Final Project¶

The project: A DIY laboratory fume hood¶

Goal¶

Design an universal (modular) ductless fume hood that can be produced in a fablab.

Requirements¶

- Most of the electrical hardware should be provided from IT waste (fans, PSU,…)

- Every mechanical component should be LASER cut, CNC milled, 3D printed or moulded

- The base design should be adaptable to many specific uses (glove box, vacuum, solvent resistant,…)

Opportunities¶

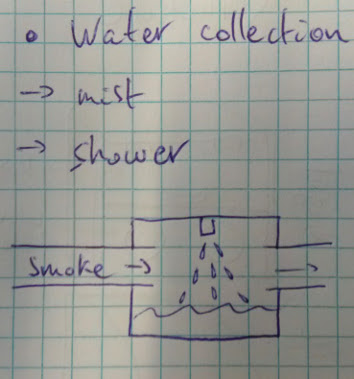

- Explore unusual dust collection technologies

- Improve the polymer molding and casting workflow

- Explore dust, fume and gas detection technologies

The draft¶

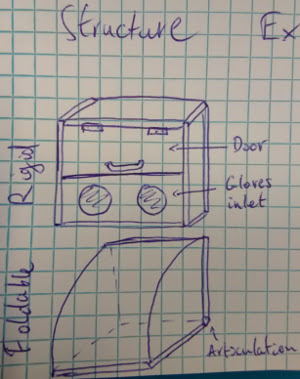

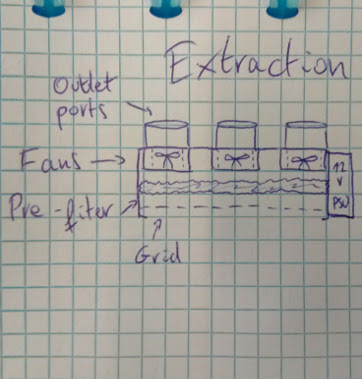

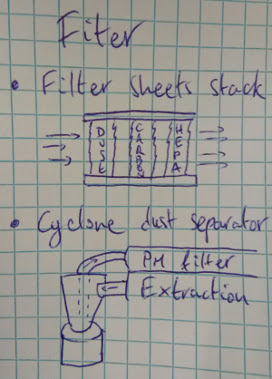

The design can be separated in 3 stages :

Structure and extraction :¶

Filtering stages :¶

The inspiration¶

Commercial models :¶

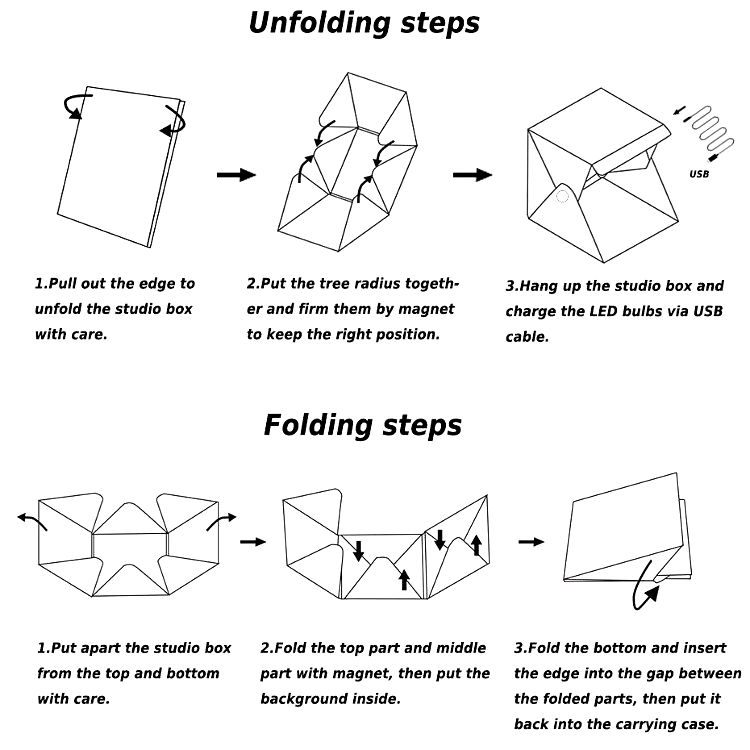

Foldable box :¶

A coworker came up with a presentation box similar to this one :

I was impressed by the simplicity of the design, I can easily be cut with fablab’s machines. Fixations can use magnets or plastic snap buttons :

I could order some but before, I will try to 3D print it.

Mini greenhouse :¶

I like this greenhouse design because it has room for storage, and I can easily imagine using it as a fume hood.

Plastic tiles lampshade¶

I fell in love with this lampshade design :

It’s made of thin plastic sheets, held together with rubber bands. This is definitely low-tech and it may be perfect for a modular structure.

Scientific publications¶

- Electrostatically driven fog collection using space charge injection

- Measurement of the particle size concentration of cigarette by the “conifuge”

- Steady Laminar Axisymmetrical Nozzle Flow at Moderate Reynolds Numbers: Modeling and Experiment

Links¶

- $5 Powerful DIY Fume Extractor @ Instructables

- Over powered fume hood is awesome @ Hackaday

- Building a Low Cost Solder Fume Extractor @ Element14

- Fume extractor @ Instructables

- Garage Dust/Sanding Enclosure @ Instructables

- How to Make Activated Charcoal

- Do-It-Yourself Ion Trapping

- Experimental electrostatic Precipitator @ Thingiverse

Material sourcing¶

The main problem I’m facing is about the structural materials. I have to find a durable material that can easily be found as scrap and I want it to be transparent. For now, I’m thinking about :

- laser-cutting leftover acrylic (PMMA), that can be found in fablabs

- 3D printing recycled PETG filament, but I’m not sure that the print will be transparent

- thermoforming PET bottles, but I don’t even know if it is possible

Plot twist¶

I figured out that this fume hood project is more ambitious that I imagined. Seriously, I could spend month trying to find a proper filtration system design.

And an important thing I learned with the Fabacademy is this equation :

Too much ambition = So time consuming = Assignment incomplete

As I was running out of time (and hardware), I decided to pause this project’s development and focus on a simpler project. From now, I am working on…

The hydroponic pallet¶

It’s a low-cost hydroponic setup, mostly made of materials that I found in the streets, or that were left unused :

- Wood pallet

- Water pump (from an faulty coffee machine)

- Power supply (from an old cellphone charger)

- Empty 1.5l water bottles

- Power cable

These parts are meant to be made in fablabs :

- 3D printed planters (custom design in OpenScad)

- 3D printed bottle caps (can be casted with polymer resin)

- Microcontroller board

- Power interface (for the pump)

- Water level sensor

Finally, the only thing that remains to buy is the hydroponic media. It can either be :

- Expanded clay balls

- Coconut fibers (better for germs)

The main goal of this project is to replace the usual PVC pipe design with something more sustainable (PVC is definitely not, unless you found it as a waste) and modular. This way you can upgrade the planters or the watering system, without having to re-build the structure.