1. Principles and practices¶

This week I worked on defining my final project idea and started to getting used to the documentation process. My plan is to build a machine that will catch and throw an american football back to you. Although football throwing machines already exist, each they are all over $2500 and each require you to manually position the football in the machine for it to throw it back. An example of one currently on the market is shown below:

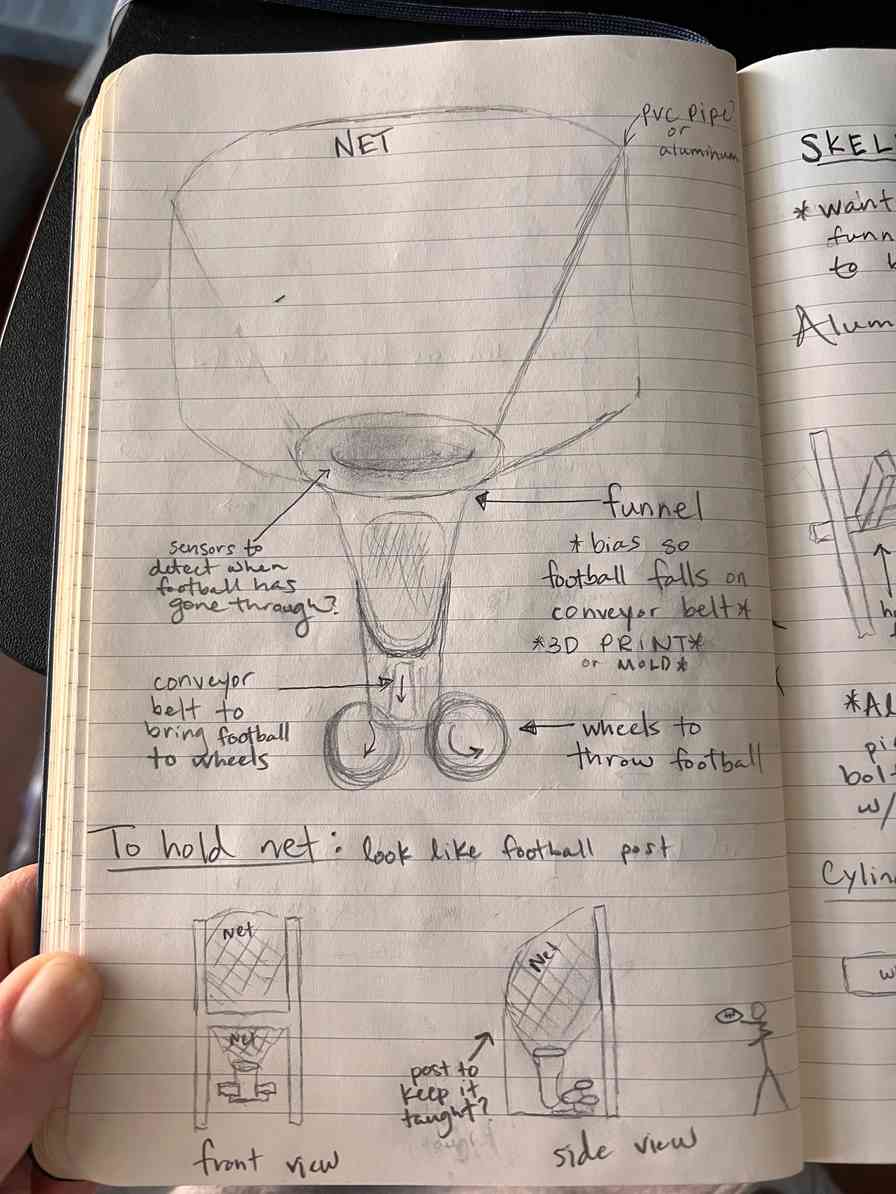

A similar design to this will be used for the throwing of the football but additional design is needed for automating the positioning of the football to catch and throw back. The idea is that a person throws a football into a net, this machine funnels the football down, and the football moves up a small conveyor belt to the two wheels that will throw the football with spin. This is illustrated below:

Conveyor Belt¶

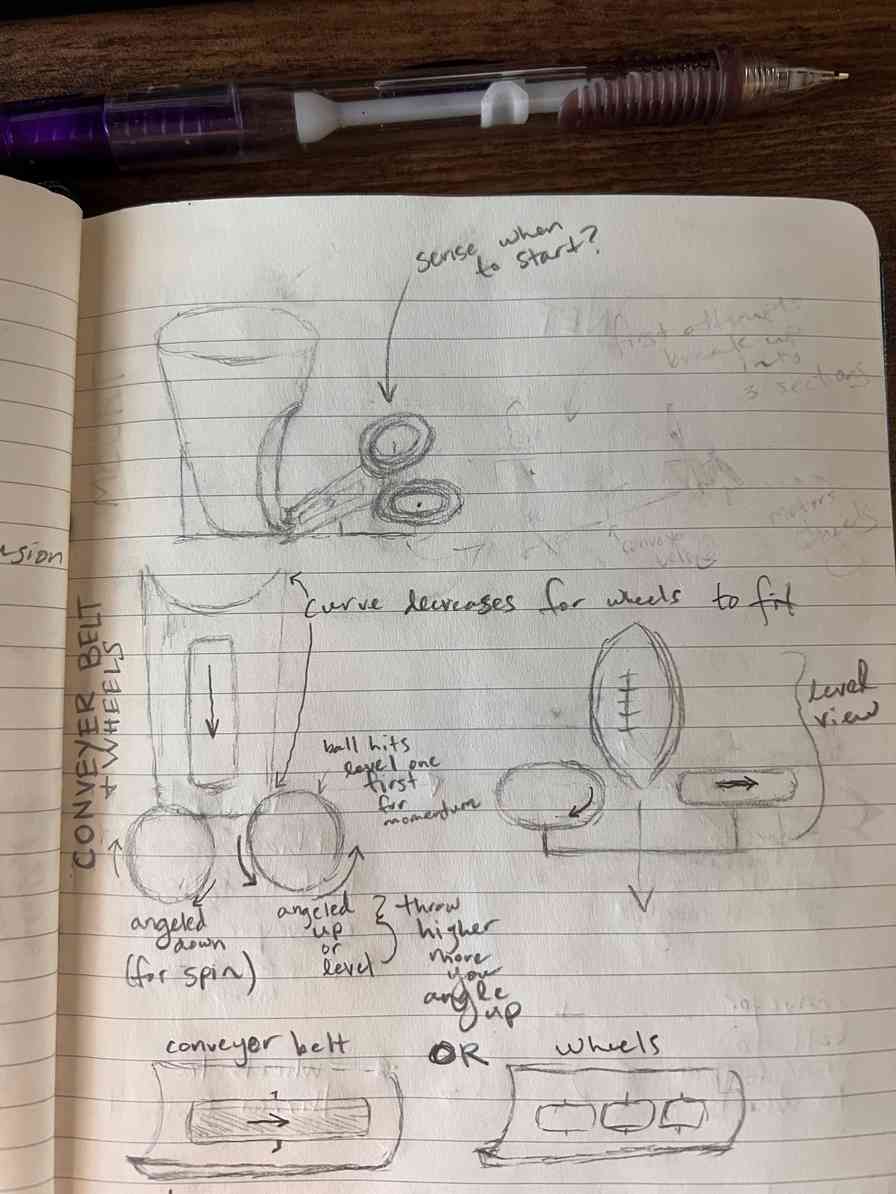

A more detailed look at the conveyor belt and wheels is shown below:

The net will need to be taut to lead the ball to the funnel. There is an opening on the funnel that theoretically will cause the football to fall onto the conveyor belt. Once the football is sensed in the funnel, the conveyor belt and wheels turn on. The conveyor belt brings the football to the wheels, which then passes the football back.

Adjustable Skeleton¶

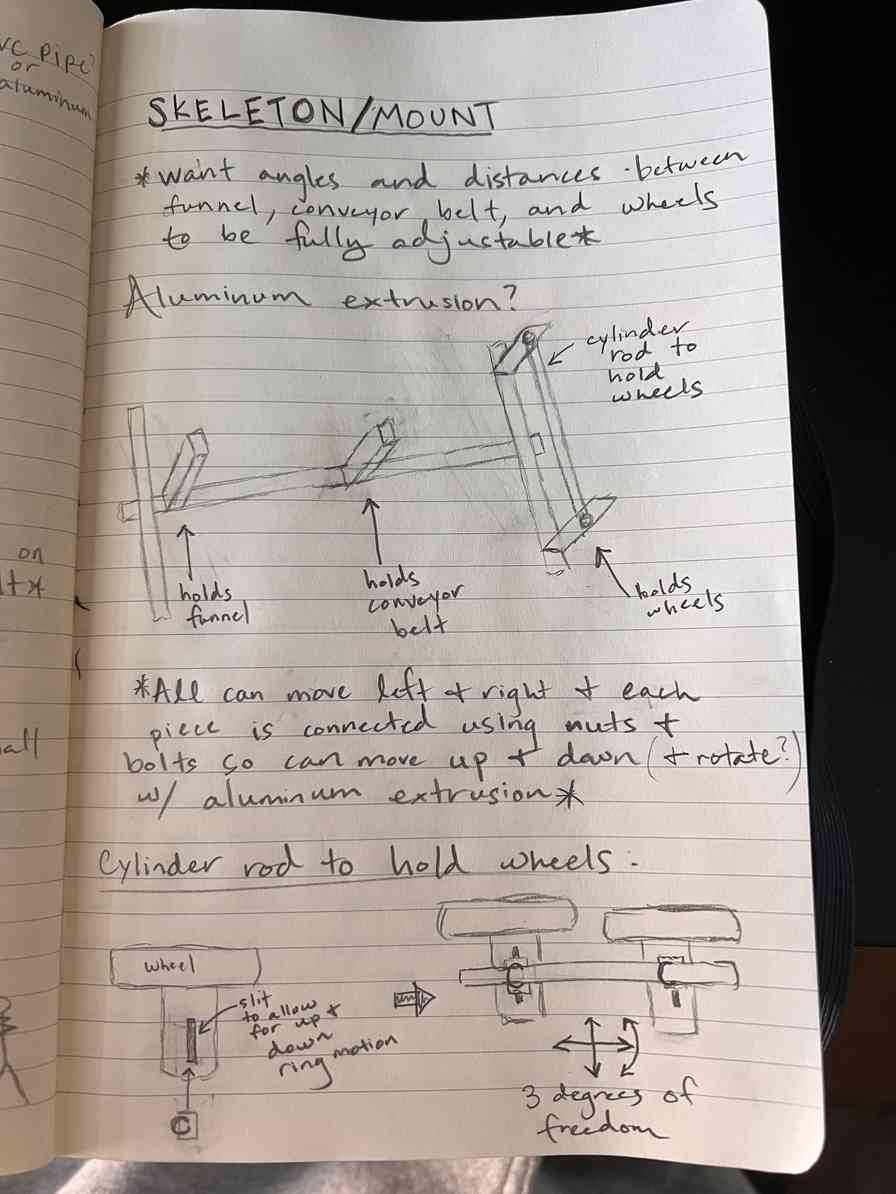

Because the necessary angles and distances between the funnel, conveyor belt, and wheels are not yet known, the skeleton for holding each of these parts needs to allow for adjustments. For this reason, the current plan is to use alluminum extrustion with nuts and bolts. This is illustrated below:

Problems to think about:¶

- Can it deal with different sized footballs?

- How to bias the football so it falls correctly on the conveyor belt?

- No current plan for an on/off switch or how to plug it into the wall

- Could we mold a case so there are no exposed electronics and the machine is rain/weather proof?

- How to make the structure easily storable and compact

- How to make the structure easily movable and adjustable to the user for different sized footballs, throwing at different angles, throw it further, etc.

Schedule:¶

Based on this current illustration I plan to use the topics each week as follows: - CAD: Attempt to 3D model full aperature - Laser Cutting: N/A based on this design - Electronics Production: Build a conveyor belt and/or - 3D printing: Print the conveyor belt pieces, and perhaps the funnel. - Electronics Design: Build circuit and PCB board that will be used for motors. - Computer-Controlled Machining: N/A based on design - Embedded Programming: Activate conveyor belt and motors when football is sensed using custom PCB board. - Molding and casting: Attempt to mold the funnel and perhaps the conveyor belt holder - Output Devices: Shine green LED when conveyor belt and wheels are turning (i.e. football is about to throw), or use LEDs to count down when it will be thrown - Mechanical Design: Begin on skeleton and mount structure - Machine Design: Continued electronics work with sensors, AC motors,etc. - Inputs: activate multiple AC motors after motion is sensed at one point and stop when motion is sensed at another point - this simulated when the football goes through the funnel (motors and conveyor belt triggered) and then when football is passed (motors & conveyor belt stops). Though, the necessity of motion sensors is still being debated. - Networking and Communications: N/A based on this design - Interface and Application Programming: N/A based on this design - Wildcard Week: TBD