18. Wildcard week¶

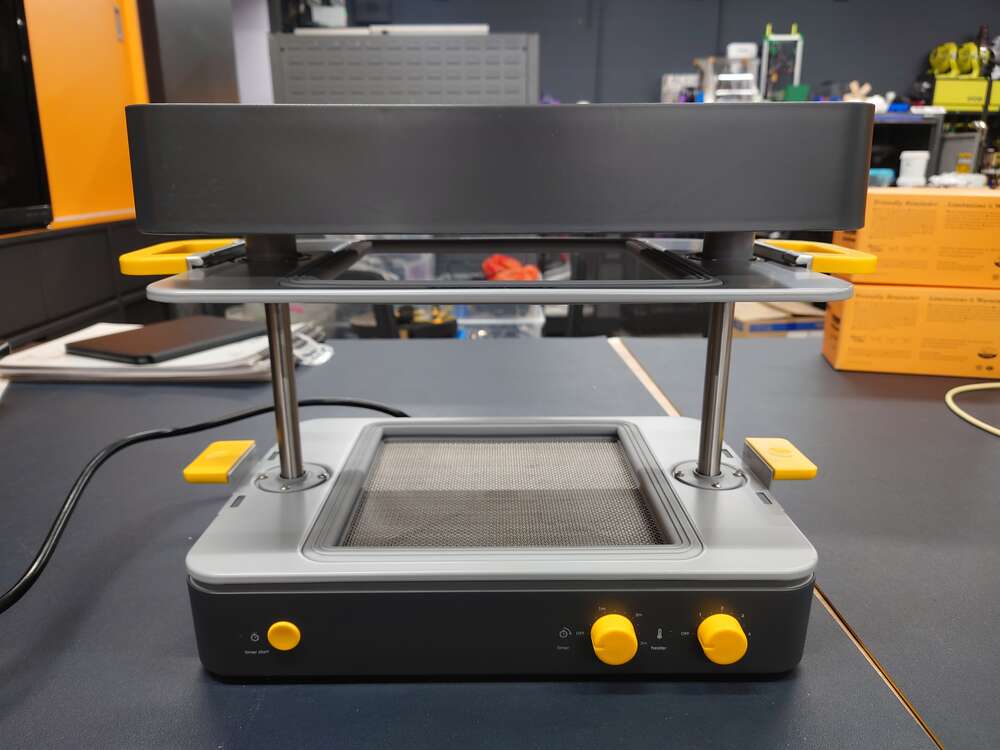

This week I use vacumn former Mayku FormBox to finish my wildcard week project.

Machine Specification¶

| Spec | Details |

|---|---|

| Height | 315mm |

| Length | 466mm |

| Width | 274mm |

| Forming bed | 200mm x 200mm |

| Draw Depth | 130mm |

| Weight | 13kgs |

| HEATED BED TEMP. RANGE | 160C - 340C |

COMPATIBLE FORMING MATERIALS

- PETG

- HIPS

- ABS

- Polystyrene

- Polycarbonate

- Polyethylene

- Acrylic PMMA

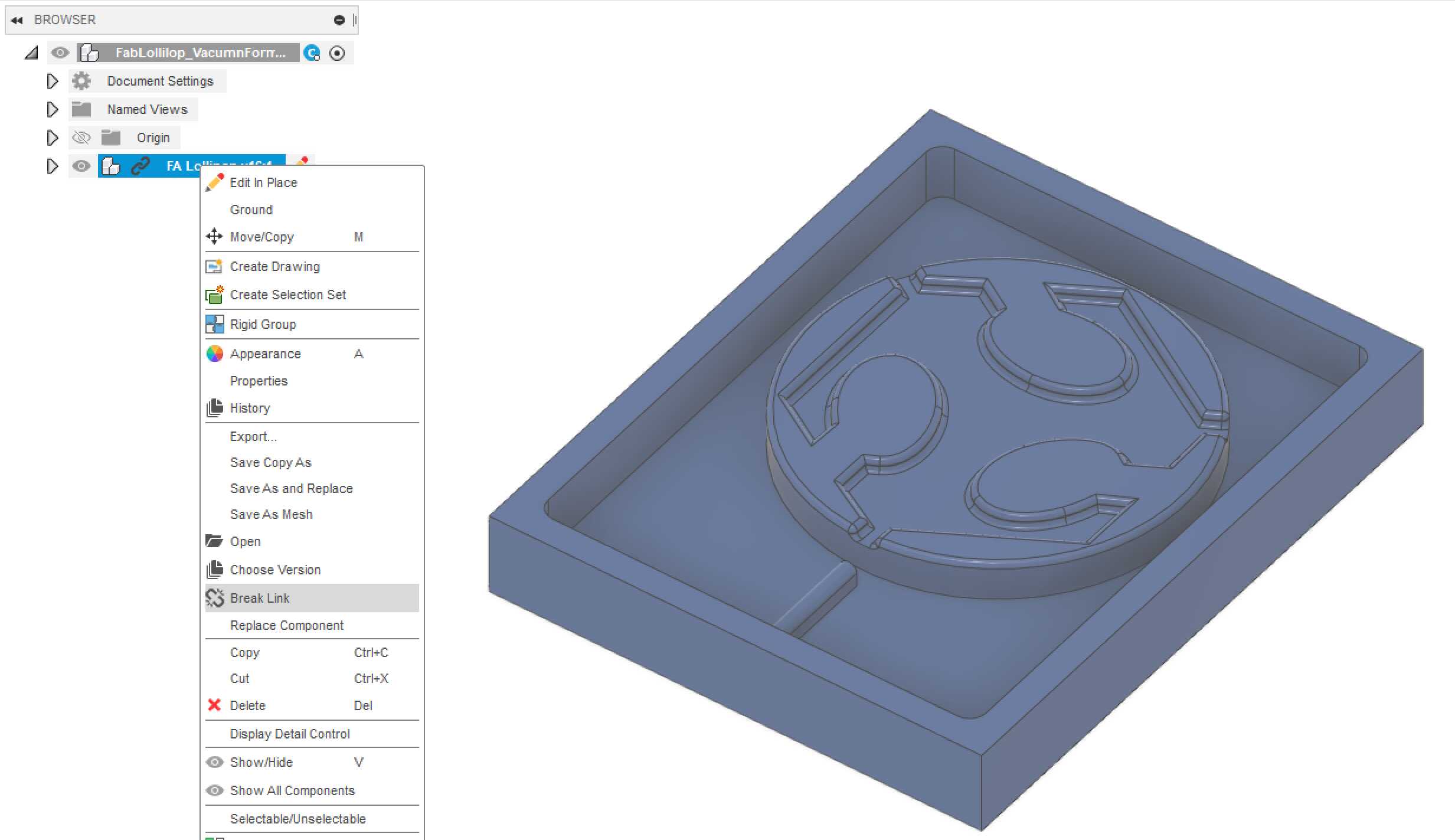

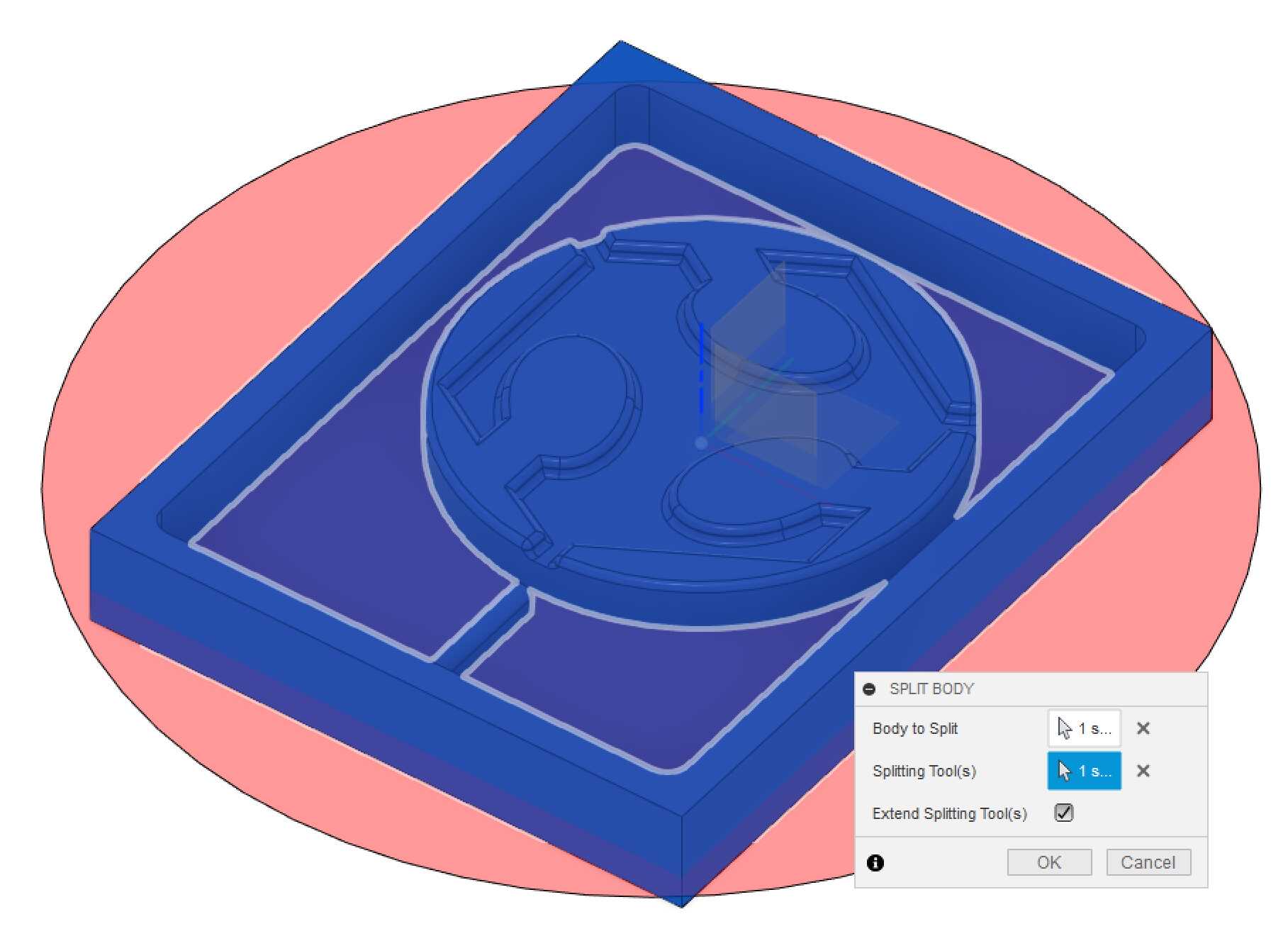

Preparing the 3D model¶

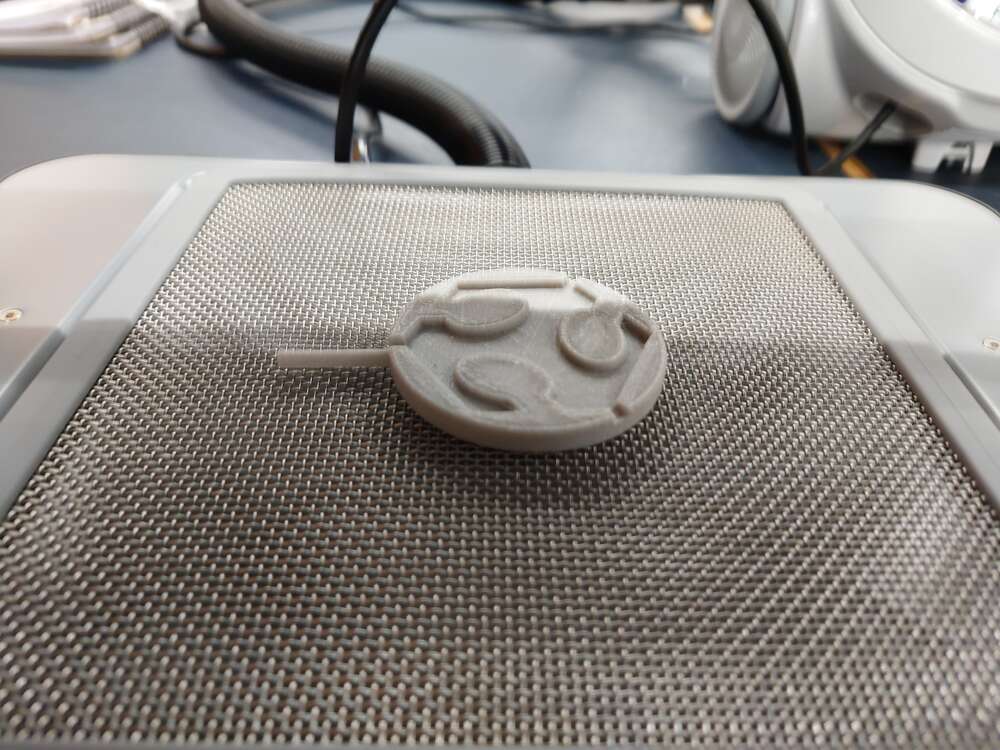

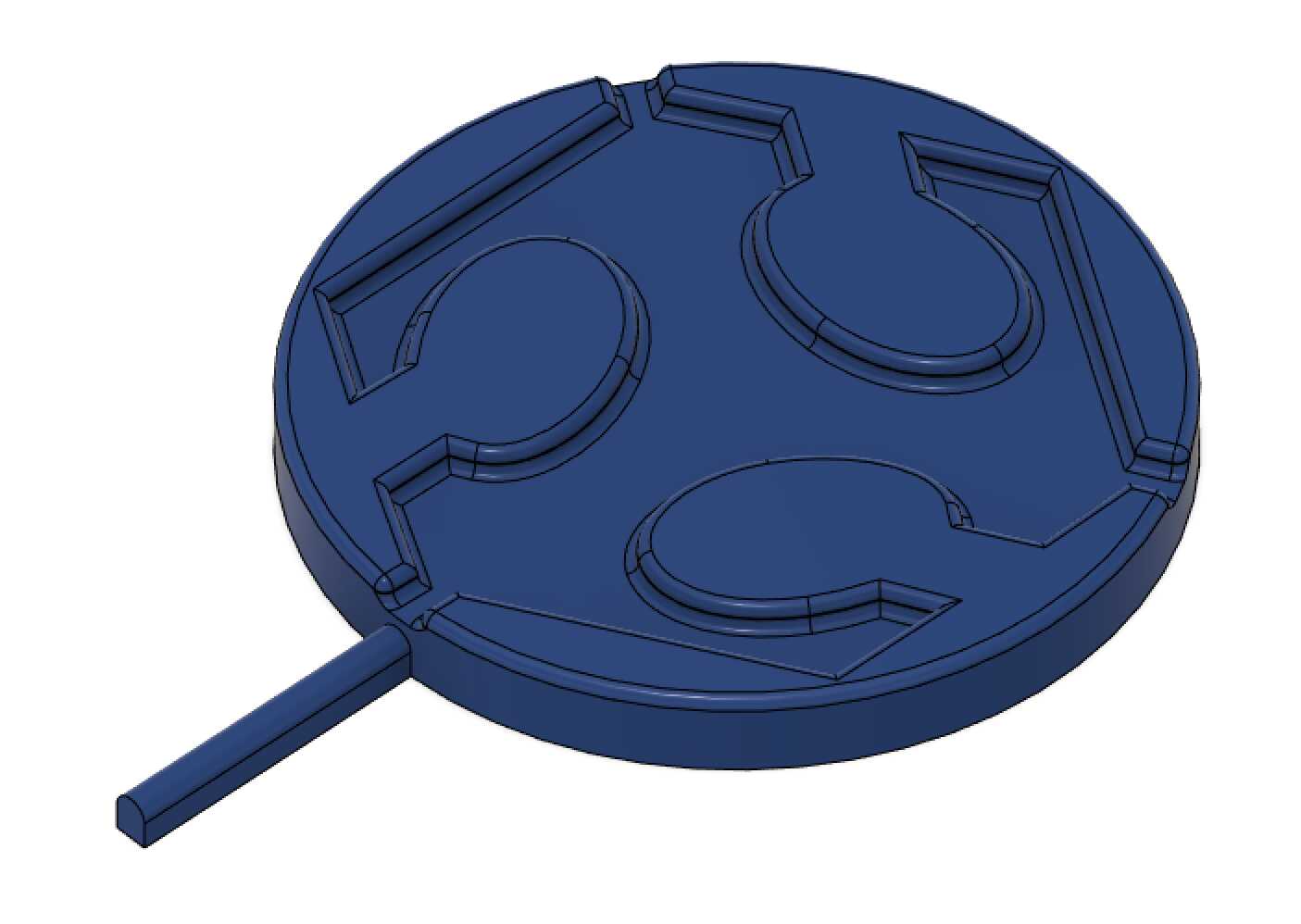

To test the vacumn former, I modified the lollipop I designed in week9. I cut out the boundaries that are unnecessary for vacumn forming process.

Printing the 3D model¶

Then I 3D printed the model. Instead of using PLA, I used PETG as the base material. Because PETG can withstand higher temperature. In my experience, 3D printed mould using PLA will normally deform while contacting with the heated film.

Vacumn Forming¶

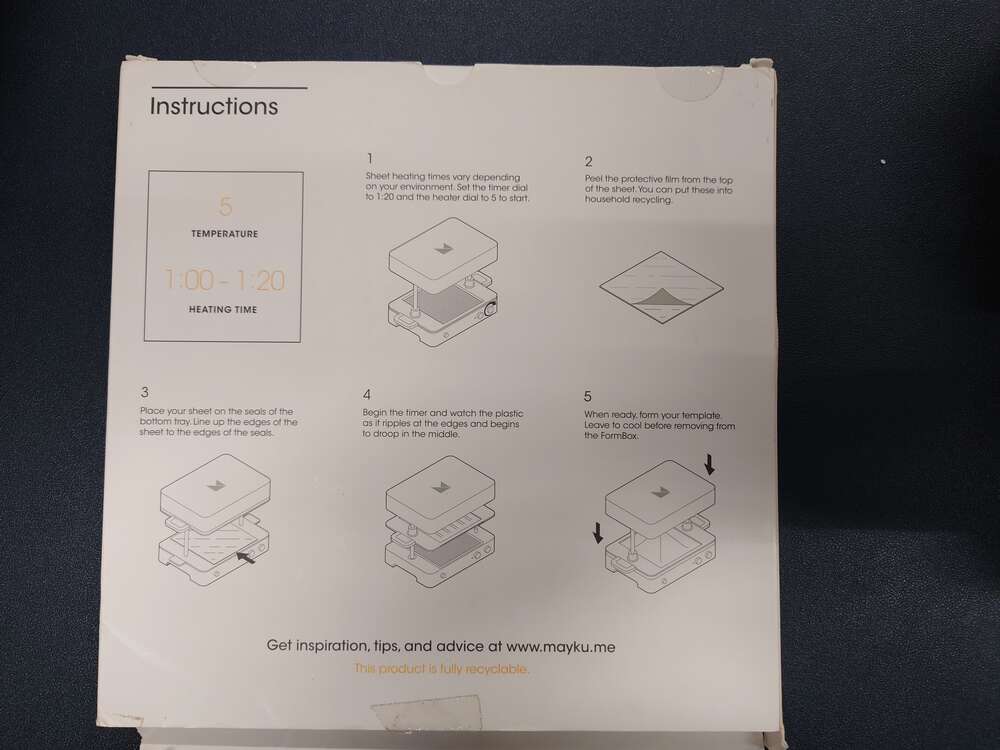

I choose this PET film that comes with the machine. I can follow the instructions wrote on its package to adjust the temperature level and heating time.

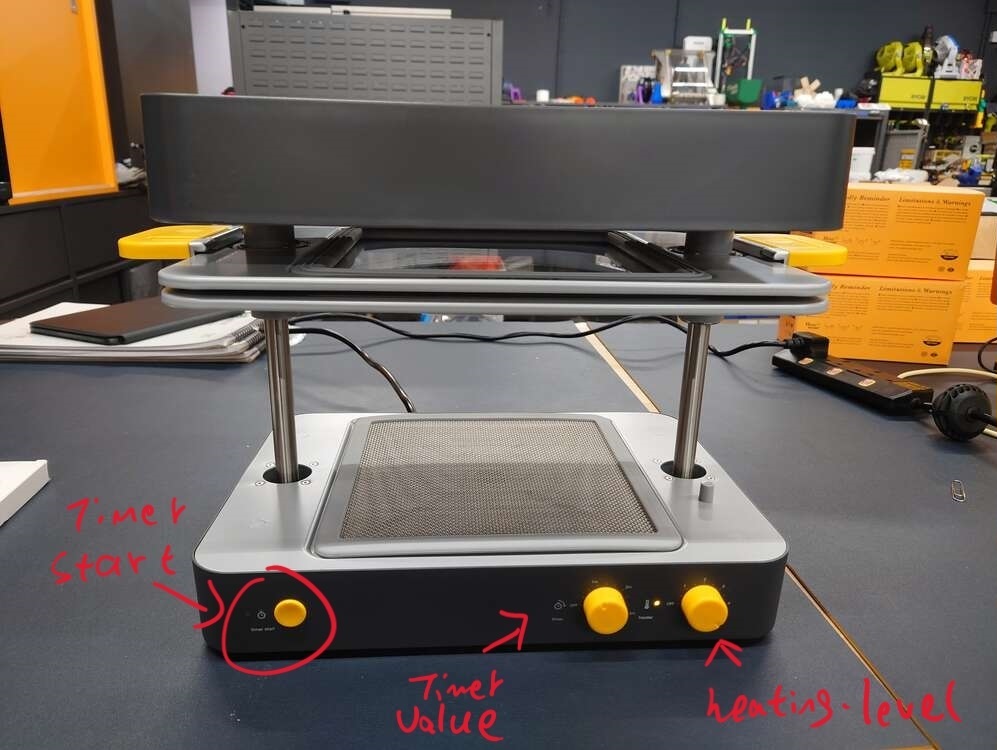

The machine is quite simple to use. There are two knobs and one button on it. One of the knob used adjusting the heating level, the other one for adjusting count down timer. The button on the left hand side is used to start the timer.

Using the vacumn forming machine¶

-

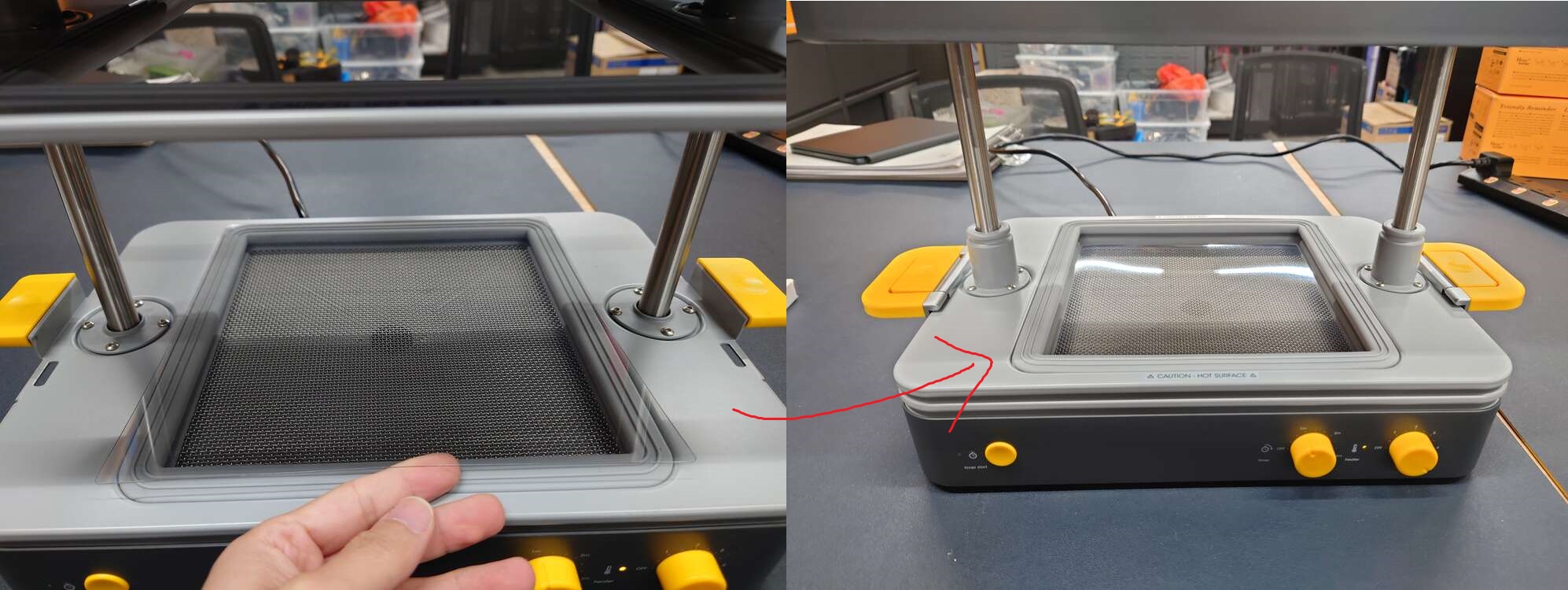

Connect the vacumn tube to the vacumn outlet at the back side of the machine.

-

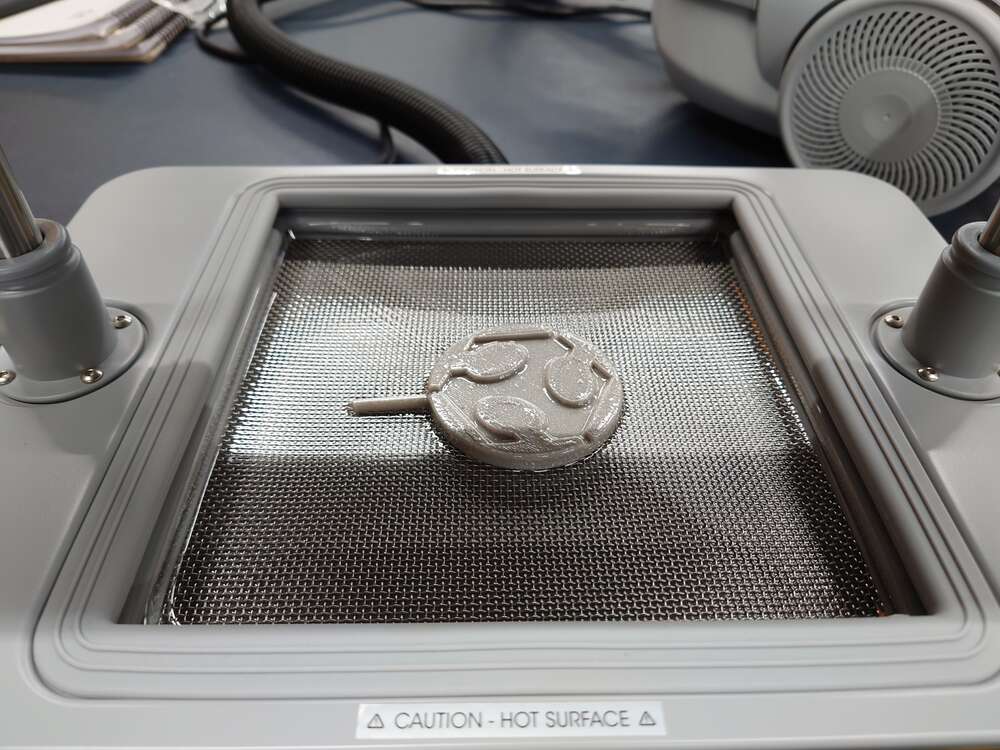

Adjust the timer knob to “1m” according the instruction of the PET sheet. Then turn the heater knob to level 5. The machine will start heating up.

-

Place the PET sheet in between the two fixing tray and lock them together by pressing the yellow handles at two sides.

-

The I lifted up the tray to the top side, it fixed on the top. I pressed the timer start button after that. The machine starts making sounds like “tok-tok” to reminds me.

-

While the PET sheet was being heating up, I put the 3D printed lollipop model to the center of the metal net at the bottom.

-

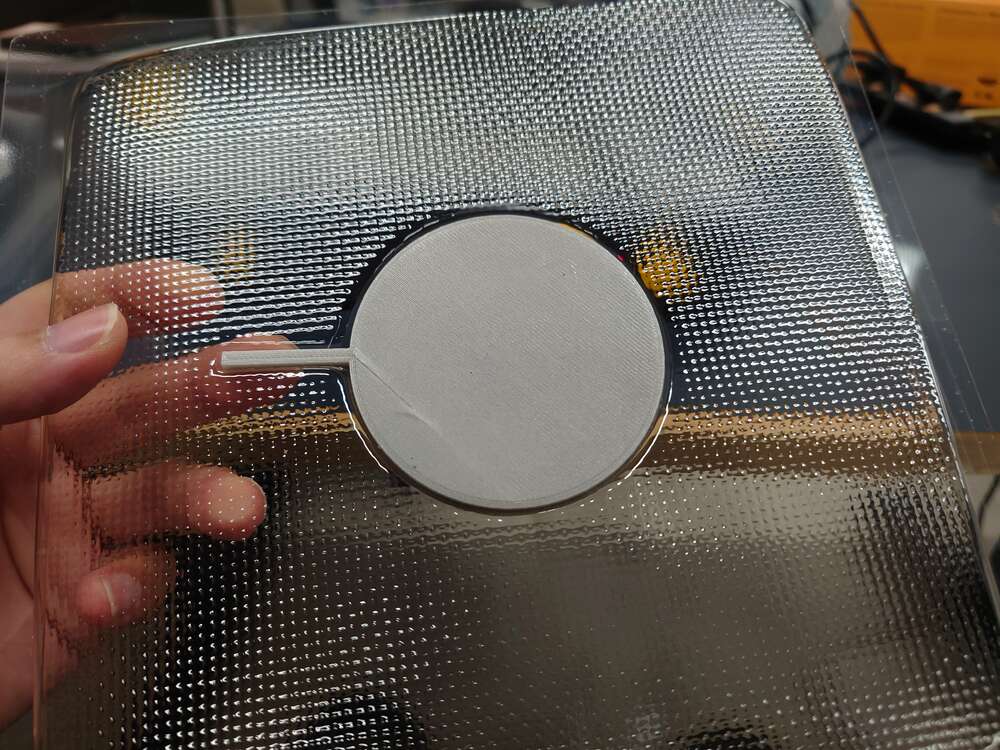

When the timer reaches 1 minute, I lower the tray that holds the PET film and turn on the vacumn machine instantly. The film was formed in 1 second. I keep turning on the vacumn until the film was cooled down.

-

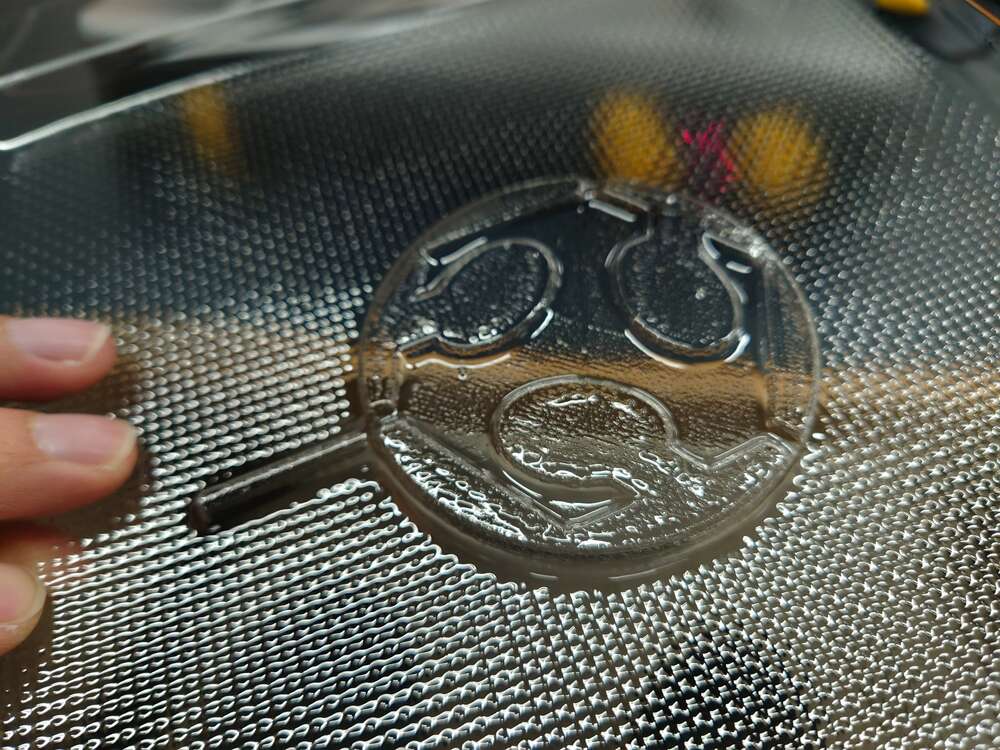

The resulted mould was not as smooth as I thought. It is because the 3D printed model has a rough surface finishing. This affects the outcome of the vacumn formed mold. However, the PET sheet reproduces the details on the model.