6. 3D Scanning and printing¶

group Assignment¶

3d printing¶

3D printer features¶

3D printers can print complex shapes for example our group assignment shows a limitation test for the printer they are also very useful when printing replacement parts for almost everything some printers have a heating bed that help distribute the heat so that when the plastic is being printed it settels to a sertain temprature slowly beacause if it didnt the shape will get curved which will rwen the print in the group assignment we fased this problem.

Limitations¶

Some of the limitations are related to the material and some for the parts it self for example the material need to be heated first then it will cool after printing which slows the process then an example for parts limitation is the size of the bed the baggier the more bigger parts can be printed and the size of the nozzle the smaller the more precise.

3d design¶

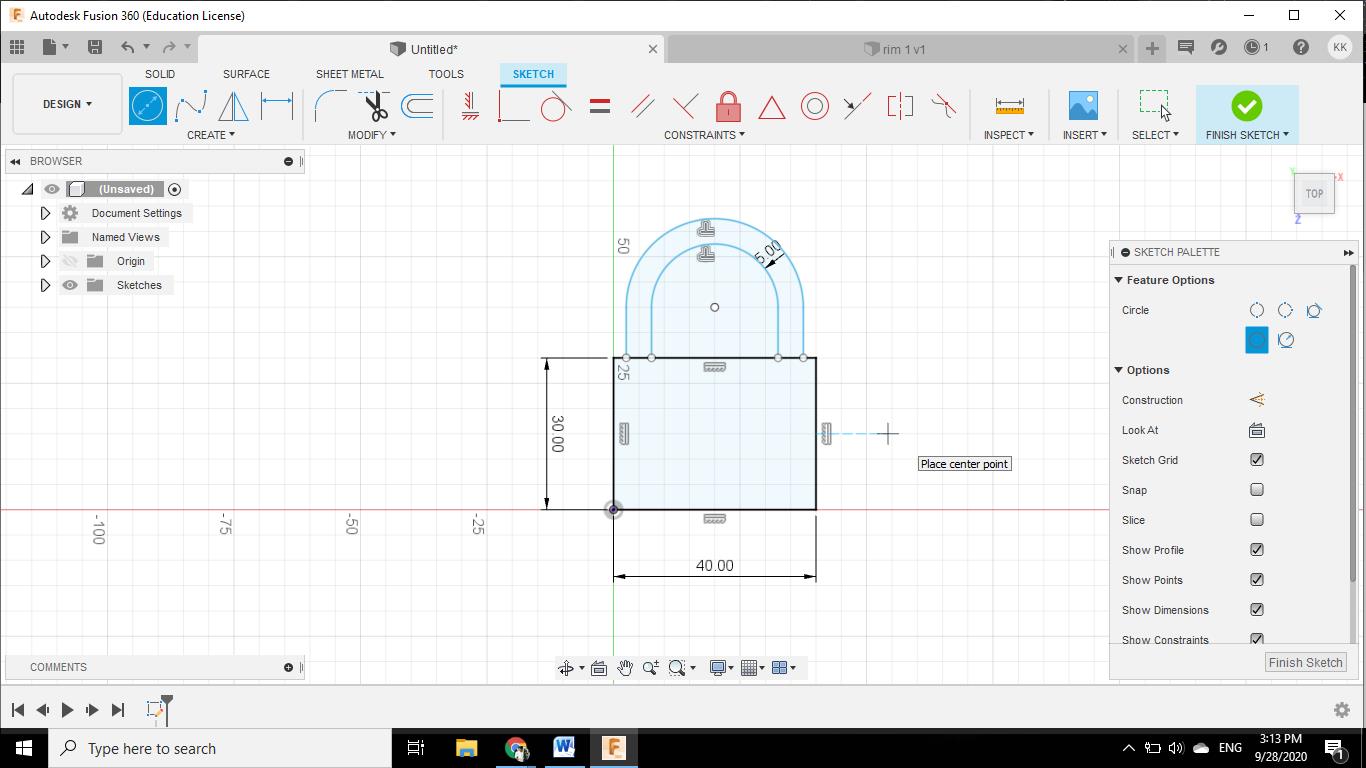

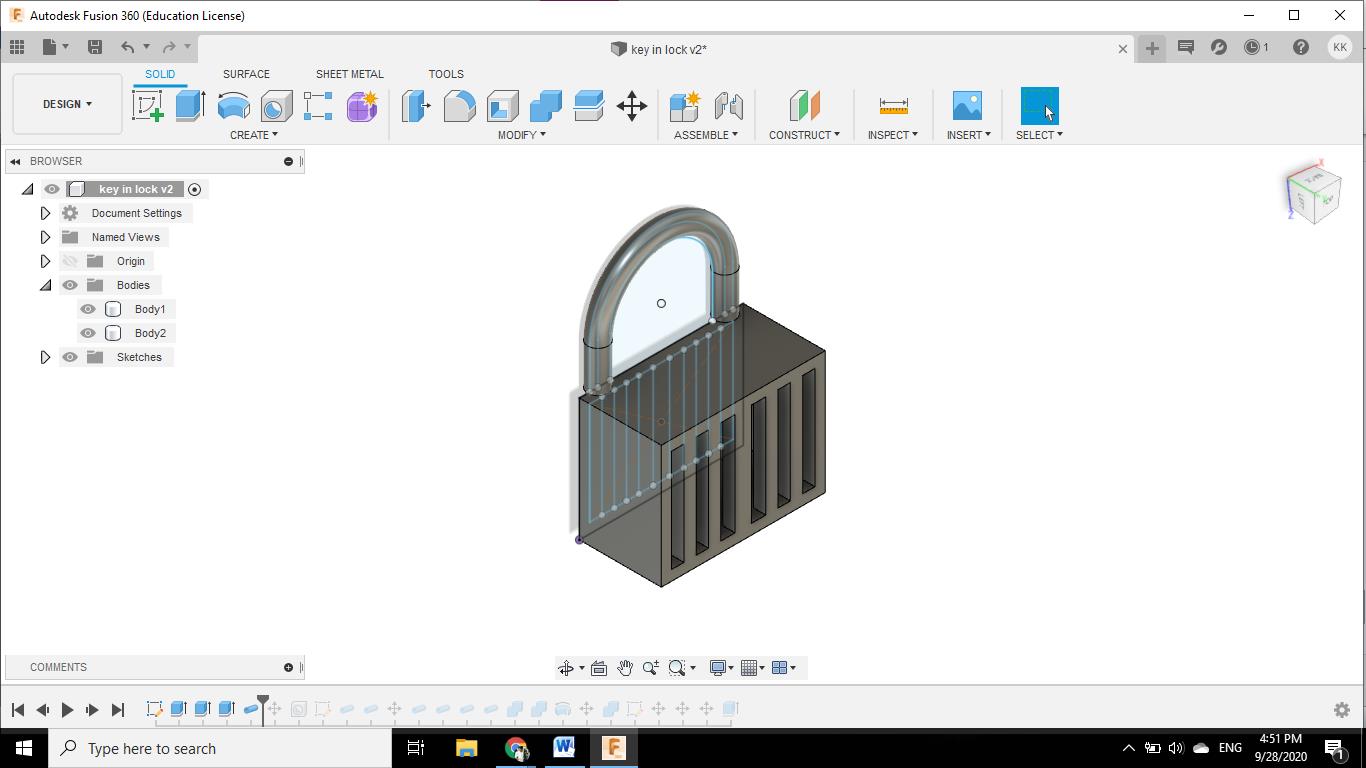

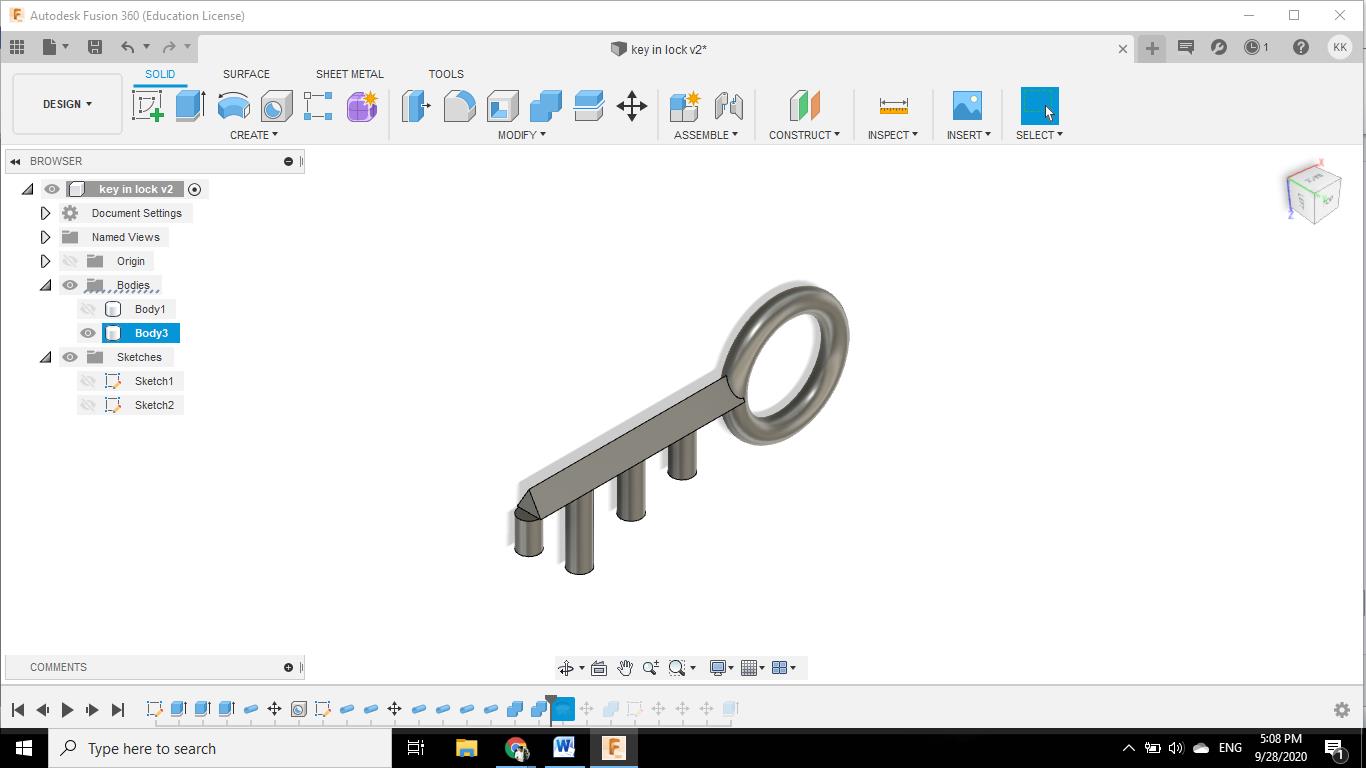

started by designing simple lock

started by designing simple lock

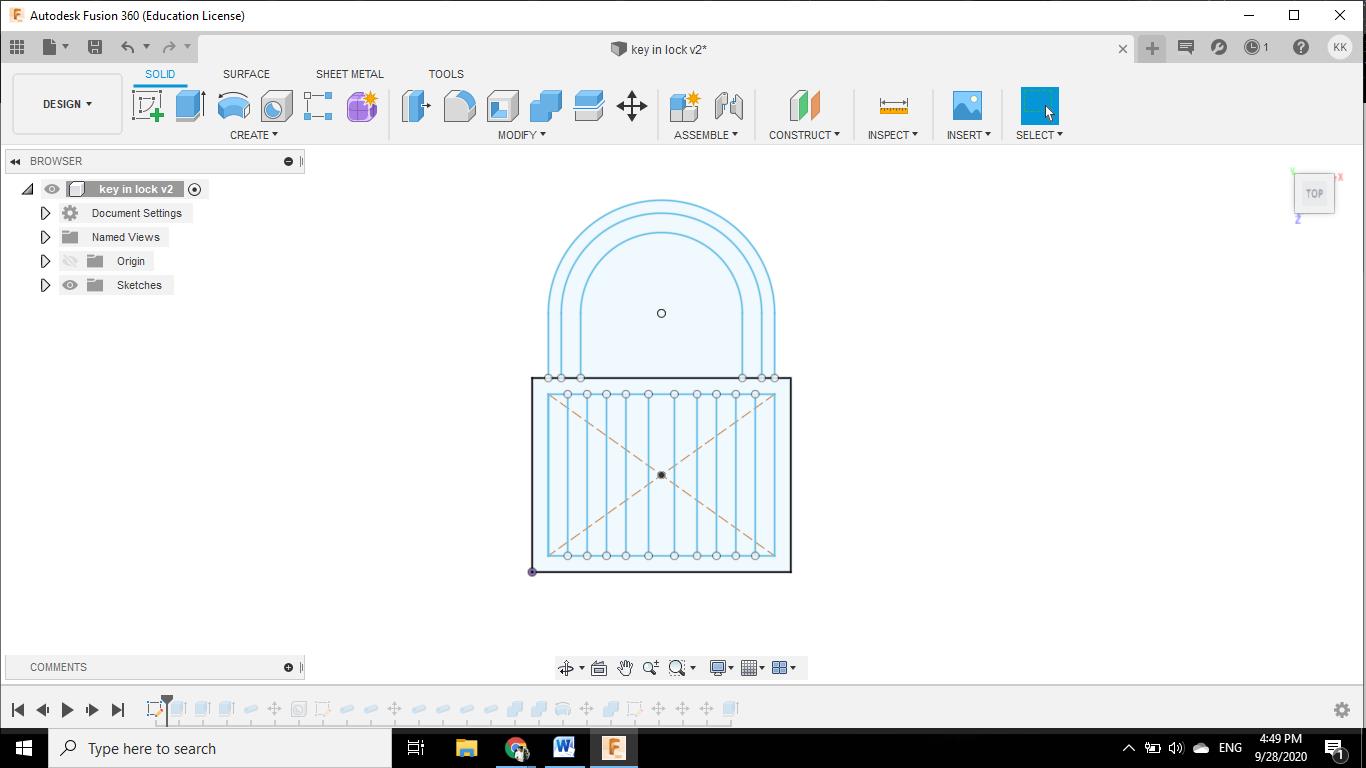

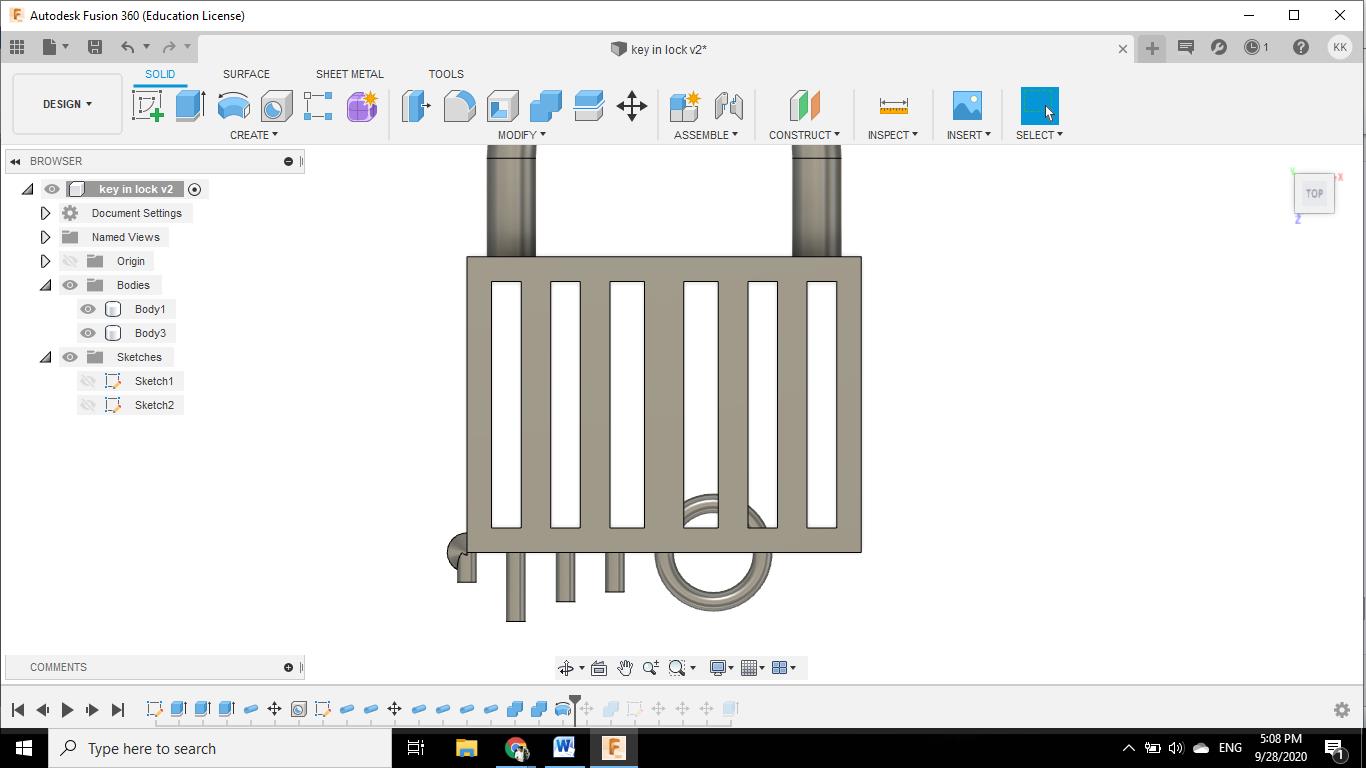

then add some of lines this well make gape so you can see what inside the lock

then add some of lines this well make gape so you can see what inside the lock

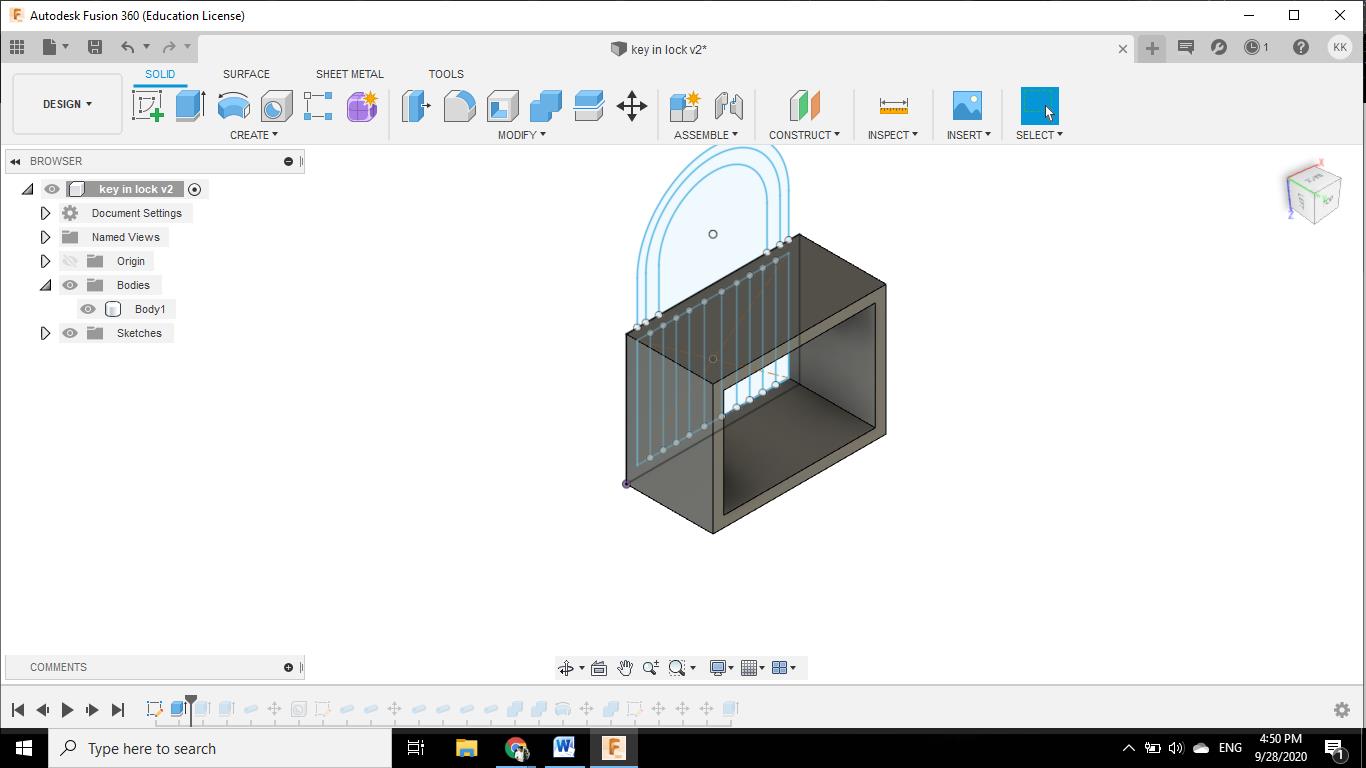

next extrude the body of the lock

next extrude the body of the lock

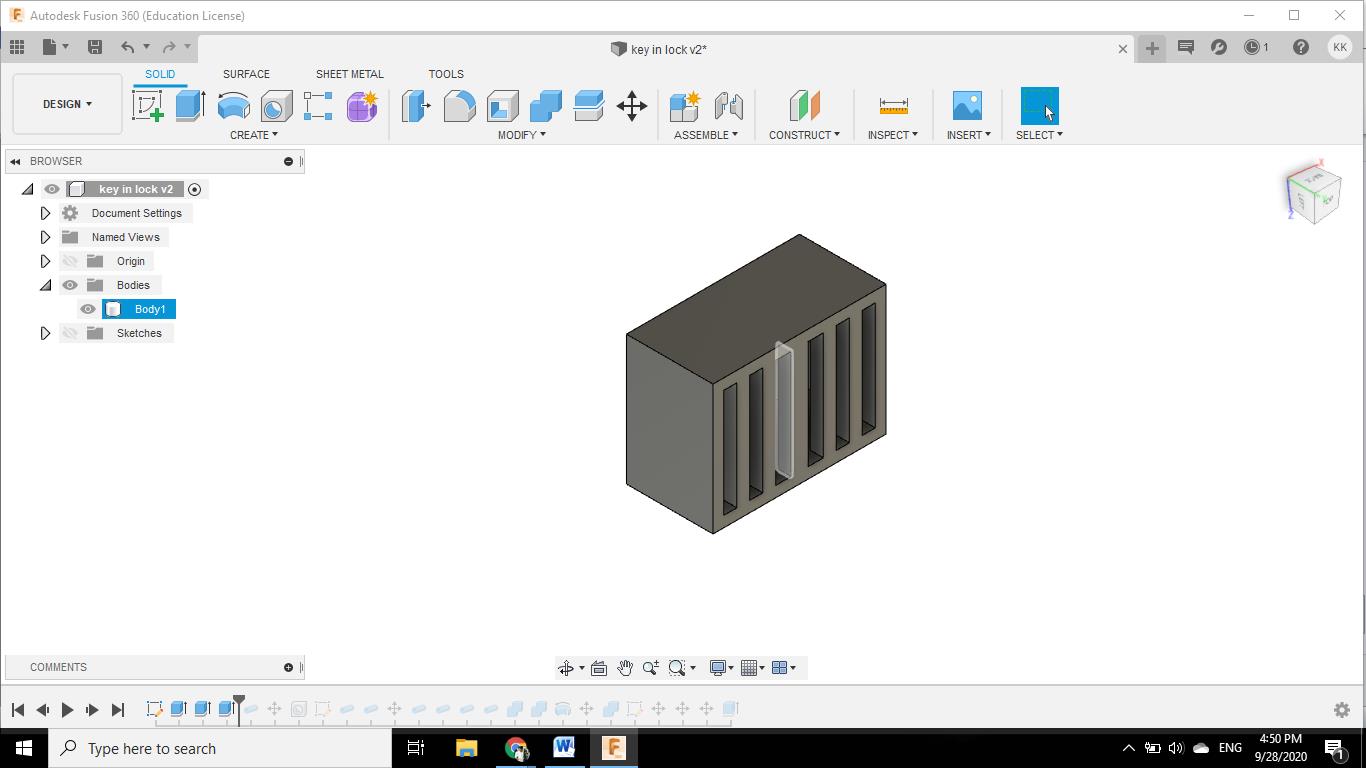

after that extrude the bars

after that extrude the bars

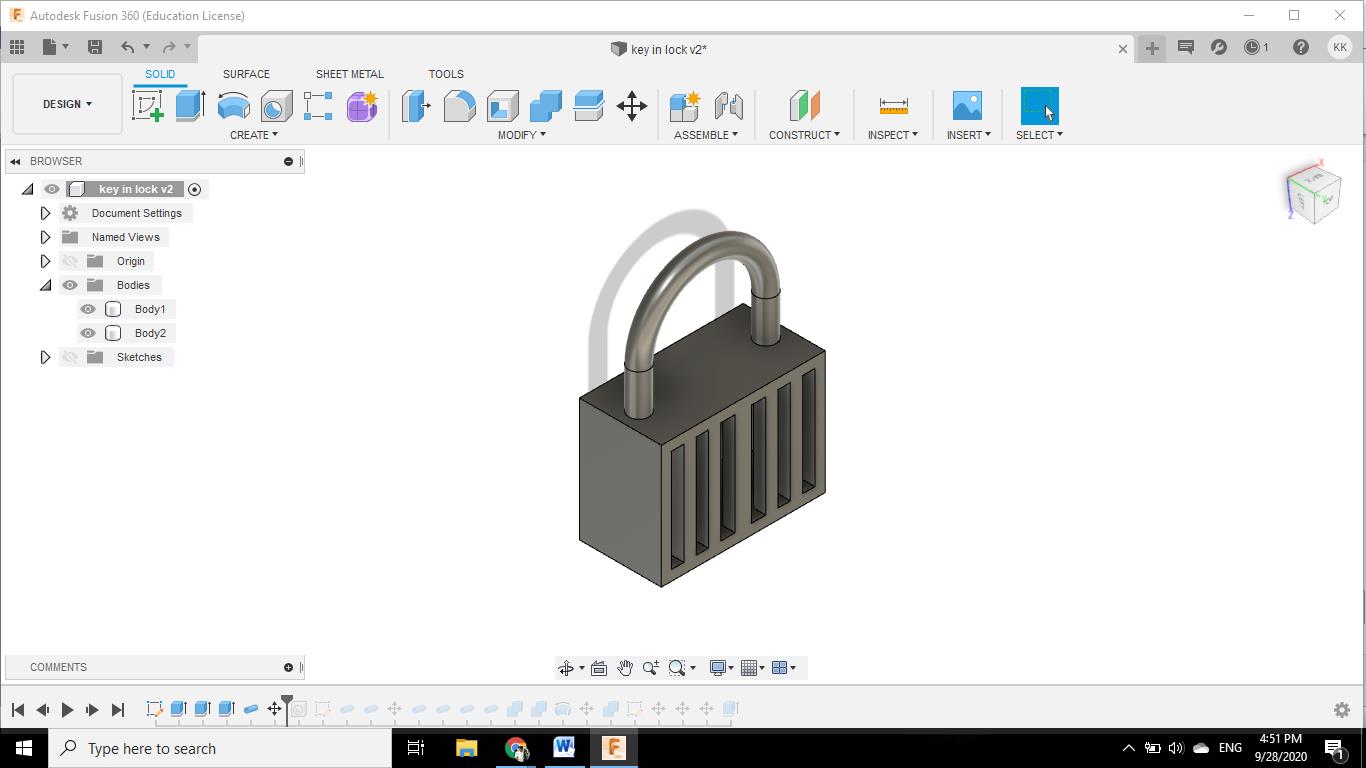

last thing in the lock was the shackle I used revolving tool to make it.

last thing in the lock was the shackle I used revolving tool to make it.

move it to the middle

move it to the middle

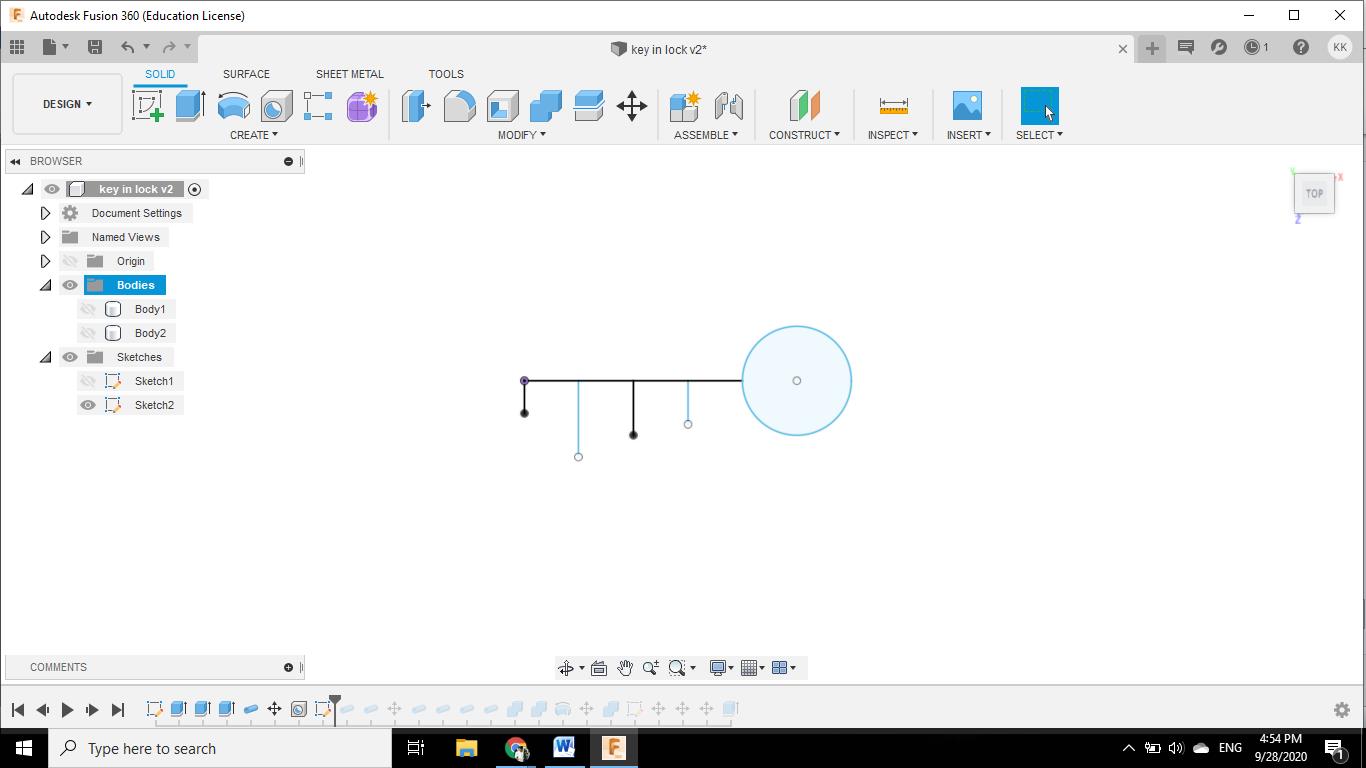

making the key design

making the key design

then revolve in base lines in the key

then revolve in base lines in the key

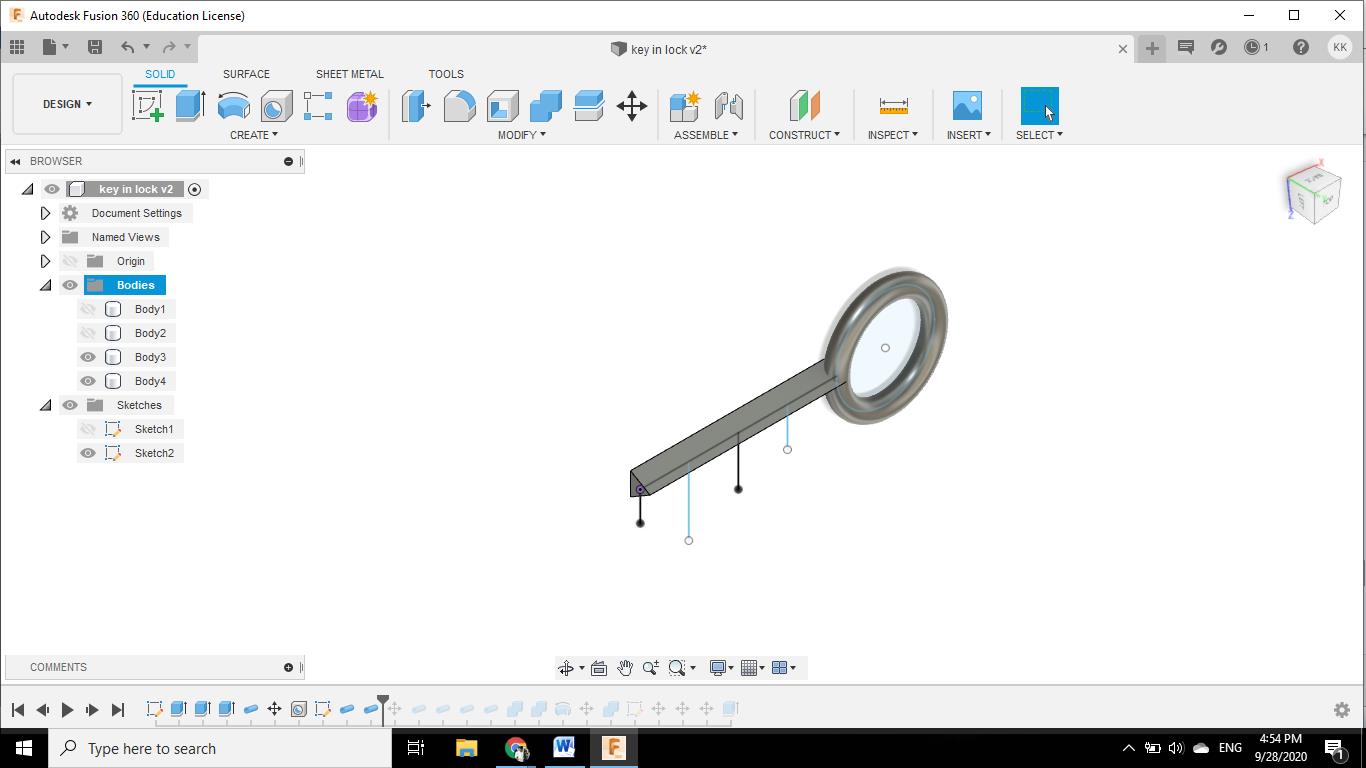

the use the revolve tool to make the key teeth

the use the revolve tool to make the key teeth

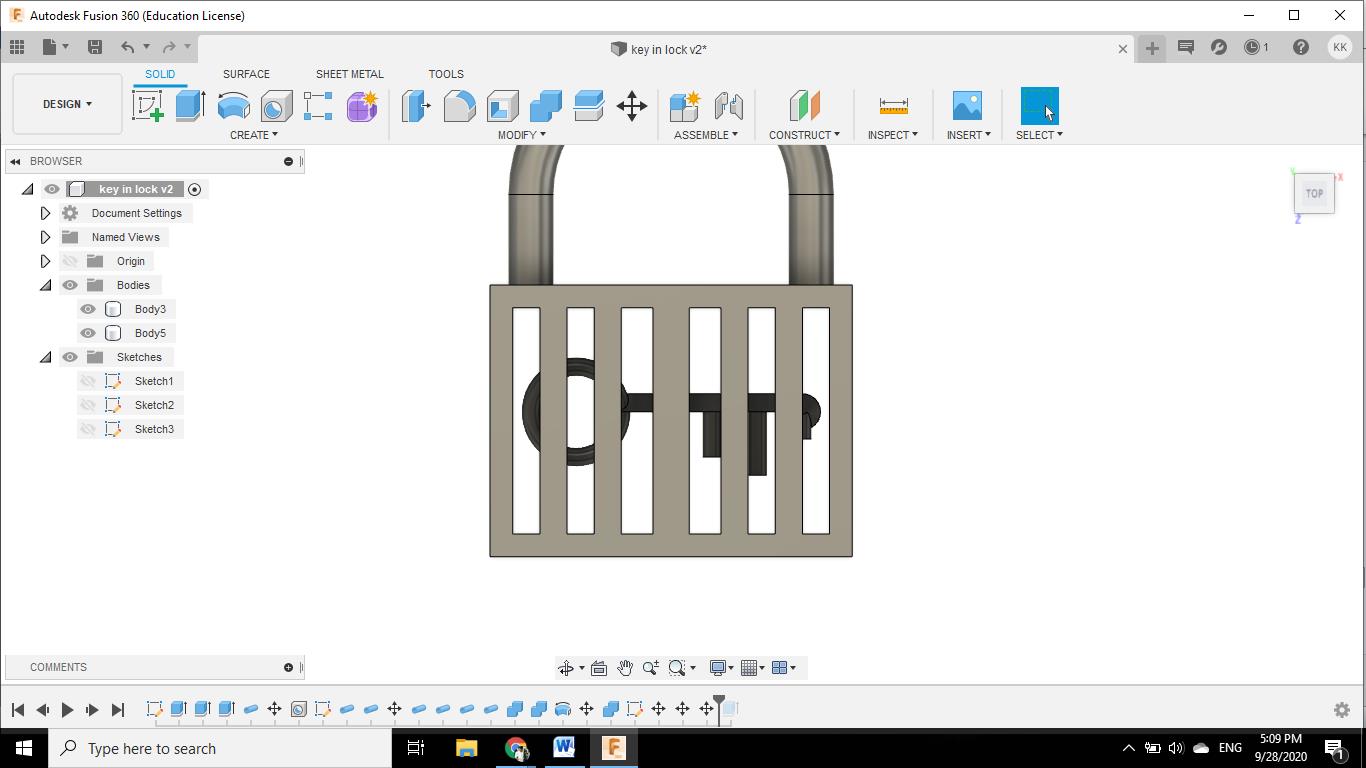

all it need to do know is to put the key in side the lock

all it need to do know is to put the key in side the lock

3d printer slicer¶

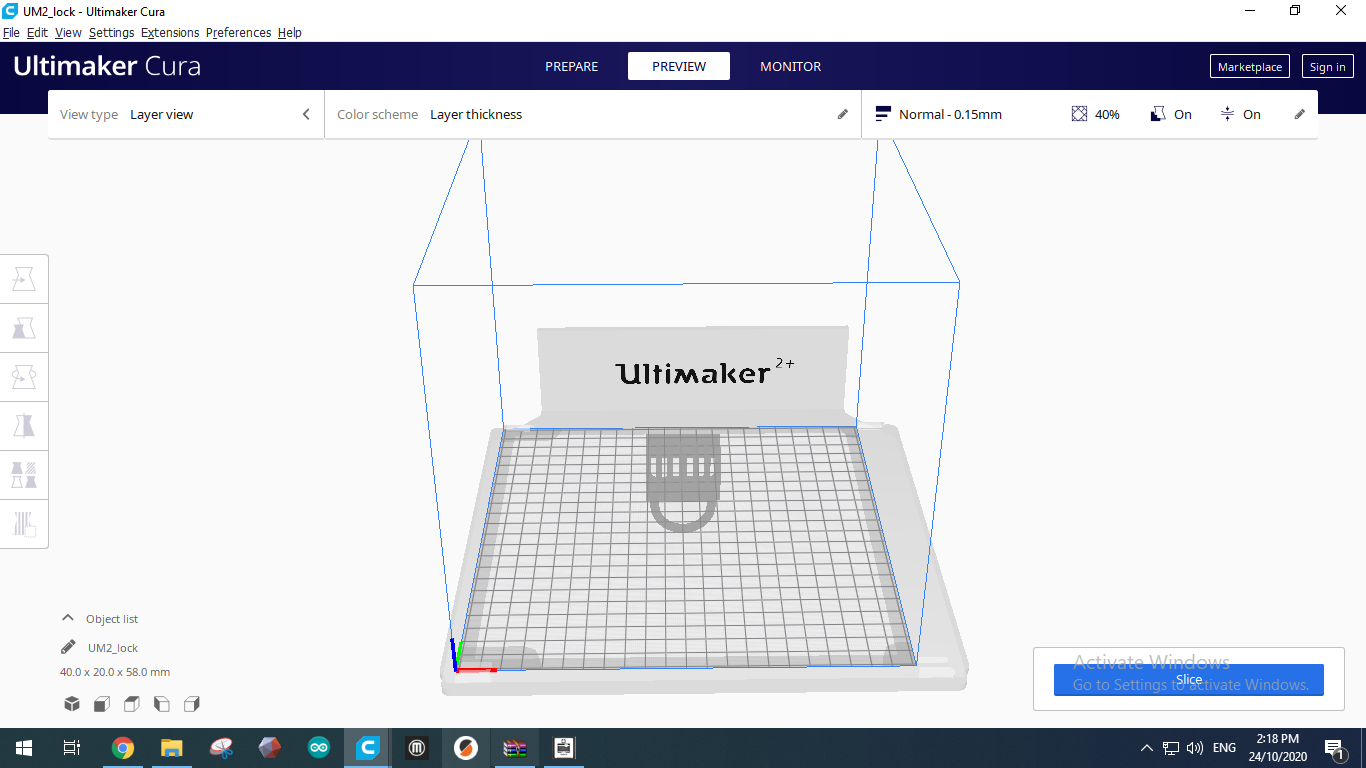

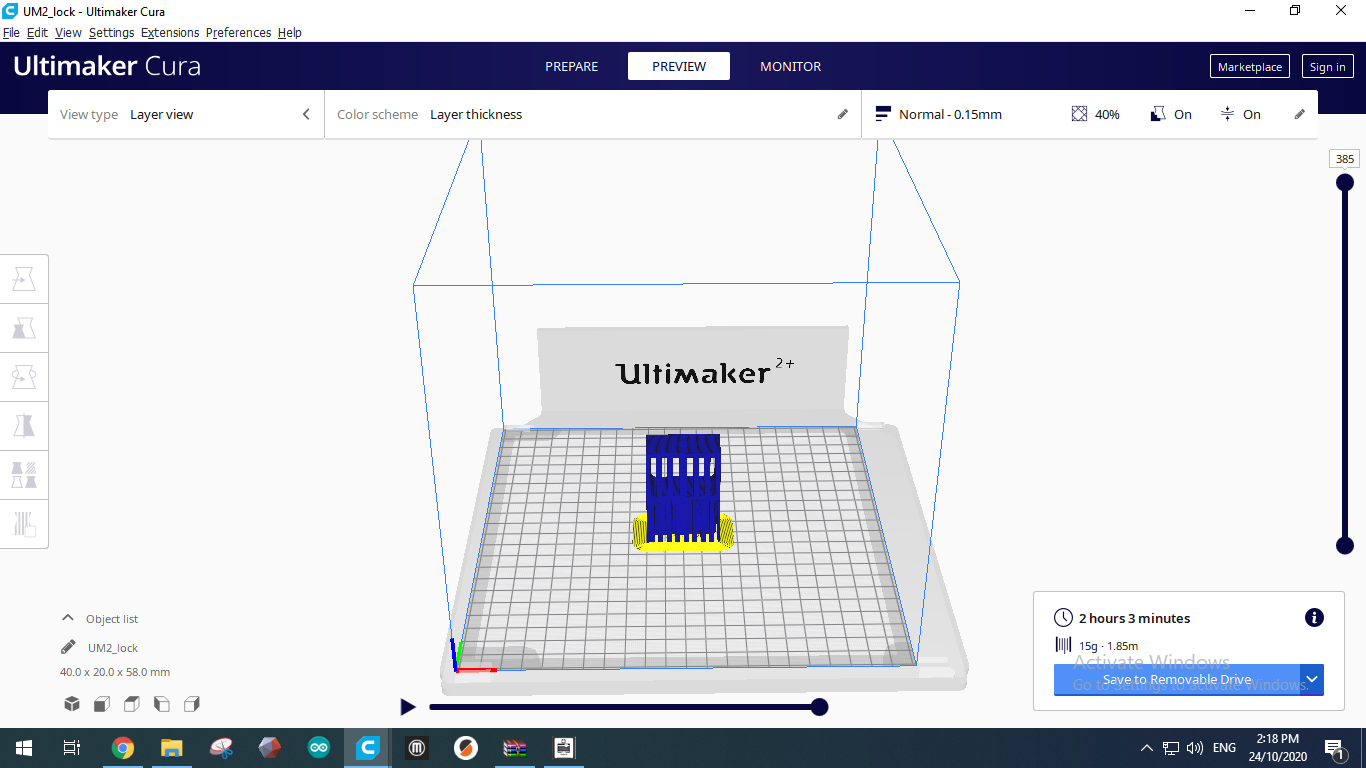

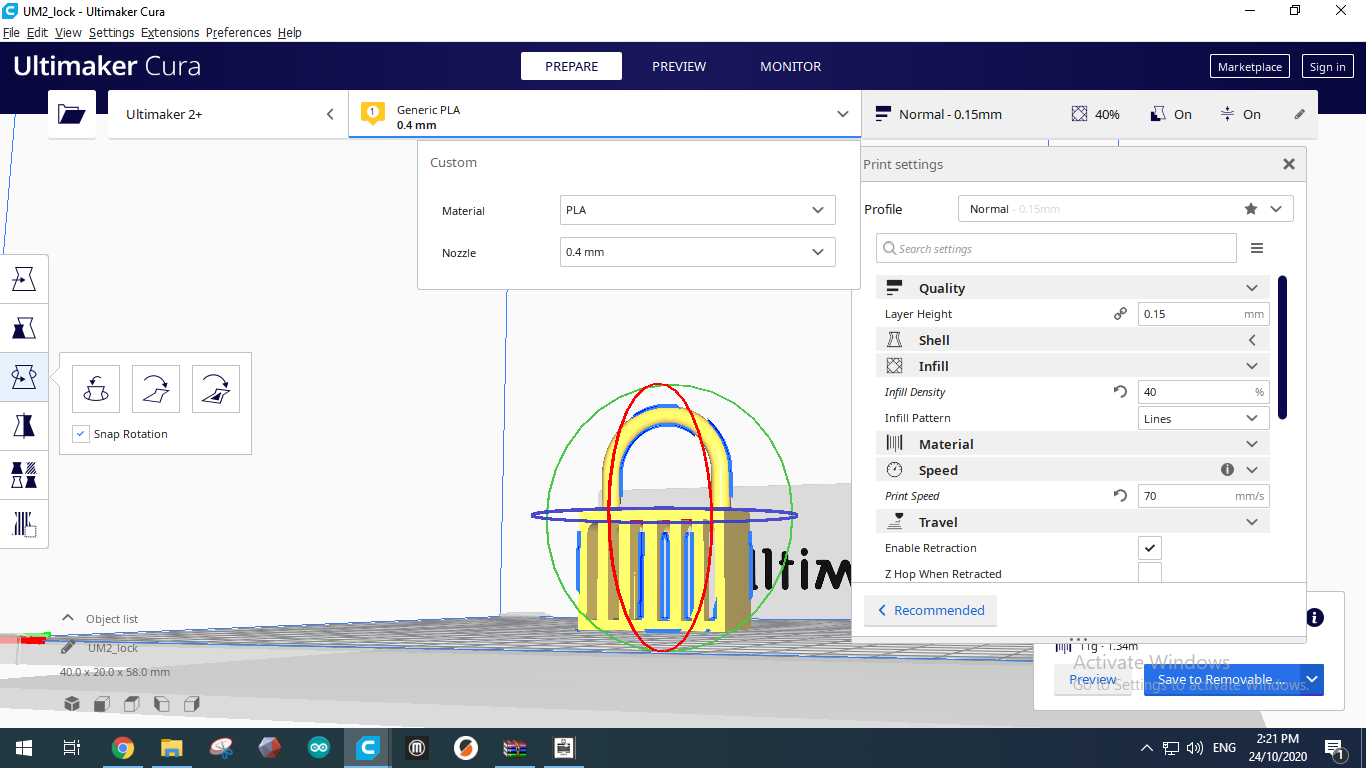

to terraform the file from the STL to Gcode that the printer can understand I used Ultimaker Cura :

first thing I did was to drag the STL file into this program

first thing I did was to drag the STL file into this program

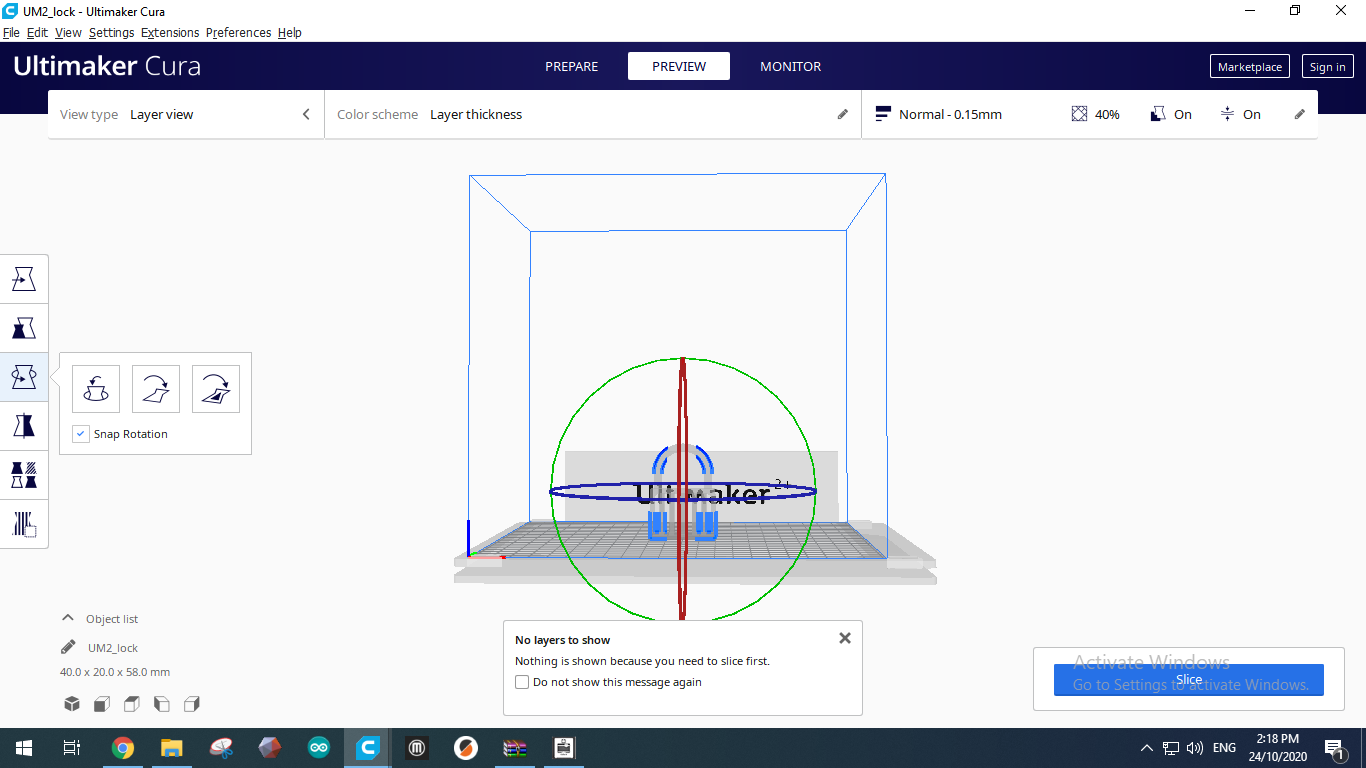

the I slice it too see how it lock , it was upside down so I need to rotate it.

the I slice it too see how it lock , it was upside down so I need to rotate it.

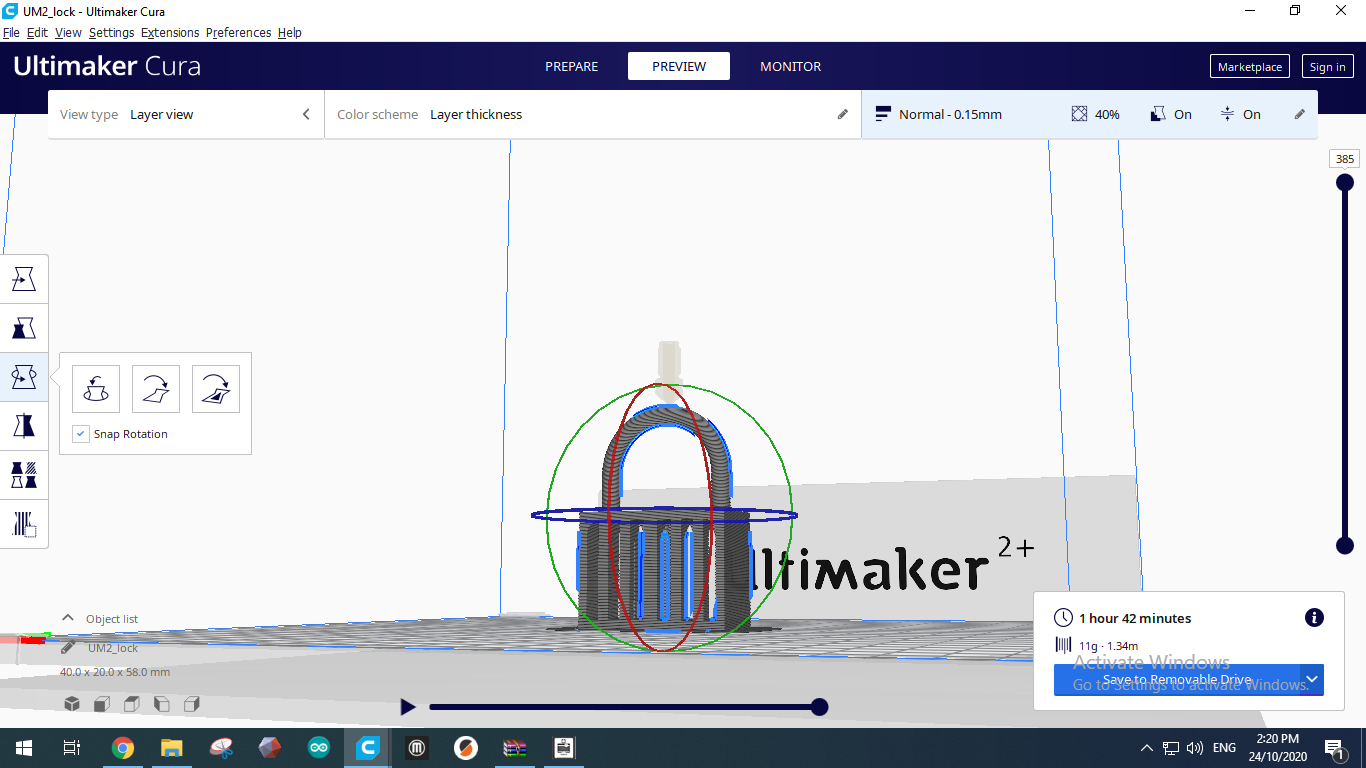

then rotate the design

then rotate the design

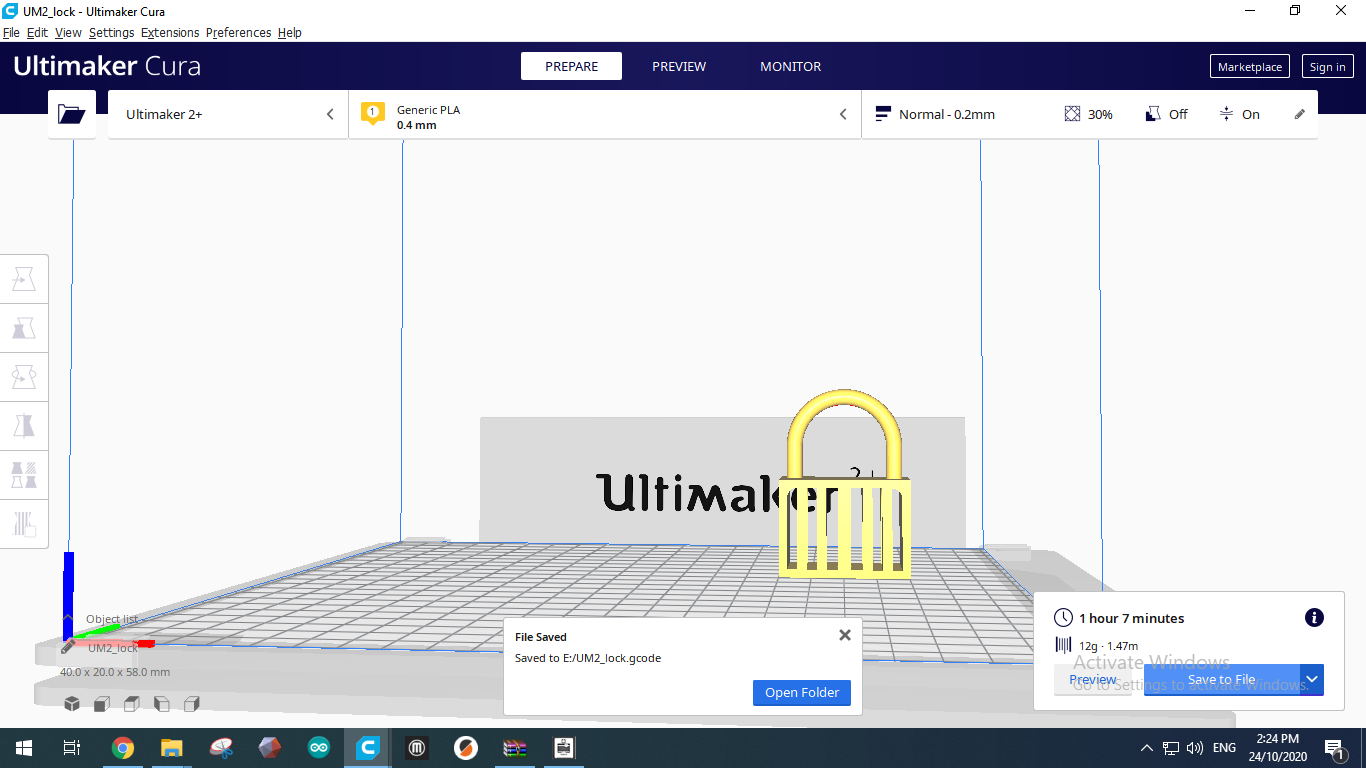

and slice it, know it look batter.

and slice it, know it look batter.

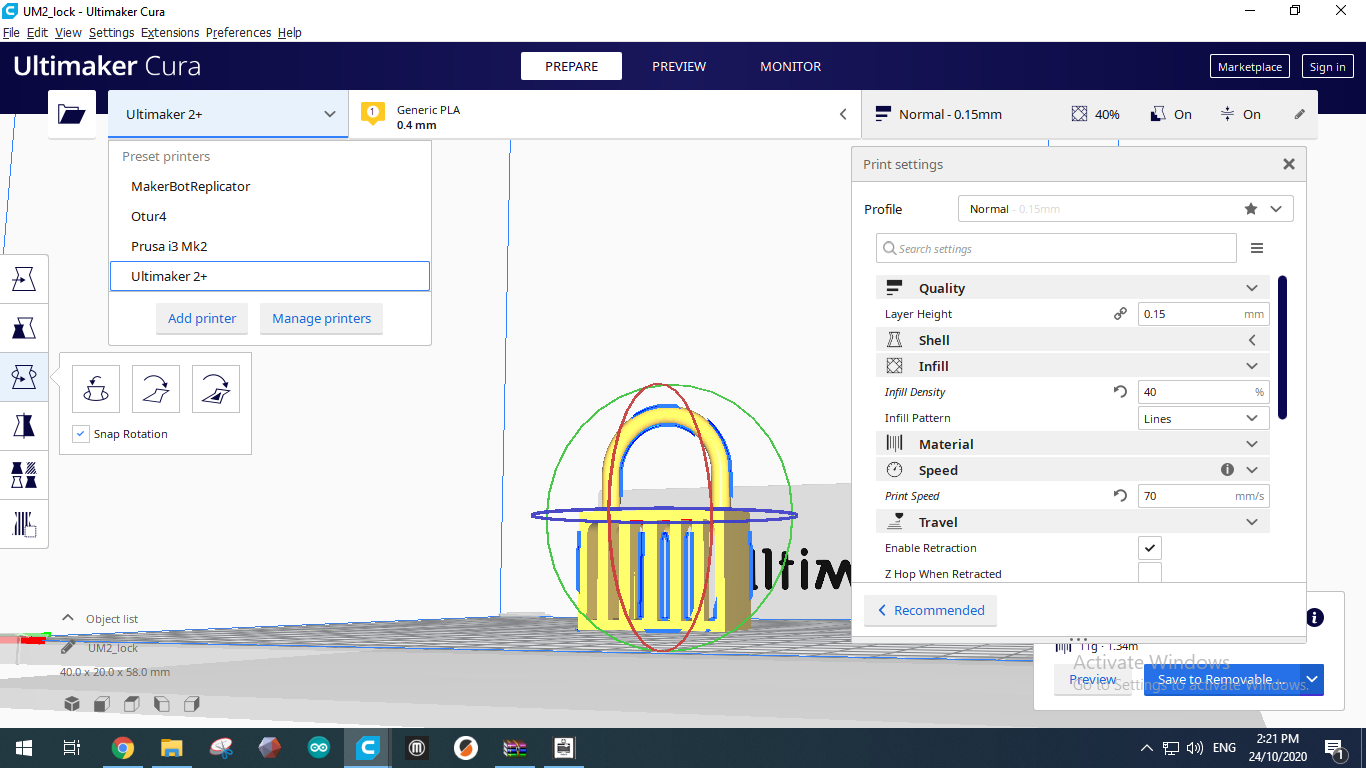

then I chose the printer that I will use.

then I chose the printer that I will use.

I chose the material and edit in printing sitting

I chose the material and edit in printing sitting

I slice it for ha last time and save it in SD card and put it in the printer

I slice it for ha last time and save it in SD card and put it in the printer

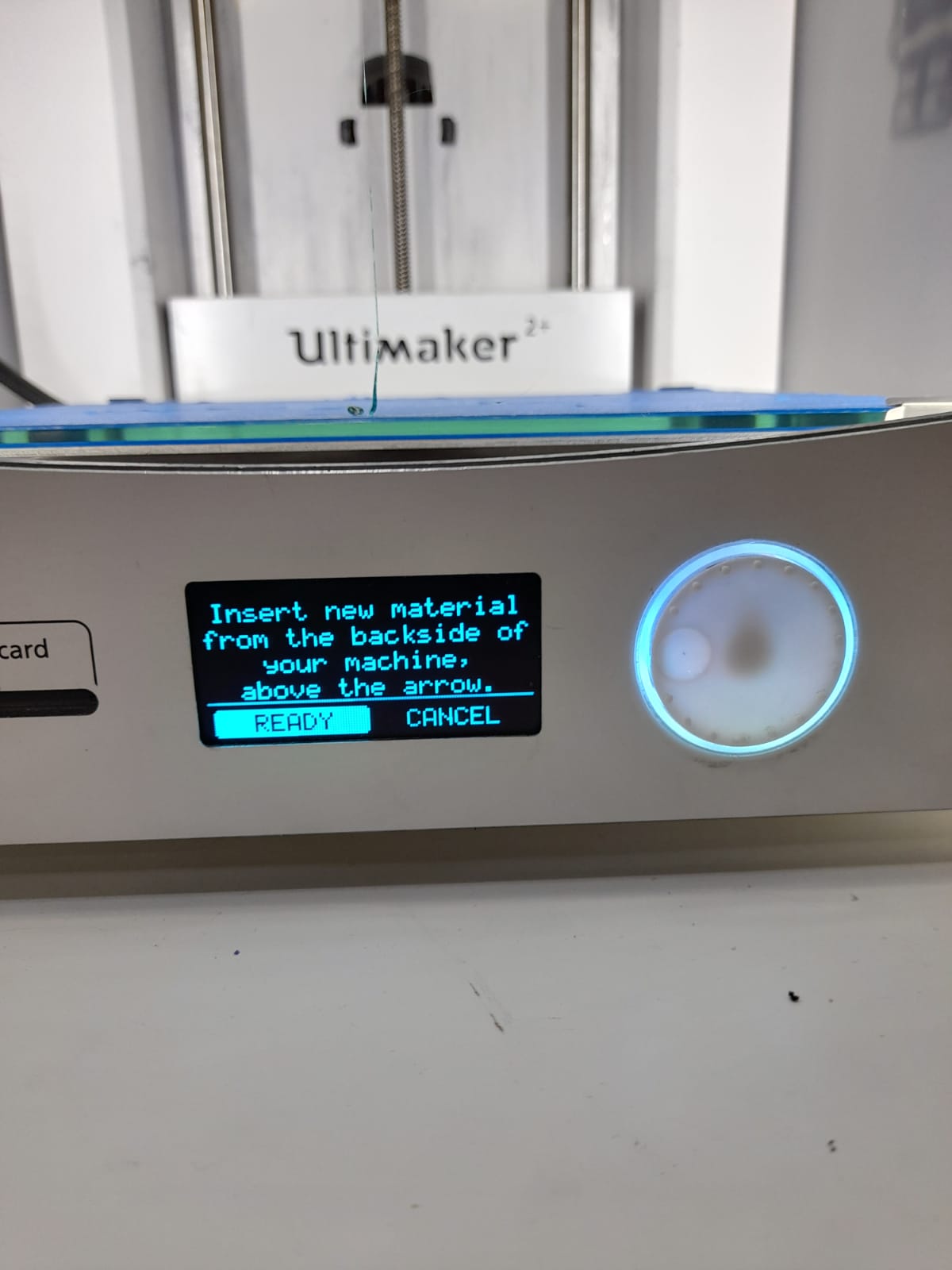

insrt the material¶

first thing we click in insert new material

first thing we click in insert new material

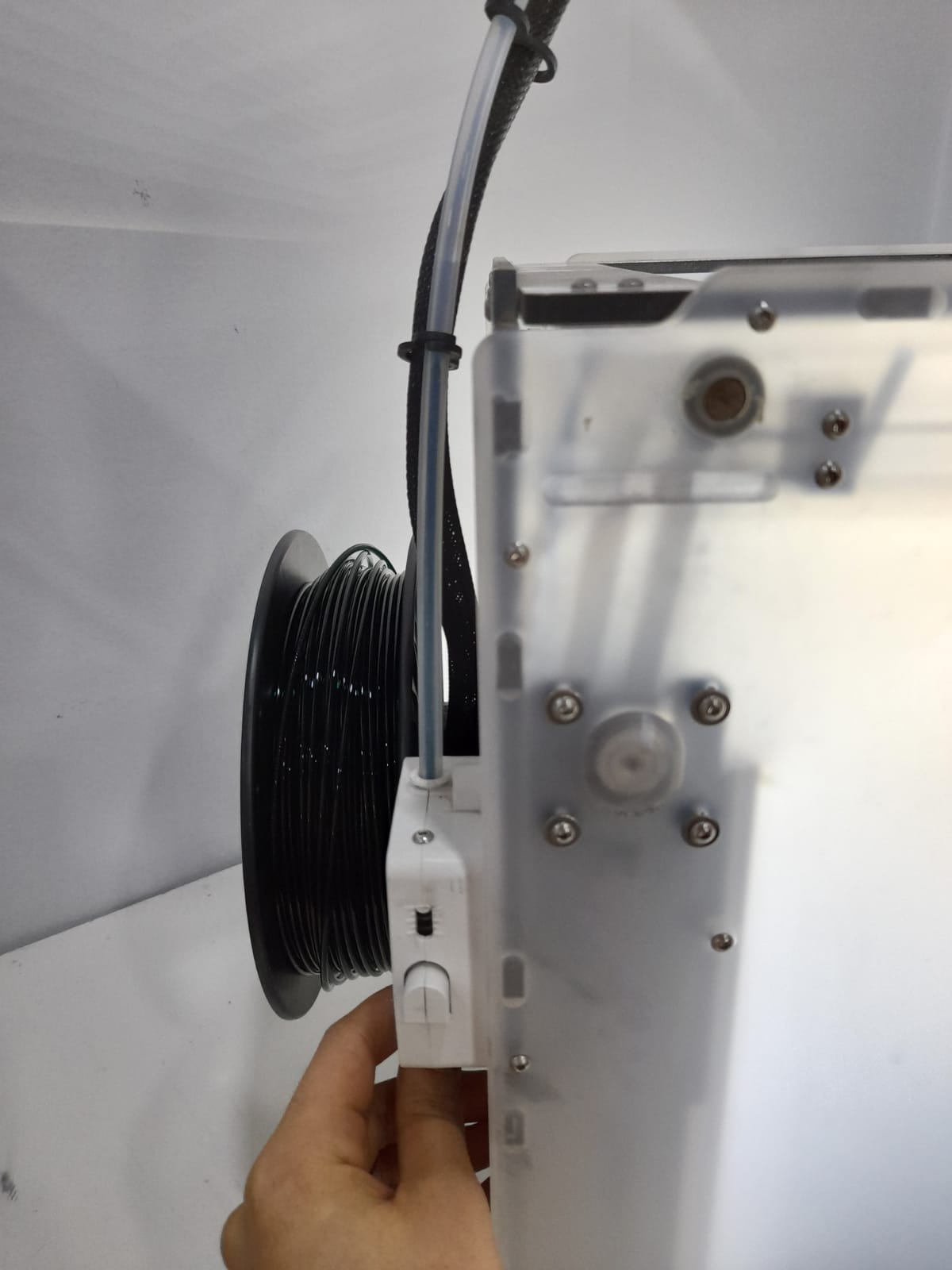

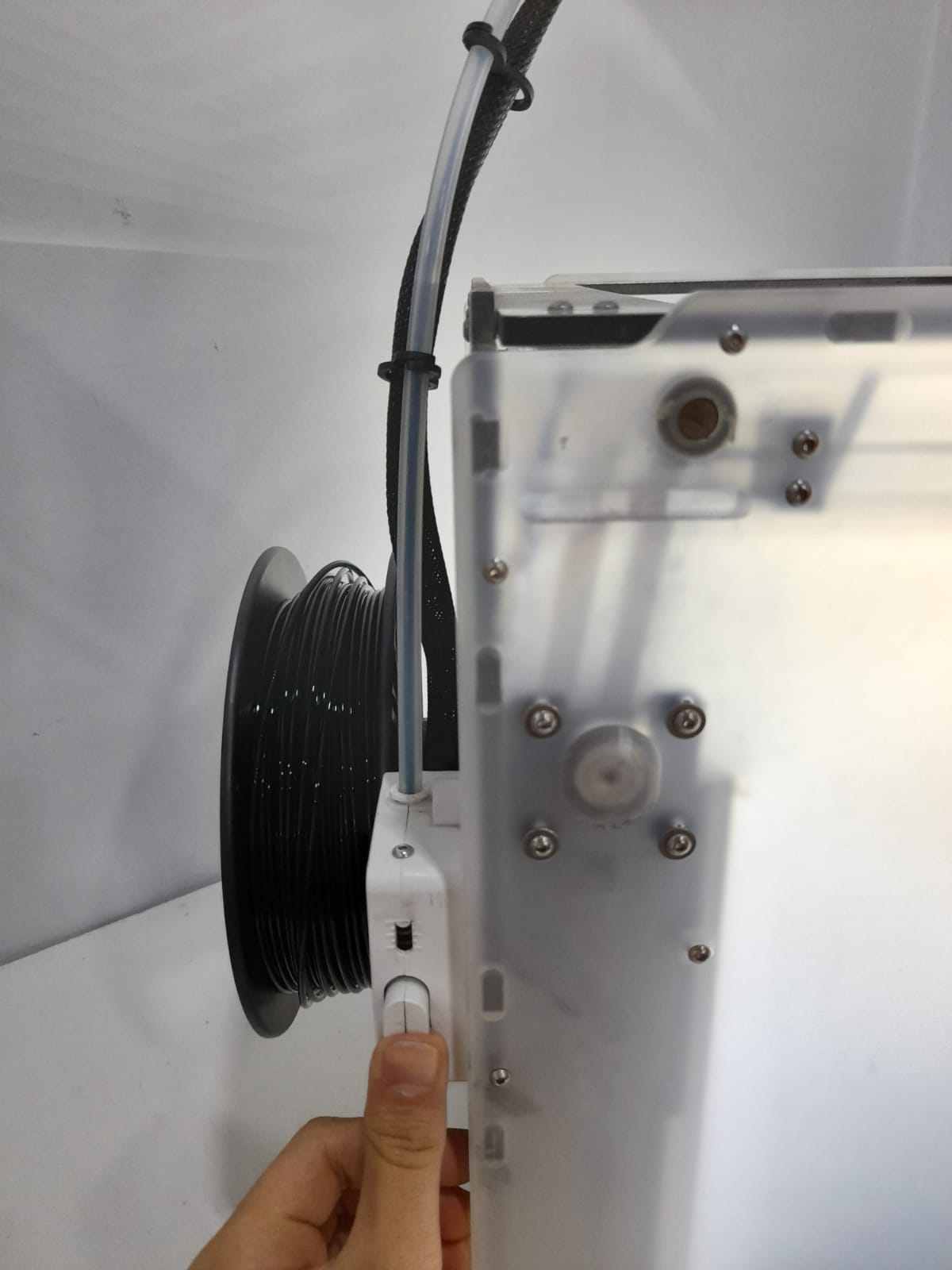

then we insert the material from the back

then we insert the material from the back

the next step is to lift the button up , then you click on ready .

the next step is to lift the button up , then you click on ready .

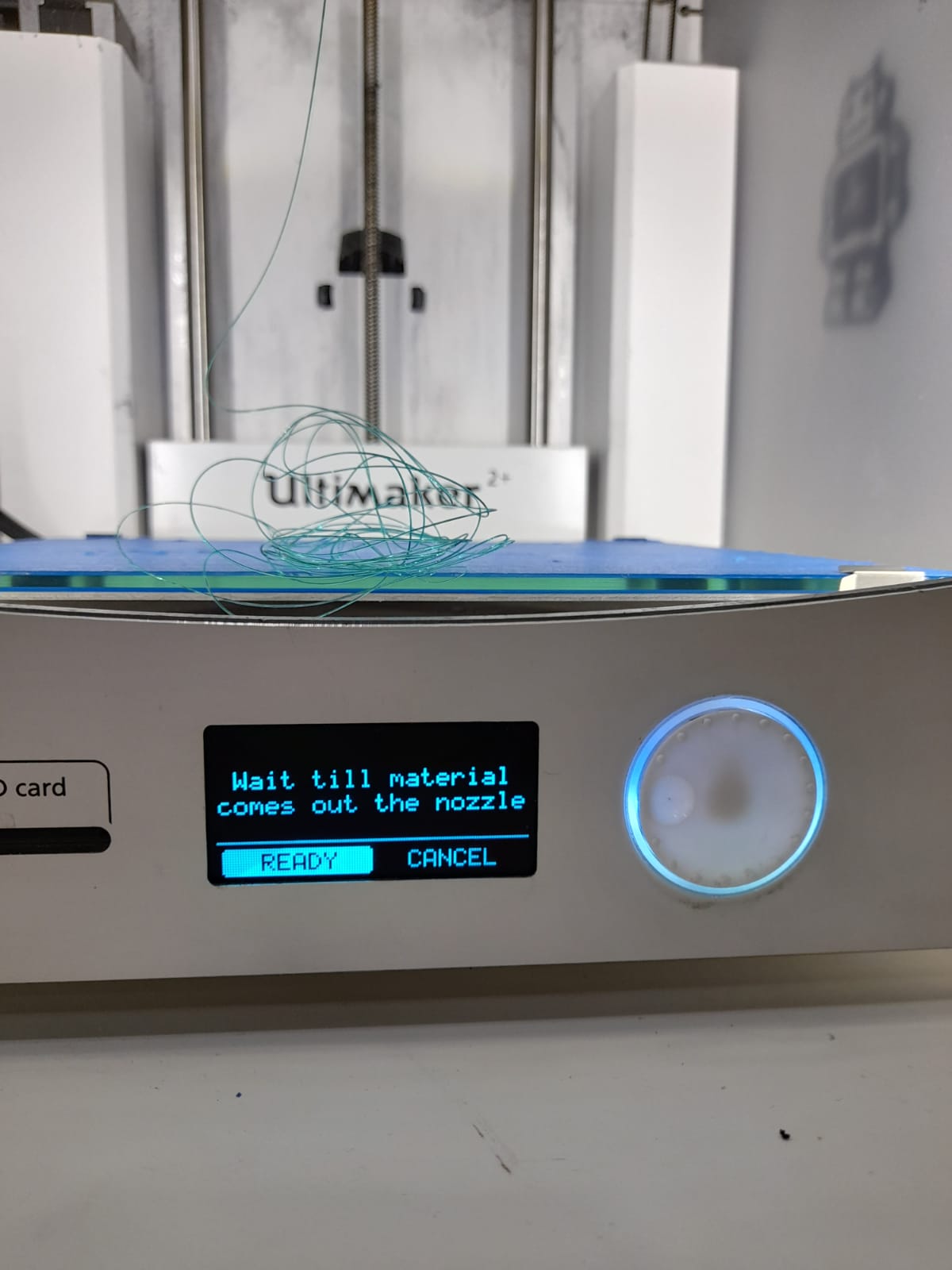

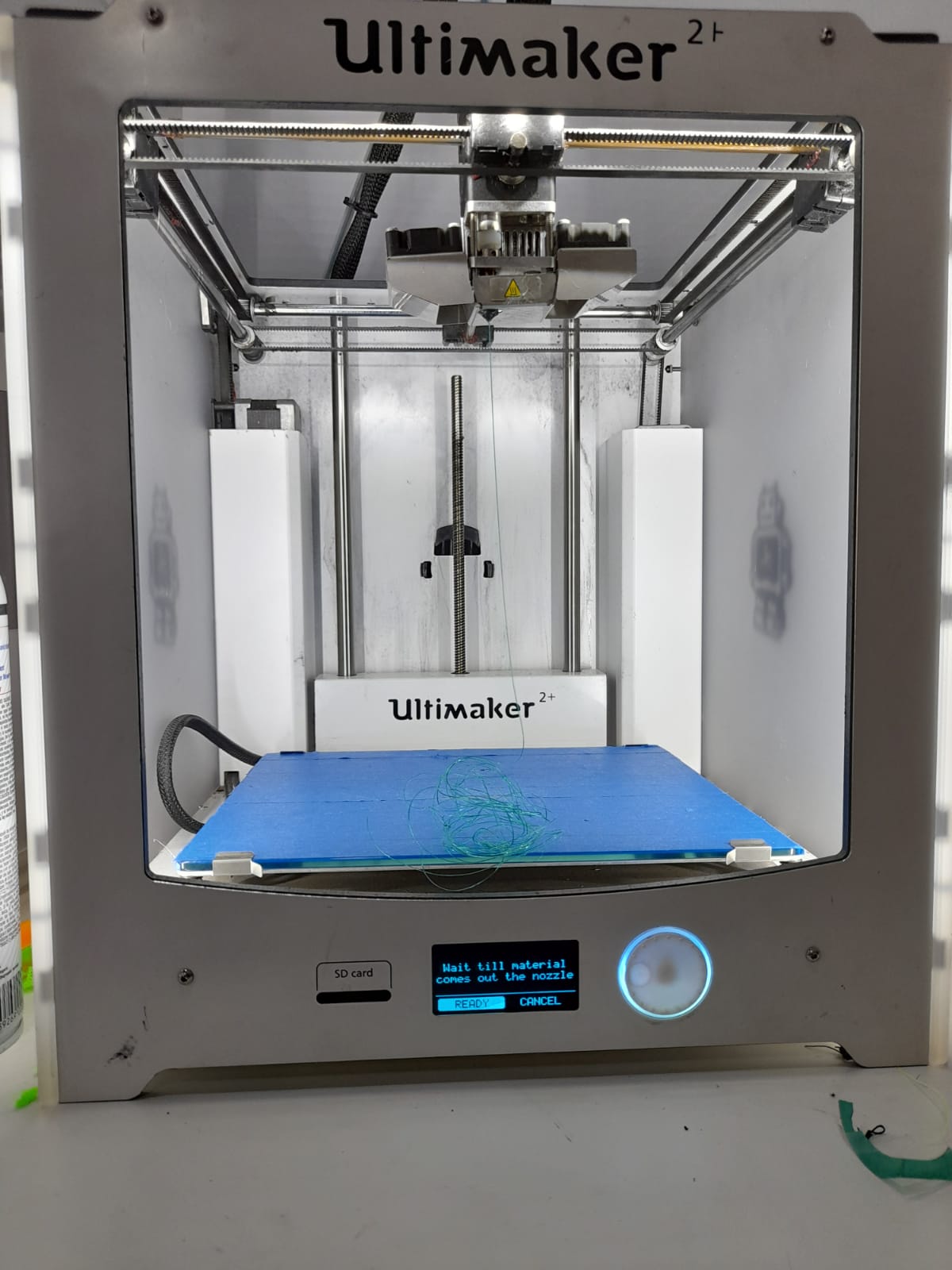

the you wait till the material come out of the nozzle

the you wait till the material come out of the nozzle

when it come out you click on ready and you remove the extra material that in the bed

when it come out you click on ready and you remove the extra material that in the bed

start printing¶

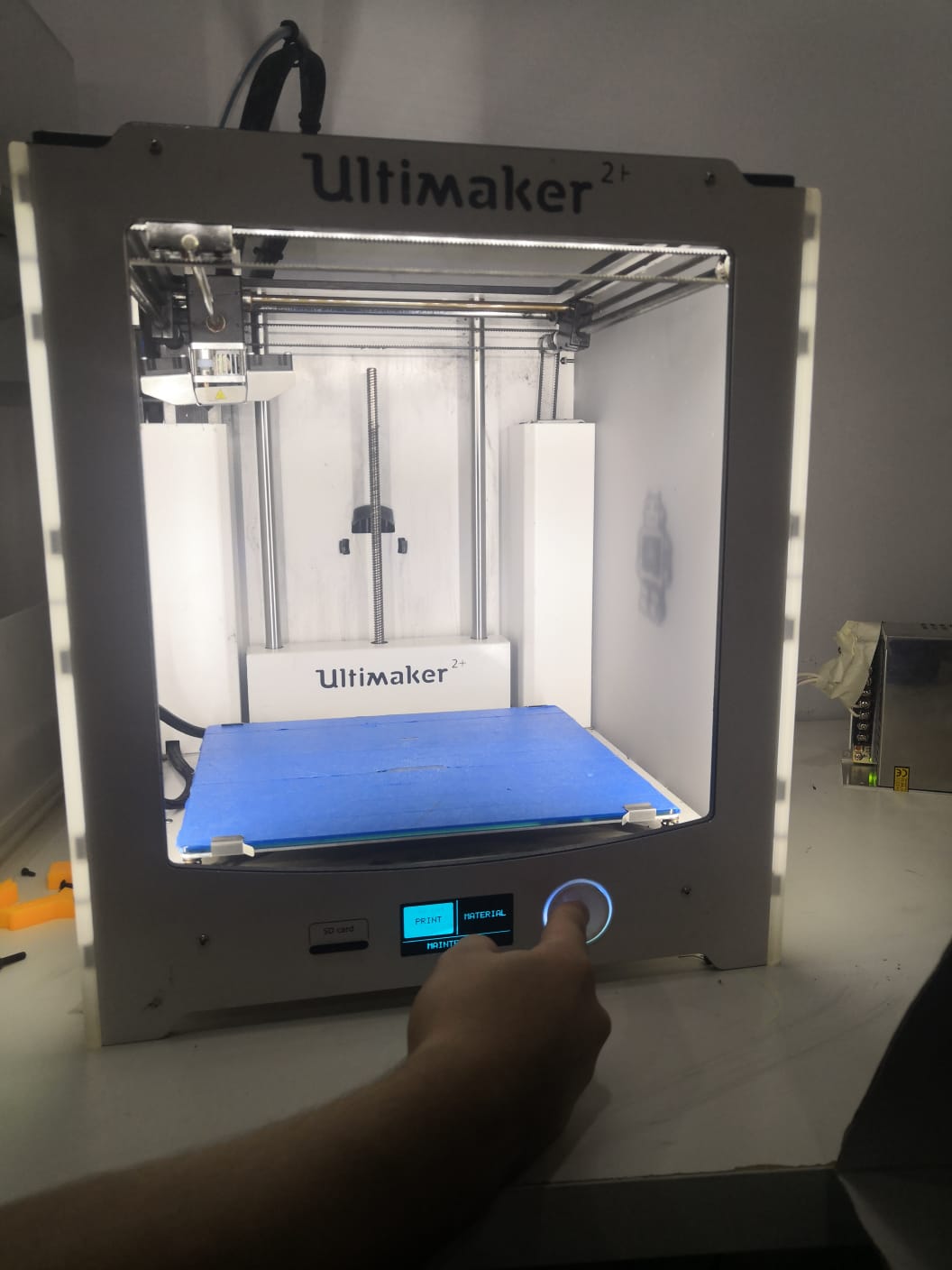

first inserting the SD cade in the machine.

first inserting the SD cade in the machine.

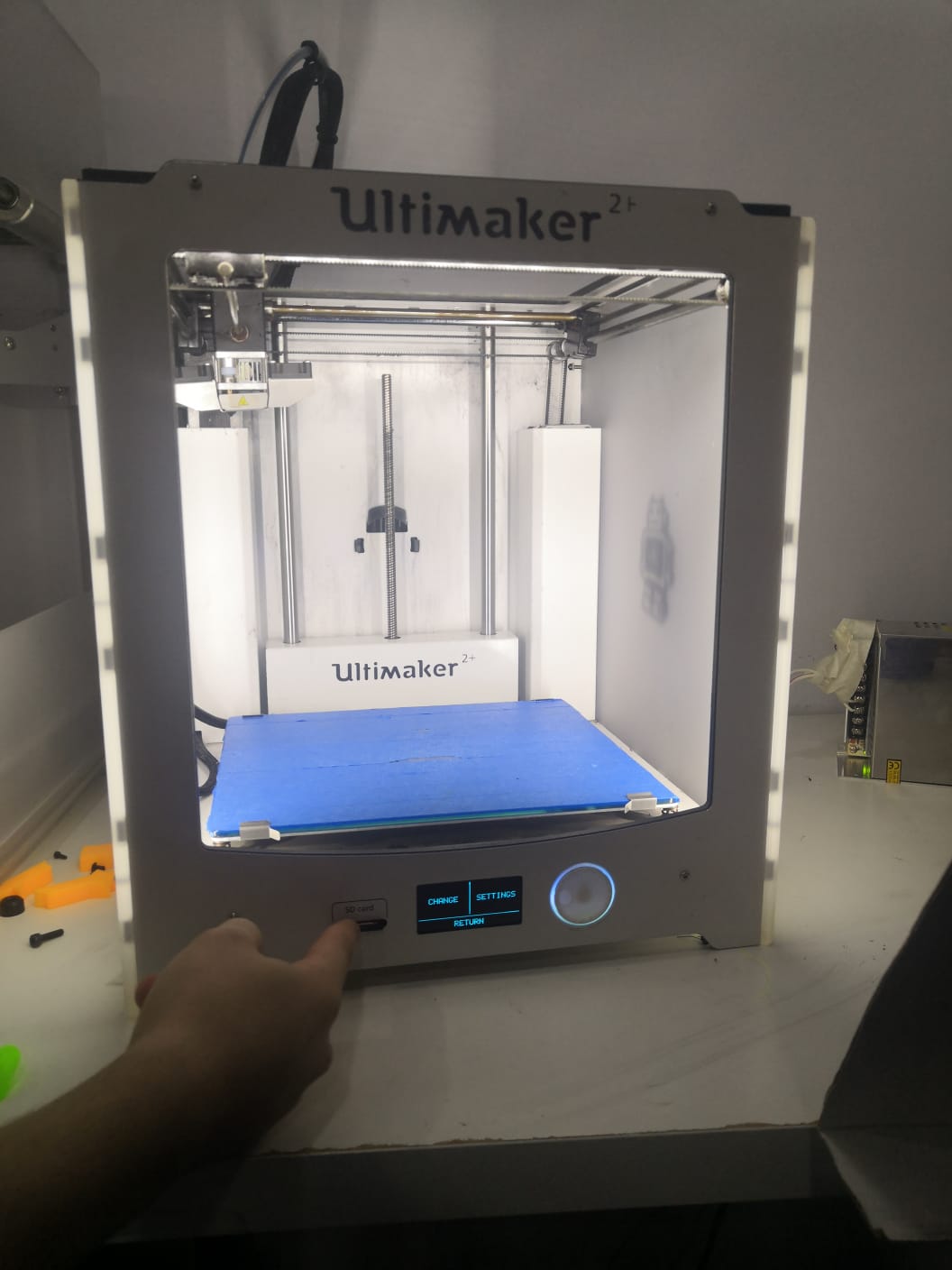

then click on the print

then click on the print

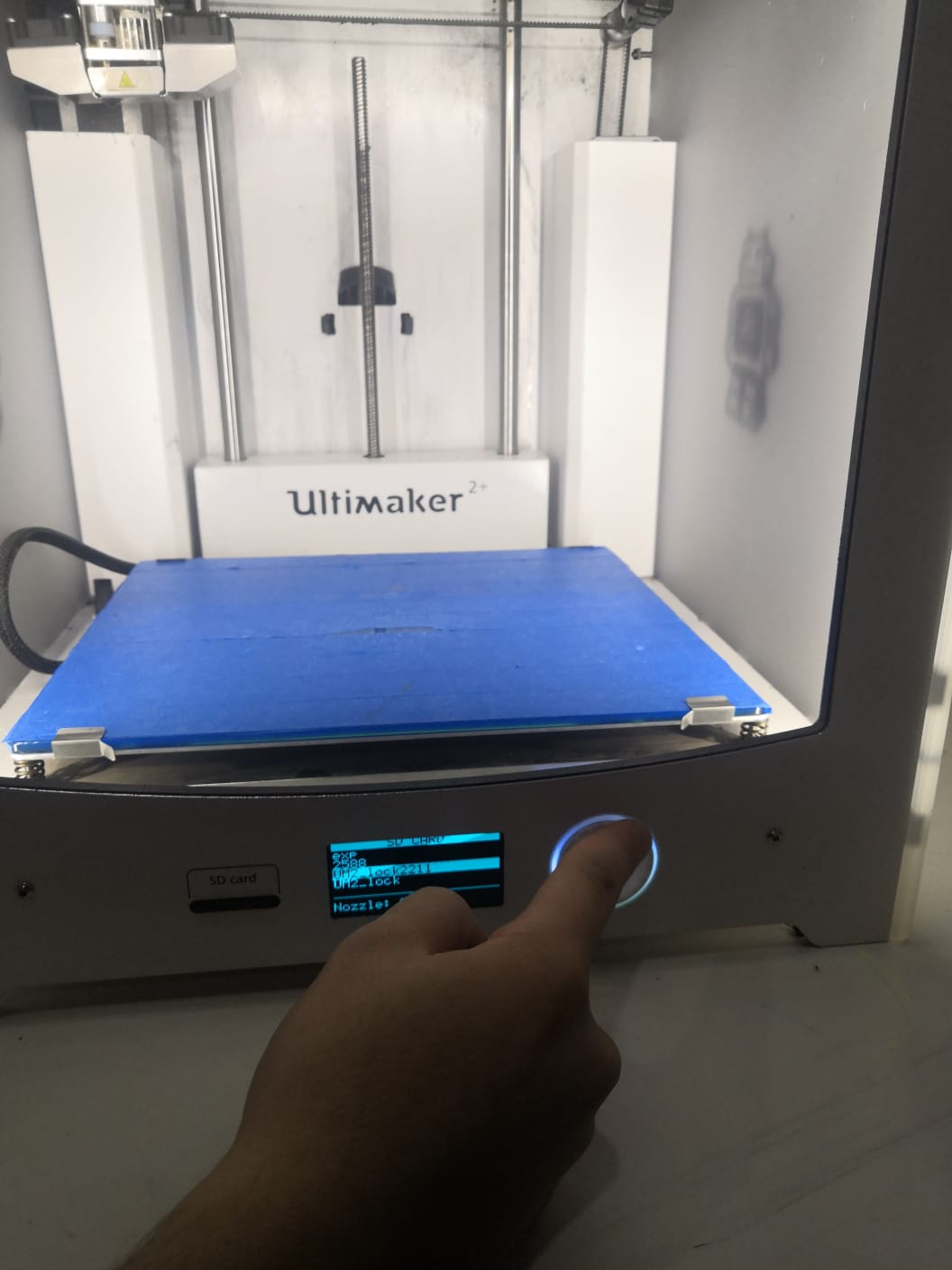

after that click in to the file that I want to print

after that click in to the file that I want to print

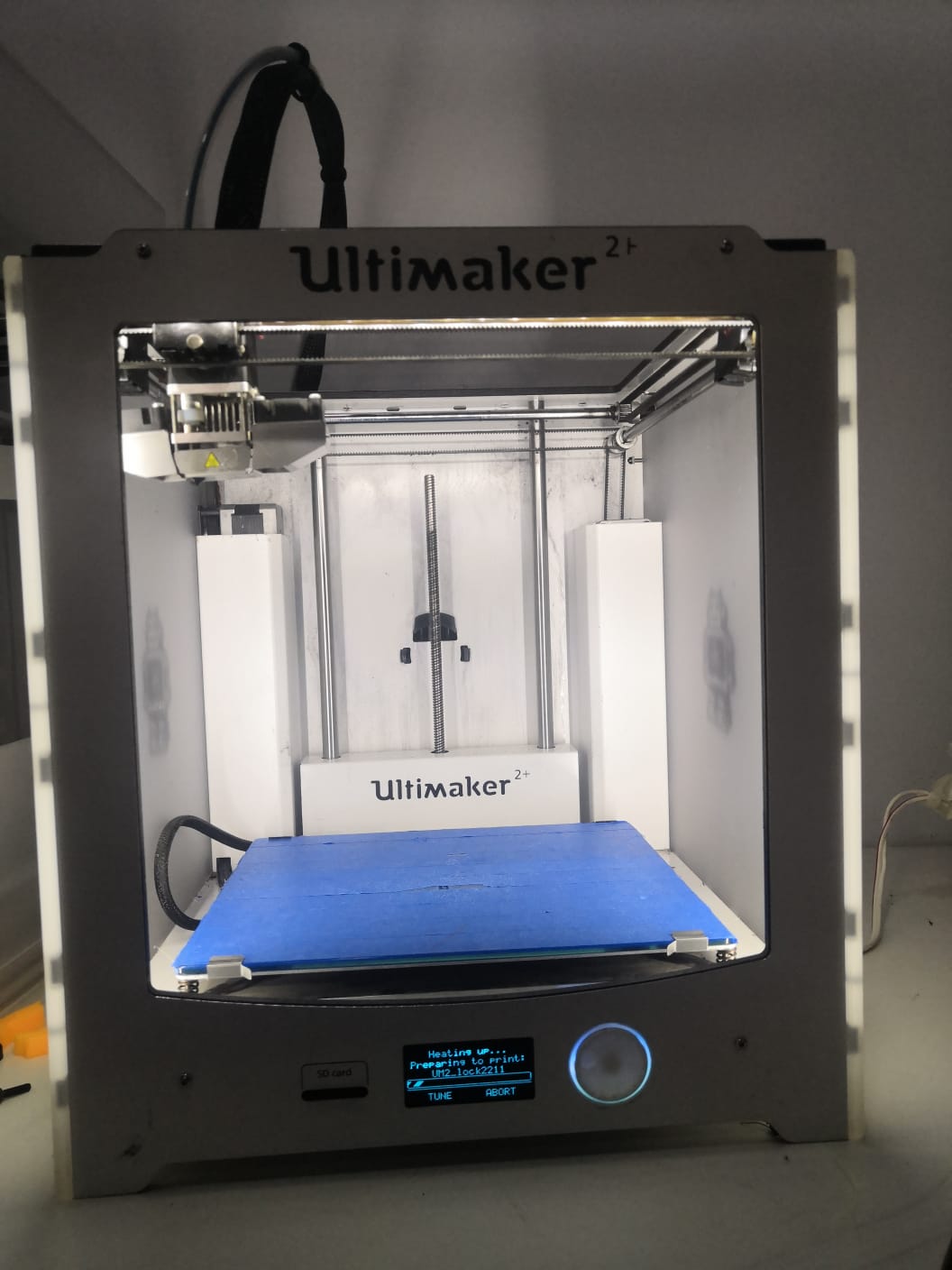

the machine then will start printing.

the machine then will start printing.

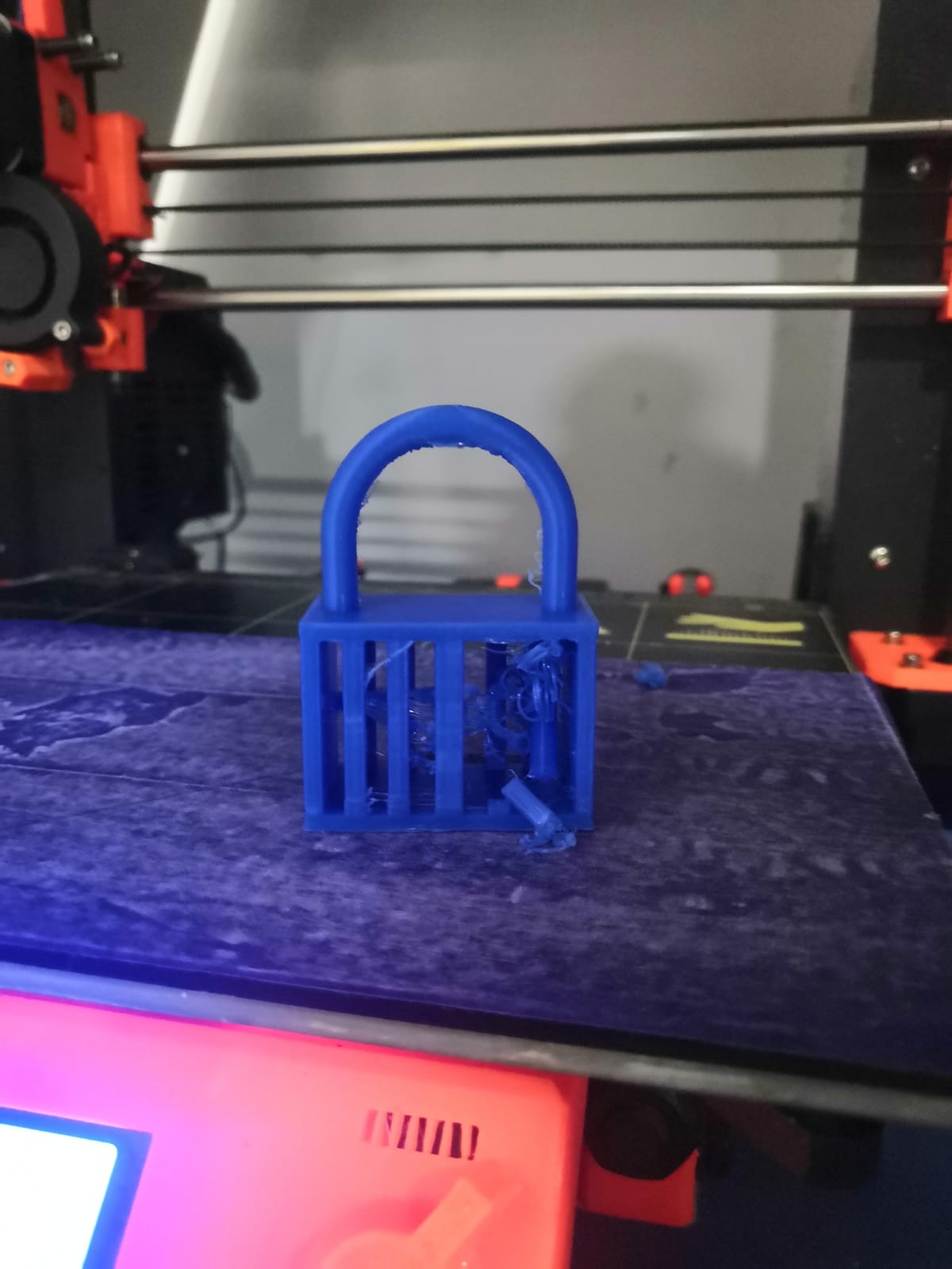

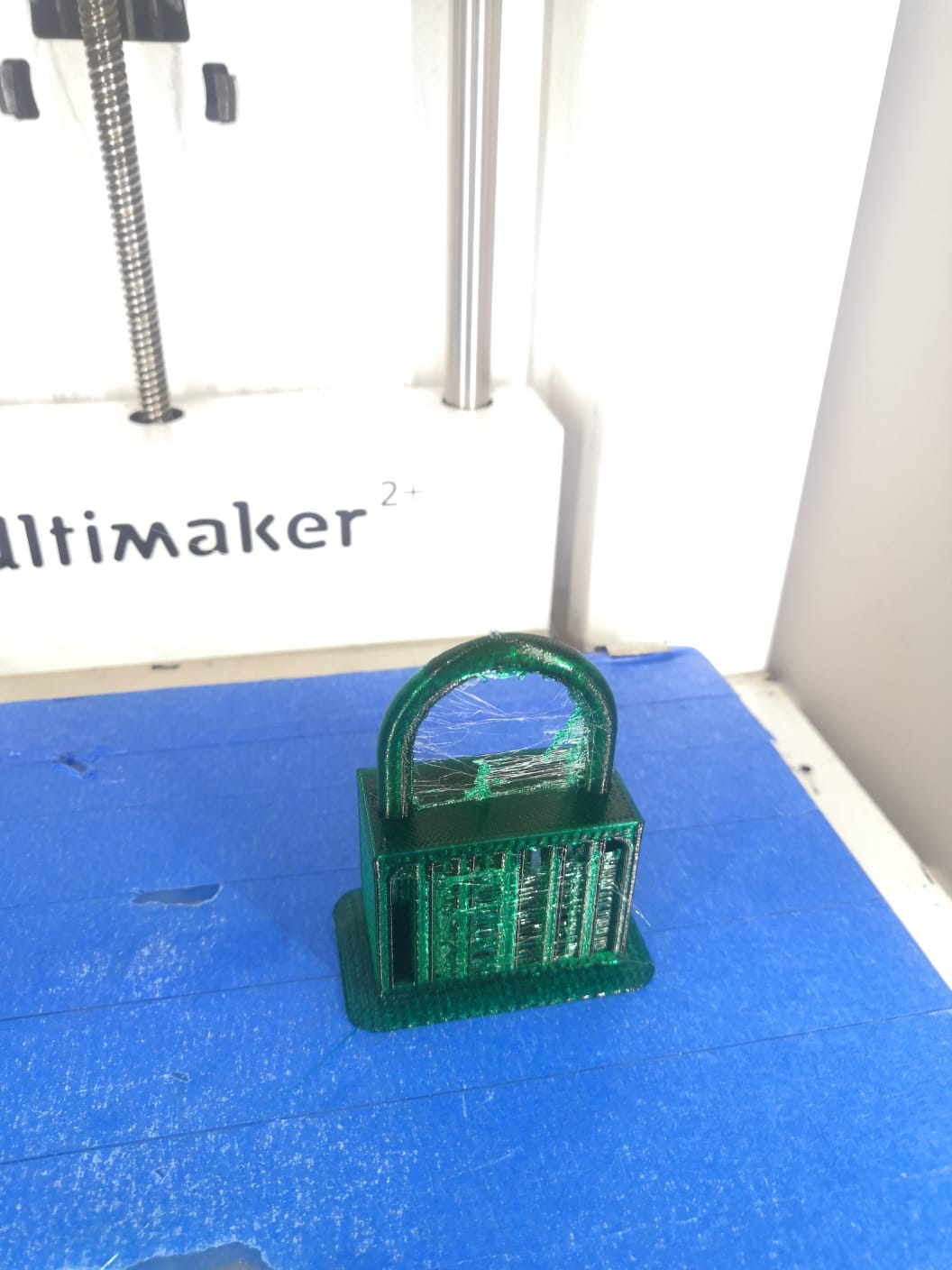

The 3d design with problem in printing deo to the key inside

I printed using prusa and after the print there was problem it was that the key didn’t print well in side the lock and this make even the wall break.

then I edit the design and remove the key

files¶

material : I used for printing PLA

for the second try I used Ultimaker 2+ and the same material PLA but different color :

this how I get it from the printer

after some cleaning this is the hero shot :

3d scanning¶

Phone application¶

the first way that I will try to scan by an app called Qlone 3D Scanner

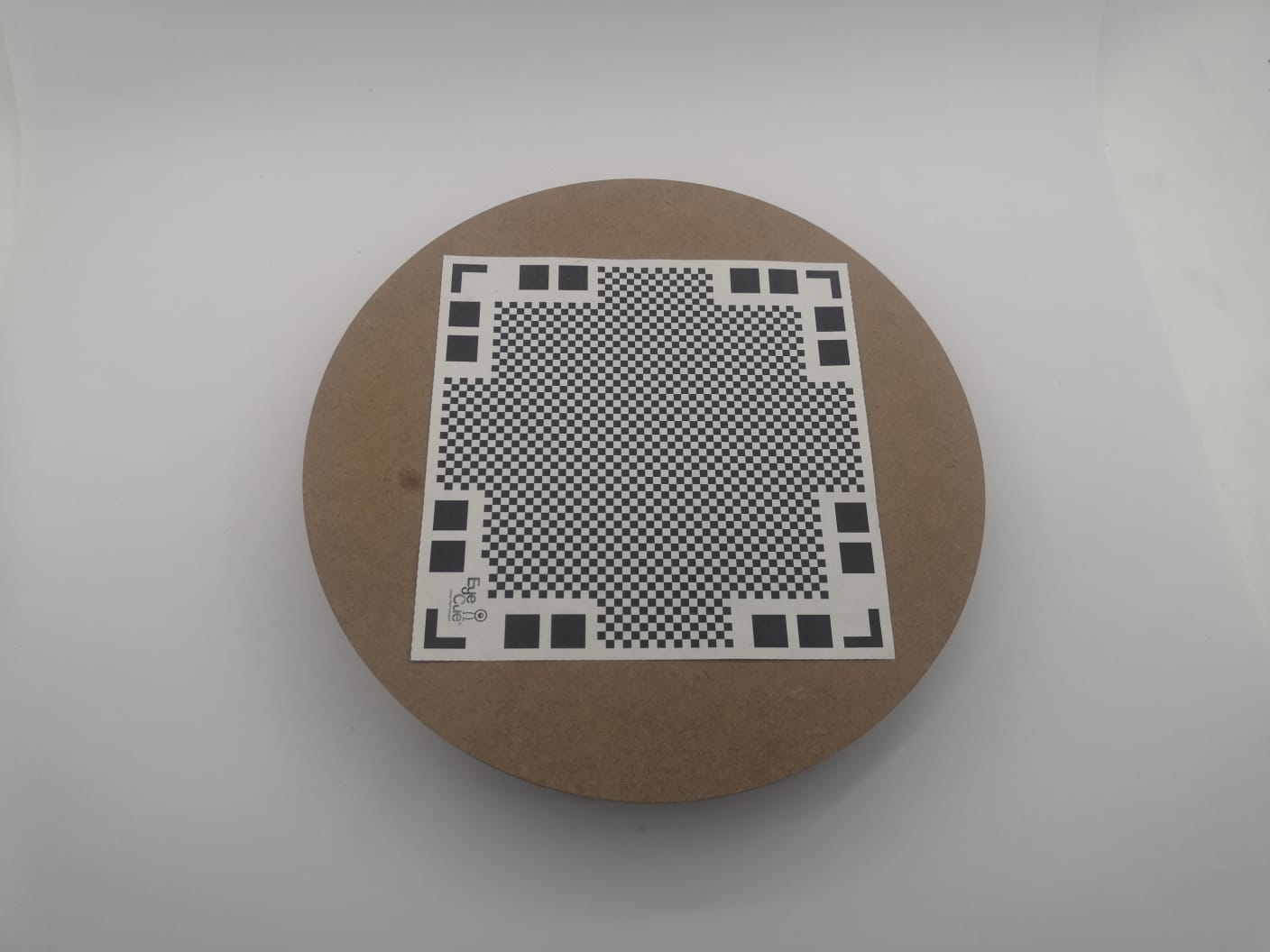

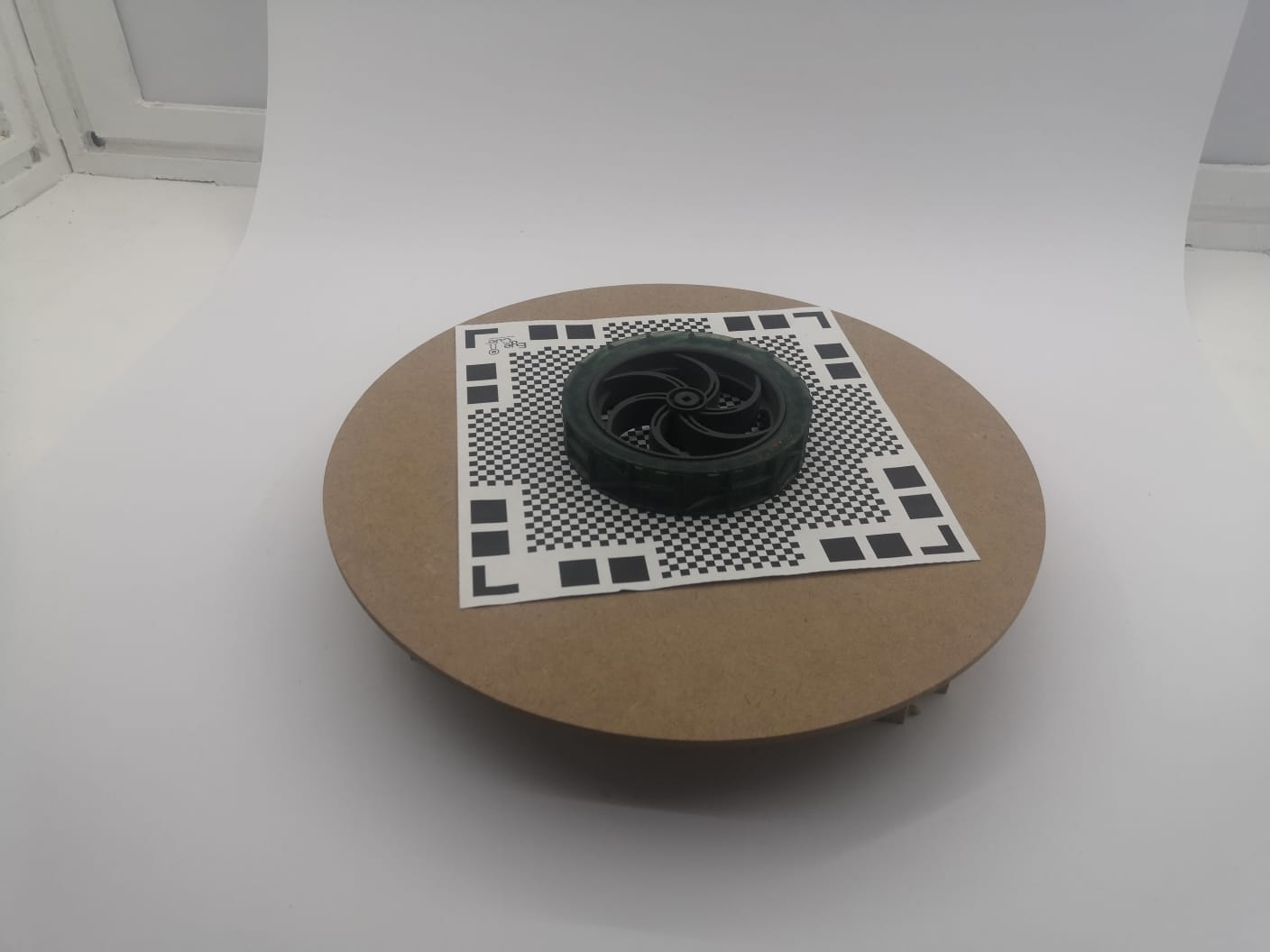

this app give you good 3D scan for small object be case it need to have something in the bad QR code on the bed so you can scan the object:

this is the bed for the app to scan from it look lick QR cod I put is in cercal thing that ease to rotate to make the scanning easer.

this is the bed for the app to scan from it look lick QR cod I put is in cercal thing that ease to rotate to make the scanning easer.

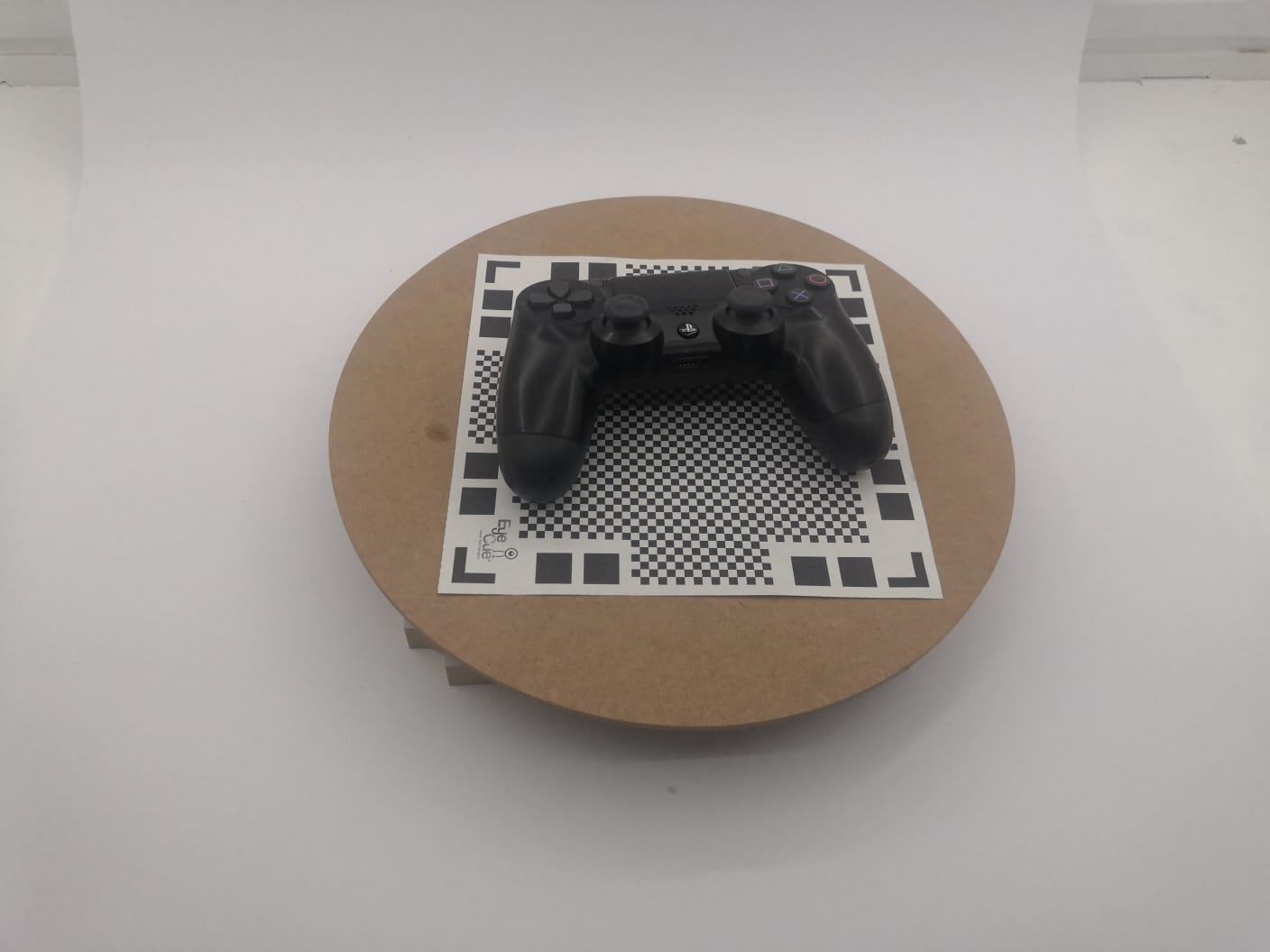

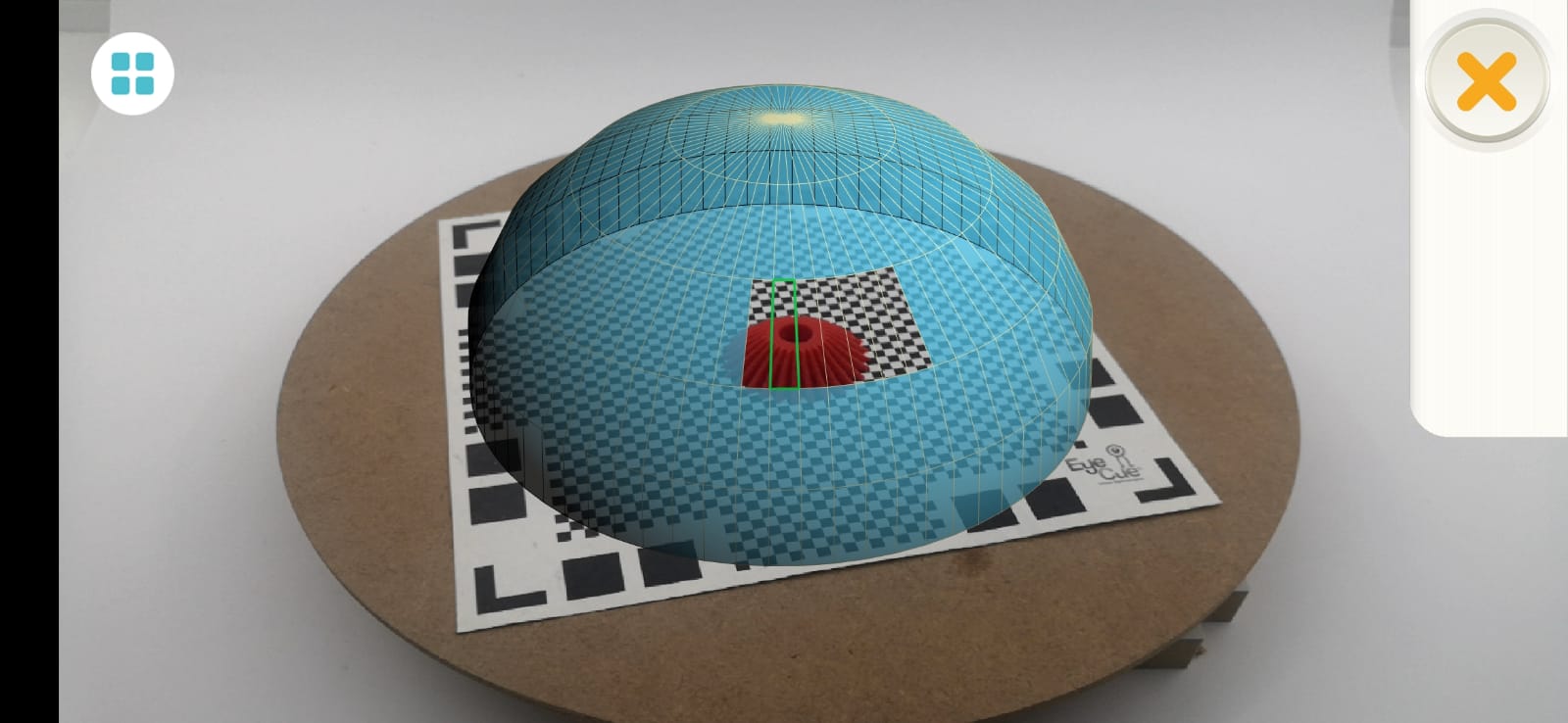

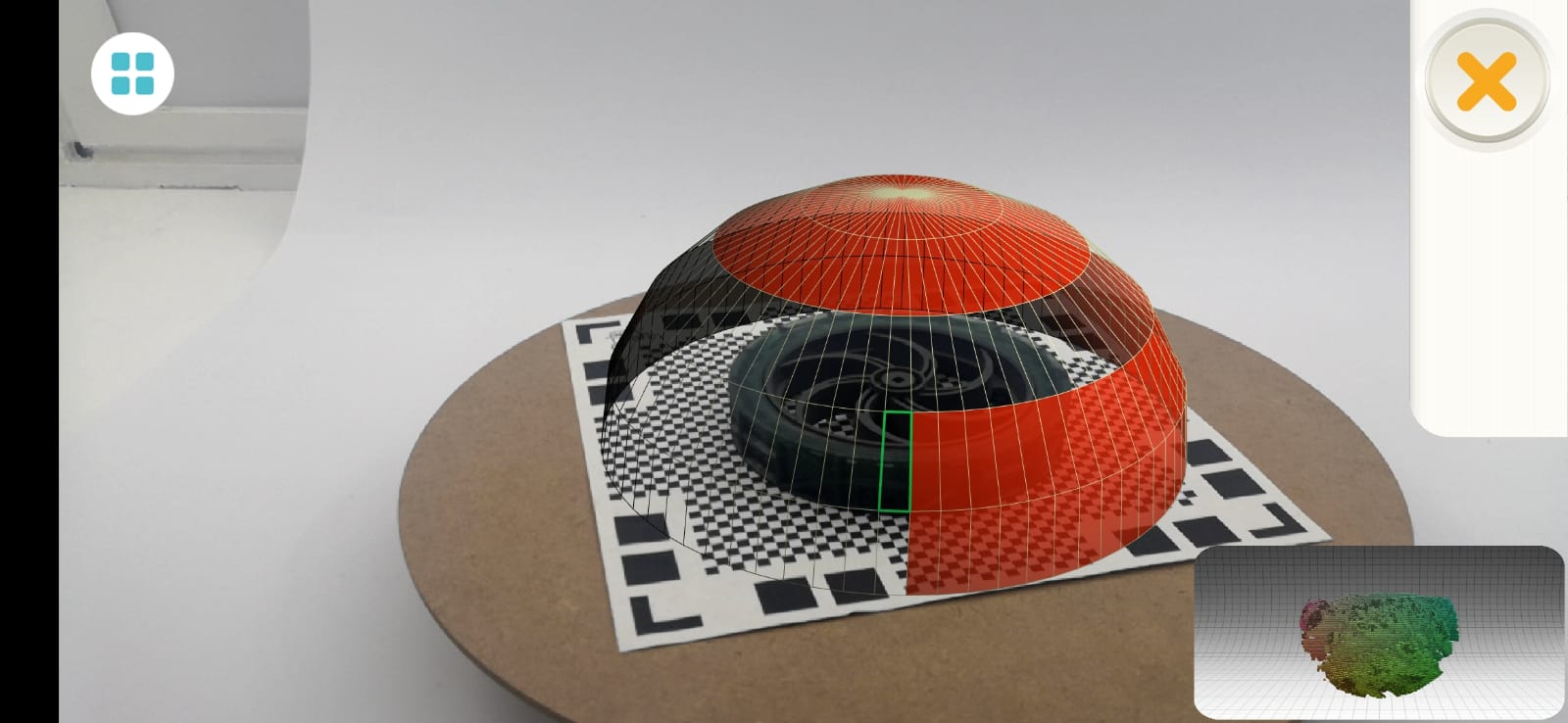

this is first object I try to scan but it didn’t because it is too big and it cover a lot of the bed

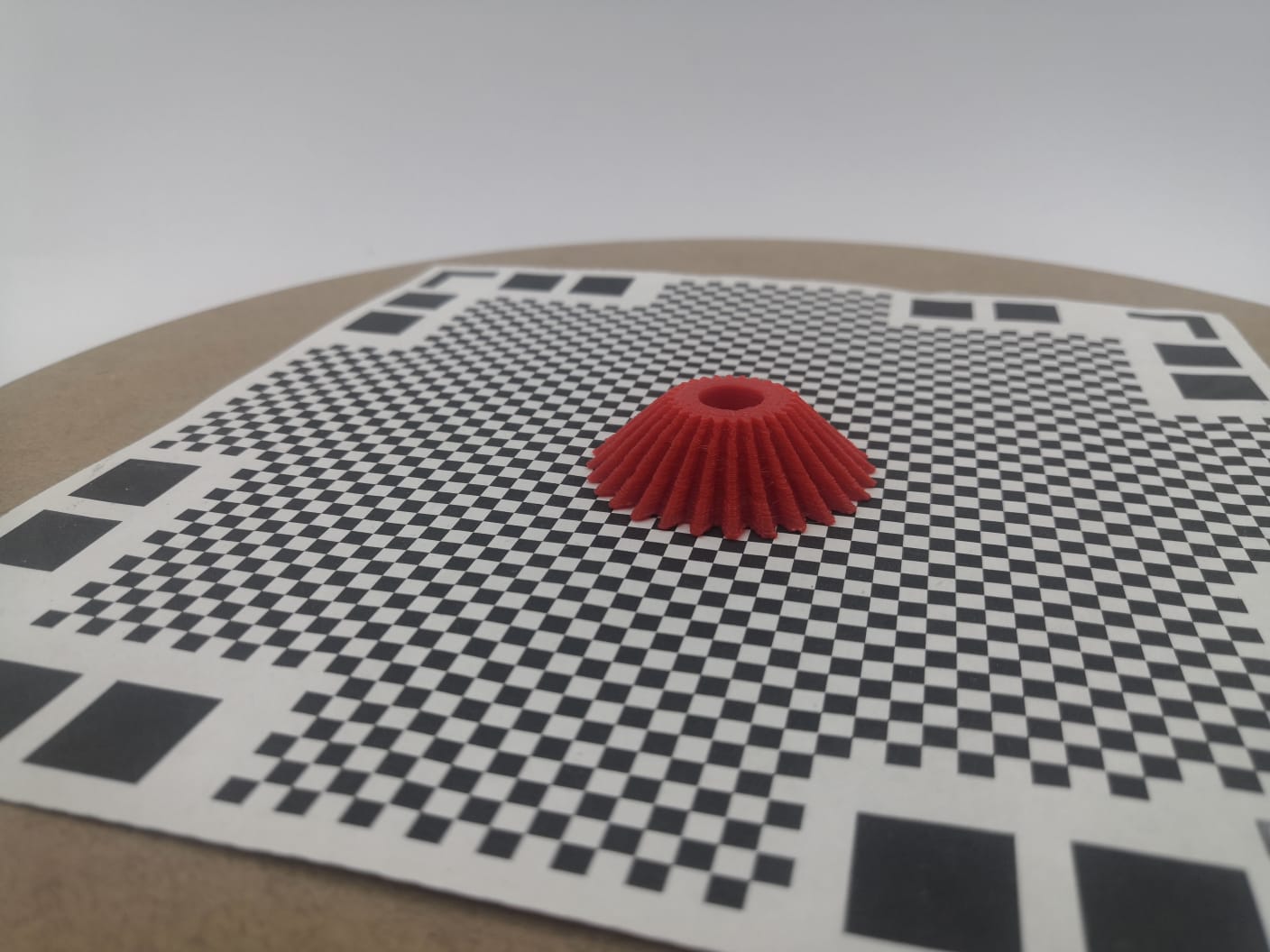

the is the second object it is small red bevel gear

the is the second object it is small red bevel gear

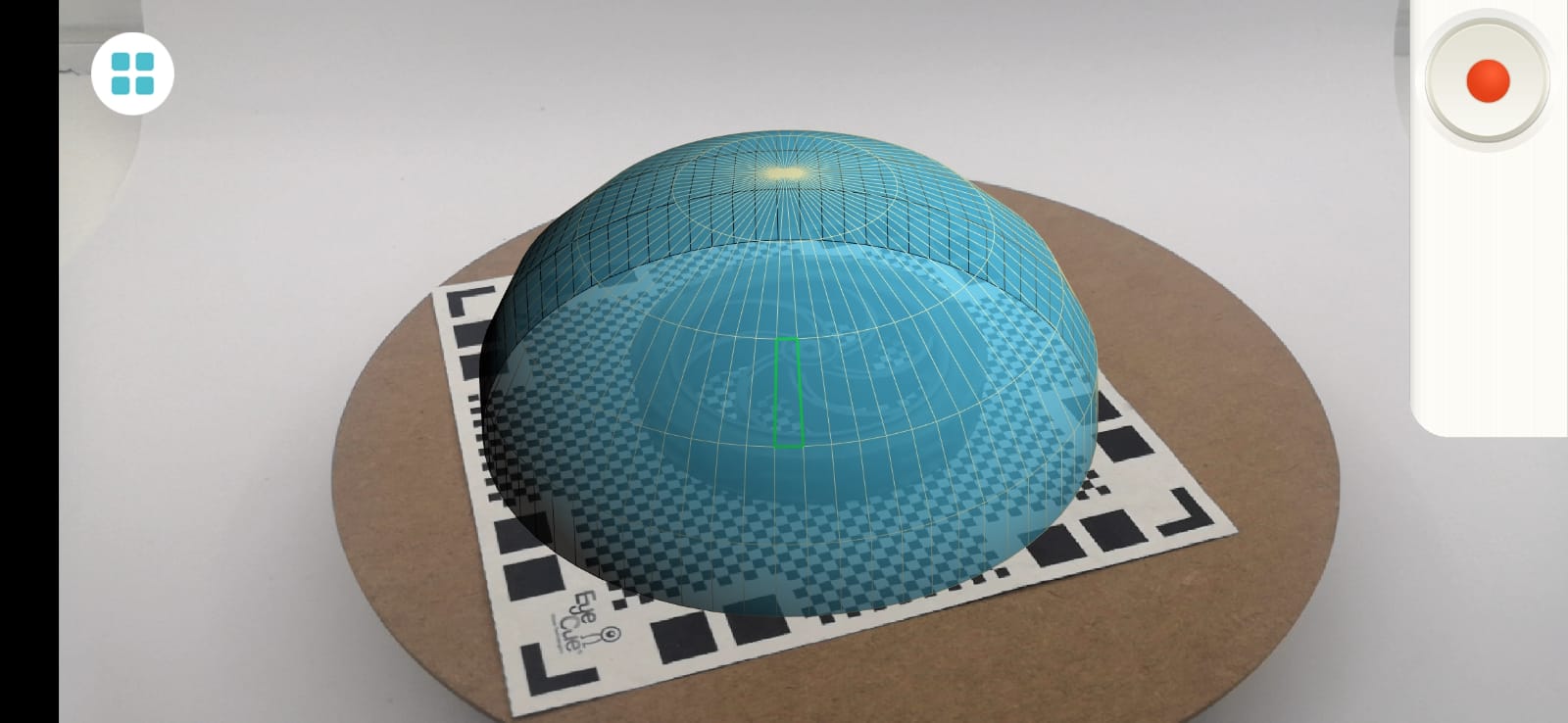

the first thing that show when you want to scan the objects half ball that cover the bed and the object .

the first thing that show when you want to scan the objects half ball that cover the bed and the object .

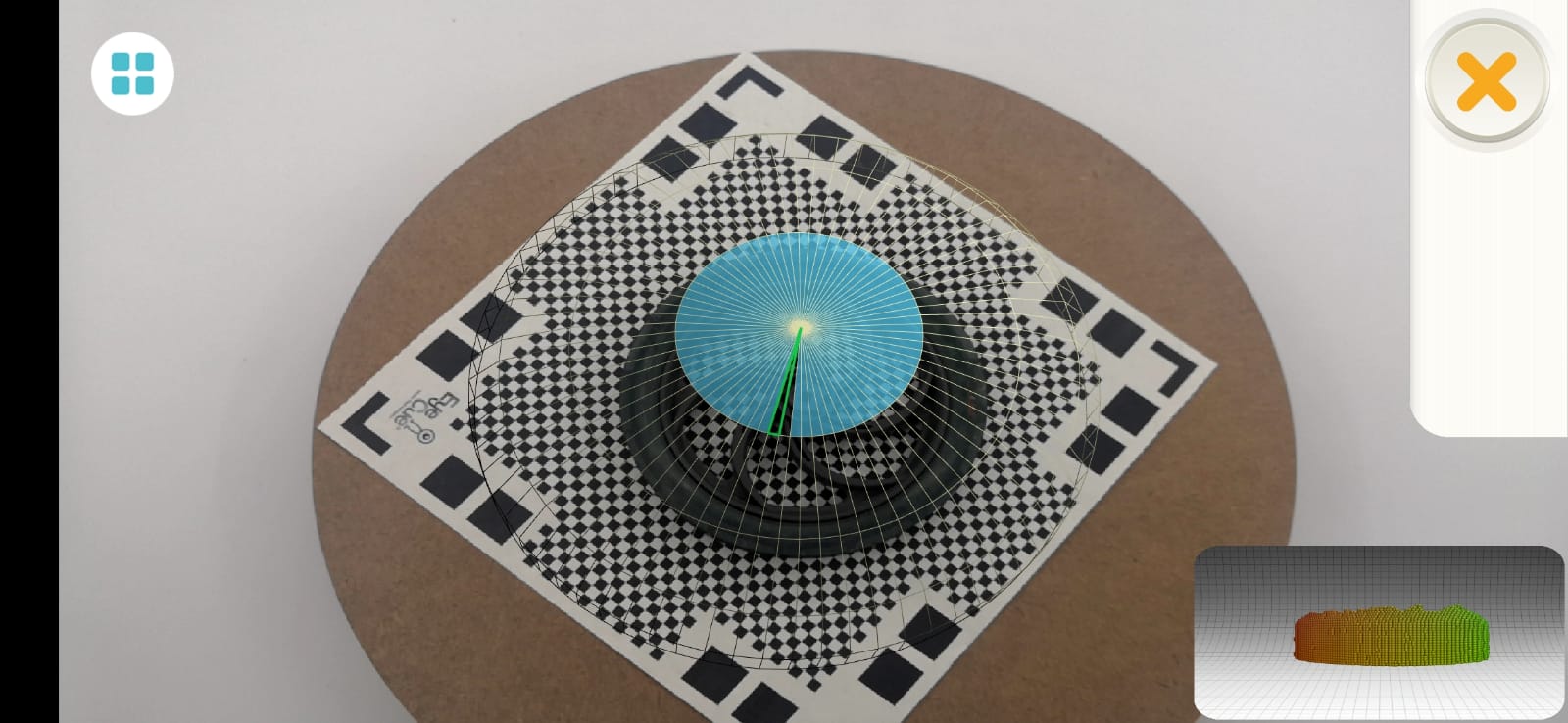

you need to cover all of this half ball till all of the blue goes.

you need to cover all of this half ball till all of the blue goes.

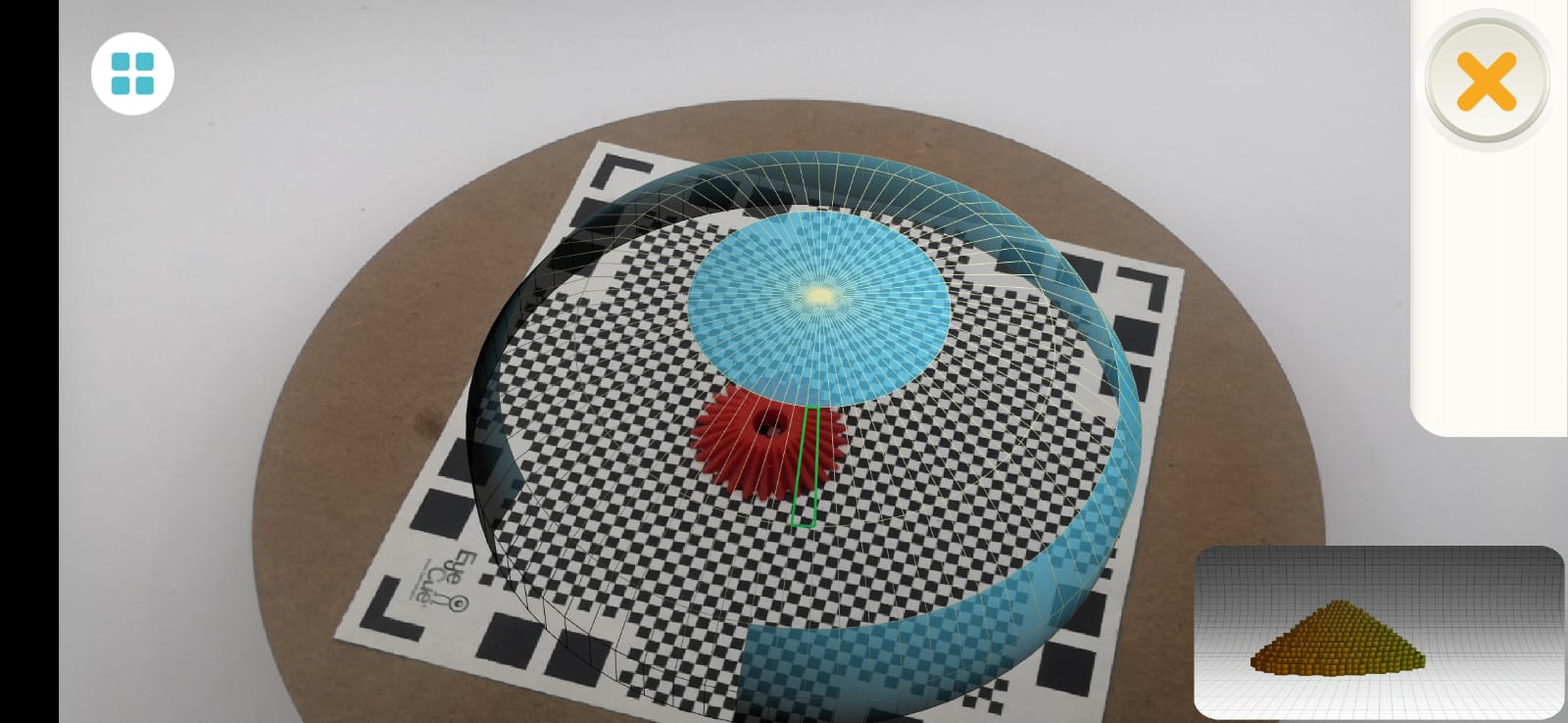

the last thing that I scanned by this app was weal

the last thing that I scanned by this app was weal

we do the same thing again.

we do the same thing again.

but when the ball turn to the red color it mean that it has problem and you should zoom in or out by your phone until it get blue again.

but when the ball turn to the red color it mean that it has problem and you should zoom in or out by your phone until it get blue again.

when the color of the ball return blue again it mean that it ready to scan.

when the color of the ball return blue again it mean that it ready to scan.

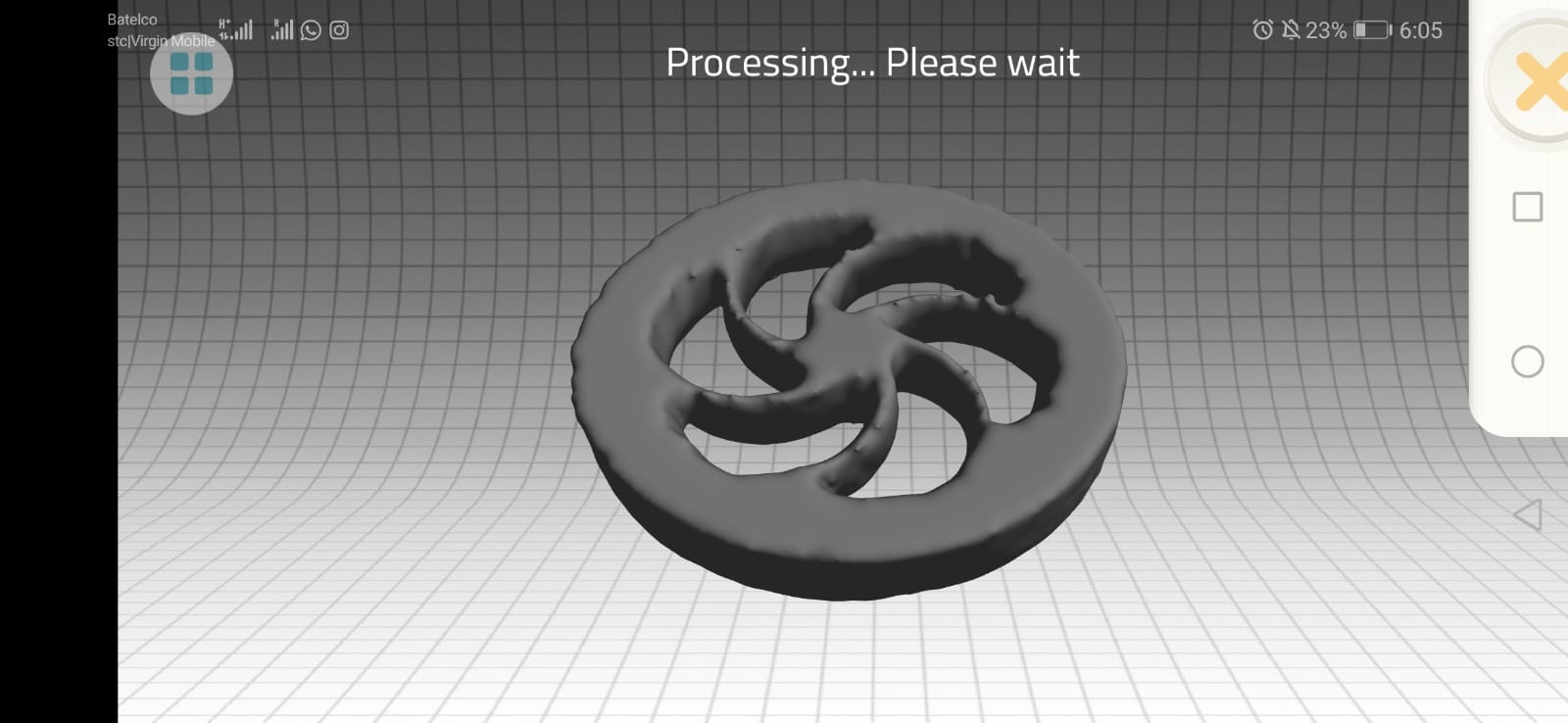

the is how it lock when the app process the data the it git from the scanning in too 3d object in the phone.

the is how it lock when the app process the data the it git from the scanning in too 3d object in the phone.

this how it lock after the processing it even it take the color of the object that is scanned .

this how it lock after the processing it even it take the color of the object that is scanned .

unfortunately if I want to git the STL file for what I scan I must pay for the app. (:

Skanect¶

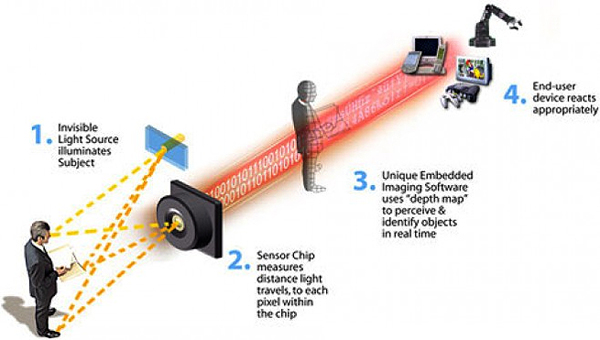

Skanect is a peace of software that transforms a Structure Sensor, Microsoft Kinect or Asus Xtion camera into a low cost 3D scanner which allows you to capture a full color 3D model of an object, a person or a room.

to have more information about how it work go to this page

I scan using this program and Xbox cam

for the equipment and the place we put the camera on the stand so it will not move to get the batter resolution, And for the person that will be scanned he sit in rolling chair so he can move easily.

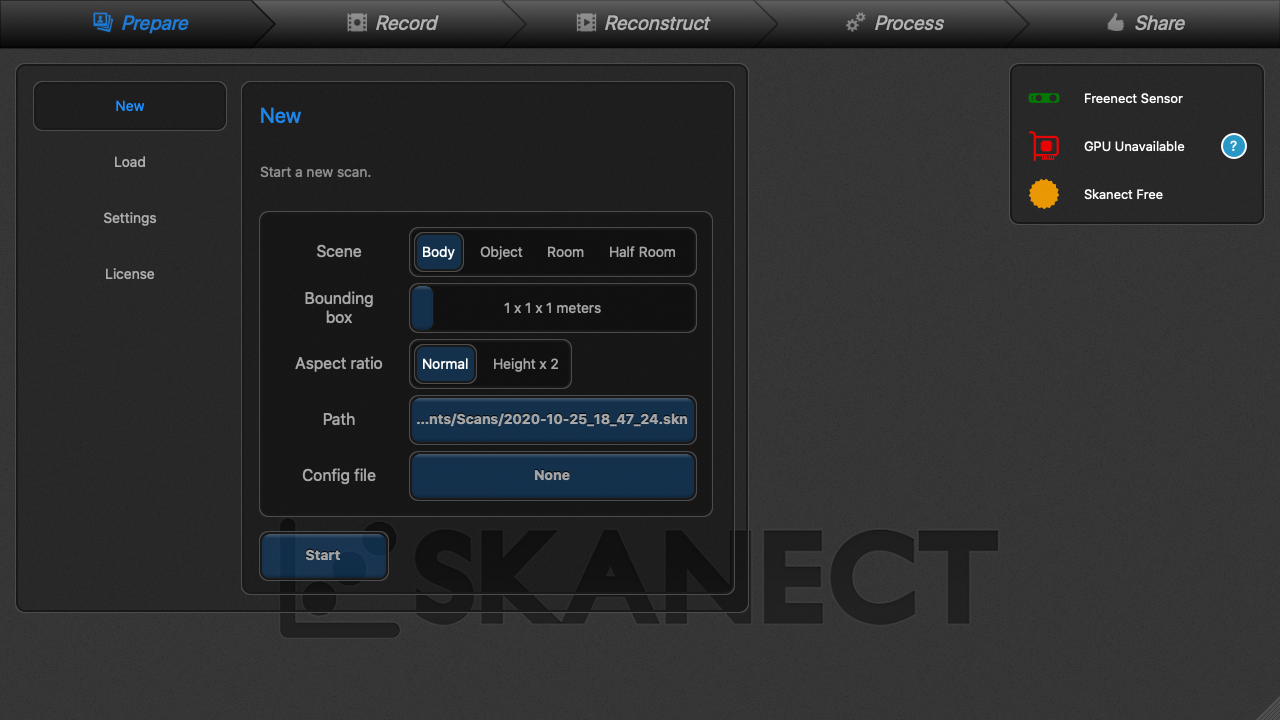

step 1 : chose New then edit the sitting

first is To chose the scene that will be scans so I chose body, next bounding box it means the diminution of what be scanned, after tat is the aspect ratio the last step is to press start.

step 1 : chose New then edit the sitting

first is To chose the scene that will be scans so I chose body, next bounding box it means the diminution of what be scanned, after tat is the aspect ratio the last step is to press start.

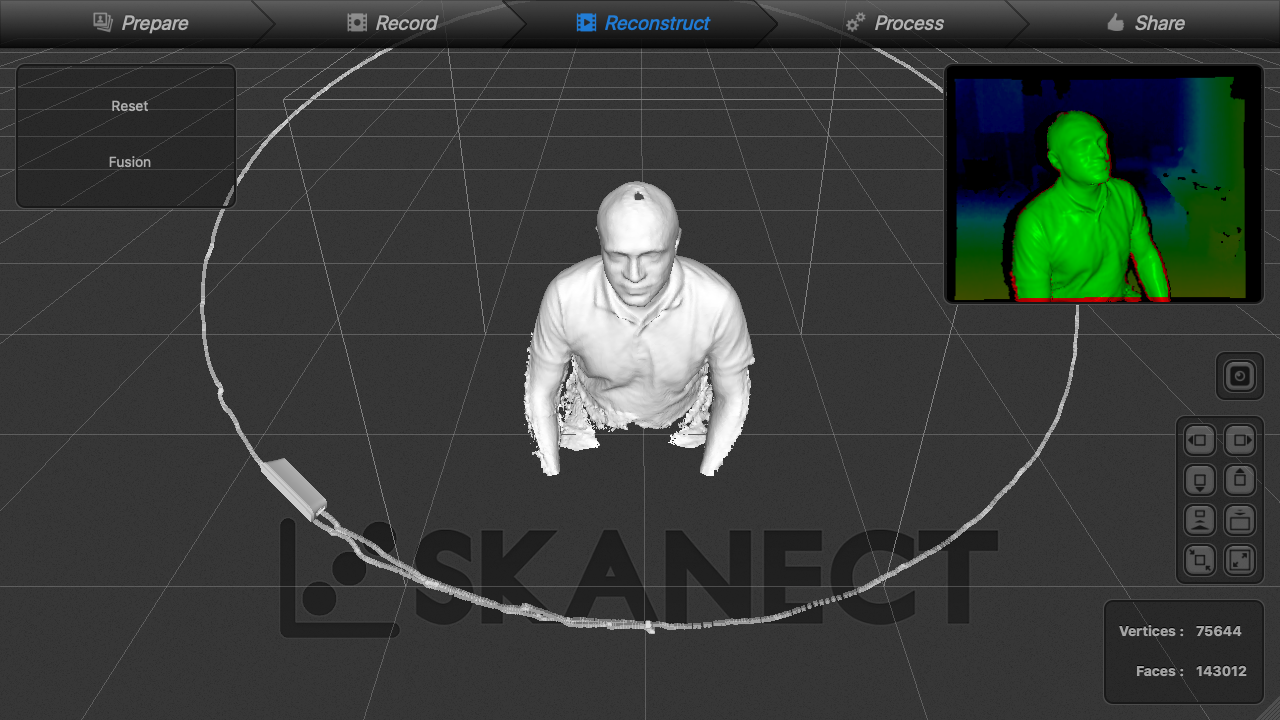

step 2 : I must make the person that will be scanned in the middle of the scanning box then I press in the record button

step 2 : I must make the person that will be scanned in the middle of the scanning box then I press in the record button

the is during the scanning process

the is during the scanning process

step 3 : as he is rotating he must look at front without moving

step 3 : as he is rotating he must look at front without moving

this is how he look after getting scanned

this is how he look after getting scanned

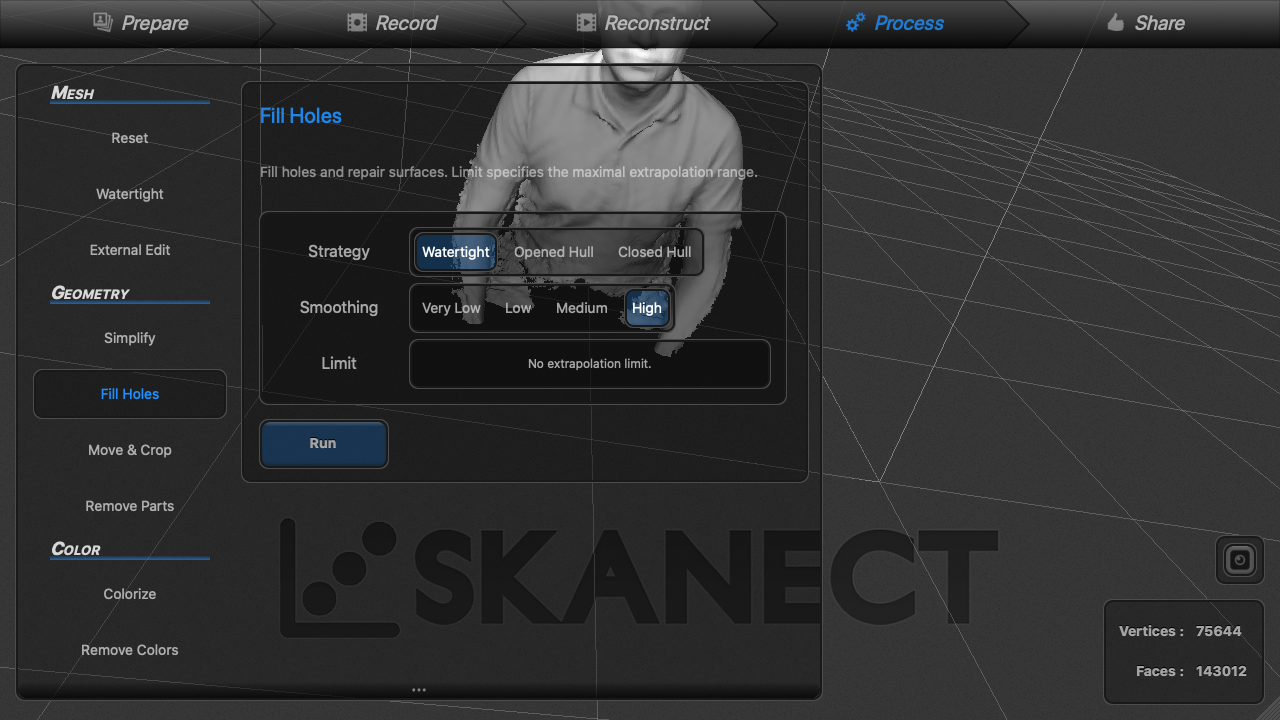

step 4 : in this step we try to make it look batter by filing it .

step 4 : in this step we try to make it look batter by filing it .

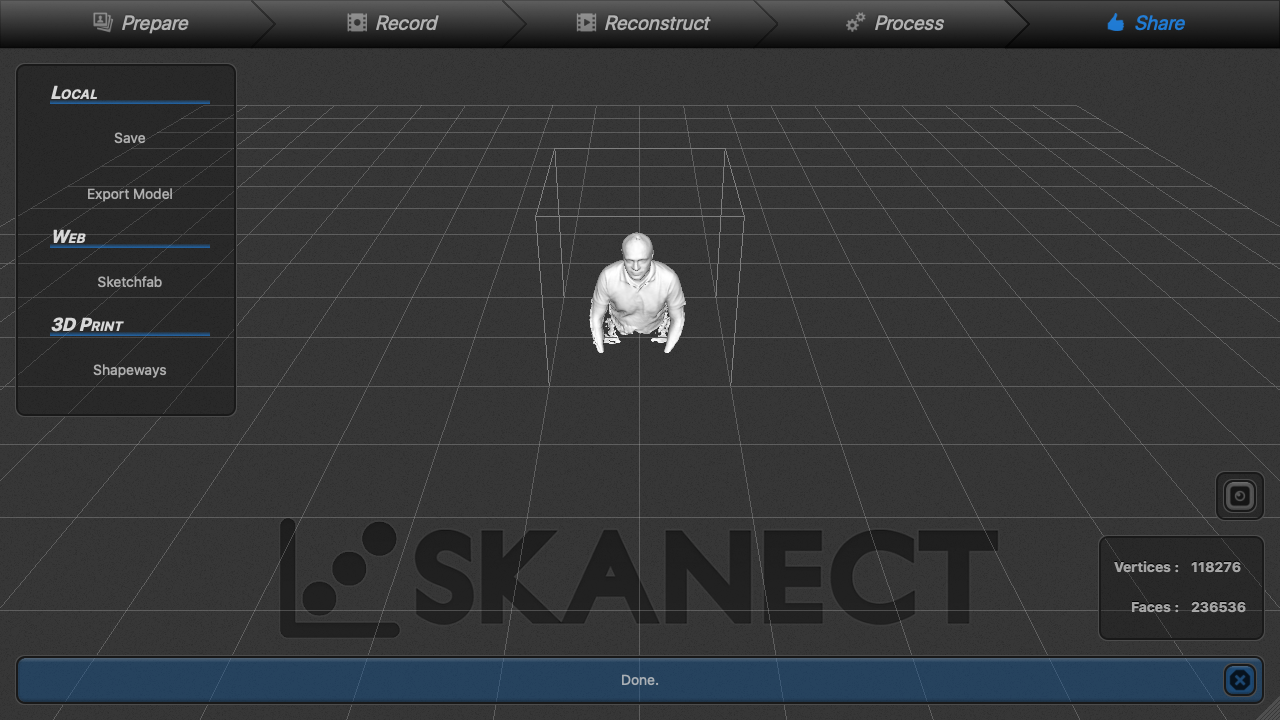

step 5 : it is the last thing just saving the as STL file

step 5 : it is the last thing just saving the as STL file