8. Computer controlled machining¶

Assignment¶

Make something big :

- Design

- Milling

- Assembly

Group assignment is documented on it’s dedicated page.

Something big…¶

I spent a lot of time trying to make wood panels from palettes. It was very time consuming so I paused this works to start designing something simpler (and useful for the fablab), a vacuum table that could be used in our CNC mill to hold materials in place without using screws or clamps.

2D drawing¶

I draw the plans in Corel Draw and exported it into .svg files.

There is one plan for the top side (with holes) and a second one for the bottom side (with air channels). Both sides must be aligned so the holes end up in front of the channels.

There is a third plan that can be used for the top and bottom sides, it’s the outline sealing groove.

Here is the link to SVG and g-code files

Gcode generation¶

To generate the gcode files, I used Easel for 3 reasons :

- This is what the ReLab recommend for the same milling machine.

- I know it well because I have been using the Carvey milling machine for a year.

- It is definitely very handy.

This is the preview of the two milling jobs, with toolpath simulation :

As you can see, the toolpath is not optimal. I think I should find a toolpath optimization software to make a more efficient gcode.

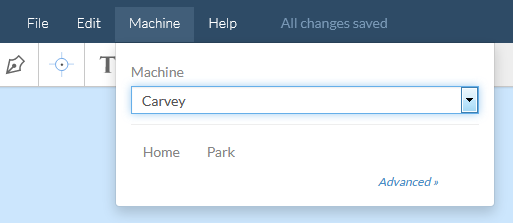

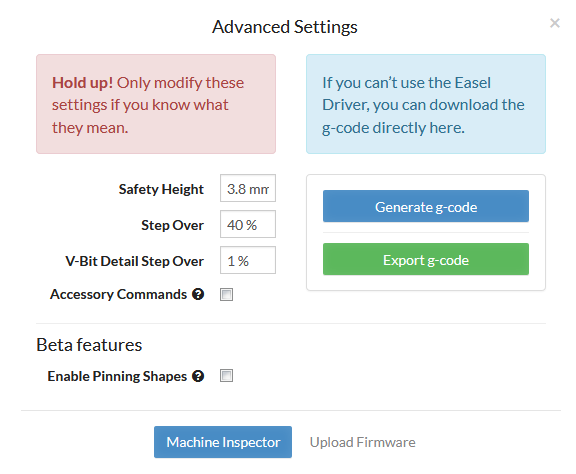

To export gcode from Easel, click on Machine → Advanced >> and the Advanced Settings window should pop-up :

Click on Generate g-code, then Export g-code.

You will get an .nc file to download. Before opening it into KinetiC-NC, use a text editor to :

- Add a % symbol before the first line

- Remove the lines starting with G21 and G10

- Remove the G30 line (at the end of file)

CNC milling¶

As material, I used scrap panels from old tables. It’s made of agglomerated wood with plastic laminate. Probably not the best choice for a vacuum table but it fitted well in the CNC machine. Let’s say it’s just a proof of concept.

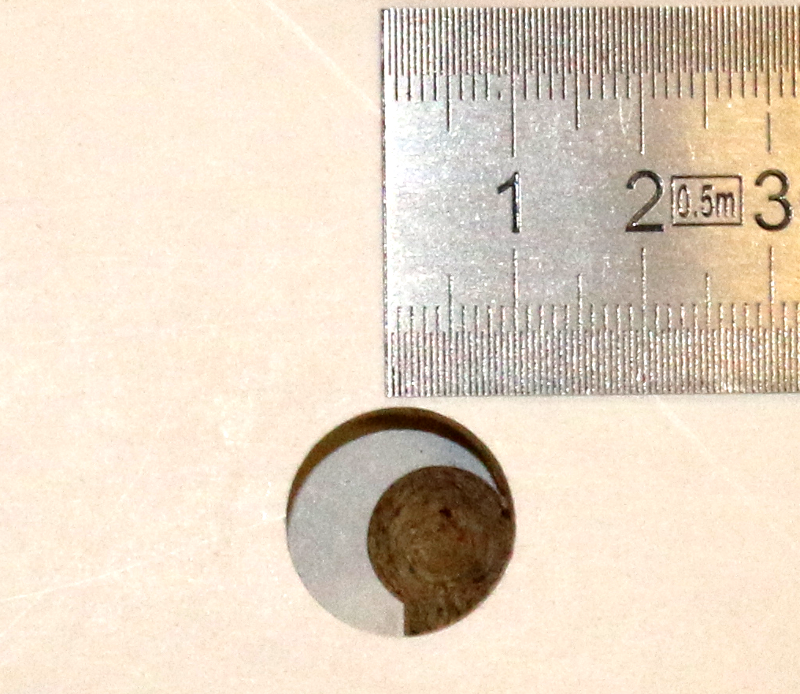

I used two end mills :

- ⅛” 2 flute straight end mill, for holes an pocket

- 90° V-bit, for air channels and glue grooves

Despite the time I spent to give the machine a perfect zero reference, the channels were misaligned with the holes. There was a 5mm gap and I still do not understand where it comes from :

I had to do a second milling of the bottom side to enlarge the channels.

Assembly¶

Prior to sealing, I had to screw the air outlet connector. I used a standard pneumatic bulkhead tube-to-tube connector :

Then I just put wood glue in the outside groove. Then I assembled the panels with clamps to keep them aligned and I put heavy stuffs on top to keep them flat.

Testing¶

With MDF¶

I blocked unused holes with nylon rivet pins. It worked very well with the vacuum pump from our lab :

Sorry for the bad quality of the gif…

PVC crash test¶

I tried to use the vacuum table to hold a thin (0.8mm) sheet of PCV in place. It did not worked as well as expected because I used an upcut end mill that lifted the sheet and left some holes uncovered.

Even if I paused milling, the sheet could not stick back to the vacuum table because PVC dust went in the way.

So I tried again with a downcut end mill and it worked good.