3D Printing and Scanning

Week 05

27th February - 5th March 2014

More time than necessary went into troubleshooting the 3D printer software and hardware problems, that's why I didn't manage to complete this assignment on time. However I do have quite some experience with FDM 3D printers and here're photos of the turntable part that I've re-designed and printed on RepRap Prusa Mendel back at our lab in Ukraine.

To fulfill the scanning assignment I used the SFM (shape from motion) or Photogrammetry technique made easily accessible thanks to AutoCad's 123DCatch software. My initial setup consisted of an object placed on a turntable, and camera on the tripod making multiple shots as the object is turned around (manually, as 33rpm i a bit too fast for 3d scanning). Uploading photos to the cloud version on 123dcatch crashed a couple of times, but after scaling down the images it did work. However, the result wasn't quite what I expected. It was a garbled surface which had nothing to do with the object I was scanning. After reading a bit on SFM technique I realised that my approach wasn't exactly how the algorithm was supposed to work.

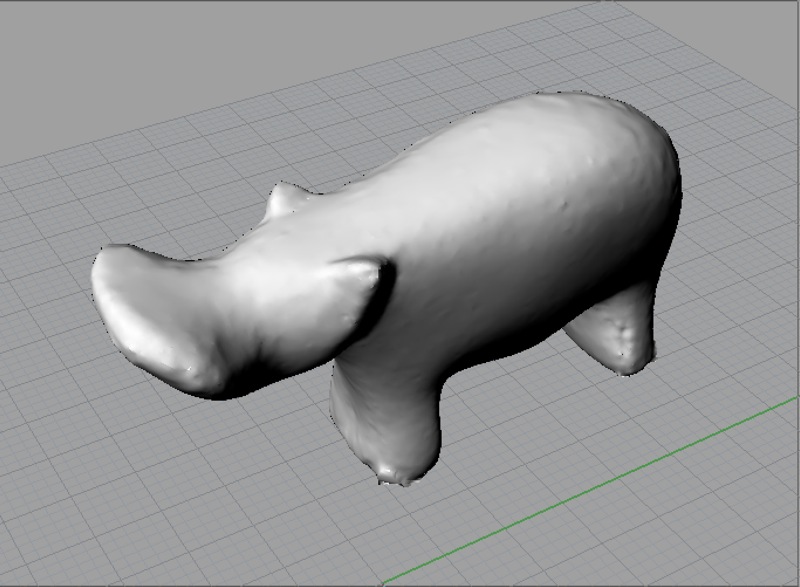

Next attempt was using a white backgound of a kitchentop. I took about 50 pictures from different angles, and put the marble hippo on different sides to shoot it in more details. Because the kitchen top was smooth white I assumed that SFM algorithm will not see any motion in the scene, besides the hippo. It worked.

Last step was downloading the hippo model in .stl format and cleaning it up a bit in Rhino. Happy 3D hippo it is. Model's surface appeared not as smooth as the marble original is, but I guess these are the artefacts introduced by marble pattern. Perhaps painting it in solid color before scanning could produce a more accurate result. Overall I'm quite please with the result, considering that it was a 1-hour process from start to finish, including all the mistakes.

Files for this assignment: