9. Molding and casting (Indonesia group)¶

This is group assignment page of Molding and casting (Indonesia Student) :

Group assignment:

- review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

- extra credit: try other molding and casting processes

Data sheets for each of your molding and casting materials¶

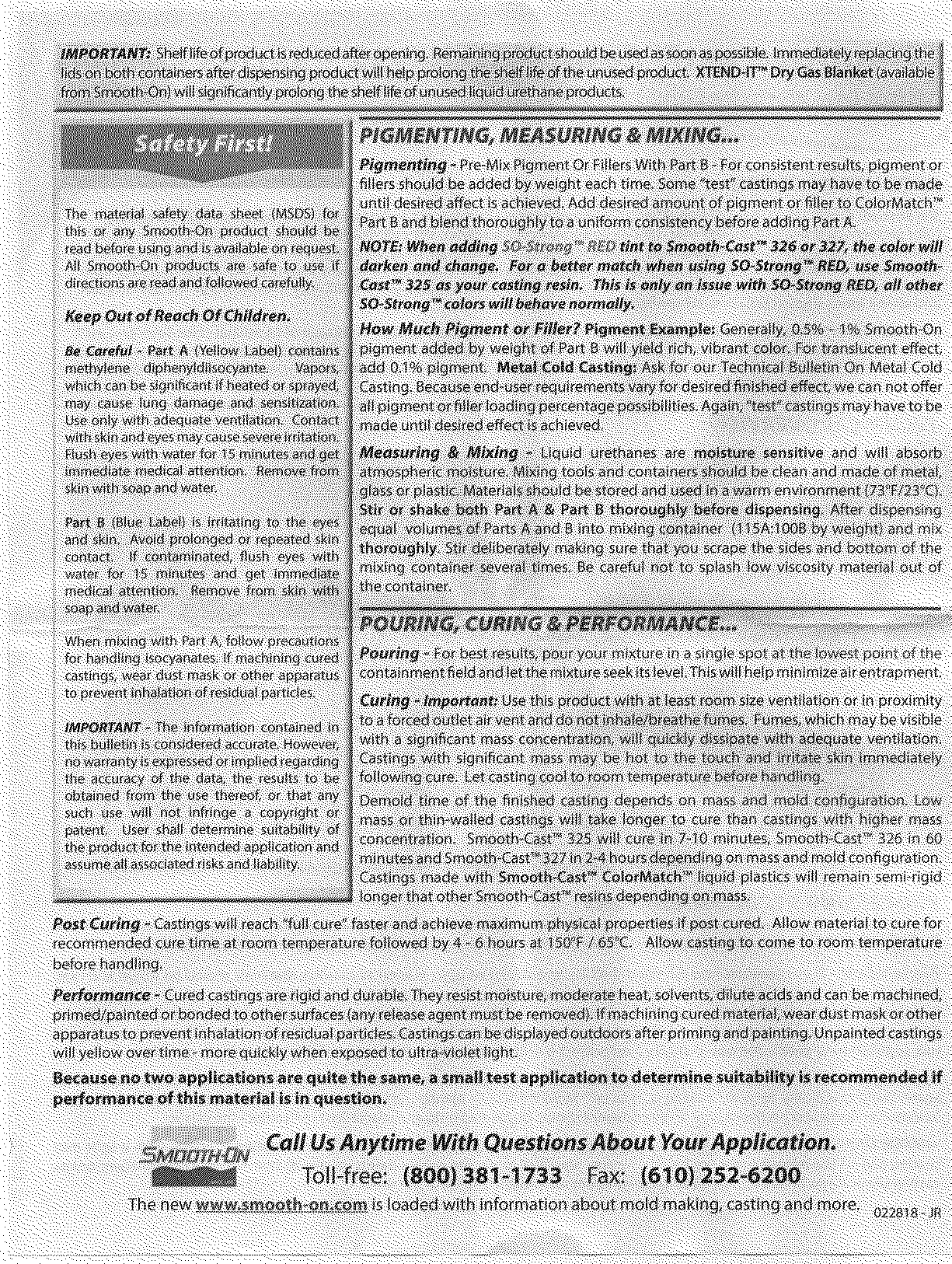

Smooth-Cast™ 325

In this assignment we use resin for casting, namely: Smooth-Cast™ 325.

The Smooth-Cast™ 325, 326 & 327 ColorMatch™ Series plastics are urethane resins that were developed specifically for adding color pigments and fillers to achieve true color representation or filler effect. The ColorMatch™ Series is formulated “color neutral”. Small amounts of pigment will yield accurate, vivid colors from cured castings using So-Strong™ tints, UVO™ pigments or Ignite™ color pigments. The ColorMatch™ Series offers the convenience of a 1A: 1B mix ratio by volume and has a very low viscosity. Demold times range from about 10 minutes to 2-4 hours (depending on product, mass and mold configuration).

Note

Large mass castings will get very hot and shrink more, depending on mold configuration.

Safety First¶

When going to do Casting activities with Resin and the like, we need to remember “SAFETY First”. Some of the equipment that must be used when working in this field include:

- Mask

- gloves

- protective glasses

try other molding and casting processes¶

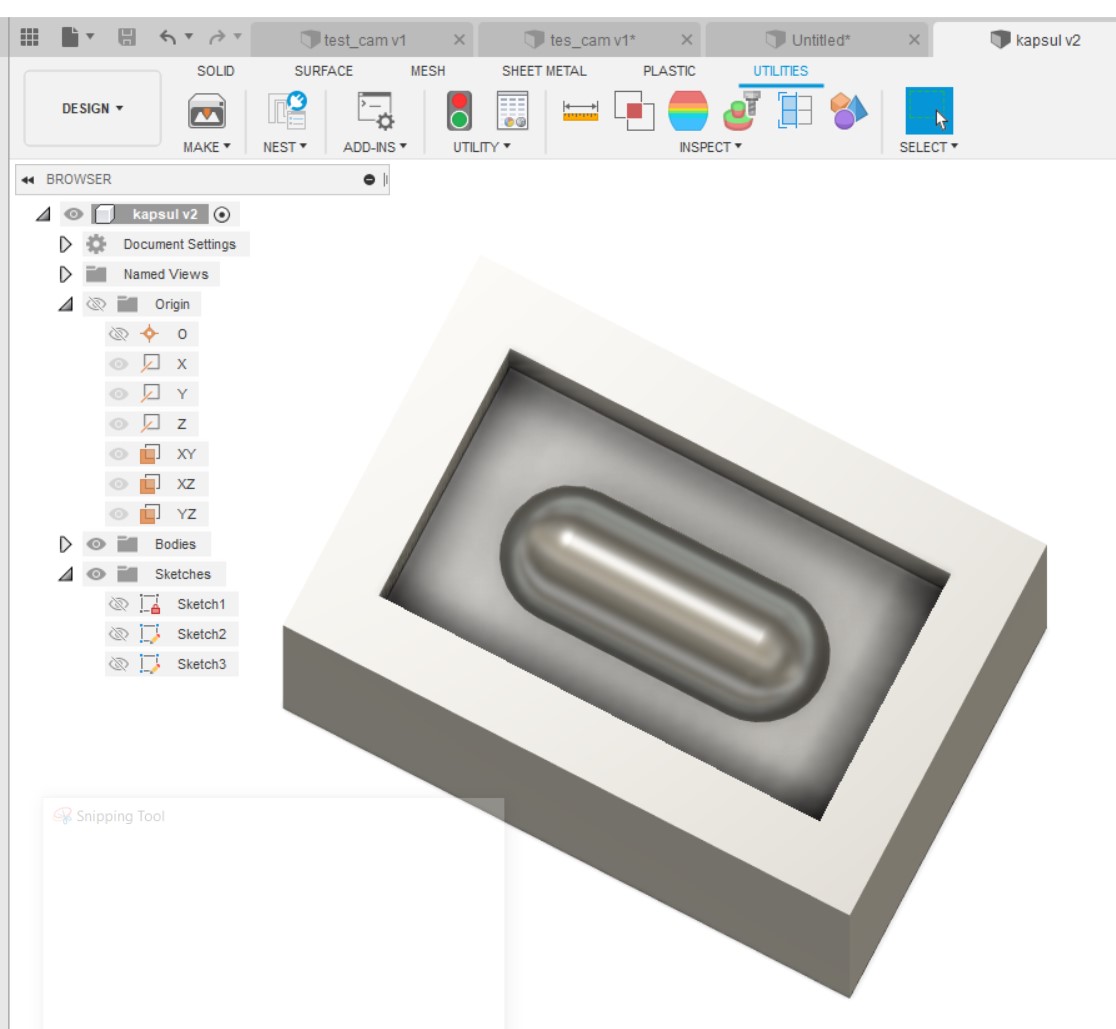

Design the model¶

In this model, we try to make a simple form, which is to make a capsule.

Materials¶

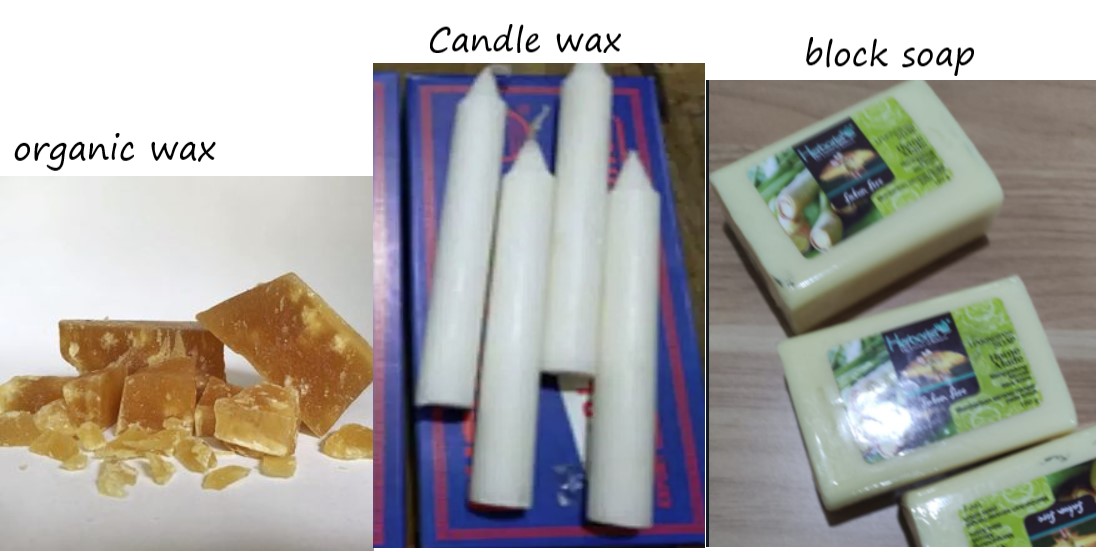

To make this model, we pay attention to the material that will be made for molding. Incidentally, machinable wax is not available in our lab, so we are trying to find alternative materials (local materials) that can be milled.

We used four types of material natural/organic wax, white candle wax/parrafin, palm oil soap, and gypsum.

The first step to prepare the molding material to be milled is to cast the wax/candle into a box that can be machined. We tried to melt by heating indirectly (using boiling water) and cast it in a box

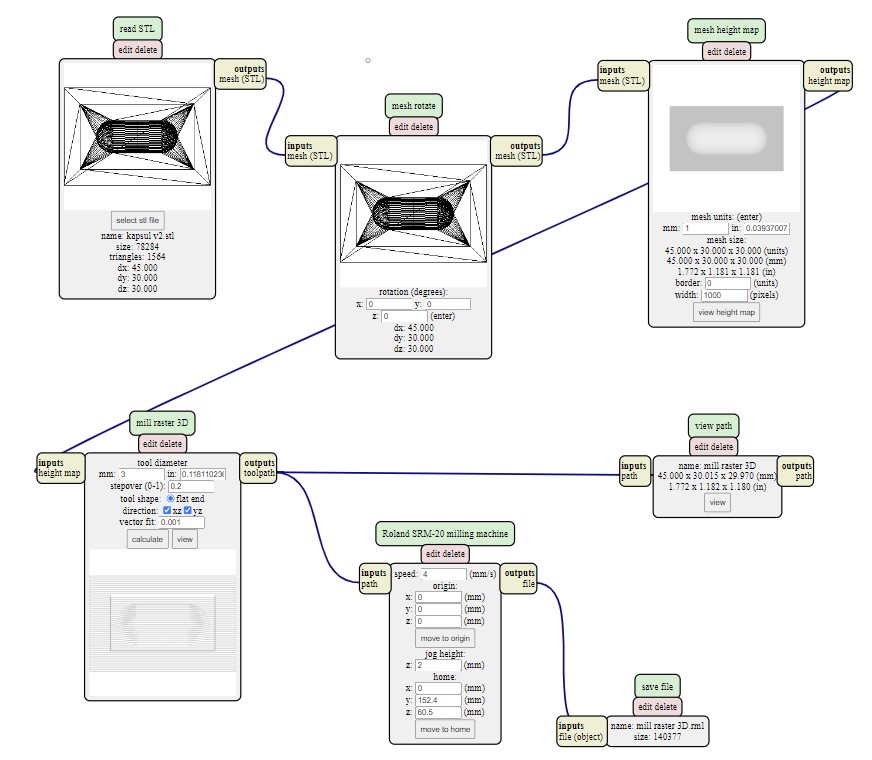

CAM¶

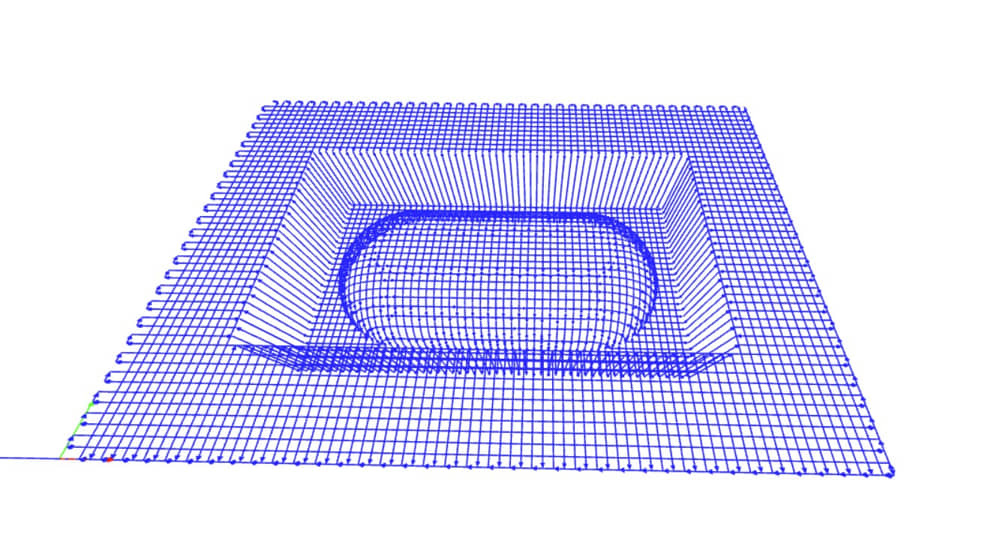

we used MODS to generate the G-Code for the SRM-20 Milling process. The files we drew from Fusion 360 were exported to .STL files. this STL file is imported into MODS - Mill 3D Stl.

Milling¶

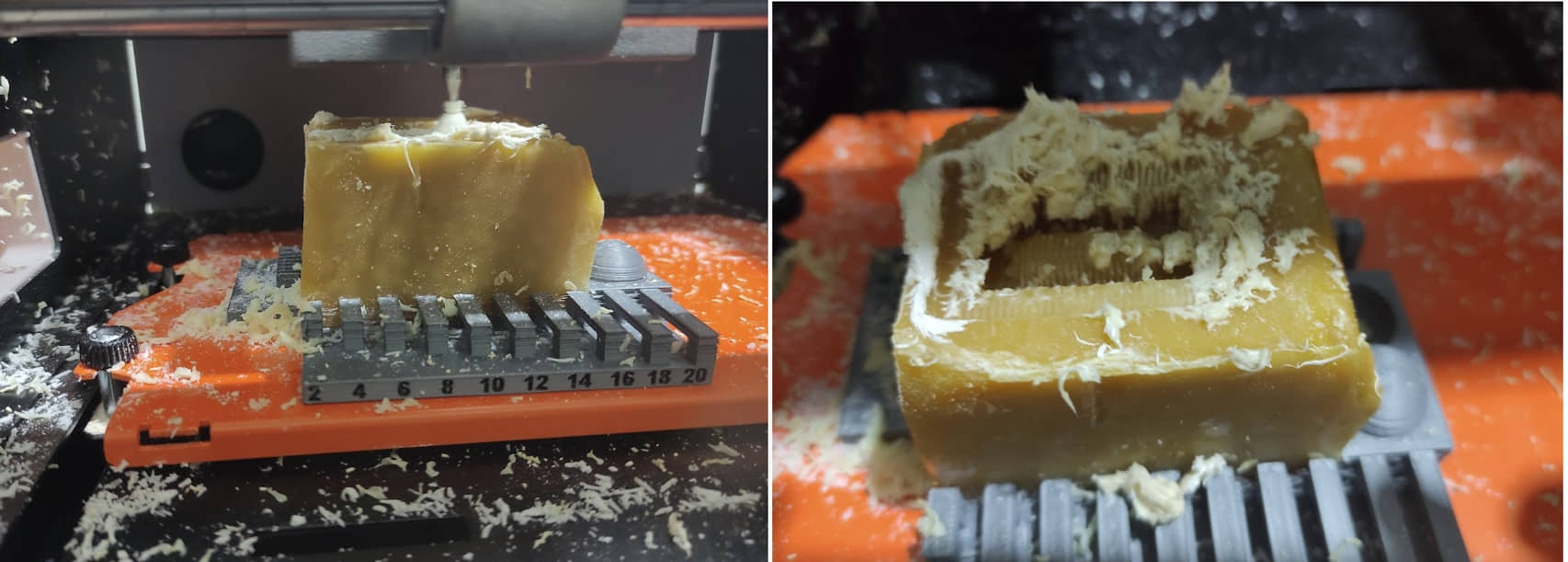

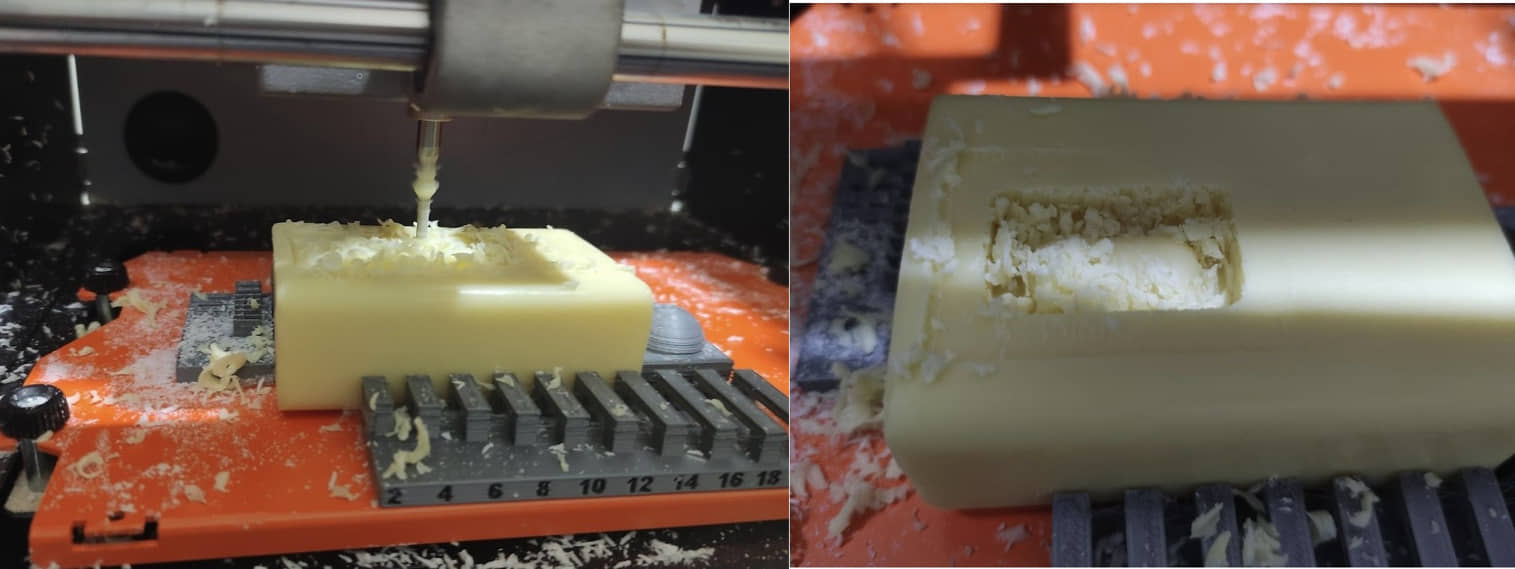

Material #1 (Candle)¶

Material #2 (natural/organic wax)¶

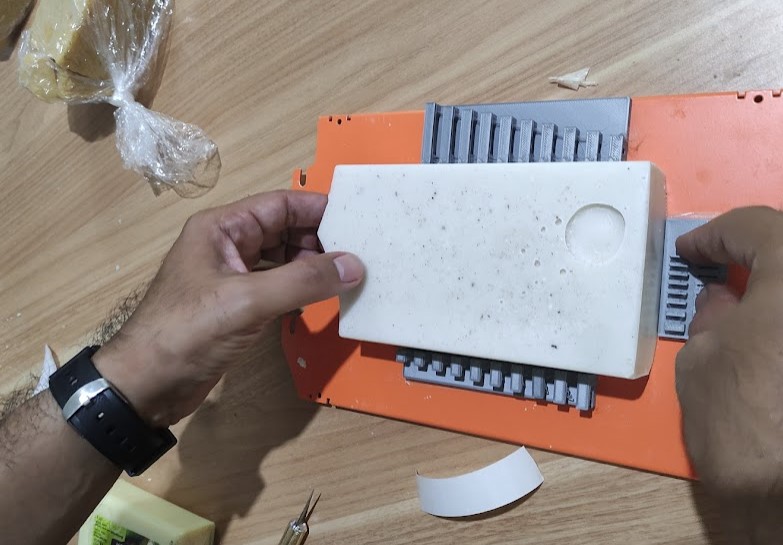

Material #3 (palm oil soap)¶

Materil #4 (gypsum)¶

For cast gypsum, we mix it with water until the gypsum is wet and easy to cast. When the gypsum mold had dried and hardened, we tried to check, it turned out to be very considerate, so we decided not to mill this gypsum mold because we estimate it could make the SRM machine weak and even damaged.

Milling Results¶

From the several materials for dies cast, ideally it does use machinable wax. But since it is not available in our labs the use of replacement materials is still possible. From some of the materials we tried, it seems that using parafine candles can be used as resin molding materials.

Cast Processing¶

What we learned is that local materials can also be used as a substitute for machinable wax, although the results are not optimal (needs to re-examine the right machining technique/parameters). The use of paraffin candles as an alternative to machinable wax is quite good for machining.