6. 3D Scanning and printing¶

1. Weekly Brief Summary¶

Used 3D Scanner and process data, then print voronoi-me 3D model.

2. Weekly Assignment Requirement¶

-

Group assignment

- Test the design rules for your printer(s)

- Document your work and explain what are the limits of your printer(s) (in a group or individually)

-

Individual assignment:

- Design and 3D print an object (small, few cm3, limited by printer time) that could not be easily made subtractively

- 3D scan an object, try to prepare it for printing (and optionally print it)

3. Group Assignment¶

FabLab KAMAKURA 2021 Lab site / 3D Scanning & 3D Printing

4. 3D Scannning¶

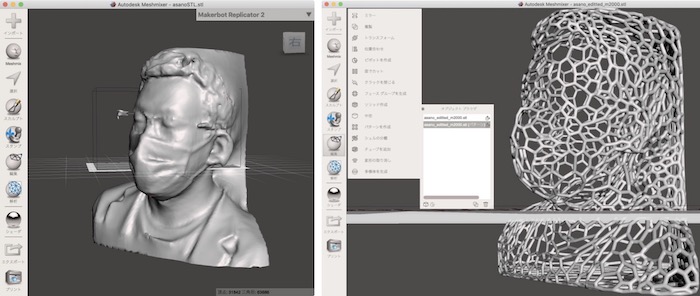

Used a Sense 3D scanner, to scan my own upper body. The scanned data can be cropped to the required area and converted to solid by pressing “Solidfy”. The finished model can be exported as a colored obj file or a shape-only stl file.

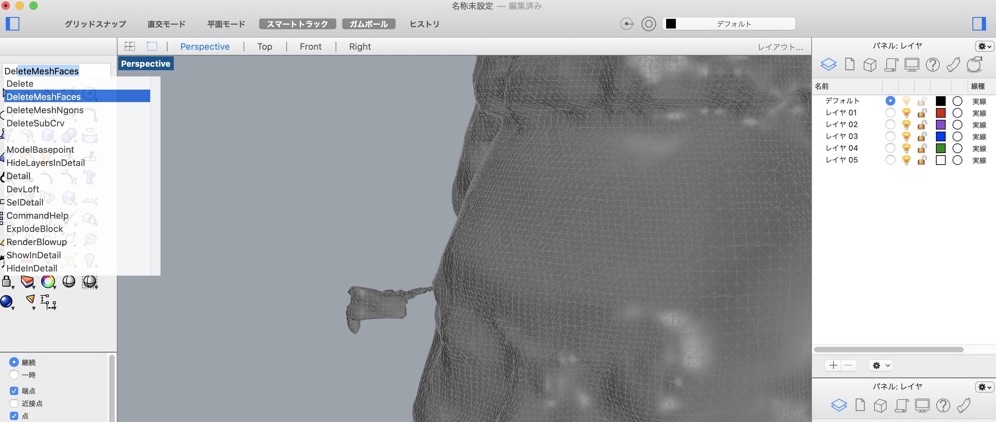

I couldn’t scan the vines of the glasses properly, so I modified them in Rhinoceros. I used “DeleteMeshFaces” to delete them, and then “FillMeshHoles” to fill in the holes.

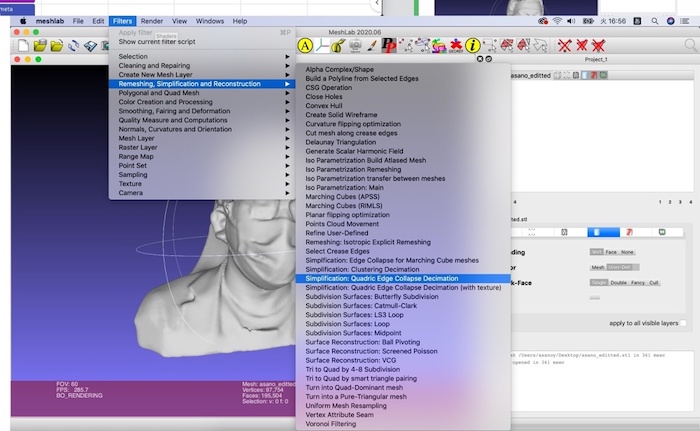

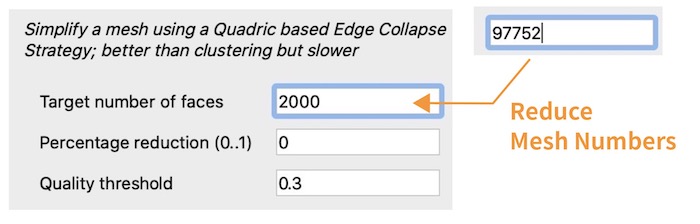

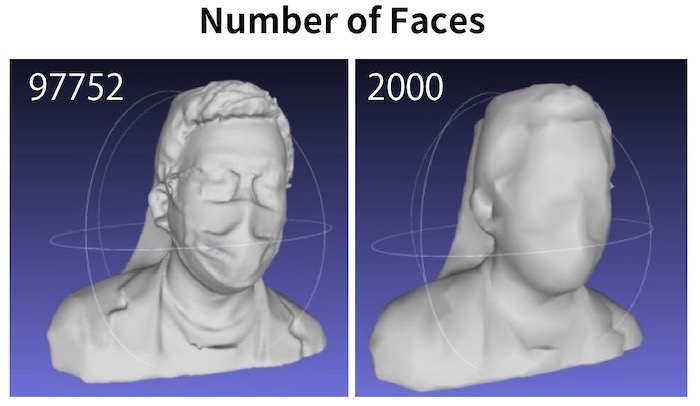

The raw data is large and unwieldy, so I used a free software called Meshlab to create the comfotable data.

Import File > Filters > Remeshing,Simplification and Reconstruction > Quadric Edge Collapse Decimation

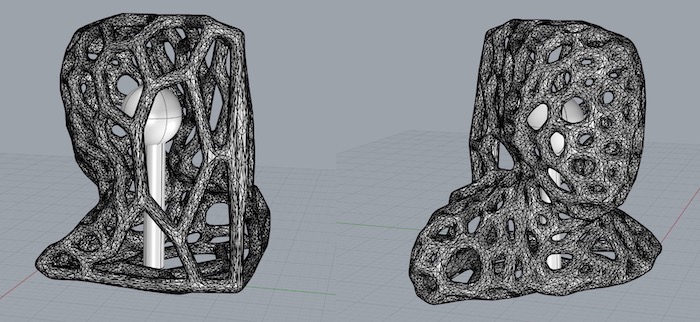

The lightened mesh data is loaded into the MeshMixer software to be processed for 3D printing.

Edit > Pattern Type > Dual Edge makes voronoi-like 3D model with holes. This kind of 3D model with many holes, is not for suitable for making by subtractive tools.

5. 3D Priting¶

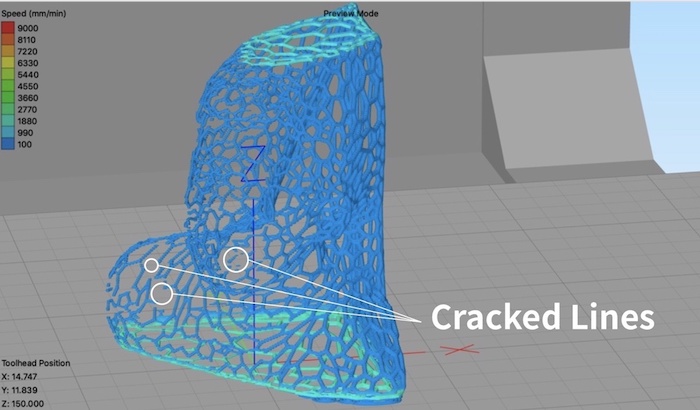

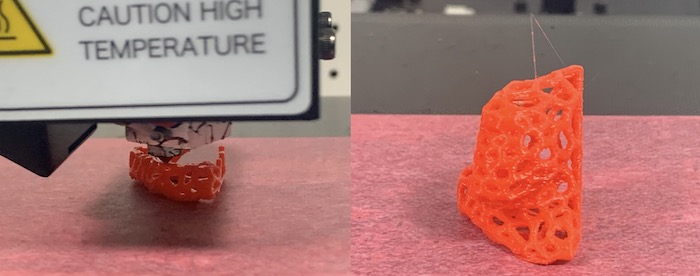

I use QIDI TECH-ONE and Simplify 3D slicer, and PLA filament in my house. Open voroni me in simplify, but some lines are cracked.

The reason for not being able to print is probably that the lines are too fine. When I tried to enlarge the model to make the lines thicker, it exceeded the modeling size.

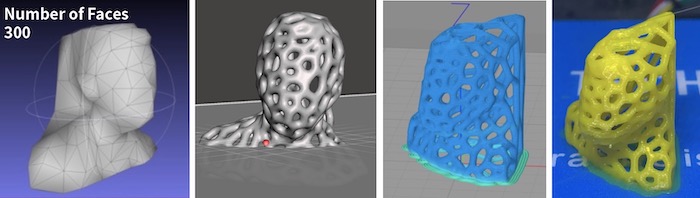

The Making Pattern function of MeshMixer is based on the lines of the mesh. Therefore, the number of meshes in the model had to be further reduced in order to make the ratio of line thickness to the model thicker.

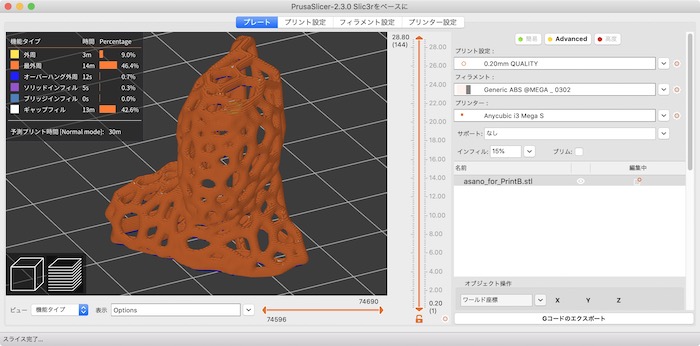

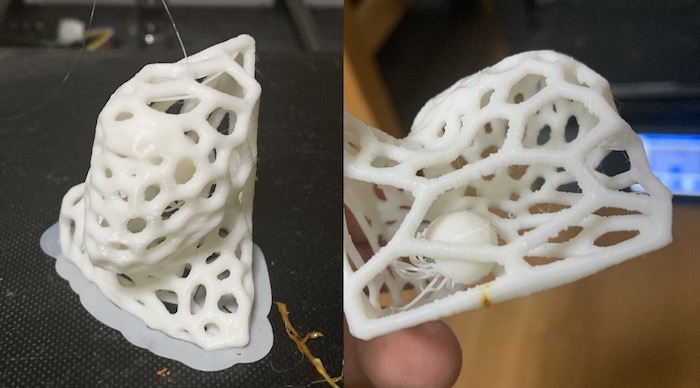

Also I use PrusaSlicer to slice data, then print another model with ANYCUBIC Mega-S and ABS filament.

I used Prusa Slicer’s default setting, 0.20mm QULATIY. It has no Support, no Brim, Layer Height is 0.2mm, Perimeter is 2 loops, 15% Gyroid infill shape, print speed is 30~60mm/s.

I also tried to add sphere in voronoied me. If printed it together, it is very difficult to make by subtrative production. I imported voronoi-me STL data in Rhinoceros, and made sphere and pillar in it. After I exported them together as one same STL, I printed it, and cut the pillar attached to sphere.

6. Voronoi Modeling in Rhinoceros/grasshopper¶

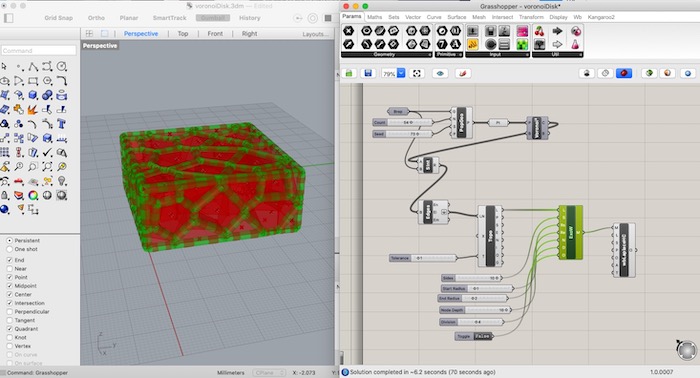

To desing a new piece, that can not be made subtractively, I selected Rhinoceros + grasshopper for 3D modeling. Because voronoi shape is difficult to be made subtractively and to design manually, so I decided to use grasshopper, Rhinoceros plugin which is good at geometric processing and automation.

I refered this tutorial, which tell me how to use grasshopper components like Populate Geometry to generate random points on one object, Voronoi 3D which can devide geometry based on points.

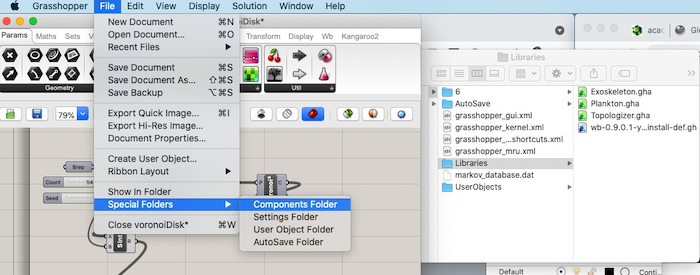

I need to use 3 plugins, Topologizer, Exoskelton and Weaverbird. To use them, I downloded thier gha file and add it for grasshopper menu, File > Special Folders > Components Folder > Libraries.

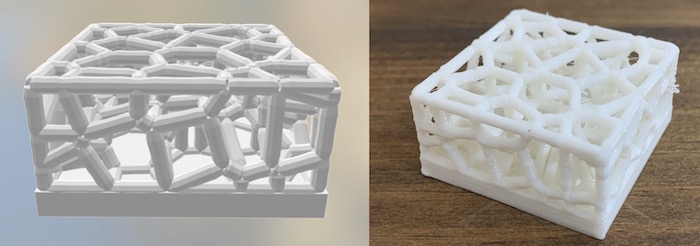

Finally I got Voronoi shaped rectangular(same goes for the inside), and print it. I found not too large angle don’t need support, so I printed it with no support.

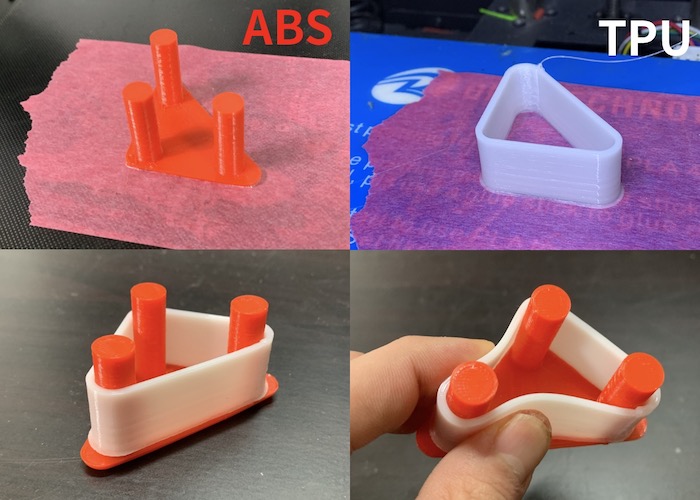

7. 3D Prit with softness¶

In my final project(pinball), I want to use some soft materials like rubber. so I tried to print TPU filament and make slingshot model. Soft material like TPU needs to be printed by slower speed than stiff materials like PLA/ABS.

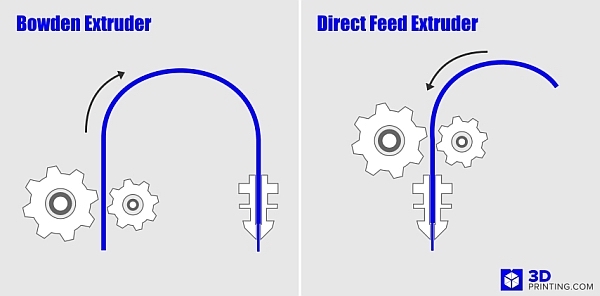

※ This image made by 3Dprinting.com, I quoted from this page.

-

For example, I printed TPU by extruding 1200mm/min, ABS/PLA by 3600mm/min in contrast. If not, TPU filament is so soft and will bent, does not print correctly.

-

Also I use QIDI TECH Ⅰ printer for printing TPU. Because TPU filament is not suitable for 3D printer with bowden type extruder, just like ANY CUBIC MEGA-S. QIDI TECH Ⅰ has direct feed extruder, its gears and extruders are in close than bowden type, so soft filament doesn’t tend to bend while printing. For slicing, I use Simplify 3D, it was not free but has many default settings of 3D printers including QIDI TECH Ⅰ.

Also I tried to make spring-like shape. Using this site as a reference, I was able to fix the filament in the shape of a spring by passing it through the shape with grooves dug in it and heating it in hot water for a while.

8. Links to Files and Code¶

3D Scanned Model

Editted 3D Model

Anotehr Editted 3D Model

Original Model

Links