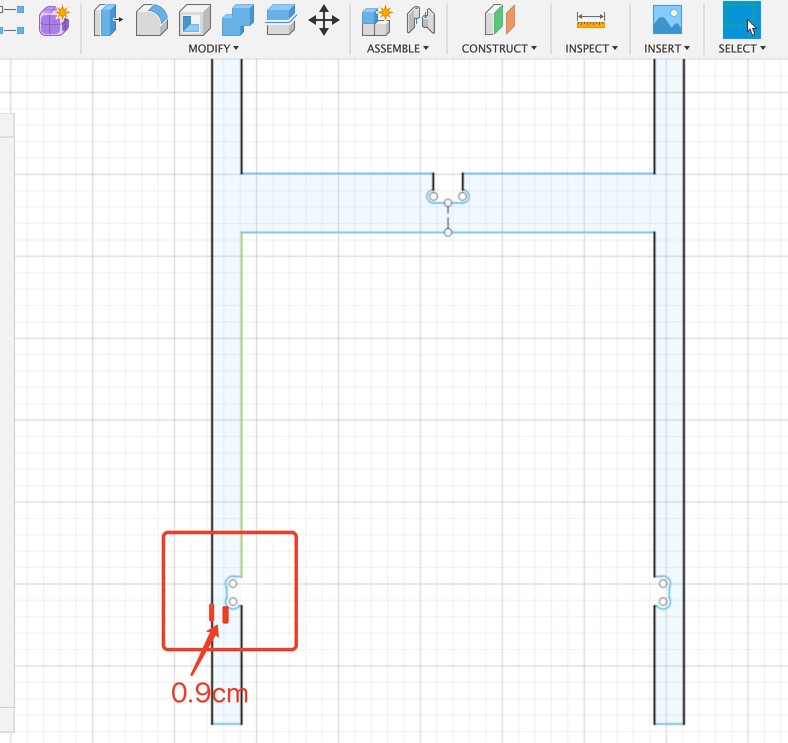

Size of legs¶

In my test model of lazer cut I used double layers for the shelf leg. At the review time, instructors suggest there is no necessary of it.

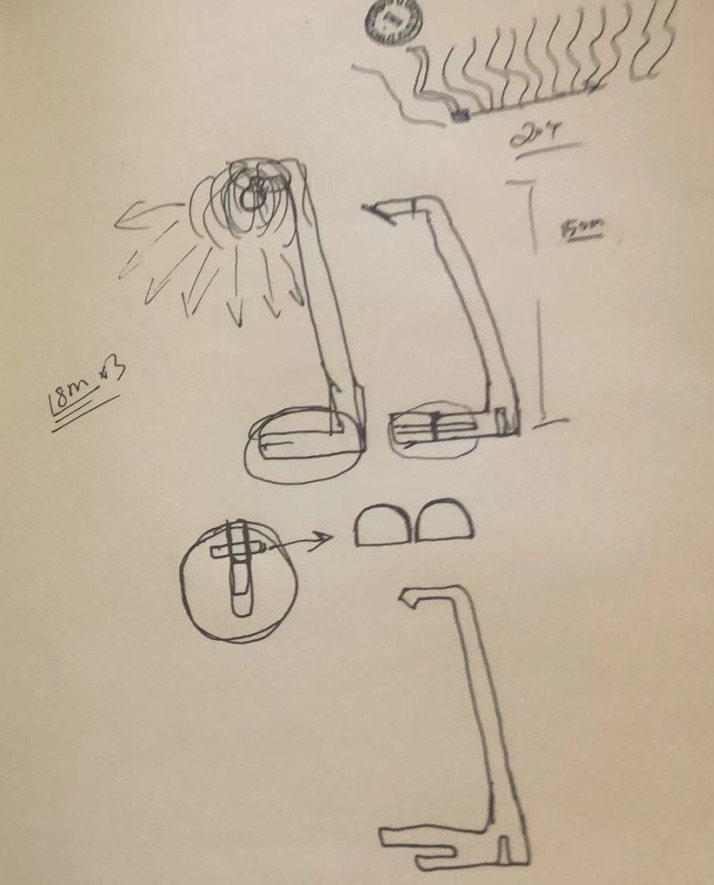

So I changed the sketch to make the legs use only one layer of wood. But the problem is the joint fit on the bottom of the legs. I wanted to make the leg in square shape, and because the thickness of the wood we are going to use is 18mm. It means the leg will be 18mm*18mm and the joint will be like this:

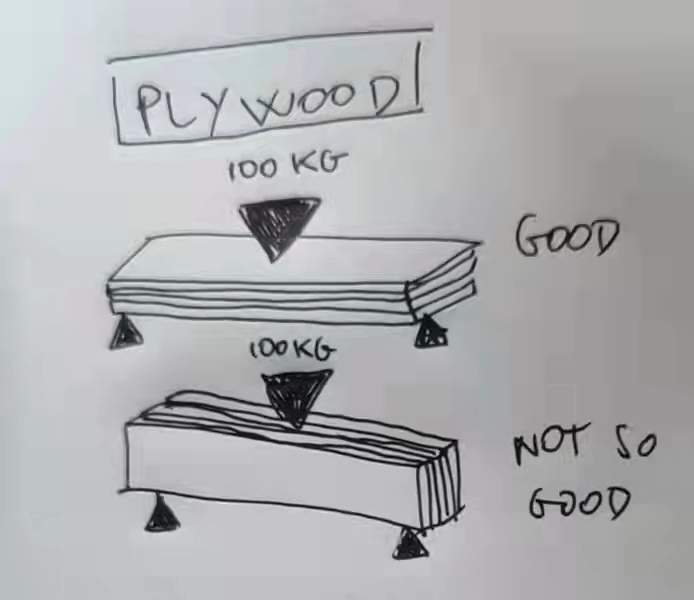

The thinnest part is only 0.9cm. The maxmim weight I want it to hold is 50kg. It will become very fragile. Our instructor showed me this picture:

So considering this issue, I change the leg size to 18mm*27mm.