Electronics Production

Week 04

19th-26th February 2014

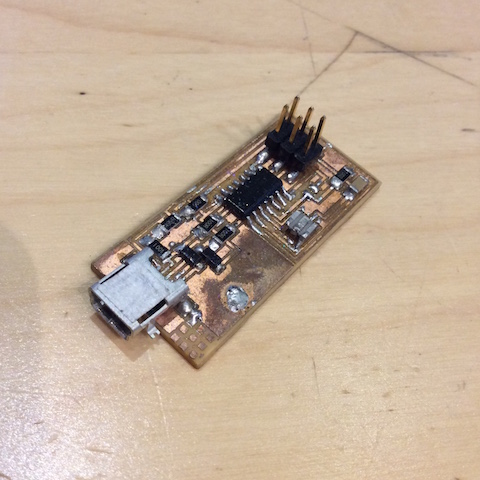

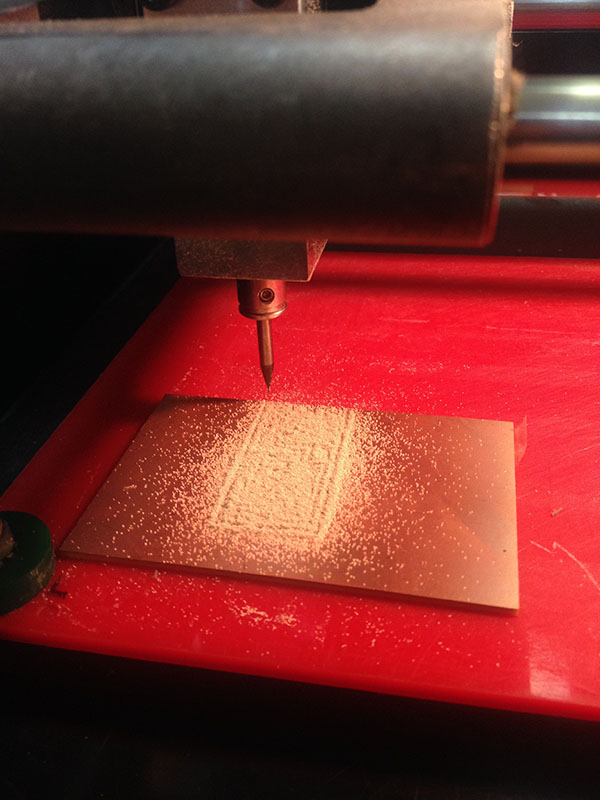

This week's assignment was pretty straightforward - mill, populate and program a circuit board. FabISP in particular. As this was the most unfamiliar terrrain to me so far - I went to the milling machine right after the class. A couple of minor inconcistencies in the provided tutorials were compensated with basic knowledge of bash shell and all in all I was holding a clean, nicely milled and cut out board within half an hour. I was rather shocked. Minor calibration error resulted in a slightly shorter board with a USB connector overhang. Mechanically somewhat less stable, but nothing critical.

Minor calibration error resulted in a slightly shorter board with USB connector overhang. Mechanically somewhat less stable, but nothing critical. Populating the board was somewhat tricky as this was my first ever surface-mounted board, but another hour of work through a magnifying glass brought about a decent result. Unfortunatelly I forgot to snap a picture of the complete board, but will add it here the next time I'm in the lab.

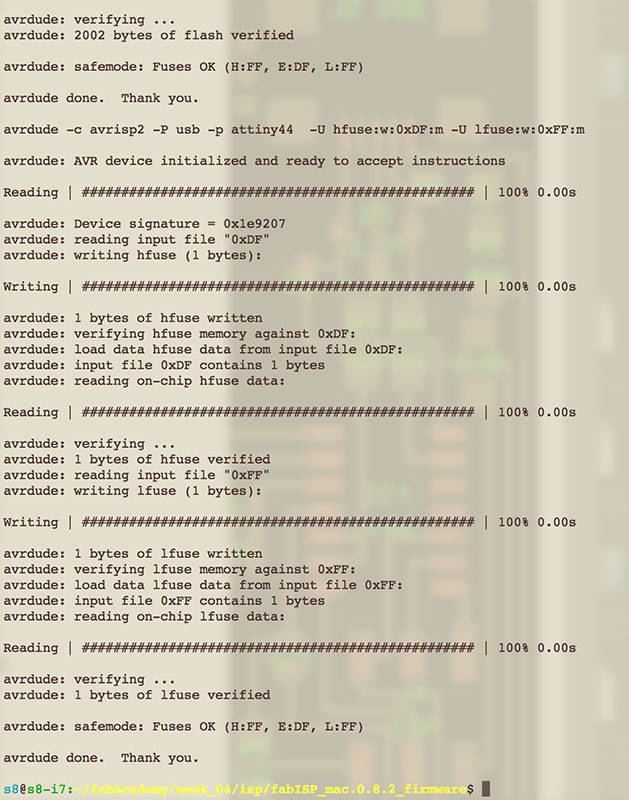

After a suspiciously smooth flow of milling and populating the board I got a bit stuck with the programming part. The programmer refused to see the board. Jumpers checked, soldering double-checked. Someone mentioned troubles with the USB 3.0 due to clock synchronization. It seemed very probable as the version of the FabISP built was based on the resonator IC, not even the quartz crystal. Uncertainty... The day was over.

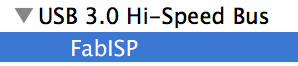

Good sleep and fresh coffee the next morning resulted in a head that was much more capable of sorting information from enldess tutorials. One of them was mentioning that the FabISP has to be powered in order to be programmed. And indeed that was the case. As soon as both cables were plugged into the board, green light lit up on the programmer and 'make install' completed without any errors. Jumpers removed and voila, the FabISP appeared in the system information pane. Done.