Output Devices

Week 12

15th-22nd April 2014

The Modela machine needed a tiny bit of maintenance before I could get started with my assignment. Previous user left quite a burr in the sacrificial board, together with a piece of a mill stuck inside. It took a quarter of an hour of cleanup and sanding to get to a satisfactory flat surface to which I could double-tape the copper-clad board.

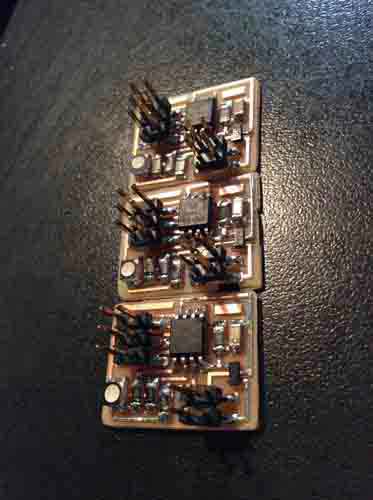

Having somewhat limited access to the machinery (I live 5 hours drive from the FabLab), I decided this week to just practice milling and stuffing the boards. I made three RGB led boards just in case I damage some. Collected all the components and took them home with me. Stuffing them in the comfort of home kitchen was actually much more productive than I expected. I was done in about an hour with all three boards. If there's anything I've already gained from this course - it's SMD soldering skills.

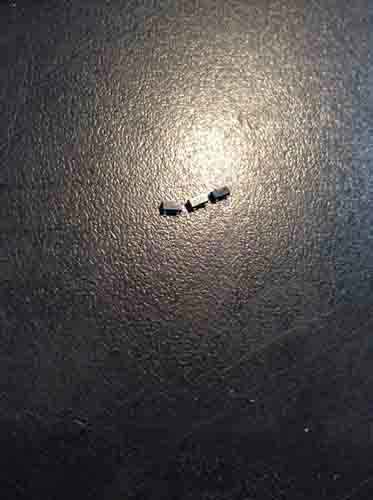

SMD components are somewhat tricky to identify though, unless you're unpacking them straight from digikey's plastic bags. Apparently at the lab we had voltage regulators and diodes in identical packages. Hence the smoke coming from all three boards when powered. It took some finger-acrobatic skills to be able to measure and identify a similarly-packaged voltage regulators using normal multimeter probes. Unfortunatelly there were not enough fingers to document the process.

After replacing diodes with appropriate power regulators - everything else worked without a hitch. Three boards programmed and powered within 5 minutes. Actually, very enjoyable result.

hello RGB board files are available here.