Composites

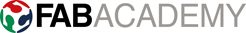

This week we decided to design a fiberglass shelf. Each member of the group will design a different textures for his shelf.First we designed the casting mold parts.

You can download the shelf and L file. We planned two identical parts that one of them is a two Milmtrim smaller.

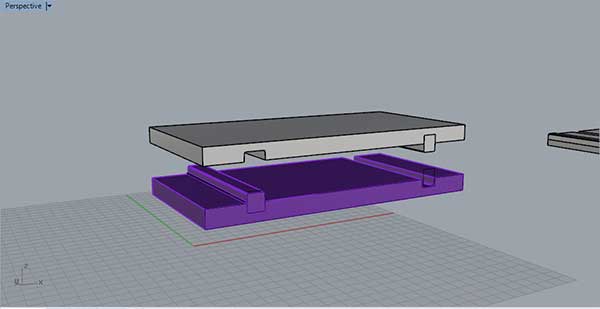

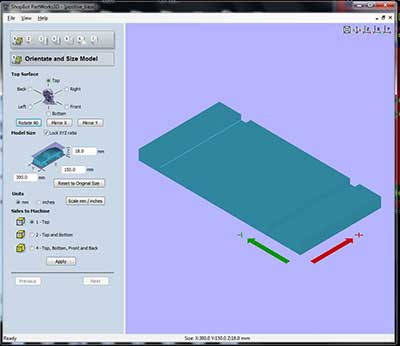

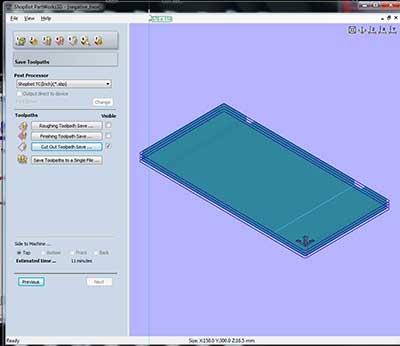

After we finished designing the parts we uploded the files to the shopbot computer for milling.

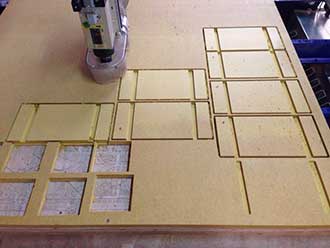

Once the machin finished milling the parts we sepreted them and conected them together.

Then we rubed the inside of the MDF with epoxy glue until they have absorbed enough glue and let the parts dry for 24 hours.

after the epoxy was dray we rubed the parts with lub

Then we rubed the inside of the MDF with epoxy glue until they have absorbed enough glue and let the parts dry for 24 hours.

after the epoxy was dray we rubed the parts with lub

and started playing with the matirials we thot of my first atempt was to use tree lifs bitwin the leyrs of fibergalss I used two leyars of faiber and two of lifs then prest the two moleds together with kalmps and let it dary for 24h.

the final result was pretty good on the fiberglass side but the material I used did not cooperate with the project.

I realize that green tree leafs have a good chance of rotting during the drying time.

for my second attempt i decided to use old t-shirt with no fiberglass.

After it braid for 24h I cut out the excess fiber and mills the L part using the shopbot.

I decided to test if the L's will fit in to the shelf as we design.